Ergon Crafco BAX 250 User manual

BAX 250

PART MANUAL - 26357

Rev. B

2

Created: 12/11

3

BAX 250

PART NUMBER 55400

4

TABLE OF CONTENTS

BAX 250................................................................................................................................... 5

Safety Precautions.................................................................................................................... 6

Limited Warranty....................................................................................................................... 7

Warranty Claim Instructions....................................................................................................... 8

Specifications............................................................................................................................9

Introduction...............................................................................................................................10

Mounting the Bax 250 Melter......................................................................................................11

Operating Instructions

Machine Start Up/Starting the Engine.................................................................. 12

Heated Hose, Wand, and Controller.................................................................... 12

Starting the Mixer.............................................................................................. 12

Dispensing the Material..................................................................................... 13

Loading the Machine......................................................................................... 14

Shutdown and Clean-out Procedure/Storing Machine............................................ 14

Instructions for Ordering Parts............................................................................ 15

Electric Hose Care and Cautions........................................................................ 15

Hose Transport Instructions................................................................................16

Maintenance

Maintenance Instructions and Chart.................................................................... 17

Temperature Control Calibration.......................................................................... 17

Service Instructions/Recommended Fluids and Lubricants.....................................18

Trouble Shooting

Hose Trouble Shooting - Hose Does Not Heat.......................................................19

Hose Trouble Shooting - Material Does Not Dispense When Pump is Activated...... 20-21

Burner Trouble Shooting.................................................................................... 22

Burner Schematic............................................................................................. 23

Parts

Bax 250 Assembly - Diagram and Parts............................................................. 24-27

Pump/Agitator Motor Assembly - Diagram and Parts........................................... 28-29

Power Pack Assembly - Diagram and Parts........................................................30-31

Control Box Assembly - Diagram and Parts.........................................................32-33

Gas Manifold Assembly - Diagram and Parts.......................................................34-35

Hydraulic Valve Assembly - Diagram and Parts....................................................36-37

Hydraulics Schematic and Parts.........................................................................38-39

LPG Piping Diagram and Parts...........................................................................40-41

Electrical Schematic and Parts...........................................................................42-43

5

BAX 250

This manual is furnished with each new CRAFCO BAX 250. This manual will help your

machine operators learn to run the melter applicator properly and understand its

mechanical functions for trouble-free operation.

Your CRAFCO BAX 250 is designed to give excellent service and save maintenance

expense. However, as with all specially engineered equipment, you can get best results at

minimum costs if:

1. You operate your machine as instructed in this manual.

2. Maintain your machine regularly as stated in this manual.

WARNING: The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Operate in well ventilated area only. Engine exhaust

is deadly.

6

SAFETY PRECAUTIONS

•High operating temperatures of sealant and machine require protective clothing, hard

soled shoes and heat resistant gloves be worn by operator.

•Always wear eye protection.

•Observe all CAUTION AND WARNING signs posted on machine.

•Avoid the entrance of water into any part of the machine.

•Avoid bodily contact with hot sealant material, serious burns may result.

•Read Operator Manual thoroughly before operating machine.

•Make sure operator is familiar with machine operation.

•Do not operate in closed building or confined areas.

•Shut-down burner and engine prior to refilling propane tank.

•When adding solid material to sealant tank, stop mixer, lift lid, place material onto lid and

close lid before restarting mixer. Hot material could splash and cause serious burns if this

procedure is not followed.

•Keep hands, feet, and clothing away from all moving parts.

•Always keep a fire extinguisher near the unit. Maintain extinguisher properly and be

familiar with its use.

•Follow operating instructions for starting and shut-down of burner. Instructions are

mounted on control box.

•Calibrate temperature control prior to initial operation and each 50 hours of operation.

See page 16 step by step instruction.

•Replace any hoses which show signs of wear, fraying, or splitting. Be sure all fittings and

joints are tight and leak-proof.

• Precaution is the best insurance against accidents.

•The BAX 250 Melter should not be left unattended with burner lit.

•Tighten all bolts and screws after every 100 hours of operation.

•Crafco, Inc. assumes no liability for an accident or injury incurred through improper use of

the machine.

7

LIMITED WARRANTY

Crafco, Inc., through its authorized distributor, will replace for the original purchaser free of

charge any parts found upon examination by the factory at Mesa, Arizona, to be

defective in material or workmanship. This warranty is for a period within 60 days of

purchase date, but excludes engine or components, tires, and battery as these items are

subject to warranties issued by their manufacturers.

After 60 days, Crafco, Inc., warrants structural parts, excluding heating system, hydraulic

components, material pump and hoses, applicator valves, and electrical components for a

period of (1) one year from date of delivery. Crafco, Inc., shall not be liable for parts that

have been damaged by accident, alteration, abuse, improper lubrication/maintenance,

normal wear, or other cause beyond our control.

The warranty provided herein extends only to the repair and/or replacement of those

components on the equipment covered above and does not cover labor costs. The

warranty does not extend to incidental or consequential damages incurred as a result of

any defect covered by this warranty.

All transportation and labor costs incurred by the purchaser in submitting or repairing

covered components must be bore by the purchaser.

Crafco, Inc. specifically disavows any other representation, warranty, or liability related to

the condition or use of the product.

WARNING: Use of replacement parts other than genuine Crafco parts

may impair the safety or reliability of your equipment and nullifies any

warranty.

8

WARRANTY CLAIM INSTRUCTIONS

Please follow the instructions stated below when calling in a Warranty Claim. Failure to

follow these procedures may be cause to void the warranty.

1. Call your local Crafco Distributor. If you do not know who your local distributor is,

call a Crafco Customer Service Representative, (Toll Free 1-800-528-8242) for

name, location, and telephone number.

2. On contacting the distributor, be prepared to identify the machine type, model

number, and serial number, also, the date of purchase if available.

3. Should the cause of the malfunction be a defective part, the distributor will advise

you of the procedure to follow for a replacement.

4. The warranty is valid only for parts, which have been supplied or recommended by

Crafco, Inc.

If you have any additional questions regarding warranty repairs and parts, please do not

hesitate to call toll free 1-800-528-8242.

CRAFCO, INCORPORATED

25527 SOUTH ARIZONA AVENUE

CHANDLER, AZ 85248

480-655-8333

Toll Free 1-800-528-8242

9

SPECIFICATIONS

Vat Capacity..................................................................25 Gallons

Melt Capacity................................................................ 20 Gallons/Hour

Tank Construction.........................................................Direct Fired Type Construction

Tank Opening Size....................................................... 18” X 6”

Maximum Heat Input.................................................... Vapor Burner 75,000 BTU’s

Burner and Temperature Control.................................. Automatic - Fail Safe

Engine - Kohler............................................................. Single Cylinder

Model CH-14 - Propane Fueled 20 BHP @ 3,600 rpm

Drive Mechanism..........................................................All Hydraulic Mixer

and Material Pump

Mixer............................................................................. High Speed Two Pitched

Blade Agitator

Dry Weight....................................................................Approximately 1,189 lbs.

Propane Bottle (1)........................................................ 100 lbs.

Generator..................................................................... 24 VAC, 3-PHASE

Hydraulic Tank Capacity...............................................12 Gallons

10

BAX 250 MELTER

INTRODUCTION

The CRAFCO BAX 250 MELTER was developed to melt CRAFCO Brand Sealant.

However, it will work equally well with all road asphalt and federal specification crack or

joint sealant.

DO NOT operate machine without following these instructions:

1. Fill propane tank.

2. Check engine crankcase oil level (refer to Engine Operator’s Manual).

3. Check hydraulic fluid level, at ambient temperature. Add fluid if necessary to bring

to correct level.

4. All toggle switches should be turned “OFF” and all temperature control dials at

minimum settings.

5. Remember that safe operation of this equipment is the operator’s responsibility.

CAUTION:

Extreme care must be used when operating this equipment. Safety is the result

of being careful and paying attention to details. Remember the propane flame is

about 2,200°F. Certain exposed parts of this machine, when operating reach

500°F.; the sealant as high as 400°F. and the hydraulic fluid may reach 200°F.

Always wear protective clothing, hard-soled shoes, and eye protection. Be sure

that all joints and fittings are tight and leak proof. Immediately replace any hose,

which shows any signs of wear, fraying, or splitting. Tighten all bolts, nuts, and

screws every 250 hours.

11

MOUNTING THE BAX 250 MELTER

1. Only mount the unit to a metal truckbed or any other non-flammable surface.

2. Mount unit 3” above the truckbed. Mount with four(4) 1/2” bolts minimum.

3. Leave 15” clear all around machine.

15"

3"

SEALANT AND MARKERS

STORAGE AREA

12

MACHINE START UP

TO START BURNER

1. Open the vent damper.

2. Open LPG tank valve and ball valve at cylinder.

3. Start engine per instruction below.

4. Turn “ON” power toggle switch at control box.

5. Set material temperature at manufacturers recommended temperature.

CAUTION:

If burner does not ignite the first time, turn temperature dial to off. Turn

temperature dial to desired setting. Burner should ignite. If burner still does

not ignite, determine cause of malfunction (see Burner Trouble Shooting Guide

pg. 22).

STARTING THE ENGINE

Choke engine, turn the ignition key to start position. Engine should start. After engine

starts, allow to warm up before using hydraulics or generator.

STARTING THE MIXER

When the sealant material reaches 275oF, engage the mixer by moving the toggle switch to

“ON” (switch located on hydraulic panel.) If the mixer does not move, allow

material to heat longer. Jamming of mixer shaft causes hydraulic oil to overheat and

machine damage could occur. Remember, mixer does not start with melter lid open. The

mixer speed is preset for optimum performance for the factory.

HEATED HOSE, WAND, AND CONTROLLER

CAUTION:

The hose must be up to temperature before dispensing can take place.

IMPORTANT!! DO NOT twist or kink hose. Avoid sharp bends and continuous

twisting. Maintain minimum 10” bend radius. DO NOT exceed 400 degrees!!

DO NOT move or bend hose when cold. Damage may result.

The heated hose supplied with the machine is Teflon lined with a stainless steel overbraid.

It has a heating element which runs down the hose to heat the material within the hose.

The hose is insulated with silicone foam rubber and is covered with a durable rubber outer

covering. The wand has an aluminum tube to protect both the wand and the operator. The

pistol grip actuator is equipped with an electric switch which when depressed sends a

signal to actuate the pump. At the end of the wand, a high temperature elasomeric output valve

is attached. The valve is pressure actuated and opens automatically when fluid pressure is

applied. The wand is equipped with a trigger lock to prevent accidental pump actuation when

not pumping material.

13

The trigger should be in the “LOCKED” position at all times except when intentionally pumping

material.

When the material temperature reaches 325oF, turn “ON” the hose toggle switch. Adjust the

temperature dial to approximately 400 degrees. The hose will come up to temperature in

approximately 30 minutes. After the hose has reached its preset temperature, the light in the

control box will turn off and the temperature may be reduced to approximately 360 degrees. It

is advisable to run the hose at the lowest temperature setting possible. When you are ready to

dispense material turn the shutdown toggle switch to the “OFF” position.

DISPENSING THE MATERIAL

NOTE: PROTECTIVE CLOTHING, GLOVES, HARD-SOLED SHOES,

AND FACE SHIELD OR SAFETY GLASSES SHOULD BE WORN

WHEN OPERATING OR FILLING THIS EQUIPMENT. READ

ENTIRE MANUAL BEFORE OPERATING.

The wand is equipped with a disposable duckbill valve on the end, which shuts off the flow of

material when the pump is turned off and prevents excessive dripping of material. This valve

also directs the material into a stream for easy application onto the pavement. Other sealing

tips are

available. See your local distributor for options.

Some difficulty may be encountered when starting up on cold days. Although the wand is

designed to heat the material all the way down to the tip, on cold days it may be necessary to

place the tip of the wand under the lid to facilitate material melting in the valve. Insert the wand

tip for only a short time before proceeding.

When the material and the hose have reached proper application temperature, you are ready

to dispense material. Install bottom reed switch and cylinder should return to top. With the

wand tip inserted into the tank, depress trigger on the wand. Material should start to flow from

the tip of the duckbill valve. Adjust the stroke of the cylinder by moving the bottom reed switch

up or down for the desired rate of flow for the application and dispense material as required.

NEVER POINT THE WAND AT ANY PART OF THE BODY OR

AT ANY OTHER PERSON. HOT MATERIALS CAN CAUSE

SEVERE BURNS. WEAR PROTECTIVE EQUIPMENT WHEN

FILLING OR OPERATING THE EQUIPMENT. READ MANUAL

BEFORE OPERATING EQUIPMENT.

14

LOADING THE MACHINE

HOT MELT MATERIALS CAN CAUSE SEVERE BURNS. PROTECTIVE CLOTHING

SHOULD BE WORN AT ALL TIMES WHEN FILLING OR OPERATING THIS EQUIP-

MENT. READ THE ENTIRE MANUAL BEFORE OPERATING.

Material may be added to the melter when it is hot or cold. The agitator will turn “OFF”

when lid is opened to add material.

Use marker adhesive boxed in the appropriate size for the BAX 250.

To load, lift the lid of the melter and slowly add material to the desired level. DO NOT

OVERFILL. DO NOT FILL MORE THAN 6 INCHES FROM THE TOP EDGE.

IMPORTANT!! Care should be taken to avoid getting foreign particles such as road gravel,

dirt, and debris in the material. Debris of this nature can clog or damage the output line

and pumping system.

The solid material must be added at intervals, which will allow the mixer to rotate without

jamming. If blocks of material are fed in too quickly, jamming will result and slow down the

melting process.

SHUTDOWN AND CLEAN-OUT PROCEDURE

When shutting down the machine for the day, Crafco recommends leaving the material

level at or below agitator paddles. This will give a fairly rapid heat up rate in the morning, but

will allow enough material to start dispensing right away when the material becomes molten.

1. Run material level below the top of the agitator paddle or as close to empty as possible.

2. Open ball valve at hose connection, place a box or metal bucket under valve.

3. Turn shot size knob to the “FULL” position and move the shutdown switch to the “ON”

position, then extend the cylinder by activating the pump. Close the ball valve.

4. Turn material temperature down to 200° F and allow material temperature to drop 100° F

while the agitator is running.

5. Turn power toggle switch to the “OFF” possition.

6. Store hose in a safe area on the truck or trailer bed and secure.

7. Turn the agitator toggle switch to the “OFF” position.

8. Turn the engine “OFF” at the engine ignition switch.

9. Close LPG ball valve and tank valve.

STORING MACHINE

The BAX 250 should be stored in an area where moisture cannot enter machine heating

system, such as controls, etc. The heated hose must be stored safe area on the truck or trailer

bed and secured before traveling. Extended down time can cause moisture build up. Do not

travel with melter running.

15

INSTRUCTIONS FOR ORDERING PARTS

Parts may be ordered from your local CRAFCO distributor or directly from CRAFCO, Inc. if

a distributor is not available in your area. When ordering parts, give the following

information:

1. Part Number.

2. Machine Model.

3. Serial Number.

Write, telephone, or fax:

CRAFCO, INCORPORATED

25527 SOUTH ARIZONA AVENUE

CHANDLER, AZ. 85248

Phone: 480-655-8333

Fax: 480-655-1712

Toll Free: 1-800-528-8242

ELECTRIC HOSE CARE AND CAUTIONS

Twisting and kinking of the electric hose (used on LF, BAX, SS60, and SS125 Melter) is the

number one cause of hose failure.

When this happens, the electric heating wires are shorted out to the metal hose cover and

the hose stops heating.

This type of failure is not covered under the Crafco warranty.

To help prevent twisting and kinking and the resulting hose damage, the operator should:

a. Not move or use hose unless it has been turned on a least 35 minutes and

set at a minimum temperature of 300°F.

b. Make sure hose swivel between hose and wand moves freely.

c. Limit the hose bending to a radius of 10 inches.

d. Avoid bending the hose over sharp edges such as the edge of the frame or

tank.

e. Avoid twisting.

f. Do not exceed 400°F. on the hose controller or material temperature.

16

g. Follow all instructions of the melter as well as those in the instruction manual.

h. Avoid pulling hose beyond its limits.

HOSE TRANSPORT INSTRUCTIONS

The heated hose must be stored safe area on the truck or trailer bed and secured before

traveling.

CAUTION:

Hose damage will occur if:

a. Hose is bent or moved when cold.

b. Hose is twisted or bent at less than a 10 inch radius.

c. Hose is moved prior to being turned on at least 35 minutes and set at

380OF.

d. Operator crosses over or under hose causing hose to twist or wires between

hose and wand connection to twist or wrap up.

e. Swivel is cold and not free to move allowing hose to twist.

f. Hose to wand wiring is pulled, stressed, or used to support the wand.

17

MAINTENANCE INSTRUCTIONS AND CHART

ENGINE

Check oil every 8 hours of operation. Change after the first 5 hours of operation and change

every 50 hours thereafter.

See engine owners manual for additional operating and maintenance instructions.

HYDRAULIC SYSTEM

Check hydraulic fluid every 8 hours. Change hydraulic filter every 250 hours. Change

hydraulic fluid every 500 hours of operation.

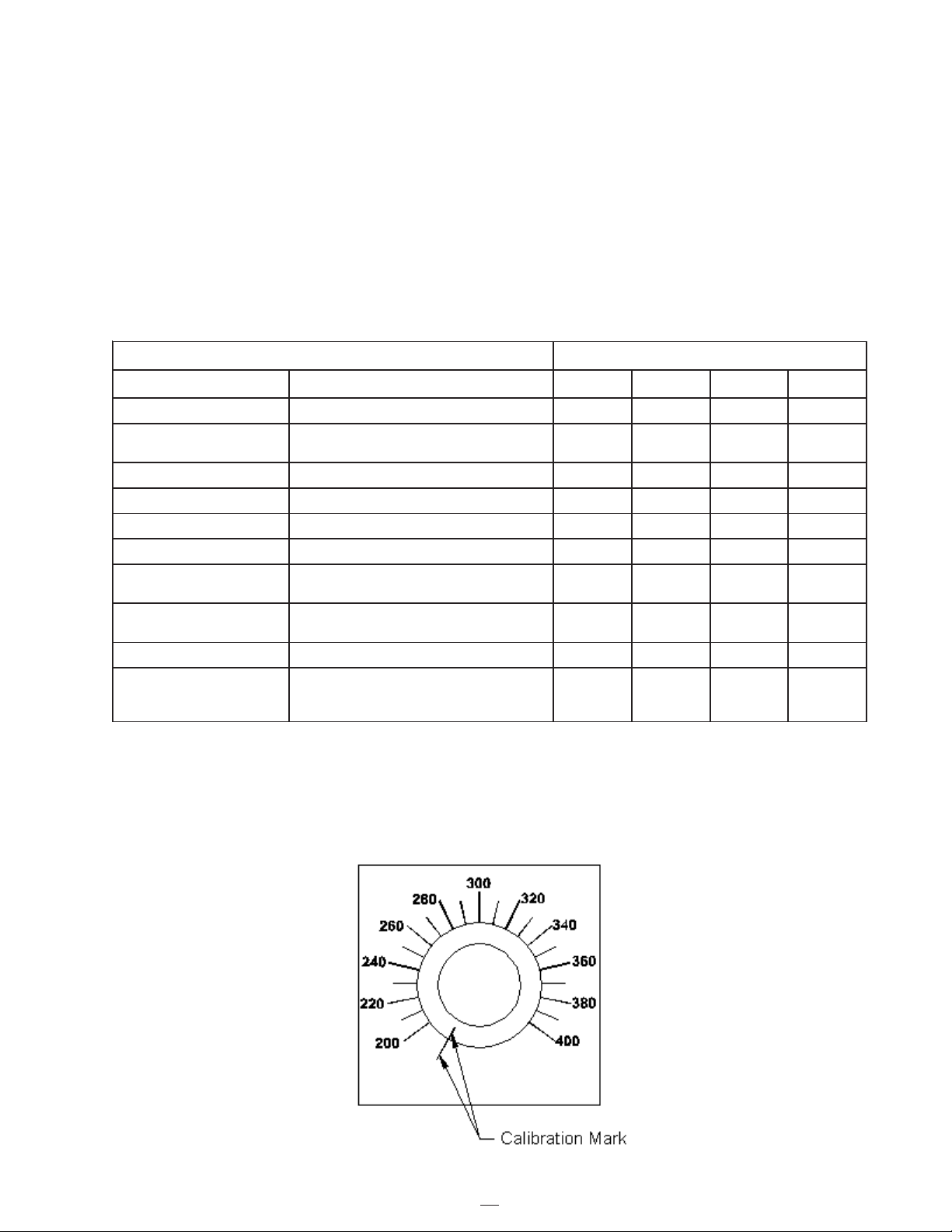

TEMPERATURE CONTROL CALIBRATION

Check control knob calibration weekly. Calibrate by aligning the line on the control knob

with the calibration line on the scale plate (see Fig. 1).

Fig. 1

SRUOH

NOITACOL ERUDECORP 8 05 052 005

levelliokcehcenignE .launamnoitcurtsnienigneeeS *

enignerehtO

ecnanetniam

dnagnitarepoenigneeeS

.snoitcurtsniecnanetniam

yrettaB .ylkeewlevelretawkcehC *

retlifliociluardyH .retliflioegnahC *

liociluardyH .liokcehC *

liociluardyH .lioegnahC *

liociluardyH dednemmocerees,lioreporproF

.stnacirbul&sdiulf

noisnettleB noisnetnokcals"2/1otnethgiT

tlebfoedis *

kcehceriW skaerbrostucrofkcehC *

noitcepsniesoH

cirtcelednaciluardyh

esoh

snoisarbadnastucrofkcehC *

18

SERVICE INSTRUCTIONS

1. Conduct a general inspection of your machine at least once a week. Replace all

worn or damaged parts, make any necessary adjustments and tighten all loose nuts

or screws.

2. Keep regular replacement items in stock for emergency repairs, to avoid costly

“down” time.

3. Watch for leaks. Tighten fitting or repair as necessary.

4. Clean machine externally periodically. Check with sealant manufacturer for

recommendation.

5. Follow recommended maintenance procedures on maintenance chart.

RECOMMENDED FLUIDS AND LUBRICANTS

NOITACILPPA DEDNEMMOCER TNIOPLLUF

lioenignE .launamsrenworelhoKotrefeR .stP4

GPL enaporP .sbL001

liociluardyH ocaxeT86-DH-liOodnoR .slaG21

19

HOSE TROUBLE SHOOTING

HOSE DOES NOT HEAT

Step 1: Is the “HEATED HOSE” switch “ON”?

YES: Go to step 2

NO: Turn switch “ON”.

Step 2: Is “HEATED HOSE” light illuminated?

YES: Go to step 3

NO: Check for tripped circuit breaker in front panel.

YES: Reset circuit breaker.

NO: Remove front panel and check for 12 volts at purple wire on

hose switch.

YES: Go to step 2a.

NO: Check for 12 volts at circuit breaker in front panel.

Step 2a: Check for 12 volts at #3 terminal (purple wire) on Pak-Stat.

YES: Go to step 2b.

NO: Check wire connections or replace switch.

Step 2b: Check for 12 volts at #7 terminal (blue wire) when Pak-Stat is on.

YES: Go to step 3

NO: Replace Pak-Stat.

YES: Check wire connections (red wire) between circuit breaker and switch

NO: Check wire connections between “ACC” teminal on ignition switch

and “A” terminal on plug #2.

Step 3: Check for 12 volts at “BATT” terminal on generator.

YES: Go to step 4

NO: Check wire connections between (blue wire) in control box to

“BATT” terminal on generator.

20

HOSE TROUBLE SHOOTING

Step 4: Check for 24 volts AC at the “BLACK”, “WHITE” and “GREEN” wires on the

generator.

YES: Go to step 5.

NO: Replace generator.

Step 5: Check for 1.08K (1080) OHMS resistance of the hose sensor (black and

white wire) at the junction box. (NOTE: One of the sensor wires must be

disconnected to check resistance).

MATERIAL DOES NOT DISPENSE WHEN PUMP IS ACTIVATED

Step 1: Is the pump cylinder extending?

YES: Go to step 2.

NO: Has the sealant had sufficient time to completely melt.

YES: Go to step 2.

NO: Allow material to heat longer.

Step 2: Has the hose had sufficient time to reach operating temperature?

YES: Go to step 3.

NO: Allow hose to heat longer.

Step 3: Check for continuity inside the control box on the red cube timer at

purple 2 and purple 4 when the wand trigger is pulled.

YES: Go to step 4.

NO: Check for continuity inside the junction box green trigger wire and red

trigger when the wand trigger is pulled wire coming from the control box.

YES: Check for damged wires between the juction box and control box.

NO: Check for continuity inside the junction box between the (2) red

trigger wires from the hose when the wand trigger is pulled.

YES: Replace terminal strip.

NO: Disconnect the hose and wand five pin plug. Check for continuity

on the wand plug between “C” and “B” pins when the wand trigger

is pulled.

YES: Your hose needs to be repaired, Contact Crafco, Inc.

NO: Your wand needs to be repaired, Contact Crafco, Inc.

Step 4: Is the top left light on the hydraulic valve illuminated when trigger is

activated?

YES: Replace coil

NO: Is the shutdown toggle switch in the “ON” position?

Yes: Turn the toggle switch to the opposited position.

No: Go to step 5.

Step 5: Is there 12 VDC between the #9 relay terminal and #12 relay terminal

in the control box when the trigger is pulled?

YES: Check the wiring between the control box and the hydraulic valve.

NO: Go to Step 6.

Table of contents