Eswood UT-20 Series Technical Document

EQUIPMENT MANUAL

FOR

UT-20 UTENSIL WASHER

(INCLUDES UT20H & UT20P MODELS)

JUNE 2011

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 2

T

ABLE OF CONTENTS

1. Important: Prior to Installation 3

2. General Description 4 & 5

3. Tec nical Specifications 6

4. Installation 7

5. Initial Start-up Procedure 8

6. Was ing Operation 9

7. S utdown and Maintenance 10

8. Trouble S ooting 11 & 12

9. Drawings 13,14,15,16,17

10. Wiring Diagram 18

11. Warranty 19

12. Spare Parts & Service 20

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 3

I

MPORTANT

:

PRIOR TO INSTALLATION

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

1

Installation must be carried out according to local regulations by

qualified trade persons. Isolating switc (es), s ut-off valves etc must

be wit in easy reac of t e mac ine for future service and

maintenance requirements. If in doubt call ESWOOD AUSTRALIA or

t eir representative for furt er information. No responsibility will be

accepted for defects or damages by improper installation, for

c anges to t e product not aut orised by ESWOOD AUSTRALIA, or

for operation outside t e tec nical specifications.

ESWOOD AUSTRALIA warrants t eir products to be free from

defects in material and workmans ip under "normal use and

service". T is does not include normal wear and tear of parts.

ESWOOD AUSTRALIA will repair or replace any parts, w ic in

ESWOOD AUSTRALIA's sole judgement are defective in material or

workmans ip, in accordance wit t e warranty offered.

T is undertaking covers t e provision of labour and parts for 12

mont s from t e date of delivery to t e purc aser. T is undertaking

applies only to state capitals. Remote areas are not covered by t is

commitment and special enquires s ould be made. (Note: T avel

time not cove ed by wa anty)

In no event will ESWOOD AUSTRALIA be liable for loss of facilities

or ot er property and suc t ings as, but not limited to, additional

labour costs, loss of revenue or anticipated profits, and ot er

damages of any kind w et er direct, indirect, incidental or

consequential.

Labour under warranty is supplied free of c arge during normal

working ours, Monday to Friday. S ould warranty work be

requested outside of our normal working ours a labour c arge will

be applied equivalent to a normal our rate wit out out of ours

penalty rates. (Refer to last page of t is manual for your closest

branc for Warranty repair services)

Note: It is t e responsibility of t e owner to ensure t e water feed to

Eswood Dis and Glass was ers is of a quality t at will not form

excessive build up of calcium and ot er dissolved minerals on t e

eating elements. Premature failure of eating elements t at ex ibit

t is cause of failure will not be covered under warranty.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 4

G

ENERAL DESCRIPTION

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

2

Powe ful Pe fo mance: T e UT-20 is a ig powered was ing

mac ine designed to strip away grease and grime from pots, baking

trays, mixing bowls, bun pans, tote boxes and kitc en utensils. T e

unit is fitted wit a ig capacity was pump directing ig volumes

of detergent ot water t roug t e knife-like jets on t e upper and

lower t ree arm revolving ydro-sweep, assuring maximum

coverage.

No Fuss Automatic Ope ation: Simply open t e co-balanced

doors, slide out t e basket onto t e lower door, place items to be

was ed face down into t e basket, slide into mac ine, close t e

door and press t e green start button beginning t e pre-selected

was cycle. A safety switc ensures t e mac ine will not operate

unless t e door is properly closed. T e UT-20 features an upper

“lift” door wit smoot wear resistant HD polyet ylene guides and a

lower co-balanced inged door for ease of operation. Digital was

and rinse t ermometers along wit electronic temperature control of

t e “final rinse” assures t e mac ine will only operate (as required

by ealt standards) at t e correct sanitizing temperature.

Cycle Selection: You can c oose between t ree automatic cycles,

two, four, & six minutes simply by t e turn of a switc . Eac cycle

consists of a was period, a dwell period, followed by a fres water

final rinse at 82 °

°°

°C.

Convenient Design: T e UT-20 is designed for front operation

delivering maximum capacity for its compact p ysical size, wit

nominal c amber opening widt of 675mm, a eig t of 740mm on

t e UT-20, 850mm on t e UT-20H and an inside dept of 686mm,

capable of andling large baking trays and large 75 litre bins and

yet compact enoug to fit in smaller kitc ens. T e UT-20 as an

attractive and easy to clean satin finis stainless steel cabinet wit

co-balanced double skinned doors for ease and safety of

operation. Wide strainer screens and a deep strainer basket trap

soil particles for a cleaner was , also prevents t e pump, drain and

was arms from blockages.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 5

Fast Low Cost Installation: Simply place t e mac ine in position,

connect t e ot water supply, connect t e waste trap to drain outlet

and t e t ree p ase electric power.

Powe ful Wash and Rinse System: T e upper and lower t ree

arm ydro-sweep give a balanced was coupled wit t e knife like

jets strategically placed along eac arm gives a powerful was ing

action and maximum coverage for maximum clean ability.

Final Rinse System: T e ot water supply at 65°C is boosted to

82°C by t e mac ines integral boiler, t en passed via t e upper

and lower T-jets over t e was ed items. T e rinse line is fitted wit

a flow cont ol for water conservation and t e boiler is insulated to

conserve energy. For low pressure supply under 200kpa a rinse

pump can be supplied.

Quality, Reliability and Pe fo mance: Eswood as a reputation

for product reliability t at is second to none. T e finest of stainless

steel and durable synt etic materials are used. All Eswood products

are fully guaranteed and backed by a national support network.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 6

T

ECHNICAL SPECIFICATIONS

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

3

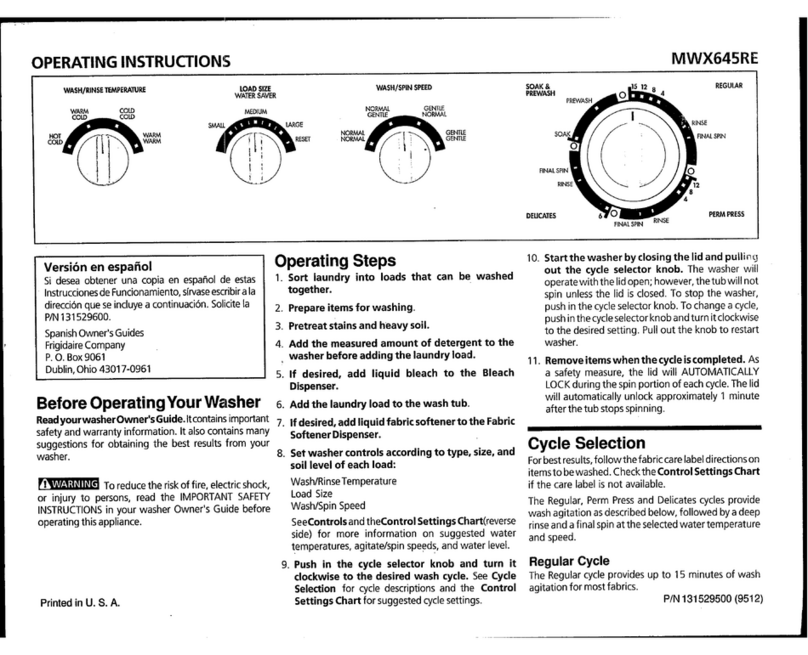

Machine Specifications

Nominal Net Weig t 150kgs

Hourly Capacity 20/24 loads per our

Total Cycle Time Selectable: 2 – 4 - 6 minutes

Dwell/Rinse Cycles 5 seconds/15 seconds

Standard Equipment Mes Basket (qty 1)

Tray Rack (1)

Open Rack 500x500mm

Wash Pump, Tank and Element

Was Pump 2.0 kW 950 litres/min

Was Tank Capacity 70 Litres

Was Tank Heater 2.0 kW

Was Water temperature 55

O

C to 60

O

C

Rinse Booste Tank and Heating

Rinse Tank Capacity 15 litres

Rinse Tank Heating 9.0 kW

Rinse Temperature 82°C to 85°C

Water Consumption 6 Litres per cycle

Hot Water Supply Pressure 200 to 400 kpa

Se vices Connections:

Electrical Requirements 415/50N, 13.5 kW

Hot Water (19∅ line) ½” B.S.P. connection

Hot Water Supply 65°C min. @200 to 400 kpa

Drain Outlet 2” B.S.P. gravity fed

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 7

I

NSTALLATION

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

4

Installation Inst uctions

1. Remove t e packing materials from t e mac ine, including

inside t e c amber.

2. Remove t e lower front panel, position t e mac ine and level

by screwing t e adjustable feet. Leave 500mm free on t e left

side under benc level for servicing.

3. Connect t e 2” B.S.P. gravity drain via a 2” trap to t e drain

outlet. Connect t e ot water supply via a min ½ ”isolating

valve (adjacent to t e unit) to t e ½ B.S.P. union at base of

mac ine. T e water supply to be a minimum temperature of

65°C and a pressure of 200-400 kpa.

Note: All plumbing work is to be done in accordance wit local

plumbing codes.

4. Ensure t at t e rotary switc is in t e “OFF” position t en open

t e control panel and connect t e 3-p ase power + N via an

isolating switc (near mac ine) to t e terminal block market L1,

L2, L3 & N, connect t e Eart to t e “E” terminal. C eck

rotation of t e was motor is as per t e arrow on motor

ousing (anti clock at motor end). Maintain rotary switc in

“OFF” position.

Note: all electrical work is to be done by qualified trades

person in accordance wit local codes and as per t e rating

plate.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 8

I

NITIAL START

-

UP PROCEDURE

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

5

1. Wit t e rotary switc “OFF”, open t e ot water supply to t e

mac ine t en turn rotary switc to “FILL” position, wit doors

closed, press green Start button, t e water from t is first

operation will fill t e rinse Boiler wit t e excess falling into t e

was tank. Open doors.

2. Place drain overflow in position if not already in place, c eck

t at t e strainer screens and strainer basket are in position.

Close door.

3. Wit t e Rotary switc still on “FILL” position, press green Start

button, t e mac ine will do a complete fill operation. Cycle

lig ts will illuminate till t e Fill is complete. Open Doors and

c eck water is near top of overflow pipe. T e was tank

eating will activate automatically.

4. Select t e 2 minute cycle by turning t e rotary switc , close

doors, the machine will not sta t till the the momete s

indicate the co ect wash & inse temp. after w ic press

green Start button and t e cycle commences wit t e

corresponding pilot lig t illuminating until t e cycle is complete.

W en finis ed c eck mac ine for leaks.

5. Turn rotary switc to “OFF” position open door and remove t e

strainer basket and screens. Remove overflow tube to drain

tank.

6. Refit t e lower panel.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 9

W

ASHING OPERATION

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

6

1. C eck t at t e Overflow Tube is firmly in t e tank waste plug.

Place Strainer Screens and Strainer Basket are in place.

2. Wit t e door closed, turn t e rotary switc to “FILL” position

and t en press t e green START button, t e cycle lig ts will

illuminate w ilst t e mac ine is filling, t en open door and

c eck t at t e water is close to overflow level.

3. Select “S ort”, “Med” or “Long” cycle, dependent on t e degree

of soil Wait till the tempe atu e displayed by the momete s

each that indicated above each, as machine will not

ope ate at low temp.

4. If no automatic detergent dispensing equipment is fitted, add ½

a cup of non-foaming commercial detergent into t e was tank,

place t e soiled items into t e Basket provided, slide Basket

into mac ine. Close door and press t e green START button,

t e cycle lig ts will illuminate till t e Cycle is complete.

5. Open Door slide Basket out onto door and remove was ed

items, To was more items repeat step 4. Except add one

level tea spoon of dete gent if no auto Dispense fitted.

Note: and feeding of detergent is not recommended for

commercial was ing mac ines and suggests an automatic

detergent dispenser be installed. C eck wit your detergent

supplier.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 10

S

HUTDOWN AND MAINTENANCE

UT-20

UTENSIL

WASHER

(INCLUDES

UT20H

&

UT20P

MODELS)

7

1. Turn t e rotary switc to t e "OFF" position.

2. Open door, remove Strainer Basket and Strainer Screens.

Empty contents into bin, t en was under tap. Remove t e

Overflow Tube allowing t e was tank to drain and do not efit

at this point.

3. To flus out t e inside of mac ine, wit door closed turn t e

switc to “FILL”, press “START” button and complete t e cycle.

Turn rotary switc to “OFF” position.

4. C eck t at t e Was and Rinse arm jets are free of foreign

matter. If necessary remove t e arms and clean under tap.

C eck t at t e Arms spin freely.

5. At t is point place Overflow and Strainer Screens and basket

back into was tank. Close t e door. Clean t e exterior wit a

damp clot . Do not pass damp cloth ove the elect ical

cont ols. Avoid abrasives or strong detergents in t e cleaning

process.

6. Leave door partially open, if possible, allowing t e mac ine to

be air dry.

7. Eswood recommends investing in a M.I.S. (Mac ine Inspection

Service) contract, to elp protect your investment by increasing

t e life and efficiency of your mac ine. T is service is

available in capital cities and regional centres w ere

recommended Eswood service agents are located. Contact

Eswood for furt er information.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 11

T

ROUBLE SHOOTING

UT-20

(INCLUDES

UT20

H

&

UT20P

MODELS)

8

P oblem Possible cause and emedy

W en mac ine is C eck t at main isolating switc is

turned on, power turned on and fuses are okay.

lig t & t ermometer

do not lig t up.

Mac ine will not start Ensure t at t e rinse

temperature as reac ed 82° C

C eck doors are fully closed.

C eck operation of Door switc .

Mac ine not filling Make sure t e water tap is turned on

correctly fully and c eck for obstructions in line

strainer (clean if necessary).

C eck if Overflow pipe is seating

Correctly, c eck “O” Ring is okay.

C eck if Solenoid valve is faulty.

Poor was C eck t at detergent feeder to

mac ine is operating correctly, if fitted.

If operational, adjust t e injector to

increase dosage.

If and-feeding wit detergent,

increase dosage.

C eck for foreign matter in was arm

jets. Clean if necessary.

C eck t at items to be was ed are

correctly placed in racks.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 12

P oblem Possible cause and emedy

C eck temperature of was tank. If

incorrect c eck t ermostat settings and

eating elements.

C eck t at t e was pump is

functioning.

Incorrect temperature of C eck t ermostat setting.

was tank

C eck eating elements.

Poor rinse C eck t at water pressure to mac ine

is not less t an 200 kPa and ensure

t at t e water isolating valve is fully

open.

C eck rinse arm jets for foreign matter

and clean if necessary.

C eck t at t e rinse solenoid is

functioning correctly.

C eck t at t e line strainer is not

partially blocked. If so, remove and

clean filter.

C eck operation of t e ball float valve.

Insufficient rinse Ensure t at temperature of

temperature incoming water supply is at least 65

O

C.

C eck t at rinse booster element

and t ermostat are functioning

correctly.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 13

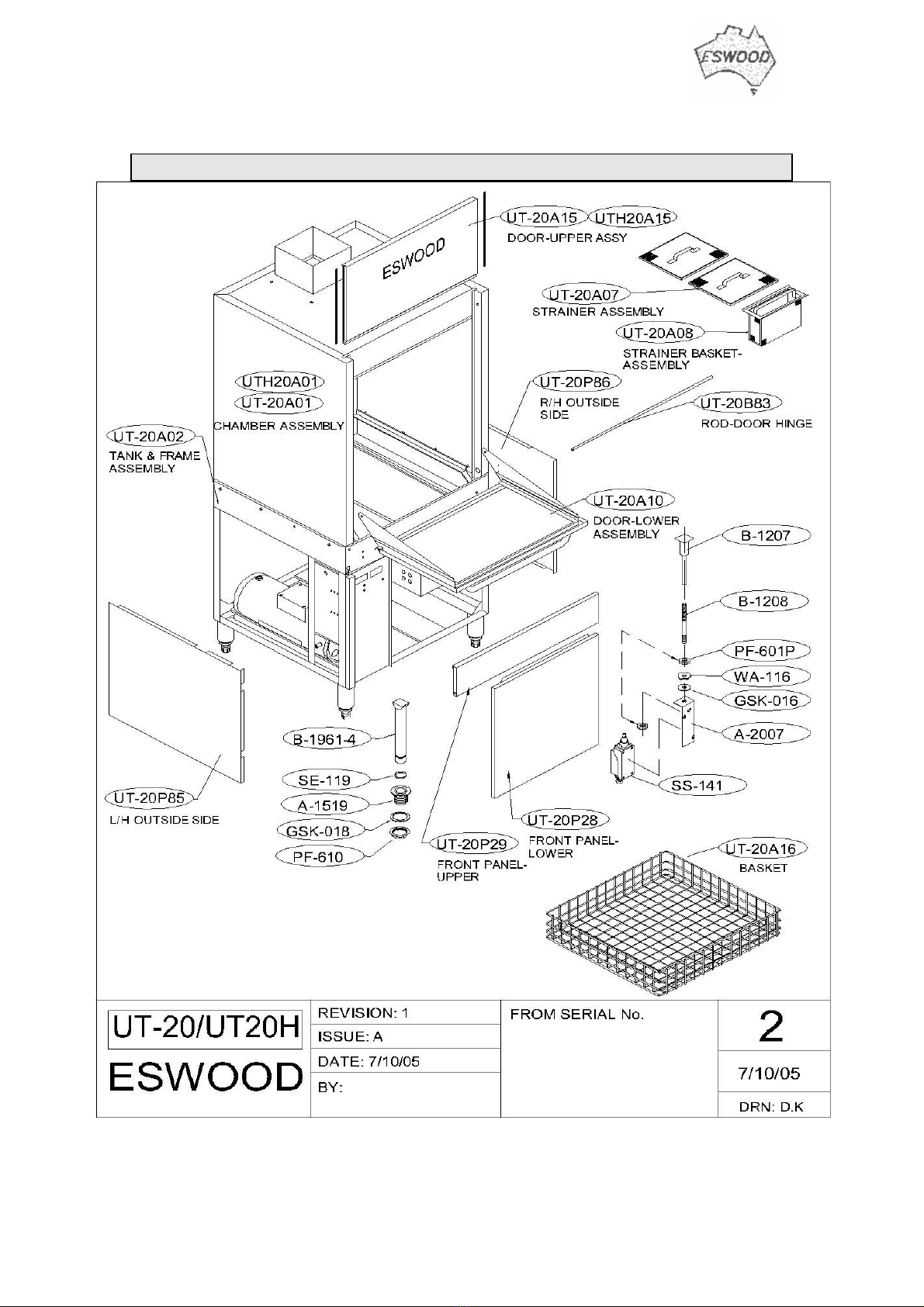

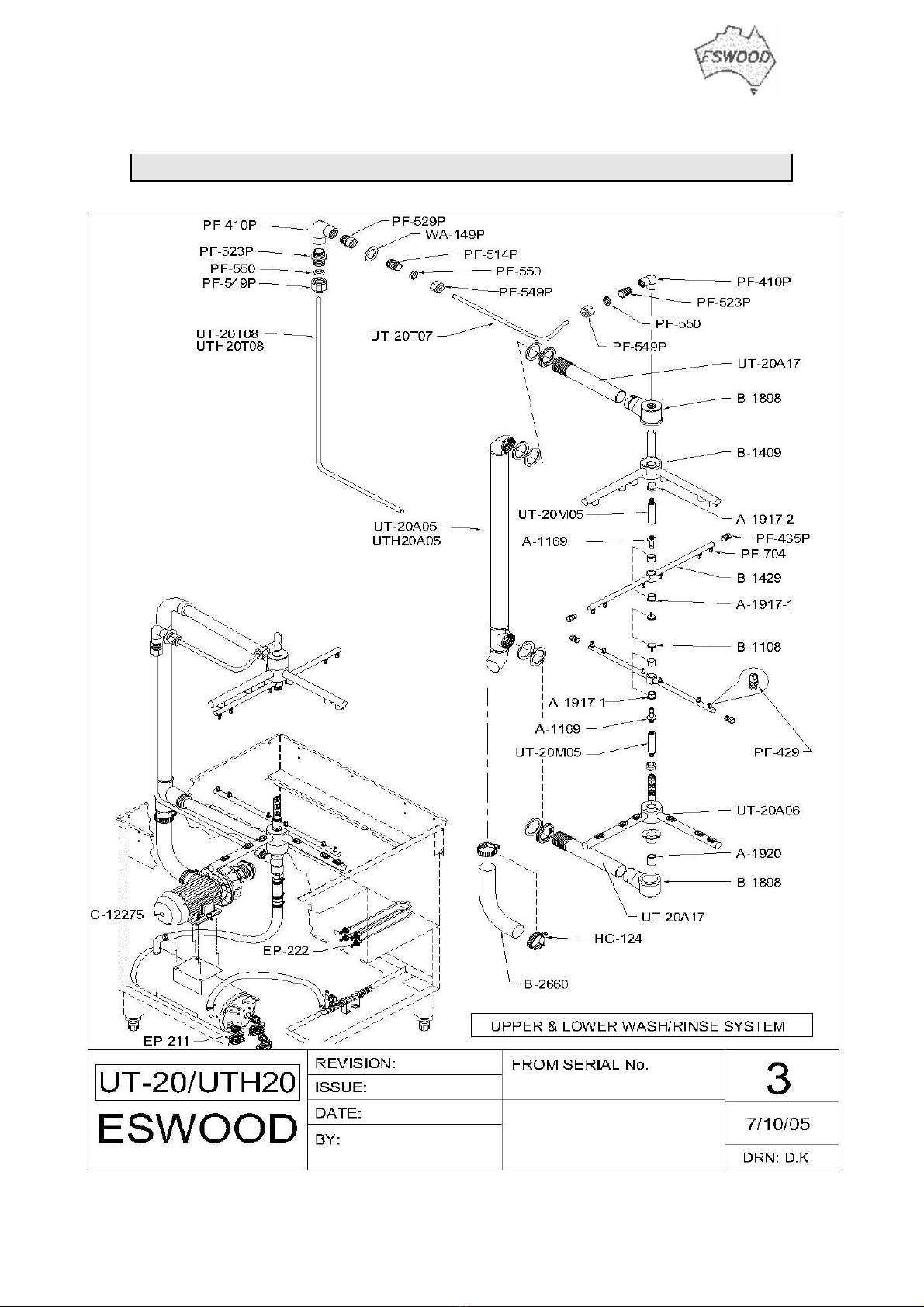

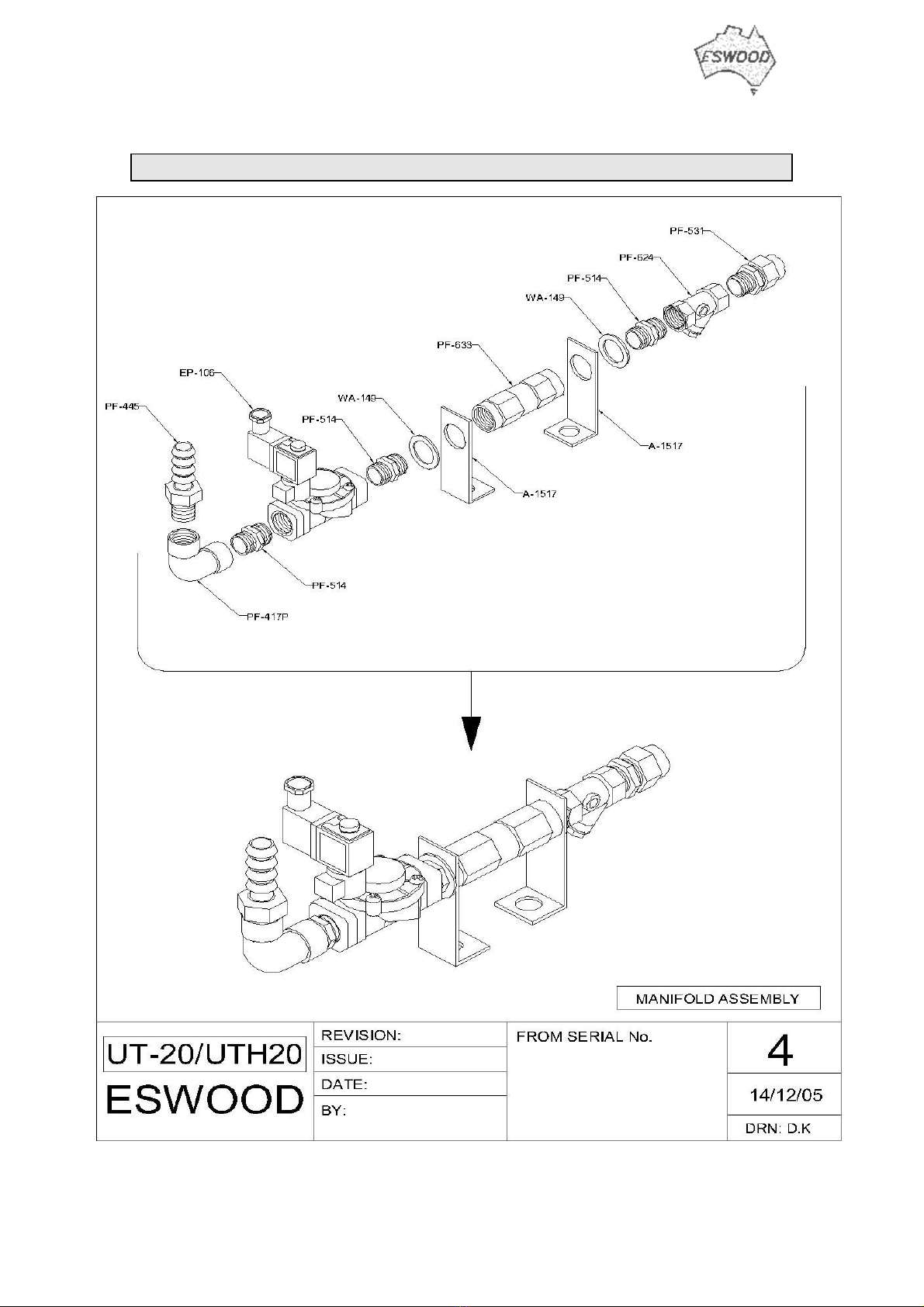

DRAWINGS

9

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 14

DRAWINGS

9

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 15

DRAWINGS

9

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 16

DRAWINGS

9

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 17

DRAWINGS

9

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 18

WIRING DIAGRAM

10

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 19

W

ARRANTY

11

Installation must be carried out according to local regulations by qualified trade

persons.

Isolating switc (es), s ut-off valves etc must be wit in easy reac of t e

mac ine for future service and maintenance requirements.

If in doubt call GOLDSTEIN/ESWOOD or t eir representative for furt er

information. No responsibility will be accepted for defects or damages by

improper installation, for c anges to t e product not aut orised by

GOLDSTEIN/ESWOOD or for operation outside t e tec nical specifications.

GOLDSTEIN/ESWOOD warrants t eir products to be free from defects in

material and workmans ip under “normal use and service”. T is does not

include normal wear and tear of parts. GOLDSTEIN/ESWOOD will repair or

replace any parts, w ic in GOLDSTEIN/ESWOOD’s sole judgement are

defective in material or workmans ip, in accordance wit t e warranty offered.

T is undertaking covers t e provision of labour and parts for 12 mont s from

t e date of delivery to t e purc aser. T is undertaking applies only to state

capitals. Remote areas are not covered by t is commitment and special

enquiries s ould be made. (Note: T avel time not cove ed by wa anty).

“To the maximum extent permitted by law, any liability on Goldstein/Eswood’s

part or on the part of its servants or agents for loss or damage of any kind

whatsoever in connection with the products, including liability for or in respect

of any claim arising out of contract, negligence or statute, shall not, in any

event, exceed 100”

Labour under warranty is supplied free of c arge during normal working ours,

Monday to Friday. S ould warranty work be requested outside of our normal

working ours a labour c arge will be applied equivalent to a normal our rate,

wit out out of ours penalty rates. (Refer to last page of t is manual for

closest branc for warranty repair services.

UT-20 UTENSIL WASHER MODELS UT20H & UT20P – JUNE 2011 20

E

SWOOD AUSTRALIA SPARE PARTS

&

SERVICE

12

Fo inqui ies and access to 24/7 se vice backup, please call ou Toll-F ee

Numbe : (Applicable to landline only c arges apply for calls made from a

Mobile P one)

1800 013 123

T is number will automatically access your nearest State office, or t e

tec nician on duty if after ours. After ours c arges apply.

This manual suits for next models

2

Table of contents