10

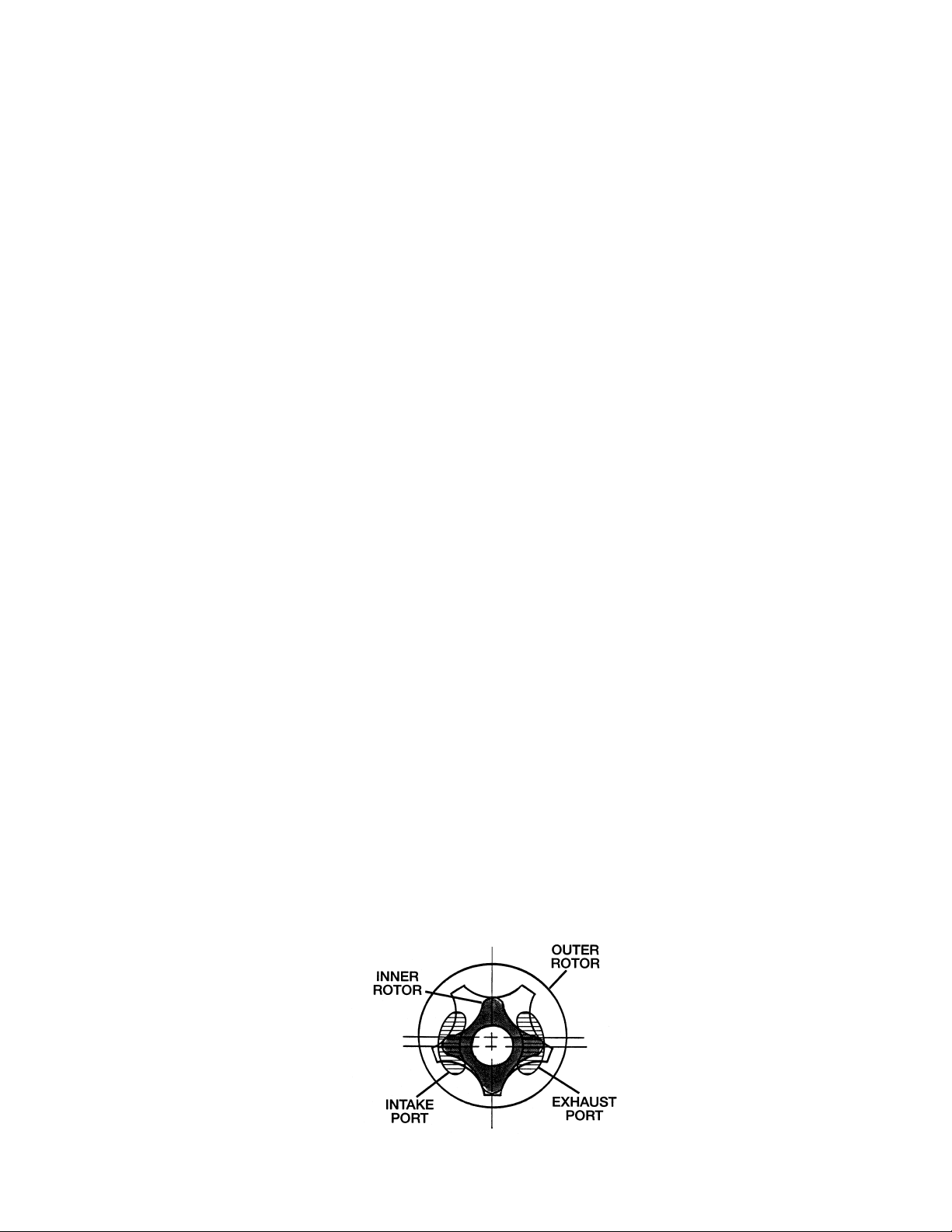

The outer rotor is held in place by a housing and is free to rotate within the housing. The pump shaft drives the

inner rotor, which in turn drives the outer rotor in the same direction, but at a slower speed.

In a gerotor pump, the pumping chamber is created between the inner and outer rotors. The boundaries of the

chamber are defined by the two contact areas where the teeth of the inner rotor meet the teeth of the outer rotor.

As the two rotors revolve, the resulting speed differential between the inner and outer rotors creates a pumping

chamber which is constantly moving. The chamber expands and contracts as the rotors turn. Inlet and outlet

ports are placed to allow gas to enter and exit the pumping chamber at the proper points. These ports, in

conjunction with the movement of the chamber, produce pumping action. A film of oil acts as a sealant and

lubricant between the two rotors, allowing pumping down to relatively low pressure levels. Because the relative

velocity between the inner and outer rotors is low, there is minimal wear of the rotating parts. As a result, the

gerotor pump is very reliable.

2.6 Pump Mechanism Description

The Model 8890 Vacuum Pump incorporates two separate in-line gerotor stages with interconnecting ports.

Relative to each other, the intake stage is at high pressure and the exhaust stage is at low pressure. Each stage

contains a two piece gerotor assembly consisting of an inner drive rotor and an outer driven rotor; the two stages

are enclosed in a common gerotor housing. The shaft turns the drive rotor which then drives the driven rotor.

Each stage has an exhaust valve with a backer valve; the backer valve prevents excessive exhaust valve travel.

The intake gerotor stage, which is the larger of the two stages, is closest to the driven end of the shaft. The intake

gerotor is larger in volume and its size determines the pumping rate of the pump. See Figure 2-3.

Gas from the system being evacuated flows into the inlet of the intake gerotor and is compressed in the gerotor

chamber. At the beginning of a pump down, the pressure of the compressed gas is sufficient to force the bypass

valve open, so most of the compressed gas is forced out the bypass valve and is vented to the atmosphere. As the

evaculation of the system continues, the pressure of the compressed gas eventually reaches a point where it is not

sufficient to force the bypass valve open.

Figure 2.3

Two Stage Gerotor Pump,

Cutaway View

At this point, all of the compressed gas instead flows from the intake gerotor into the inlet of the exhaust gerotor,

is compressed again, and with the help of the lubricating oil, pushes the exhaust valve open. From there, the

compressed gas flows out the pump’s exhaust port and is vented to the atmosphere. Both the bypass valve and the

exhaust valve have backer valves to provide extra opening resistance.

A small orifice is located in the exhaust stage. The function of this orifice is to reduce the noise level of the

pump. The orifice allows a small amount of air at atmospheric pressure to enter the gas being discharged from the

exhaust stage. This reduces the pressure differential between the atmosphere and the gas leaving the pump,

thereby reducing noise from the pump exhaust. When the pump motor is shut off while the pump is still

connected to a vacuum, the orifice vents the pump, preventing oil suckback.

The pump is mounted inside an oil case which is a reservoir for the oil that lubricates the pump. The motor shaft

drives the pump shaft via an electric motor coupling. There is a coupling body on the end of each shaft; a

coupling spider between the two coupling bodies transfers the power from the motor shaft to the pump shaft.