ERAE Electronics Industry elt3220 User manual

ServiceManual

ServiceManual

32inch

32inch

LCDTV

Liquid Crystal Display

Quality Assurance Dept.

Quality Assurance Dept.

CONTENTS

CONTENTS

vSPECIFICATION

SPECIFICATION

.. 3

.. 3

v

vELECTRICALINSPECTION OF LCD PANEL

ELECTRICALINSPECTION OF LCD PANEL

.. 4

.. 4

v

vMODULEPRECAUTIONS

MODULEPRECAUTIONS

.. 8

.. 8

v

vTROUBLESHOOTING

TROUBLESHOOTING

11

11

v

vREPLACEMENTMETHOD OFPARTS

REPLACEMENTMETHOD OFPARTS

15

15

v

vFIRMWARE DOWNLOADING

FIRMWARE DOWNLOADING

... 22

... 22

v

vA/S SPARE PARTS

A/S SPARE PARTS

.

.

... 25

... 25

Quality Assurance Dept.

Quality Assurance Dept.

2/26

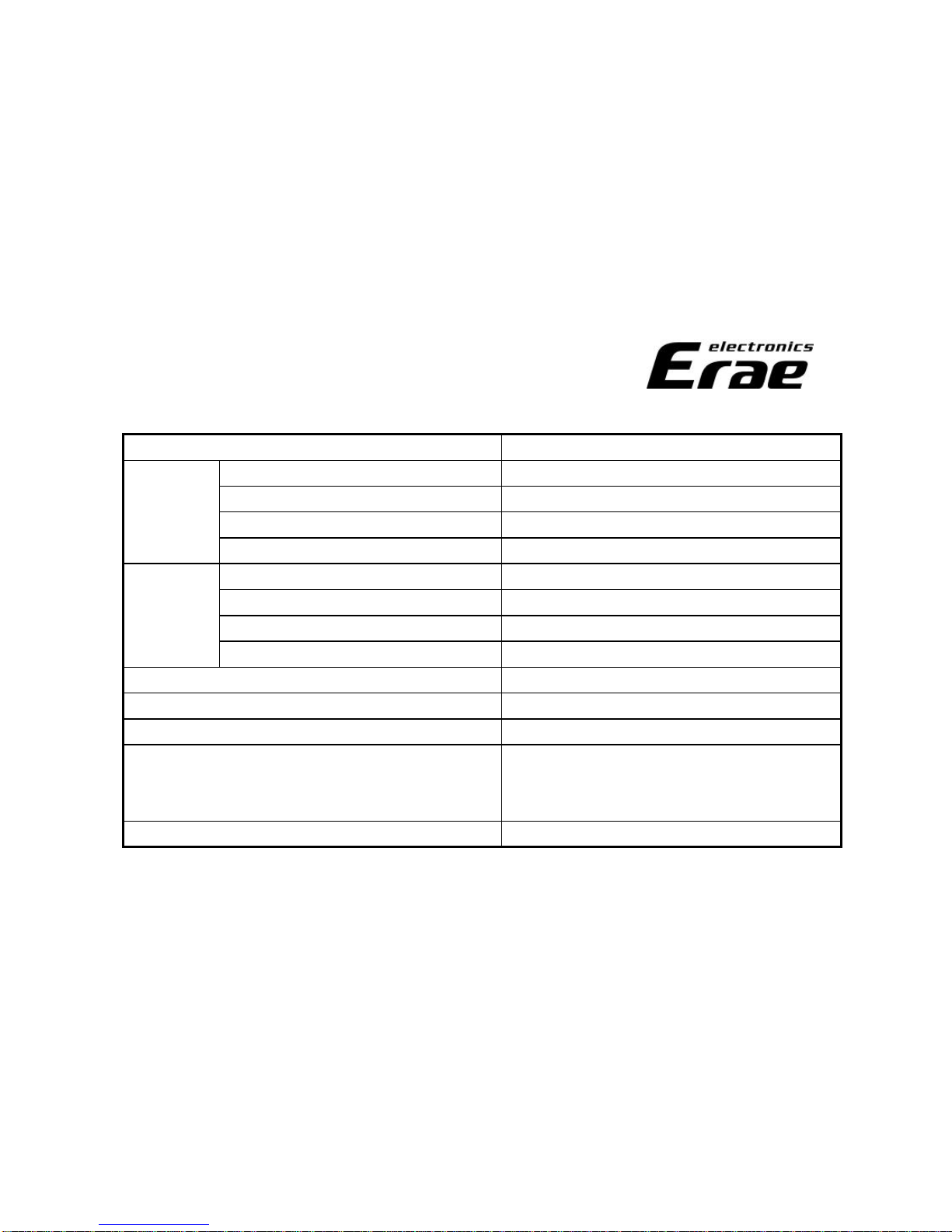

uSPECIFICATION

qTV

1.Input Signal:

PAL,SECAM,SD, HD,VGA~SXGA

2.Tuner :PAL, SECAM

3.Input Voltage :AC100V ~240V,@50/60Hz,3.5A(MAX)

4.Power Consumption:125W(Typical)

5.LCD Module:V320 (CMO)

6.Feature:

-AV Input-Component1Input (DVD)

-Component2Input (DTV)-D-SUB (Analog RGB 15PIN)

-DigitalRGB (DVI-D)-S-video2input

-S-Video1 Input-Composite1 Input

-Composite2 Input -Headphone

-SCART1Input (Full)-SCART2Input (Half)

-Tuner (PAL, SECAM)-AudioInput (Composite,Component1/2,S-Video,PC)

-RS-232C(9pin),TCP/IPSupport (0~254set)

7.Function: ARC,PIP,PBP (4:3,16:9),MTS,TTX

Quality Assurance Dept.

Quality Assurance Dept.

3/26

uElectricalInspectionofLCDPanel

Quality Assurance Dept.

Quality Assurance Dept.

4/26

(1)TheDefinitionoftheDotDefect:

Ifthe sizeof dot defect islarge than singledot,it canberegardedasone dot defect.

a)Bright dot:Dot appearsinbright display andthe sizeisfixedinblack pattern.

(It excludesthe particleissueandCFdefect.)

b)Dark dot:Dotappearsindark display andthe sizeisfixedinpurered,green,bluepattern.

(It excludesthe particleissue.)

c)2dot adjacent =1pair =2pair, the phenomenonisshownasbelow:

2 dot adjacent 2 dot adjacent

2 dot adjacent

(Vertical) 2 dot adjacent

(Slant)

uElectricalInspectionofLCDPanel

Quality Assurance Dept.

Quality Assurance Dept.

5/26

Not allowableFunctionalfailure(V-line/H-line/Cross line etc.)

Judgedby 3% ND Filter in50%gray pattern.

(Ifbothcustomer andCMOagree mutually,

CMOwill set uplimit sampleandapply tothe

criteria withthe customer.

Mura

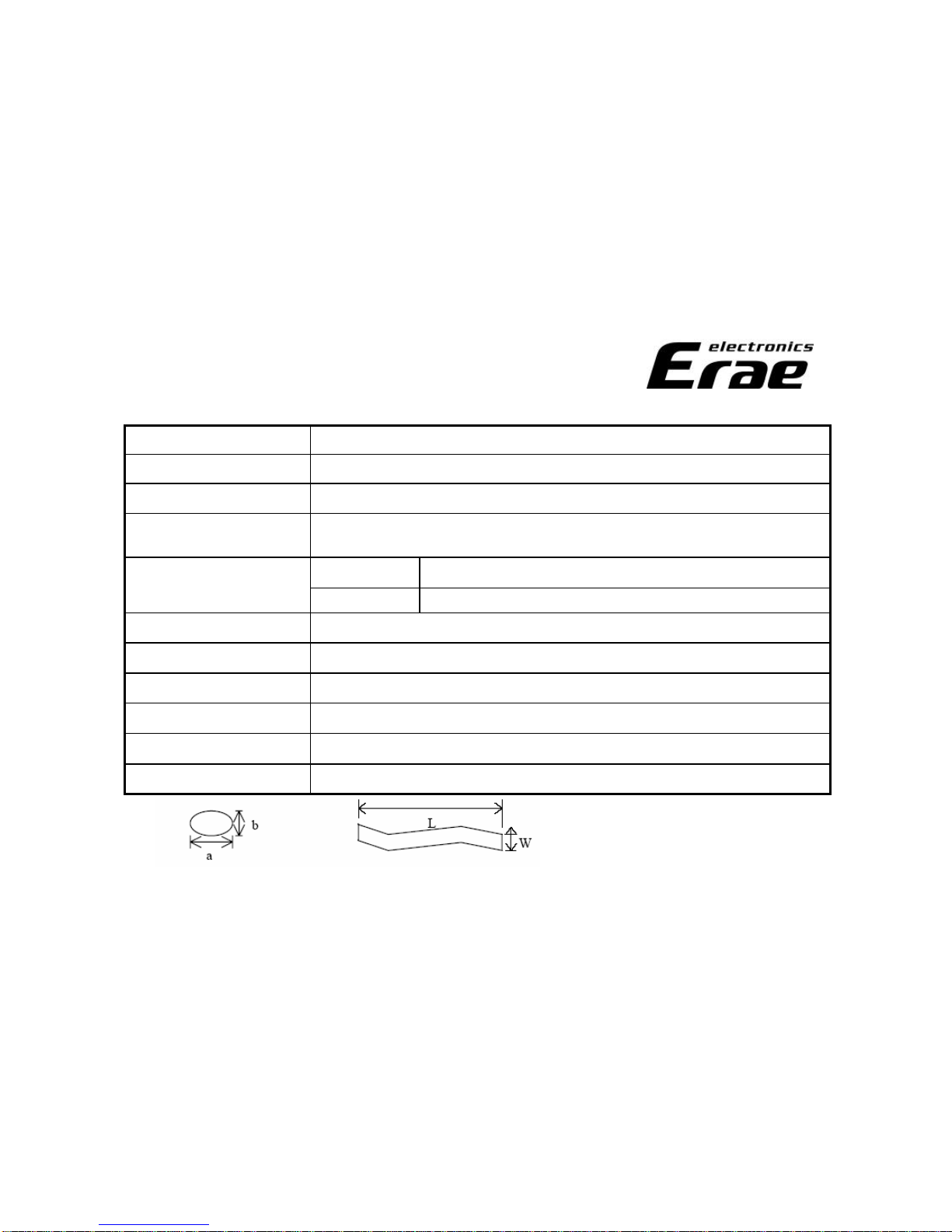

0.15<W 0.25mm,0.3<L 10mm,N 4Foreign Black/ White/ Bright Line

0.5<D 1.2mm,N 10Foreign Black/ White/ Bright spot

N 7Totalbright anddark dot

L ≥5mmMinimum DistanceBetween Dark dots

N 03dotsadjacent or more

N 22dotsadjacent

N 7Random

Dark dot

L ≥5mmMinimum DistanceBetween Bright dots

N 03dotsadjacent or more

N 02dotsadjacent

N 2Random

Bright dot

StandardItem

uElectricalInspectionofLCDPanel

Quality Assurance Dept.

Quality Assurance Dept.

6/26

0.3<D 1.2mm,N 10

Dent/Air Bubble

0.15<W 0.25mm,0.3<L 10.0mm,N 4.

Polarizer Scratches

The stain,whichcan’t bewipedoff,isnot permitted.

StainonPolarizer

Out of spec.isnot permitted.

Outline size

Oxidized/rusty connector isnot permitted.

Connector

Incorrect position,missedlabelisnot permitted.

Tape/Label

The crack isnot permitted.Crack

Nodisplay of backlight unitisnot permitted.Break down

Backlight

Incompleteassembly isnot permitted.

Metalframe

(Bezel)

Broken cable,burnedconnector isnot permitted.

CCFL cable

Missed,incomplete,or deformedassembly isnot permitted.

Screw

StandardItem

D=(a+b)/2 W:width, L:length

uElectricalInspectionofLCDPanel

Quality Assurance Dept.

Quality Assurance Dept.

7/26

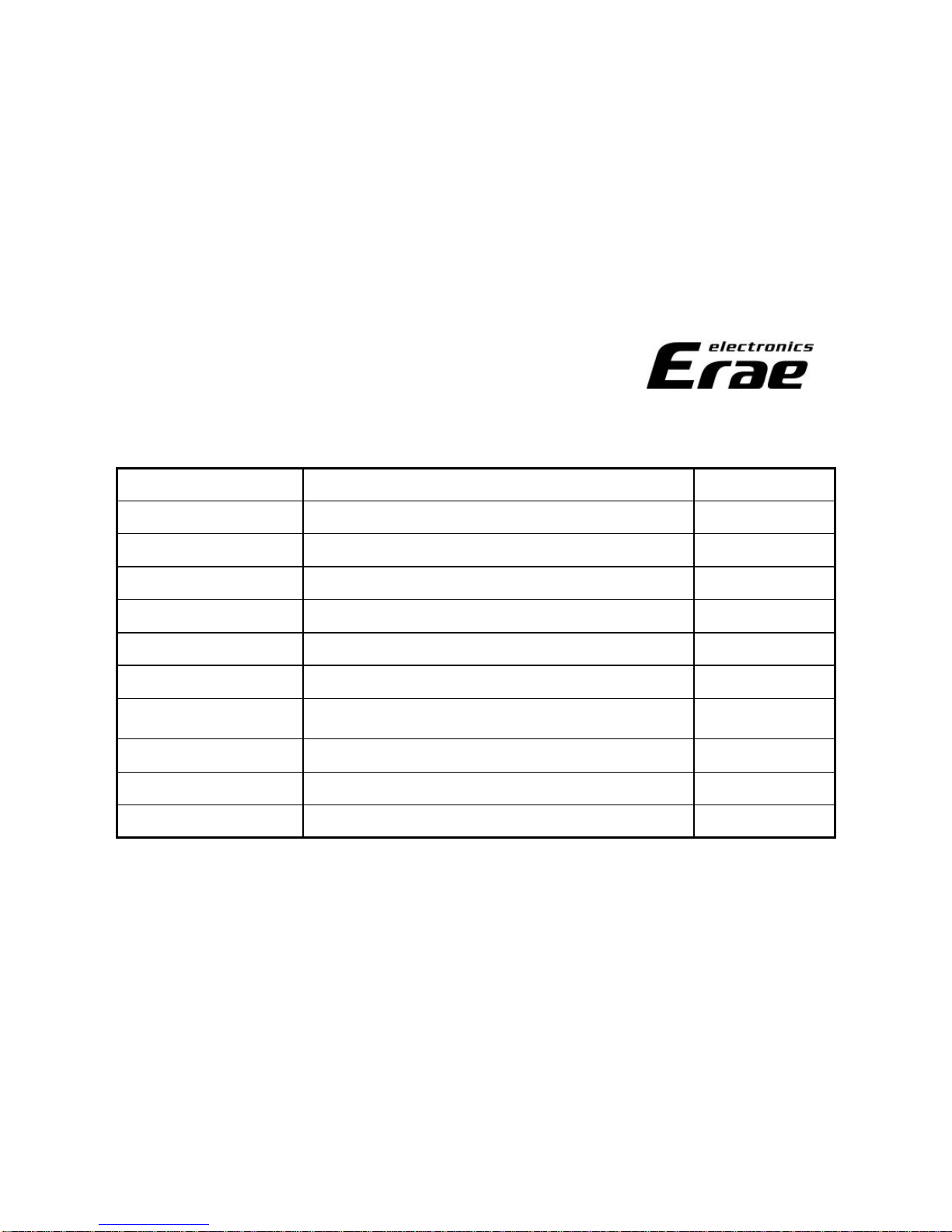

-ClassificationTable ofdefects

MinorPolarizer bubbleappearsindisplayPolarizer bubble

MinorUniformility isappearedindisplayMura

MinorForeign materialappearsindisplayForeign material

MinorPolarizer isdamagedonthe surface

ScratchandDent on

polarizer

MinorBright dot,dark Dot or dotadjacent appear indisplayDotsdefect

MajorAbnormalsignaloutputsindisplayIrregular display

MajorNosignaloutputsindisplayNodisplay

MajorAbnormalcross line appearsindisplayCross line

MajorAbnormalline appearsinhorizontaldirectionHorizontalline

MajorAbnormalline appearsinverticaldirectionVerticalline

Defect typeDescriptionInspection Item

uModule Precautions

1.GENERAL PRECAUTIONS

1.1Handling

(a)When the moduleisassembled.Itshouldbeattachedtothe system firmly using every mounting holes.

Be carefulnot totwist andbendthe modules.

(b)Refrainfrom strong mechanicalshock and/or any forcetothe module.Inadditiontodamage,thismay

causeimproper operationor damage tothe moduleandCCFT back-light.

(c)Notethat polarizersarevery fragileandcouldbeeasily damaged.Donot press or scratchthe surface

harder thana HBpencillead.

(d)Wipeoff water dropletsor oilimmediately. Ifyouleavethe dropletsfor a longtime,staining and

discolorationmay occur.

(e)Ifthe surfaceofthe polarizer isdirty,cleanit using someabsorbent cottonorsoft cloth.

(f)The desirablecleanersarewater,IPA(Isopropylalcohol)or Hexane.Donot useKetonetypematerials

(ex.Acetone),Ethylalcohol,Toluene,EthylacidorMethylchloride.It might permanent damage tothe

polarizer duetochemicalreaction.

(g)Iftheliquidcrystalmaterialleaksfrom the panel,itshouldbekept away from the eyesor mouth.In

caseof contact withhands,legsorclothes,it mustbewashedaway thoroughly withsoap.

(h)Protect the modulefrom static,itmay causedamage tothe CMOS gateArray IC.

Quality Assurance Dept.

Quality Assurance Dept.

8/26

(i)Usefinger-stallswithsoft glovesinorder tokeep display cleanduring the incoming inspectionand

assembly process.

(j)Donot disassemblethemodule.

(k)Donot pull or foldthe lamp wire.

(l)Donot adjustthe variableresistor whichislocatedonthe module.

(m)Protectionfilm for polarizer onthe moduleshallbeslowly peeledoff just beforeusesothat the

electrostaticcharge canbeminimized.

(n)Pinsof I/Fconnector shallnot betoucheddirectly withbarehands.

1.2Storage

(a)Donot leave the moduleinhigh temperature,andhigh for a long time.It ishighly recommendedto

storethe modulewithtemperaturefrom0to35°Candrelative humidity of less than70%.

(b)Donot storethe TFT-LCD moduleindirect sunlight.

(c)The moduleshallbestoredina dark place.It isprohibitedtoapply sunlight or fluorescentlight

during the store.

Quality Assurance Dept.

Quality Assurance Dept.

9/26

1.3Operation

(a)Donot connect, disconnect the moduleinthe “Power On”condition.

(b)Power supply shouldalwaysbeturnedon/off by “Power on/off sequence”.

(c)Modulehashigh frequency circuits.Sufficient suppressiontothe electromagneticinterferenceshall

bedone by system manufactures. Grounding andshielding methods may beimportant tominimize

the interference.

(d)The cablebetween theback-light connector anditsinverter power supply shallbea minimizedlength

andbeconnecteddirectly.The longer cablebetween theback-light andthe inverter may cause

lowerluminanceof lamp (CCFT)andmay requirehigher startup voltage(Vs).

1.4Others

(a)Ultra-violet ray filter isnecessary for outdoor operation.

(b)Avoidcondensationof water.Itmay result inimproper operationor disconnectionof electrode.

(c)Donot exceedthe absolutemaximum rating value.(the supply voltage variation,input voltage

variation,variationinpart contentsandenvironmentaltemperature,andsoon)Otherwisethe

modulemay bedamaged.

(d)Ifthe moduledisplaysthe samepatterncontinuously for a long periodof time,It canbethesituation

when the image “Sticks”tothe screen.

(e)Thismodulehasitscircuitry PCB’sonthe rear sideandshouldbehandledcarefully inorder not to

bestressed.Quality Assurance Dept.

Quality Assurance Dept.

10/26

Quality Assurance Dept.

Quality Assurance Dept.

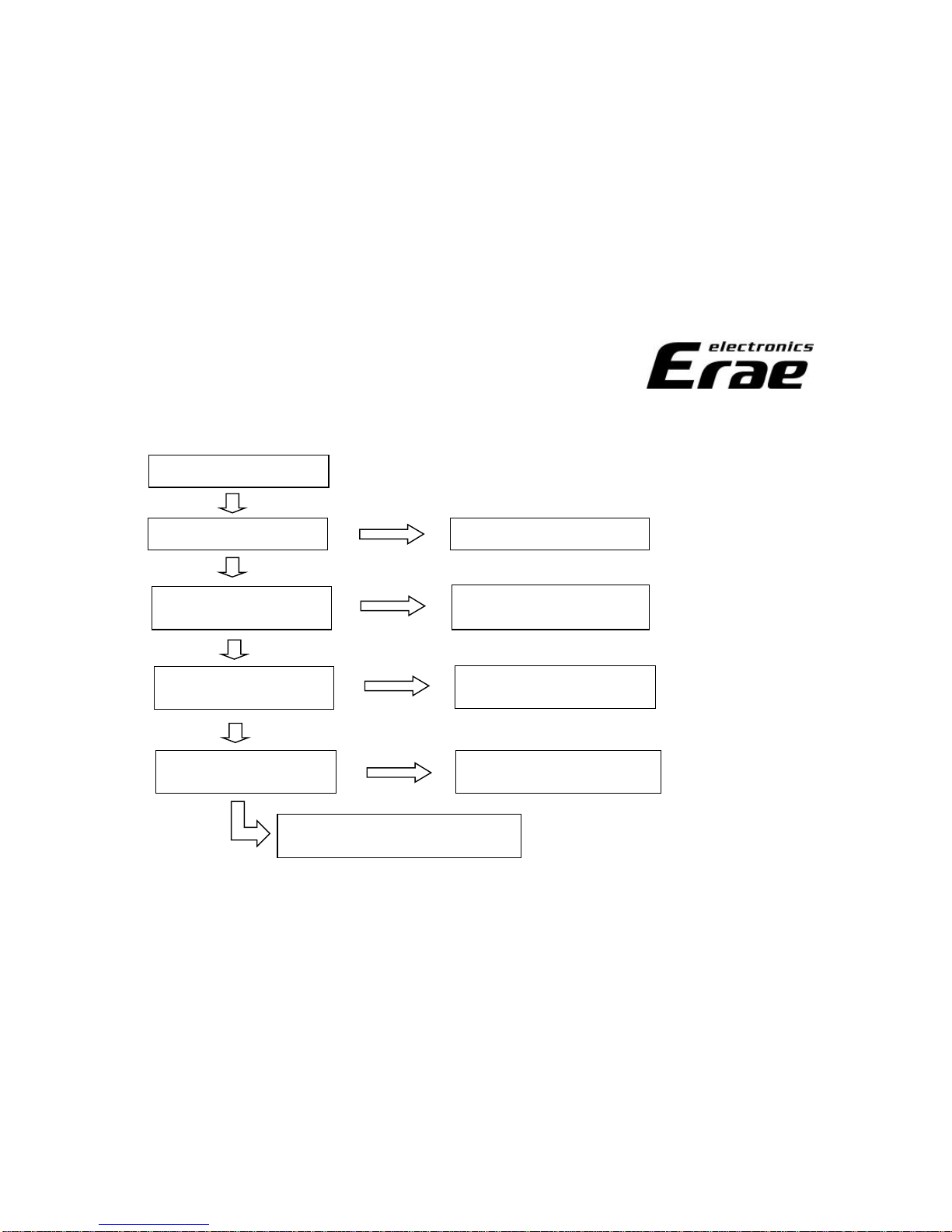

uTroubleShooting

1. NoPower

Nothing output of image.

CheckInput of AC. Connect plugwiththe set.

Check ST-BYLED ON,

MainS/WON.(ACON) Check ACLine Fuseand

ReplacethePSU

Check ST-BYLED COLOR ReplacetheA/D BOARD.

Check theset condition

after dc power on. Check theIRboardorA/D

andreplacethedefect B/D.

Confirmthe Nodisplaysection.

Normal Abnormal

Normal

Abnormal

Normal

Abnormal

YellowLED

RedLED

2

1

11/26

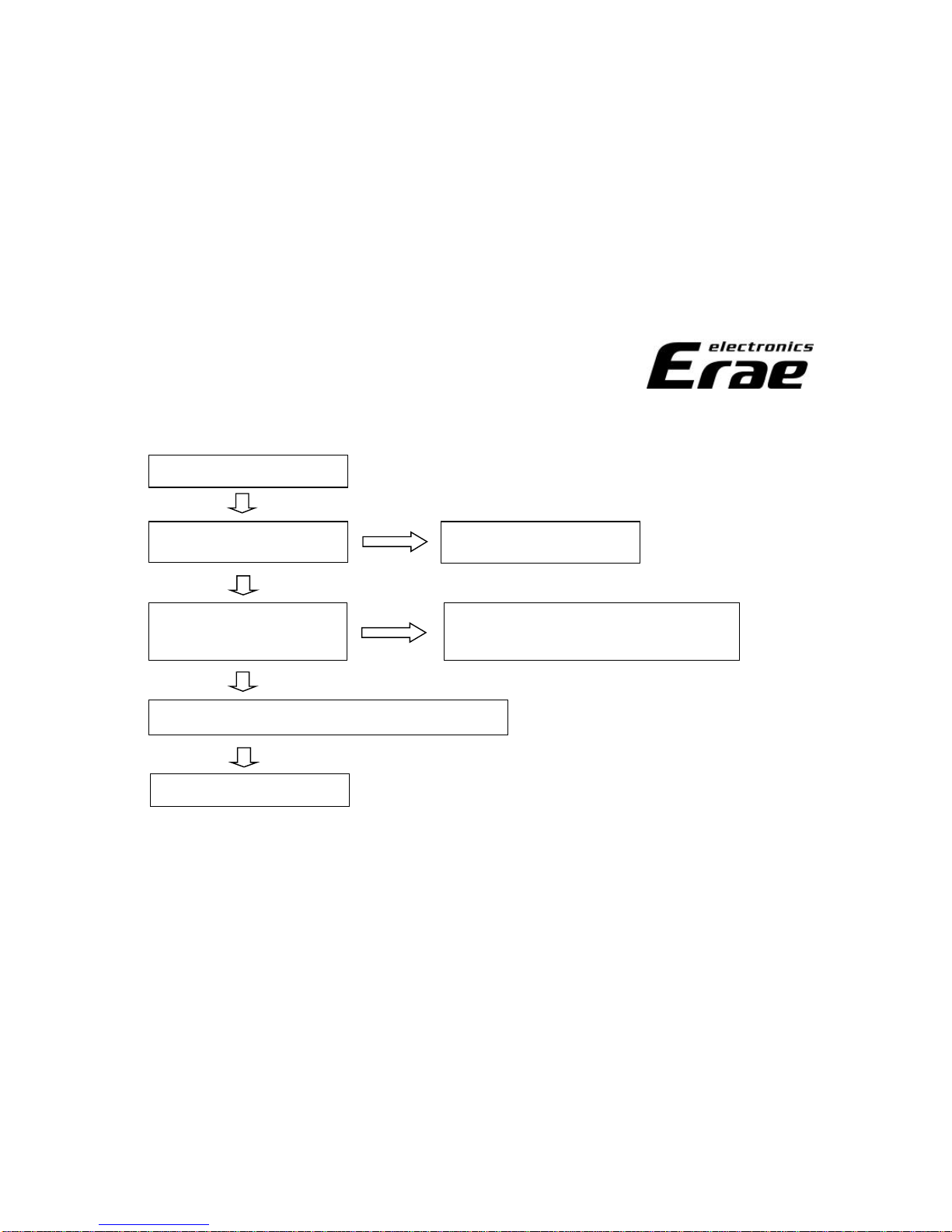

uTroubleShooting

2. NoVideo

AbnormalPicture.

Check theST-BYLED.

Check thefunctionofremote

controller. (power on/off)

Check theinverter cableandLVDS cable.

Check theIRB/D orA/D and

Replacethedefective B/D.(power on/off)

LCD PANEL DEFECTIVE.

Check thePSUor A/D and

Replacethedefective B/D.

Quality Assurance Dept.

Quality Assurance Dept.

Normal

Normal

Normal

Abnormal

Abnormal

12/26

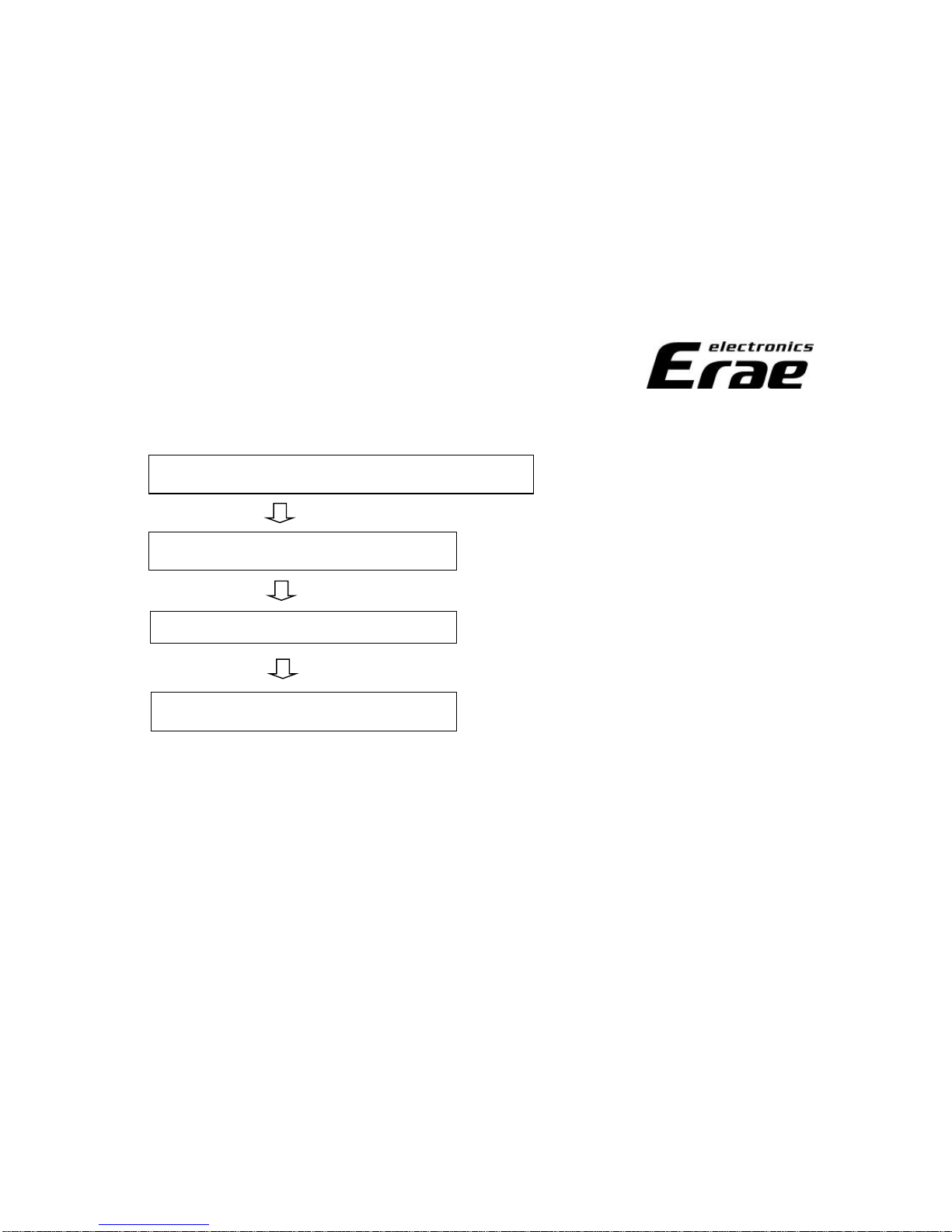

uTroubleShooting

3. NoSound

Check theconnectionof speaker toset after set reset.

Check theconditionafter swap the A/D.

Check theFFCcablebetween I/OandA/D.

Check theconditionafter swap the I/O.

Quality Assurance Dept.

Quality Assurance Dept.

13/26

uTroubleShooting

4. Not Searching on TV

Check theFFCcablebetween A/D andTuner B/D.

Check theconditionafter swap the A/D B/D.

Check theconditionafter reset the set.

Quality Assurance Dept.

Quality Assurance Dept.

14/26

Quality Assurance Dept.

Quality Assurance Dept.

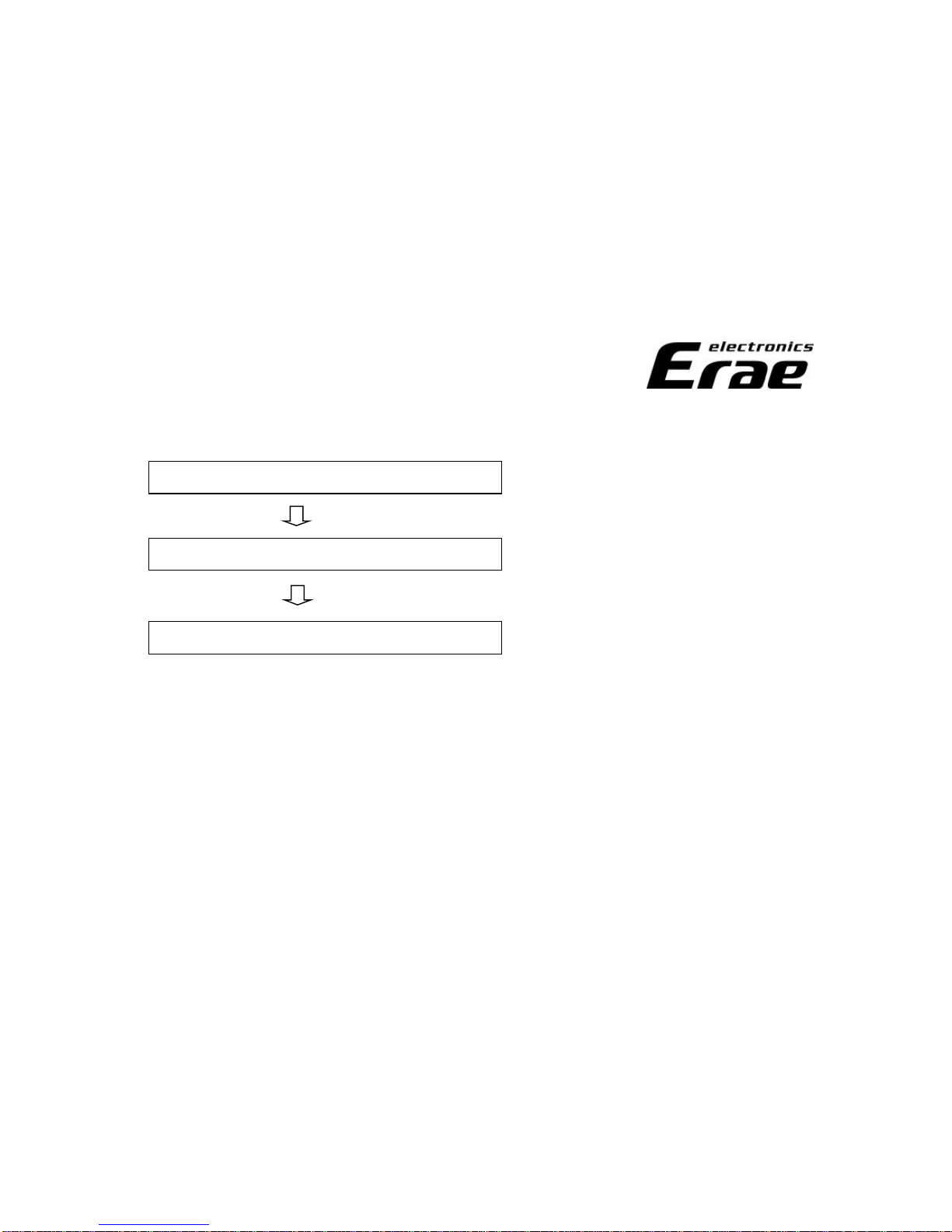

uReplacement Methodofparts

1. PSU

B. Removetheback cover

1.Removetheback cover from the set.

2.Markedscrew’skindby positioncolor.

A.Makeit ready

1.Lay the product downonthe soft mat for

protection.

2.Removethestandfrom the product by taking the

screws(red)out asper the picture.

3.Keep thestandaway from any possiblescratches.

4.Locatethe eliminatedscrewsinsafe for later use.

15/26

BHM 5X16

ZB

Torque

10±1kgf.㎝

BHM

5X10 ZB

BHM

4X10 ZB

Torque

10±1kgf.㎝

BHTT

4X10 ZB

Torque

7±1kgf.㎝

Quality Assurance Dept.

Quality Assurance Dept.

D. CheckPoints

1.Insulator shouldbeplacedunder the PSU,when PSUisfixedonthe set.

2.Doublecheck the connectionof cablebeforereassembling.

C. Replace thenewPSU

1.Removethewirefrom the PSU.

2.Replacethenew PSU.

uReplacement Methodofparts

1. PSU

16/26

PSU

Quality Assurance Dept.

Quality Assurance Dept.

A.Makeit ready

1.Lay the product downonthe soft mat for

protection.

2.Removethestandfrom the product by taking the

screws(red) out asper the picture.

3.Keep thestandaway from any possiblescratches.

4.Locatethe eliminatedscrewsinsafe for later use.

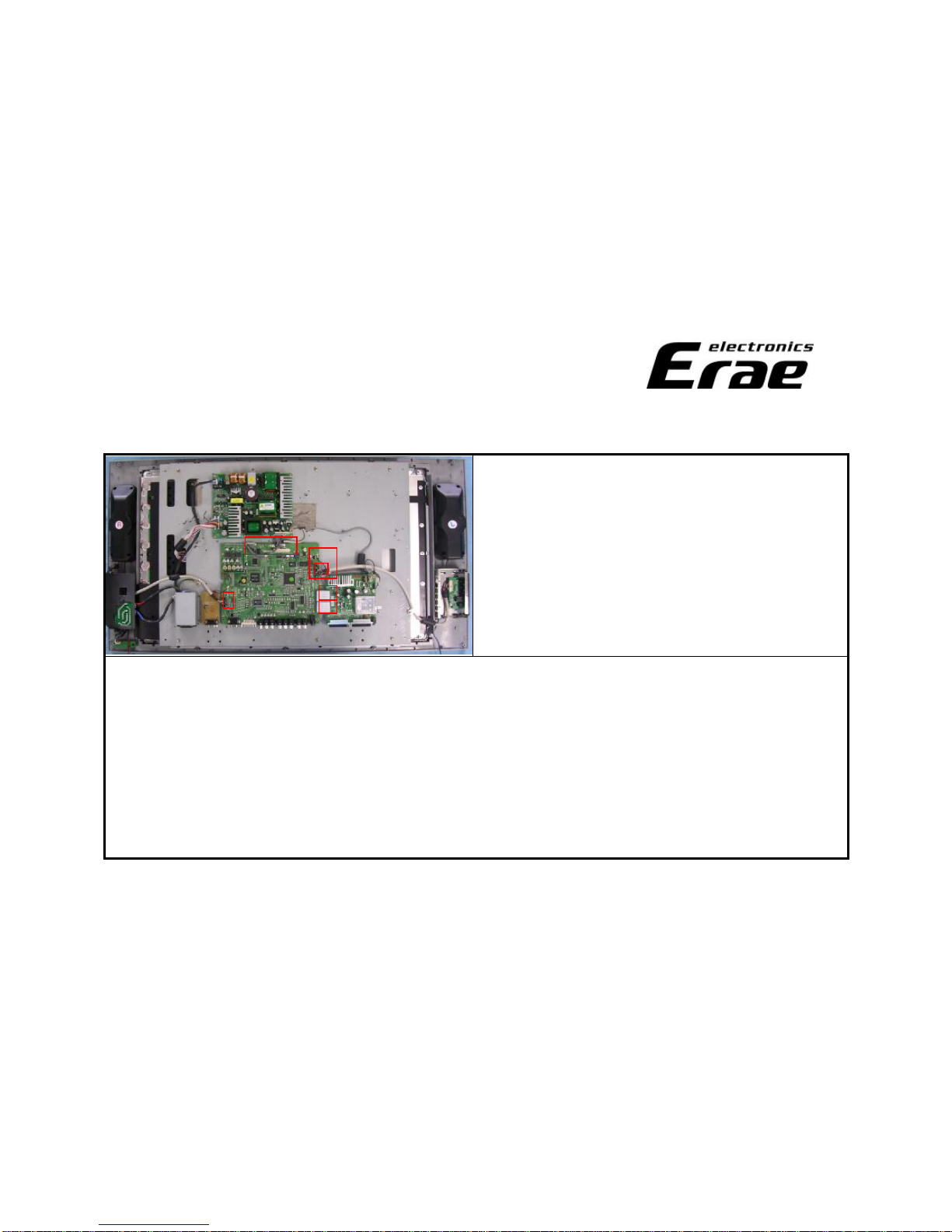

uReplacement Methodofparts

2. A/D (main) Board

17/26

BHM 5X16

ZB

B. Removetheback cover

1.Removetheback cover from the set.

2.Markedscrew’skindby positioncolor.

Torque

10±1kgf.㎝

BHM

5X10 ZB

BHM

4X10 ZB

Torque

10±1kgf.㎝

BHTT

4X10 ZB

Torque

7±1kgf.㎝

Quality Assurance Dept.

Quality Assurance Dept.

3.Locatethe eliminatedscrewsinsafe for later use.

C. Removetheshield mainandjack housing

1.Removetheshieldmainfrom the set.

(BH M 3X6ZN)

2.Removethejack housing from the a/dandtuner

board.

(BH T3X82S ZB,SPECIALWASHER,SPECIAL NUT)

uReplacement Methodofparts

2. A/D (main) Board

18/26

BHM

3X6 ZN

Special

Nut

Special

Washer

BHT3X8

2SZB

Quality Assurance Dept.

Quality Assurance Dept.

uReplacement Methodofparts

2. A/D (main) Board

4.Observe tousesuitablescrewswhen dodisjointing

andassembly.

D. Replace thenewA/D board

1.Removethepower cableandLVDS cablefrom the

defective A/D board.

2.Must observe lest cableshouldbedamagedat FFC

cableseparation.

3.Replacethenew A/D board.

A/DTUNER

BHM

3X6 ZN

19/26

Quality Assurance Dept.

Quality Assurance Dept.

*ExtraCheck Points

1.Check out ifthe sameproblem occurseven after the reassembling.

2.Iffine,commit anaging test noless than10minutes.

3.Apply theinput/output functionof Composite,S-Video,Component AudioandVideo,andcheck outif

they work well.

4.Wear a wrist bandtoprotect staticelectricity when handing

C. Check theCable connection

1.Doublecheck the belowpoints.

-FFCcable24Px50mm

-ACPower Wire

-OSD Wire8P 800mm

-Power Wire12P120mm

-SubA/V wire20P

uReplacement Methodofparts

2. A/D (main) Board

20/26

Table of contents

Other ERAE Electronics Industry LCD TV manuals