6

The control panel of a fire fighting booster is different

than the panel of a regular booster. Fire fighting

boosters are designed to work continuously during

a fire. Due to the law, these boosters do not include

thermal protection protecting the electrical engine

against fire.

Fire fighting boosters run only during fire. Thus,

there is a weekly test program aiming to minimize

the possible failures arising from long-term stand-by

and to detect and intervene to any available failure.

Fire fighting fighting booster works for a set period

of time automatically on a set date and time, and

stop. By ensuring the pumps operate one at a time

during the time set on the weekly test program, all

the pumps are operated in order.

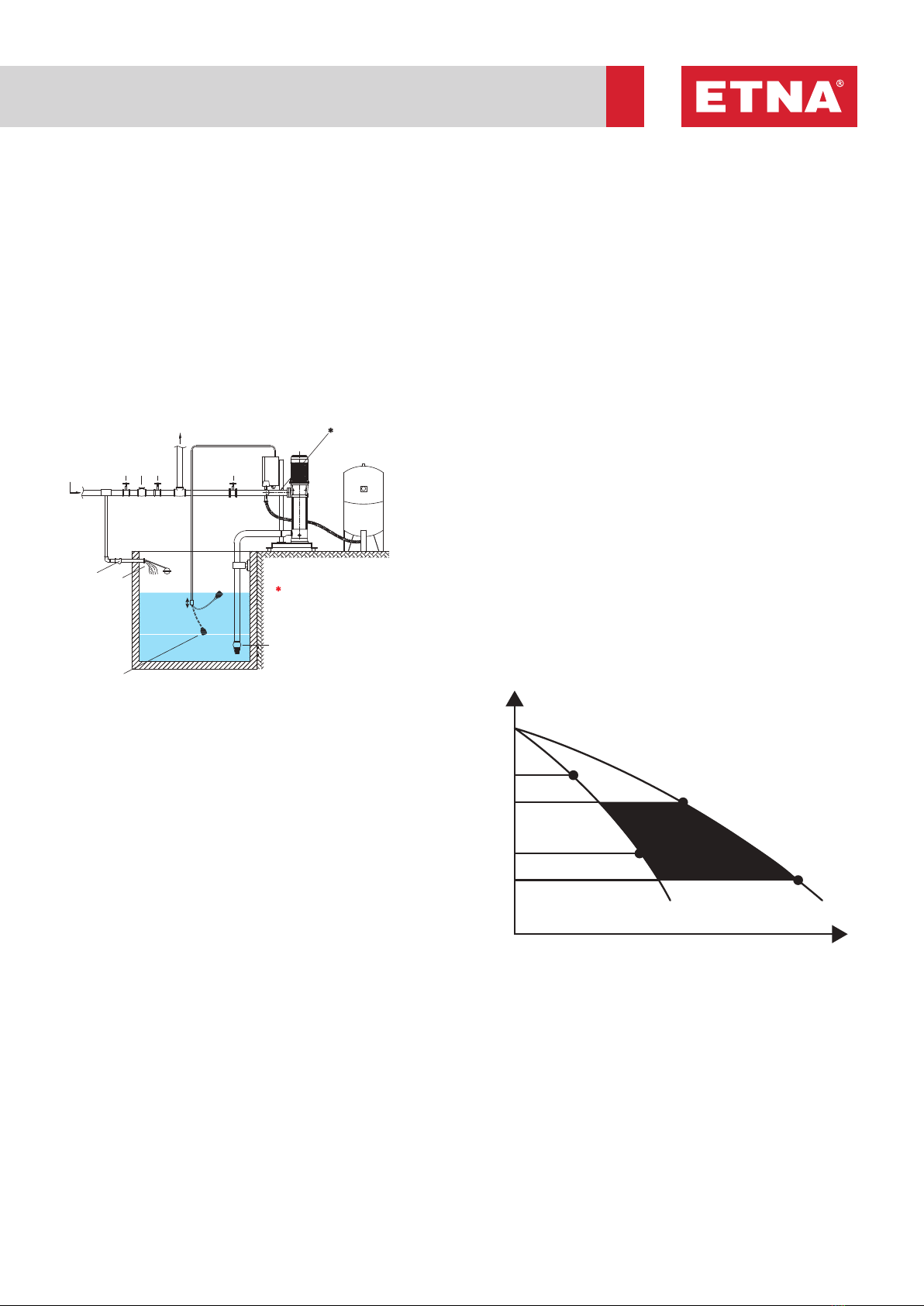

If the water level falls below the minimum level in the

water tank, the device will not be able to supply the

required pressure and falls down to the calibration

set pressure (a value just below the operating

pressure). At this point, an audio and visual alarm

is activated. Thanks to the electronic circuit. If the

system demands water from the system during the

weekly test program, the test ends and the booster

starts working regularly.

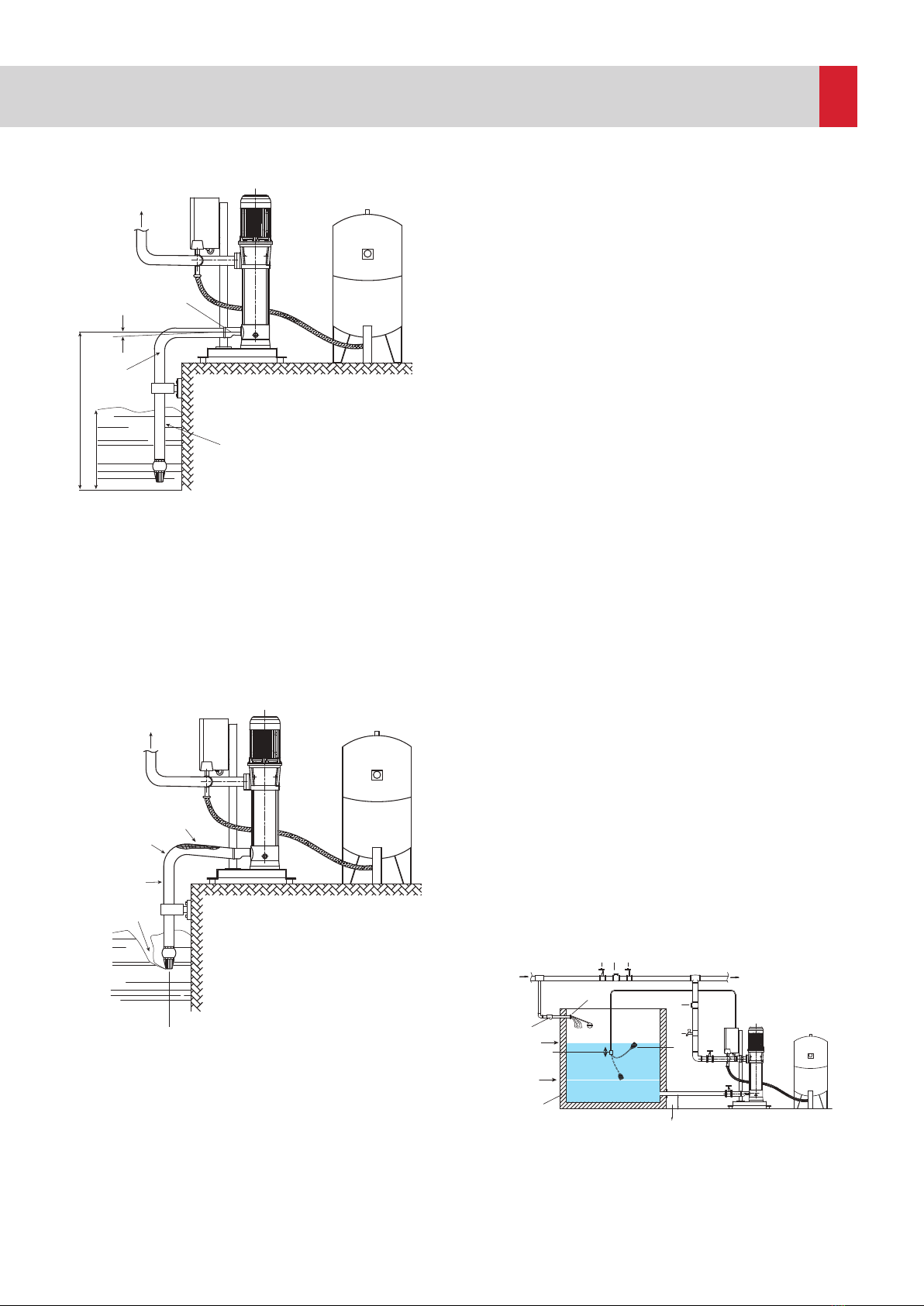

15.2 Installation

• Install the fire fighting pump in a humid-free

environment without the risk of frost and

explosion, and good ventilation.

• To keep the temperature constantly above +4 °C

in the booster room or the booster station, the

appropriate environment and the tools should

be provided.

• The rooms should be large enough to allow

comfortable entry and exit.

• If the chamber is below the surface level, stairs

allowing easy entry and exit should be built.

(Because it is very important to intervene to the

failures in cases of emergency.)

• The room should be well illuminated and the

room should have a sufficient number of plugs.

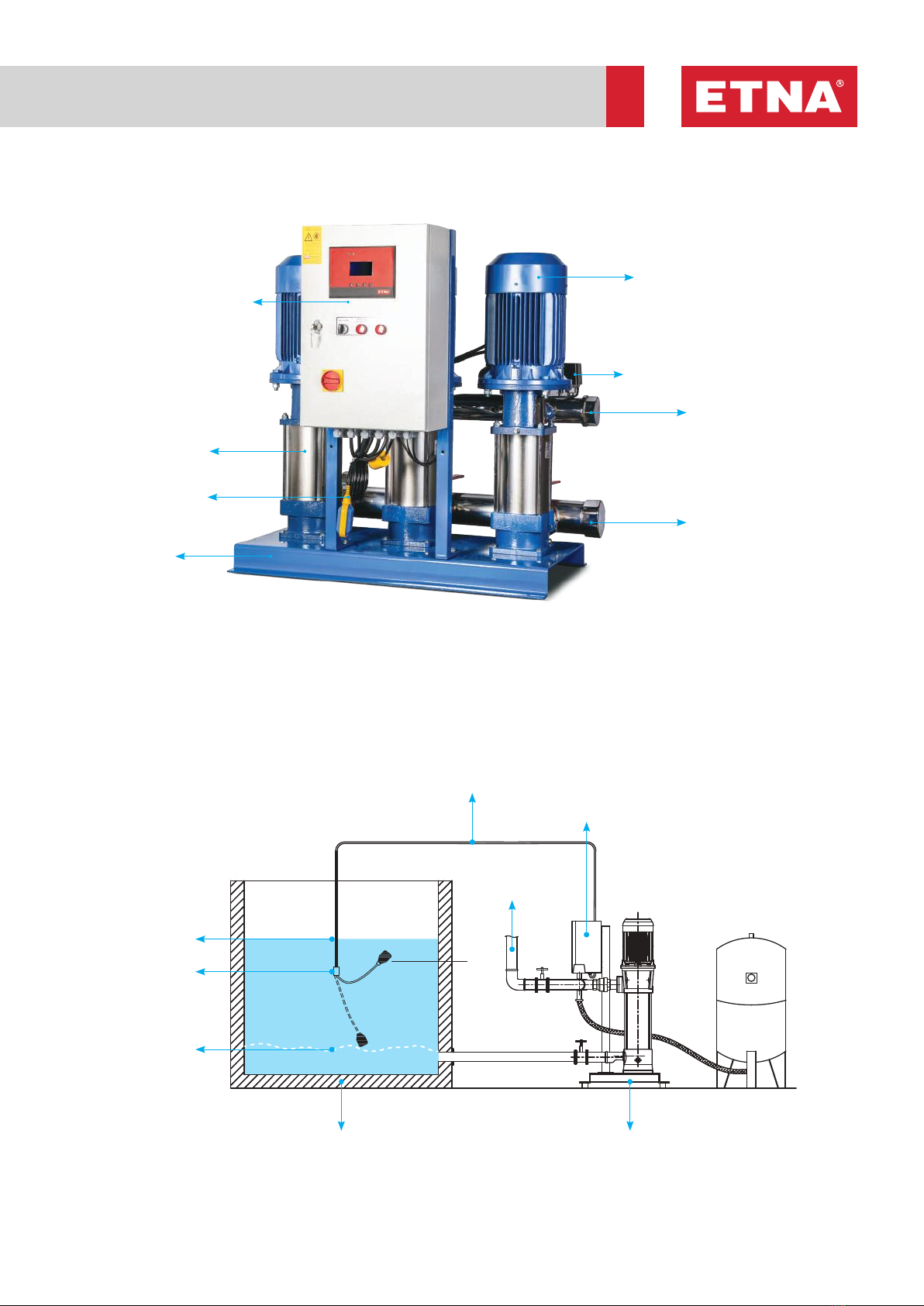

• The fire fighting booster should be placed near

the water tank or cistern as close as possible. It

is required for the suction pipe to be short and

its diameter to be equal to or larger than the

diameter of the suction pump, and space should

ensure that the assembly will be made using a

minimum amount of curves or brackets.

• Pipe connections (collectors,suction line, delivery

line) should be arranged in a way that their inlets

and outlets do not prevent accessing the parts

required to be accessed during emergencies

and the control panels.,

• While placing the fire fighting boosters, it should

be considered that the engine and/or the pump

group may be required to be disassembled

and taken out of the room. (Pipe and collector

connections should not prevent dismounting

and removing the pump and/or engine that are

the other boiler room equipments.)

• The floor should be inclined enough to allow

water drainage. If the group chamber is below

the surface level, the accumulated water should

be discharged using submerged pump and the

submerged pump should be backed up.

• If there is a risk of flood in the chamber, electrical

control panels should be mounted as high as

possible. If required, it should be carried to a

section where there is no such risk.

• If the controlpanels are onthechassis of thepump

group, it should be ensured during assembly that

the control panel is easily accessible and its cover

is easily openable (for repair and maintenance).

• If the control panels are separate from the pump

group, it should be ensured during assembly

that the control panel is easily accessible and the

front panel is directly seen when entered into the

room.

• Control panels should be grounded.

16. Jockey Pump in a Booster Unit

The jockey pump in a booster set generally to

maintain the small amount of water demands in

death hours of a day instead of running the main

pump in a huge plant.

17. Maintenance

The booster sets do not require specific inspections

at regular intervals. As a precaution, however, we

recommend that you carry out some or all of the

following checks at varying intervals depending on

the operating conditions;

• Leaks

• Thermal protector activation

• No. of starts per hour

• Noisy operation

If any malfunctions are found, refer to the next

section for possible causes and remedies, Check

membrane tank air pressure regularly every 6

months (page 7). The pump does not require any

scheduled routine maintenance. It may require

extraordinary maintenance which is generally

cleaning the liquid end or replacing the mechanical

seal or other worn parts. In this case, please refer to

the pages 12 - 25.