Evinrude Trailblazer E2020 User manual

MODEL

AND

SERIAL

NUMBER

ID

ENTIFICATION

EVINRUDE

MOTORS

MILWAUKEE,

WIS.,

U.

S.

A.

MOD

EL

NO.

Q

SER

I

AL

NO.

OUTBOARD

MARINE

CORPORATION

OF

CANADA

LTD

PETERBOROUGH

CANADA

MADE

IN

CANADA

SEE

YOUR EVINRUDE

DEALER

FOR

SNOWMOBILE ACCESSORIES.

PARTS

AND

REPAIR

SERVICE

Be

su

re

that

only

factory

approved

parts

are

used

in

your

;·

ehi

cle

. De

alers

usually

have

a

complete

stock

of

genuine

0:\1C p

arts

a

nd

c

an

p

rovide

expert

service

.

Replacement

pR

rts

not

of

our

manufacture

ha

ve

not

been

approved

f

or

your

Snowmobile.

If

fail

u

re

occ

u

rs

in

parts

not

made

or

approved

by OMC,

your

wRrrRnty

is

void.

Your

dealer

can

be

found

in

the

ye

llow

pages

of

your

phone

directory

under

"Snow

Vehicles."

FOREWORD

his

Ow

ner s

~l

an

u a

l

ha

s b

ee

n

pr

e

pared

to

assist

you

in

th

e

op

e

ration

an

d

~intenance

of

your

n

~

w Evi

nrude

Tr

ail-Bl

aze

r.

It

co

ntai

ns

info

rm

ati

on

J.at

you

s

hou

ld k

now

in order to reali

ze

peak

pe

rf

o

rm

anc

e a

nd

pl

eas

ur

e

~

operatio

n. Please

re

ad

the

e

ntire

b

ook

c

ar

efully

an

d k

ee

p it

han

dy

for

1n.tre

refe

rence

.

Many Evin

rude

Dea

le

rs or OMC S

er

v

icentre

s in s

now

ar

eas will s

tock

s

er

vice

parts

and

will

have service

inform

at

io

n for

th

e

compl

ete uni

t.

For servi

ce,

always

co

nta

ct

you

r Evin

rud

e dealer.

Sp

ec

ify t he

mo

del

n

umb

er of the

com

pl

e

te

un

it

and

the

en

gine spec

if

ic

at

ion

numbe

r.

TABLE

OF

CONTENTS

'

ARTS

AND

REPAIR

SERVItE

WDEL

AND

SERIAL

NUMBER

Insid

e

Fr

o

nt

Cover

Inside

F ro

nt

Cov

er

'PECIF

ICA

TIONS

AND

FEATURE

S . . . . . . . . . . . . .

2-3

'

l,;:C::L

REC

OM

MENDATIONS

. . . . . . . . . . . . . . . . .

4-5

0

1rC

2+4

Fu

el

Conditioner

. . . . . . . . . . . . . . . . . . . . 5

I

~A

K

-

Dl

P

ERIOD

...

............

. .

..

......

5

'

0:::-."TROL

S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

-

Sand

Bra

ke

and

Parking

Lock

. . . . . . . . . . . . . . . . . 6

-

::\eutr

al

C

ontrol

.

....

. .

....

.

.....

. .

...

. . . . 6

-

Choke

..

. . .

..

.

....

.

..

.

...........

.

....

. 6

-

Prime

r . .

....

.

....

. . .

..

.

...............

6

-

Co

mp

res

si

on Re

li

ef

. .

...

. . .

....

.· .

.....

.

...

6

- T

hrottl

e . . . . .

.....

.

..

..

. .

..............

6

-

!gnition

/ L

ights

Switch

. . . . . . . . . . . . . . . . . . . . . . 6

-

~anua

l

starter

Handl

e . . . . . . . . . . . . . . . . . . . . . . 6

-

Rever

se

Control

. . . . . .

......

.

............

. 7

-

Headlig

ht

Retractin

g

Lever

. . . . . . . . . . . . . . . . . . . 7

-H

ood

Lo

ck

Lever

. . . . . . . . .

..

.

.. ..

.......

. . 7

-

:..ighter

. .

..

....

.

..

. .

..

. .

.....

. .

..

• . .

...

7

-

Fue

l

Le

ve

l

Gau

ge . . . . . . . . . . . . . . . . . . . . . . . . . 7

-

Tacho

me

ter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

-

Speedo

me

ter

/

Odomet

er

.....................

7

-

Inst

rumen

t

Panel

D

oo

r . . . . . . . . . . . . . . . . . • . . . 7

:

ow

TO

G

ET

STARTED

. . . . . . . . .

........

.

..

8-9

-E

me

r

ge

ncy

starting

. . . . . . . . . . . . . . . . . . . . . . . 9

ETY

PR

ECAUTION

. . . . . . . . . . . . . . . . . . . . .

10

E2020

TUNE-

UP

....

. . . . .

..

•.....

. . .

......

.

...

11

-

Rai

si

ng

H

oo

d . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

-Carbur

e

tor

High Sp

ee

d

Needl

e Valve . . . . . . . . . . . 11

-L

ow

Spee

d Ne

edl

e and

Idle

Adju

s

tm

e

nt

Scr

ew . . . . .

12

-

Spark

Plug

Recomm

e

ndation

and

Repl

acem

e

nt

. . . . .

12

DRIVE

TRAIN

• . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

-Transmission

Be

lt

Inspection

an

d Re

placement

. . . . 13

-Pro

ce

dure

for

Ins

t

all

i

ng

Transm

i

ssion

Belt

. . . . . .

14

-

Brak

e

Adjustment

...

...

..

...

.

..

.

......

..

.

15

-D

r

iv

e

Chain

Adjustm

e

nt

. . . . . . . . . . . . . . . . . . . .

15

-Driv

e

Chain

Lubri

c

ation.

. . . . . . . . . . . . . . . . . . .

16

-

Reversi

ng

Mechanism

Lubrication

. . . . . . . . . . . . .

16

-

Track

Tension

. . . . . . . . . . . . . • . . . . . . . . . • . .

17

-

Tra

ck

Alignm

e

nt

. . . . . . . • . . . . . . . . . . . . . . . .

17

-S

ki

Ali

g

nment.

. . . . . . . . . . . . . . . . . . . . • . . . . .

18

BATTERY

MAINTENANCE

AND

SPECIFICATIONS

. . .

1

~

BATTERY

WARRANTY

.

.•.

.

..

.........

. . . . .

19

OFF

SEASON

STORAGE

. . . .

•.•.•...

.

...

. •

..

•

20

-Aft

er

storing

Bef

or e U

sing

.

.. ..

........

.

....

20

SERVICE

MANUAL

. . . . . . . . . . . . . . . . . . . . . . . . 20

PREVE

N

TIVE

MAINTENANCE

. . . . . . . . . . . . . • . . 21

-

Ca

r

bur

e

tor

-

Air

Filter

. . . . . . . . . . . . . . . . . . 21

-Chain

and

Track

. . . . . . . . . . . . . . . . . . . . . . . . . 21

-

Fu

el

Filter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LUBRI

C

ATION

RECOMMEND

A

TI

ONS

..

.

.....

....

22

SERVI

CE DIAGNOSIS .

..

. .

.............

...

23

-

24

OWNER'S

WARRANTY

CE

RTIFI

CA

TE

.•

Inside

B

ac

k Co

ver

WARRANTY

SERVICE

. •

.....

..

. . .

Insid

e

Ba

ck

Cover

WARRANTY

. . . . . . . . . . . . . . . . . . . . . . .

Ba

ck C

over

@ OUTBOARD MAR

INE

CORPORATION

ALL

RIGHTS RESERVED

1971

MODELS:

E2025

(ELECTRIC START 1

FEATURES... • Capacitor Discharge (C.D.) Ignition • Dash Mounted Fuel Gauge

•

One

Piece Polycarbonate Hood

• Retractable Sealed Beam Headlights

• Steel Skis With Replaceable

Runners

• Compression Relief

• Super-Range Automatic

Torque-Sensing

Transmission

• Neutral Lockout

• Reverse Gear

2 • Wide Track Stability

• Safety Padded

Steering Bar

• Cigarette Lighter

On

Electric Start Model

• Chrome Wrap-Aroum

Front & Rear

BumpE

• Power

Tune

d Muffle!

"

• Under Seat Storage

Compartment

• Polyurethane Track

• Low Cen.ter Of Gravity

• Reaction Balanced (Opposed Firing)

Two Cylinder Engine

SPECIFICATIONS

AND

FEATURES

CAUTION: Snow

Vehic

les

are

n

ot

manufac

tu

red

for

hi

gh-

way u

se

and

the

ma

n

ufac

t

urer

does

n

ot

repre

sent

that

they

a r e equi

pped

with

all

the

devic

es l

ega

lly

req

uir

ed

for

such

us

e.

DIMENSIONS IN INCHES

LENGTH

- - - - - - - - - - - - - - 103"

WIDTH - - - - - - - - - - - -

37"

HEI

GHT

-

With

windshie

ld - - - - - - -

41.4"

Without

windshie

ld - - - - - - - - - - 3

7"

TRACK

WIDTH - - - - - - - - - - - - - - -

20.5"

ENGINE - - - - - - - - - - OMC 2-

cyc

le

oppos

ed

twin

BORE

- - - - - - - - - - - - - - - - - - 2.750

STROKE -------------------

2.250

DISPLACEMENT

26.7

cu

in

(437

C.C.)

COOLING - - - - - - - - - - - - - - -

·Air

CARB - - - - - - - - - -

Tillo

t

son

HD-llA

IGNITION -----

Capaci

to

r

discharg

e (C.D.)

RA

TING - - -

Maximum

30

HP

at

5800

rpm

VARI

ABLE

SPEED

DRIVE

Centrifuga

l

operated

sheave

en

gages

V-

belt

Overall

r

at

io 5 to 1

FINAL

DRIVE - - - - - - ASA 35

double

c

hain

Sprocket

r

atio

16

to

42

REVERSE TRANSMISSION Dog

clutch

and

bevel

gea

rs

COMPRESSION

RELIEF

T

hi

s

control

is

u

sed

to

ease

starting

by

reduc

i

ng

the

i

ni

ti

al

compre

ssion.

Pull

it

out

before

starting

.

After

machi

ne

is

sta

rted

be

sure

to

pus

h

it

i

n.

MUFFLER

Tuned

for

maxim

um

p

er:

o:-=...._;

BRAKE - - - - - - - - - - -

Disc

typ

e,

han

d ope

:-

.>.l:-::.

TRACK

-

One

pi

ece

mo

l

ded

po

lyuret

hane

t!'"?.CL..

full

y

ad

jusra!::e

SKIS - - - - - - - -

Formed

steel,

eq

ui

ppe

d wi

th

shocl:-

a

bsorbing

leaf

sp

ring

s a::::!

rep

lac

eab

le

wea r rtm::!e:-s

SEA

TING

CAPA

CITY

- -

Two

ad

u

lts

. Vinyl coa

ted

co,e

:-

.

mol

ded

urethan

e foam cust::

o::_

HOOD - - - - - - - - -

FUEL

TANK

CAPACITY

Mo

l

ded

pol

ycar

bo

=

6 U.S.

gallons

or

5 I

mp

e

!""'

.a:

gall

<r

..s

ENGINE

FUEL

M

IX

TURE

- - - - - -

Ga

s/ o

il

rati

o 2

.;

::

GASOLINE -------------

Pre

mi

um

l

eaded

LUBRICANT - - - -

Evinrude

Snowmobil

e

L

ubr

ic

~

::.

(in

Canada

) OMC 2-cy

cl

e

motor

o

il

SPARK

PLUG

AND GAP - - - - - - -

Ch

amp

i

on

l:

J2.j -

.028..

to

.033..

g2;J

HEADLIGH

TS

-

Retractable

sealed

beam

- - - - - -

TAIL

LIGHTS - - - - - - - -

O

UTB

OA

RD

MA

RINE CO

RP

O

RA

TION

reserves

the

ri

ght to

ch

ang

e w

ei

ght, construc-

tion,

mat

e ri

als

,

specif

i

cat

i

on

s or

pr

i

ces

w

it

hout

notic

e and

witho

ut

obligat

ion.

3

FUEL

RECOMMENDATIONS

The

corre

ct

fuel

mixture

ra

tio

is

50

par

ts

of

a g

ood

g

rade

,

regu

l

ar

lead

ed

gasoline

to

one

part

Evinrude

50:1

Sn

ow-

mobil

e

Lubr

ican

t , or

in

Canada

OMC 2-

cycle

motor

011.

In

some

gaso

lines

the

amount

of l

ea

d

has

b

een

replaced

with

phosphorus

.

Since

ph

osph

o

rus

is

detrim

e

nt

al

when

used

in

2-

cyc

le

engines,

th

e

us

e

of

these

gas

ol

in

es

is

not

r

ec

ommended

.

lf

rec

om

m

ende

d l

ubr

ic

ant

is

not

available,

use

an

ash

l

ess

outboard

or

ash

l

ess

sn

owmob

il

e

oil

m

ix

ed

at

24:1

ratio

.

Automotive

oils

and 24:1

premix

fue

ls

shoul

d

not

be

u

sed

exc

e

pt

in

eme

r

ge

nc

ies

when

the

reco

mm

en

ded

o

il

is

not

available.

It

sh

o

uld

be

r

ecog

ni

zed

that

a

ut

omo

ti

ve

o

ils

ar e

formulated

to

fit

the

nee

ds

of

4-

cycle

a

utom

ot

ive

en

gi

nes

and E

vi

nr

ude 50:1 Snowmobile

Lubricant

and

OMC

2-

cyc

le

mo

t

or

oils

ar e

formulated

f

or

t

he

2-

cycle

en

gine

installed

in

your

snowmobile.

4

Use

th

e

follo

wing t

ab

le

to

determ

in

e

the

5

0:

1 fuel

and

oil

miXture

for

U.S. a

nd

Imperial

mea

sur

e

s:

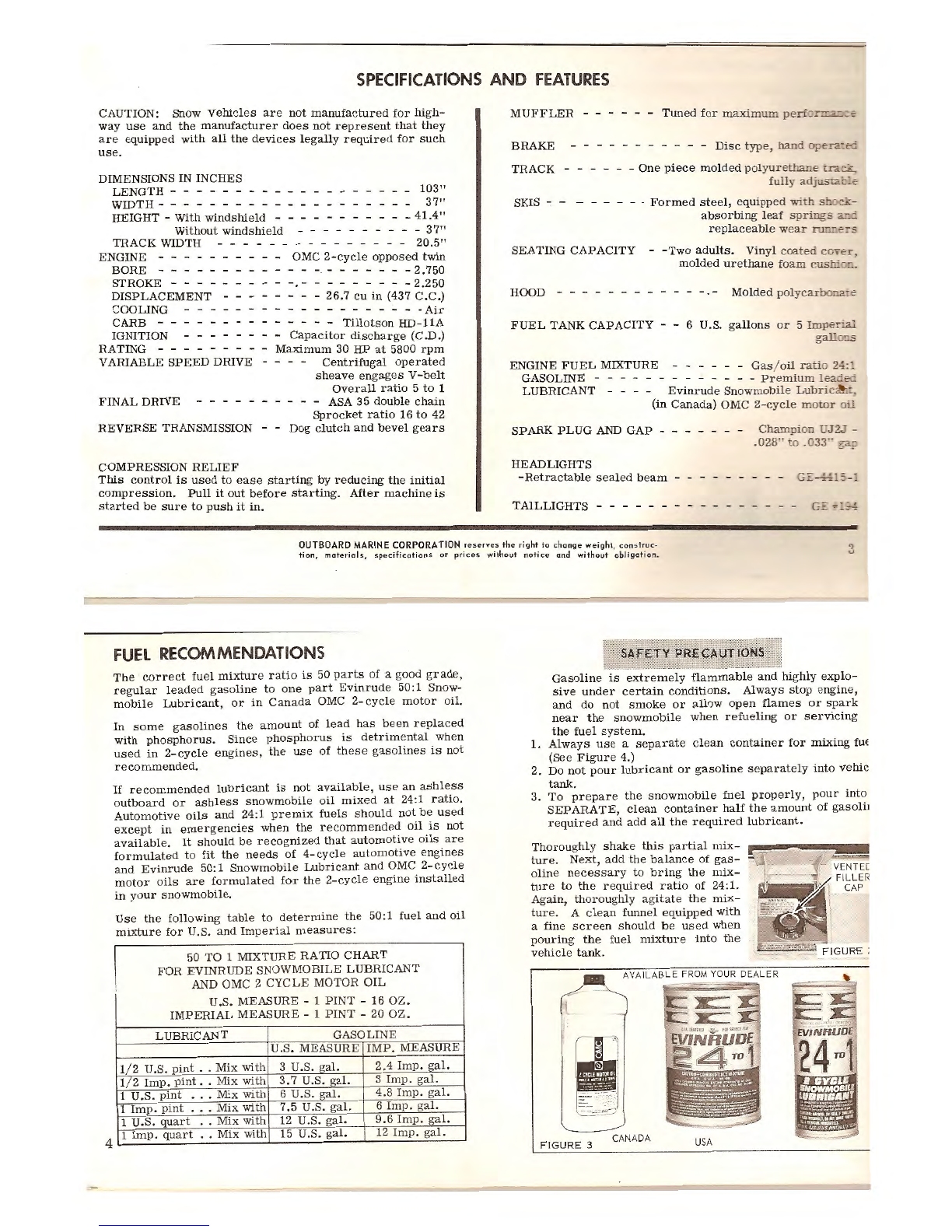

I 50 TO 1 MIXTURE RATIO

CHART

FOR

EVINRUDE SNOWMOBILE

LUBRICANT

AND OMC 2

CYCLE

MOTOR

OIL

U.S. MEASURE - 1

PINT

-16

OZ.

IMPERIAL

MEASURE - 1

PI

N

T-

20 OZ.

LUBRICANT GASOLINE

U.S. MEASURE

IMP.

MEASU

RE

1/ 2 U.S.

pint

. .

Mix

with

3 u.s.

gal.

2.4

Imp.

ga

l.

1/ 2

Imp.

pint

. .

Mix

with

3.

7 u.s.

gal.

3 Imp.

ga

l.

1

U.S.

pint • . .

Mix

with 6 u.s.

ga

l.

4.8

Imp.

g

al.

1

Imp.

pint

.

•.

Mix

with

7.5

U.S.

ga

l.

6

Imp.

gal.

1 U.S. q

ua

rt

.•

Mix

with 12 U.S.

ga

l.

9.6

Imp

.

ga

l.

1

Imp.

qu

art

..

Mix

with 15 U.S.

gal.

12 I

mp.

ga

l.

Gasoline

is

extreme

ly

flammable

and

hi

g

hl

y explo-

sive

und

er

certain

condition

s.

Alwa

ys

stop

engi

ne,

and

do

not

sm

oke or a

ll

ow

open

fl

ames

or

spark

n

ea

r t

he

snowm

ob

il

e

whe

n

refu

e

lin

g

or

servici

ng

th

e

fuel

system.

1.

Always

use

a

separat

e c

lean

containe

r

for

mixin

g

fuE

(S

ee

Fi

gure

4.)

2. Do

not

pour

lubri

cant

or

gasoline

separately

into

vehic

ta

nk.

3.

To

prepare

the

snowmob

il

e

fuel

prope

rly, po

ur

into

SEPARATE

clean

co

ntain

er ha

lf

t

he

amount

of

g

asolil

requ

i

red

and add

a

ll

the

required

lubri

cant

.

Thoroughly

shake

this

part

i

al

mix

-

tur

e.

Next,

add

the

balance

of

ga

s-

o

lin

e

necessary

to

bring

th

e m

ix-

ture

to

the

required

rati

o

of

24:

1.

Agai

n,

thoroughly

agitate

the

mix

-

tu

re

. A

clea

n

funnel

eq

u

ipped

with

a

fine

screen

sh

o

uld

be

us

ed

when

pou

rin

g

th

e

fuel

mix

tu

re

i

nto

the

vehicl

e

tank.

F I

GURE

3

CAN

A

DA

USA

FUEL

RECOMMENDATIONS

..

continued

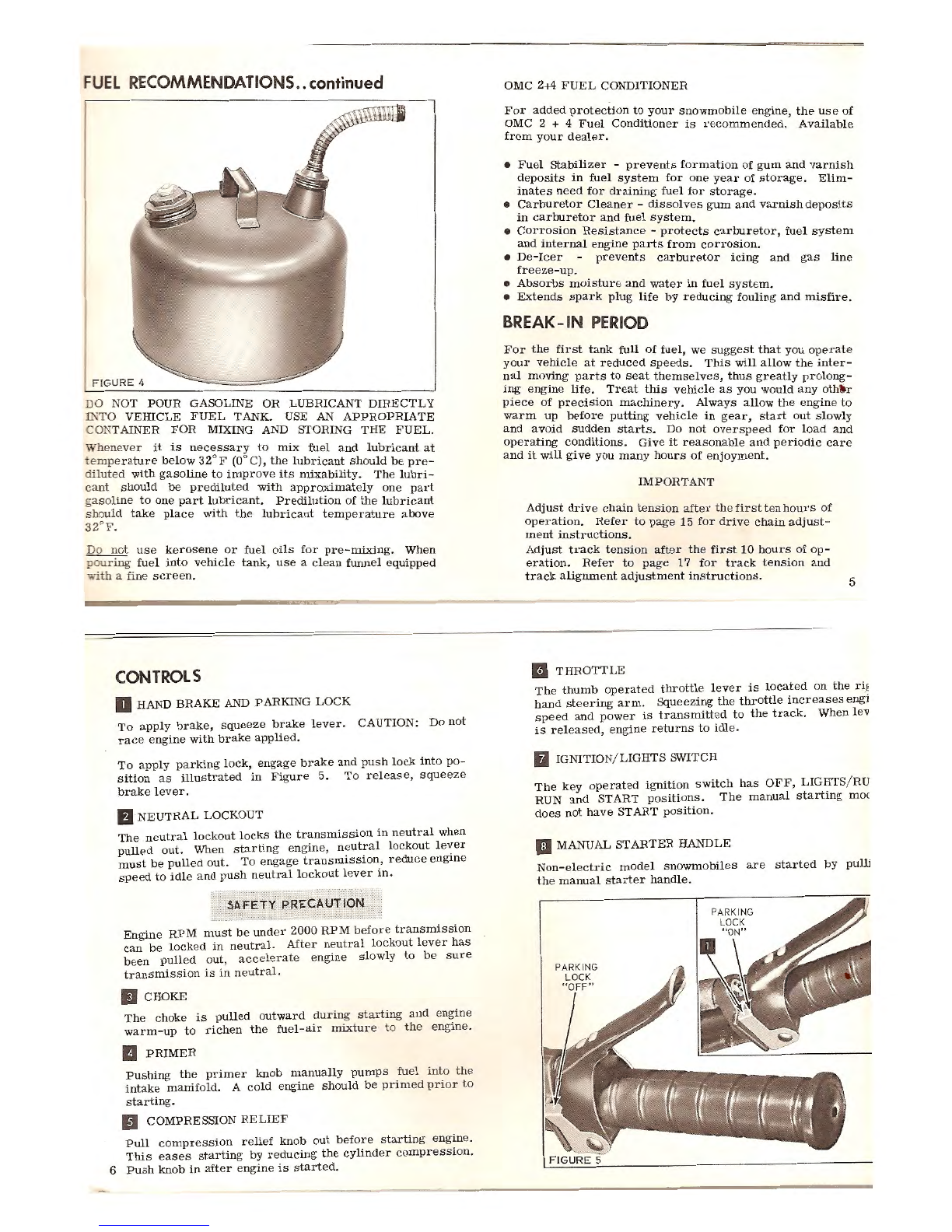

DO NOT

POUR

GASOLINE OR LUBRICANT DI

RECTLY

IXT

O

VEHICLE

FUEL

TANK. USE AN

APPROPRIATE

CONTAINER

FOR

MIXING AND STORING

THE

FUEL

.

Whe

never

it

is

necessary

to

mix

fuel

and

lubricant

at

te

mp

erature

below

32

°F (0°C), t

he

lubricant

should

be

pre

-

dil

ut

ed

with

gasoli

ne

to

improve

its

mixability.

The

lu

bri

-

c

ant

should

be

prediluted

with

approximate

ly

one

part

ga

soline

to

one

part

lubricant.

Pre

dilu

tion

of

the

l

ubrica

nt

sho

uld

take

place

with

the

lubricant

temperature

above

32°F .

Do

not

use

kerosene

or

fuel

oils

for

pre

-

munng.

When

pou

ring

fuel

into

vehicle

tank

,

use

a

clean

fu

nn

el

equ

ipp

ed

v.it

h a

fine

screen.

CONTROLS

D HAND

BRAKE

AND pARKING LOCK

To

apply

brake,

squeeze

brake

l

ever.

CAUTION: Do

not

race

eng

ine

with

brake

applied.

To

apply

parking

lock,

en

g

age

b

rak

e

and

push

lock

into

po-

sition

as

illustrated

in

Figure

5.

To

release

,

squee

ze

brake

l

ever.

II

NEUTRAL

LOCKOUT

The

neutral

lo

c

kout

locks

the

transmission

in

ne

utral

when

pulled

out.

When

startin

g

engine

,

neutral

lo

cko

ut

l

ev

er

mu

st

be

pulled

out.

To

engage

transmission,

reduce

engme

speed

to

i

dle

and

push

neutral

lock

out

lever

m.

SAFETY

PRECAUTION

En

gine

RPM

must

be

und

er 2000

RPM

before

trans

mi

ssion

can

be

locked

in

neutral.

After

ne

utral

lockout

lever

has

been

pulled

o

ut

,

acc

el

era

te

en

gine

sl

owl

y to

be

sur

e

transmission

is

in

neu

t

ral.

II

CHOKE

The

choke

is

pulled

outward

duri

ng st

arti

ng

an

d

en

g

in

e

warm-up

to

richen

the

fuel

-a

ir

mixture

to t

he

eng

in

e.

II

PRIMER

Pushing

th

e

primer

knob

manually

pumps

fuel

int

o the

intak

e

manifold

. A

cold

engine

should

be

pn

med

pn

or

to

starting.

11

COMPRESSION

REL

IEF

Pull

compression

relief

knob

out

before

startin

g

engine.

This

e

ases

starting

by

reducing

th

e

cylinder

c

ompression.

6

Push

knob

in

after

engin

e

is

started.

OMC 2+4

FUEL

CONDITIONER

For

added

protection

to

your

snowmobile

en

g

ine,

the

use

of

OMC 2 + 4

Fue

l

Conditioner

is

recommended.

Availab

le

from

yo

ur

dealer.

•

Fuel

stabilizer

-

prevents

formation

of

gum

and

varnish

depos

its

in

fuel

system

for

one

year

of

storage.

Elim

-

inates

need

for

draining

fuel

for

storage

.

•

Carb

ur

etor

Cleaner

-

disso

l

ves

gum

and

varnish

deposi

ts

in

carburetor

and

fuel

system.

•

Corrosion

Resistance

-protects

carburetor,

fue

l

syst

em

and

internal

engine

parts

fr

om

corros

ion.

•

De

-Icer

preve

nts

ca

rbu

retor

icing

and

gas

line

freeze

-

up.

•

Absorbs

moisture

and

water

in

fuel

system.

•

Extends

spark

pl

ug

life

by

reducing

fouling

and

misfire.

BREAK

-IN

PERIOD

For

the

first

tank

full

of

fuel,

we

suggest

that

you

operate

your

vehicle

at

red

uc

ed

speeds

.

This

will

a

ll

ow

the

inter-

nal mowing

parts

to

seat

th

emselves,

th

us

greatly

prolong-

ing

engi

ne

life

.

Treat

this

vehicl

e

as

you

would

any

ot

h' r

pi

e

ce

of

precision

machinery.

Always

allow

the

engine

to

warm

up

before

putting

vehicle

in

gear,

st

art

out

slowly

and

avoid

sudden

starts.

Do not

over

s

peed

for

load

and

operating

conditions.

Give

it

reasonab

le

and

periodic

c

are

and

it

will

g

iv

e

you

many

hours

of

enjoymen

t.

IMPORTANT

Adjust

drive

c

hain

tensi

on

afte

r

the

firs

tten

hours

of

operation.

Refer

to

page

15 f

or

d

rive

chain

adjust

-

ment

ins

tructions.

Adjust

track

tension

after

the

first

10

hours

of

op-

erat

ion.

Refer

to

page

17

for

track

tension

and

track

alignment

adjustment

in

structions.

B

THROTTLE

5

The

thumb

operat

ed

throttle

l

ever

is

l

o

c

a

~

ed

on

th

e

ri~

hand

st

ee

ring

arm

.

Squeezin

g

the

throttl

e

mcreases

eng1

speed

and

power

is

transmitt

ed

to

th

e

tra

c

k.

When lev

is

releas

e

d,

engin

e

returns

to

i

dle.

D IGNITION/LIGHTS SWITCH

The

key

operated

ignition

switch

has

OFF,

LIGHTS/ RU

RUN

and

START

pos

iti

ons.

The

manual

startm

g moe

does

not

have

START

position

.

liJ

MANUAL

START

ER HANDLE

Non-elec

t

ric

model

snowmobiles

are

started

by

pull

i

the

manual

start

er

handle.

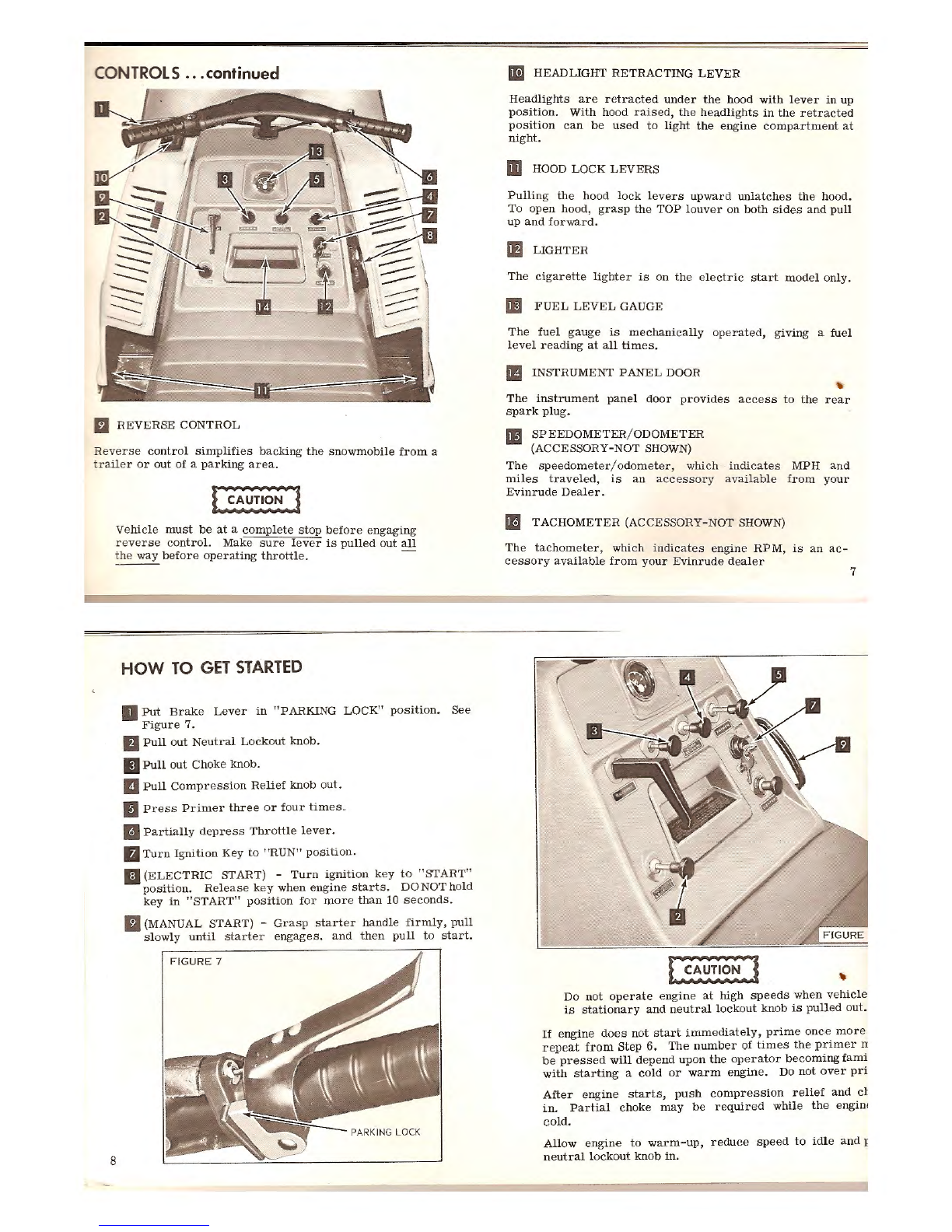

CONTROLS

.

..

continued

Ill

REV

ERSE

CONTRO

L

Rever

se

control

simplifies

back

i

ng

the

snowmo

b

ile

from

a

t

ra

iler

or

out

of

a

parking

area

.

Vehicl

e

must

be

at

a

complete

stop

before

en

gaging

reve

rse

control.

Make

sure

l

ever

is

pulled

out

all

t

he

way

before

operating

throttle

. -

8

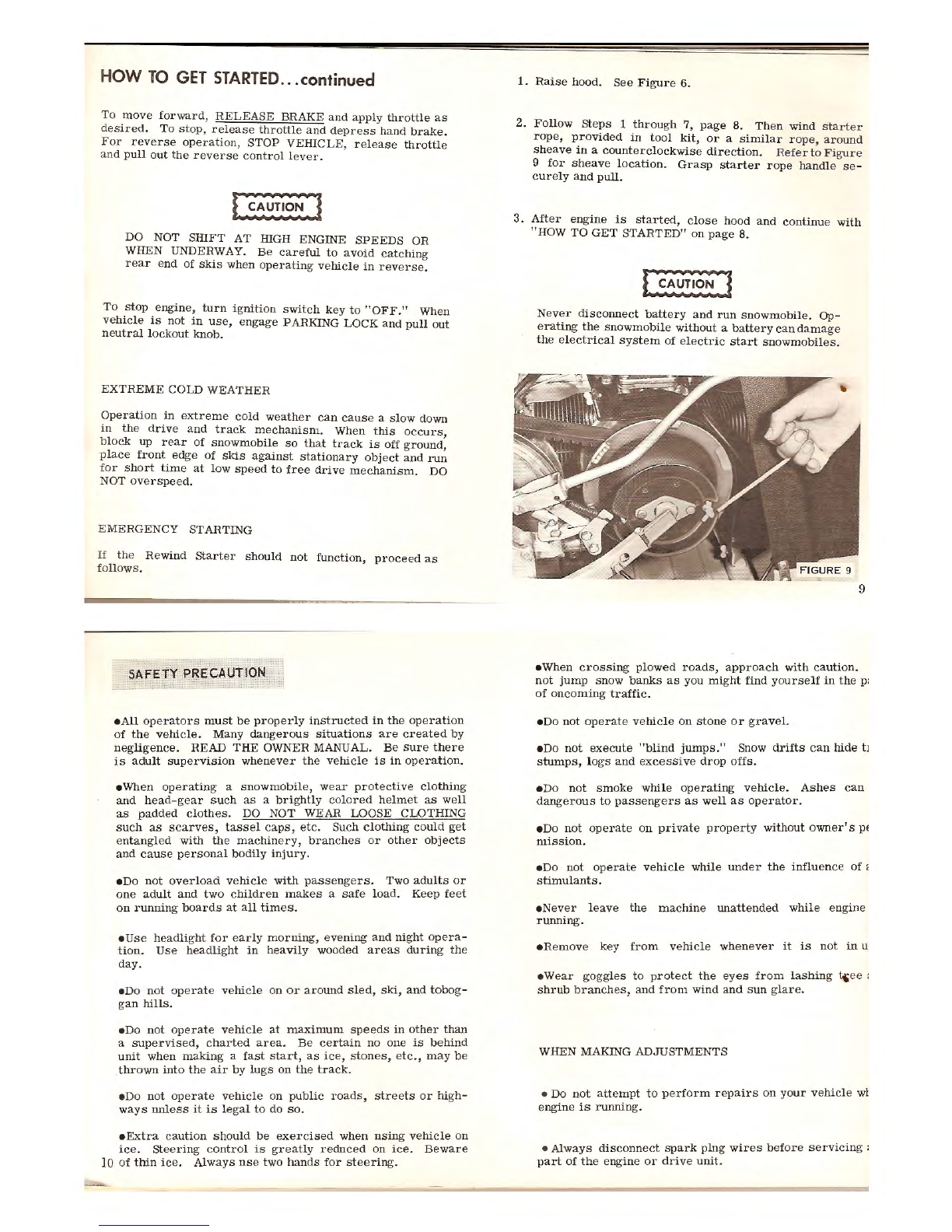

HOW

TO

GET

STARTED

II

Put

Brake

L

ever

in

"PARKING LOCK"

position.

S

ee

Figure

7.

IJ

Pull

o

ut

Neutral

Lockout

knob

.

IJ

Pull

out

Choke

knob

.

II

Pull

Compression

Relief

knob

out.

II

Press

Primer

three

or

four

time

s.

IJ

Partially

depres

s

Throttle

lev

er .

11

Turn

Ig

nition

Key

to

"RUN"

position

.

II

(ELECTRIC

START} -

Turn

ignition

key

to

"START"

posit

i

on

. Re

lease

key

when

engme

starts.

DO

NOT

hold

key

in

"S

TART

"

positio

n

for

more

than

10

seconds.

II

(MANUAL START) -

Grasp

starter

handle

firmly,

pull

slow

ly

un

t

il

starter

engages

. a

nd

th

en

pull

to

start

.

1m

HEAD

LI

GHT

RETRAC

T

IN

G

LEVER

Headlights

are

r e

tracted

u

nder

t

he

hood

wi

th

le

ver

in

up

posi

ti

o

n.

With

h

ood

ra

i

sed,

the

headlights

in

t

he

retracted

position

can

be

used

to

ligh

t

the

eng

i

ne

compartm

ent

at

night.

ID

HOOD LOCK

LEVERS

Pull

in

g

th

e

hood

lock

levers

upwa

rd

unlat

ches

the

ho

od

.

To

open

hood,

grasp

t

he

TOP

l

ouver

on

bo

th

sides

and pu

ll

up

and

forward.

IB

LIGHTER

The

cigarette

ligh

ter

is

on

th

e

elec

t

ric

st

art

model

only.

IEJ

FUEL

LEVEL

GAUGE

The

fuel

gauge

is

mechanically

operated,

giving

a

fuel

level

reading

at

all

times.

II

INSTRUMENT

PANEL

DOOR

The

in

strument

panel

door

provides

access

to

th

e

rear

spark

plug.

II

SPEEDOMETER

/

ODOMETER

(ACCESSORY-NOT SHOWN}

The

speedometer/

odometer,

which

indicates

MPH

and

miles

tra

ve

led,

is

an

accessory

available

from

yo

ur

Ev

i

nr

u

de

Dea

l

er.

lf':1

TACHOMETER

(ACCESSORY- N

OT

SHOWN)

The

tachometer

,

which

in

di

ca

tes

engine

RPM

, is

an

ac -

cessory

ava

il

ab

le

from

your

Ev

in

r

ude

dea

l

er

7

Do

not

operate

engine at

high

speeds

when

vehicl

e

is

stationary

and

neutral

lock

out

knob

is

pulled

out.

If

eng

i

ne

does

not

st

art i

mm

ed

ia

tely,

prime

once

m

ore

r

epea

t f

rom

S

tep

6.

The

number

of

times

the

primer

n

be

pressed

will

depend

up

on the

operator

becoming

fami

with

starting

a

co

ld

or

war

m

engi

n

e.

Do n

ot

over

pri

After

eng

i

ne

starts,

push

co

mpress

ion

reli

ef

and

ct

in.

Partial

choke

m

ay

be

re

q

uire

d

while

the

engin•

co

ld

.

Allow

engi

ne to

wa

rm

-

up,

reduce

s

pe

ed

to

idl

e

and

I

ne

utral

loc

kout

knob

i

n.

HOW

TO

GET

STARTED

..

.

continued

To

move

forward,

RELEASE

BRAKE

and

apply

t

hrottle

as

desired

.

To

stop

,

release

th

r

ottle

and

depress

hand

brake

.

For

reverse

operation,

STOP

VEHICLE,

release

throttle

an

d

pull

out

the

reverse

control

l

ev

er.

DO

NOT

SffiFT

AT

ffiGH ENGINE

SPEEDS

OR

WHEN UNDERWAY.

Be

careful

to

avoid

catching

rear

end

of

skis

when

operating

vehicle

in

reverse

.

To

stop

engine

,

turn

ignition

switch

key

to

"OFF

."

When

ve

hicle

is

not

in

use,

engage

PARKING LOCK

and

pull

out

neutral

lockout

knob

.

EXTREME

COLD WEATHER

Operat

i

on

in

extreme

co

ld

weather

can

cause

a

slow

down

in

the

drive

and

track

mechanism.

When

this

occurs,

blo

ck

up

rear

of

snowmobile

so

that

track

is

off

ground,

p

lace

front

edge

of

skis

against

stationary

object

and

run

fo

r

short

time

at

low

speed

to

free

drive

mechanism.

DO

NOT

overspeed.

EME

RGENCY STARTING

If

t

he

Rewind

starter

should

not

function,

proceed

as

follo

ws.

SAFETY PRECAUTION

e

All

opera

to

rs

must

be

properly

instructed

in

the

operatio

n

of

the

vehicle

.

Many

danger

o

us

situations

are

created

by

negligence

. READ

THE

OWNER MANUAL.

Be

sure

there

is

adult

supervision

whenever

the

vehicle

is

in

operation.

e

When

operating

a

snowmobile,

wear

protectiv

e

clothing

and

head-gear

such

as

a

brightly

colored

helm

et

as

well

as

padded

clothes

. DO N

OT

WEAR LOOSE CLOTHING

such

as

scarves,

tassel

caps,

etc.

Such

clothing

could

get

e

ntangled

with

the

machinery,

branches

or

other

objects

and

cause

personal

bodily

injury.

eDo

not

overload

vehicle

with

passengers

. Two

adults

or

one

adult

and

two

children

makes

a

safe

load.

Keep

feet

on

runnin

g

boards

at

a

ll

times

.

e

Use

headlight

for

early

morning,

evening

an

d

night

opera-

tion

.

Use

headlight

in

heavily

wooded

areas

during

the

day.

e

Do

not

oper

a

te

v

ehicle

on

or

around

sled,

sk

i,

an

d

tobog-

gan

hills.

e

Do

not

operate

v

ehicle

at

max

imum

speeds

in

other

than

a

supervised,

charted

area

.

Be

cert

a

in

no one is

behind

unit

when

making

a

fast

start,

as

ice,

stones,

etc.

, m

ay

be

thr

ow

n

into

the

air

by

lugs

on

th

e

track

.

eDo

not

operate

v

ehicle

on

public

roads,

streets

or

high-

w

ays

unless

it

is

legal

to

do

so.

•

Extra

caution

should

be

exercised

when

using

vehicle

on

ice

.

Steering

control

is

greatly

reduced

on

ic

e.

Beware

10

of

t

hin

ice.

Always

use

two

hands

for

steering

.

1.

Rai

se

hood.

See

Figure

6.

2.

Follow

Steps

1

thro

u

gh

7,

page

8.

Then

win

d

st

arter

rope,

provided

in

tool

kit,

or

a

similar

rope,

around

sheave

m a

counterclockwise

direction.

Refer

to

Fi

gure

9 f

or

sheave

location.

Grasp

starter

rop

e

handle

se-

c

urel

y

and

pull

.

3.

After

engine

is

started,

close

ho

od

and

continu

e w

ith

"HOW

TO

GET

STARTED"

on

page

8.

Never

disco

nn

ect

battery

and

run

snowmobile.

Op-

erating

the

sn

ow

mobile

without

a

battery

can

dam

age

the

ele

c

tr

ical

system

of

electr

ic

start

snowmobiles.

9

•When

crossing

plowed

roads,

approach

with

caution.

n

ot

jump

snow

banks

as

you

might

find

yourself

in

the

p:

of

oncoming

traffic.

eDo

not

operate

vehicle

on

stone

or

grave

l.

eDo

not

execute

"

blind

jumps."

Snow d

rifts

can

hide

tJ

stumps,

logs

and

excessive

drop

o

ffs.

eDo

not

smok

e

while

operating

vehicle

.

As

he

s

can

dangerous

to

passengers

as

well

as

o

perator.

e

Do

not

operate

on

private

property

wit

hout

owner's

p!

mission.

eDo

not

operate

veh

ic

le

whil

e

under

the

influence

of

~

stimulan

t

s.

e

Never

leave

the

machine

unattended

while

e

ngine

running

.

•R

emove

k

ey

fr

om

ve

hicl

e whe

ne

ver

it

is

not

in

u

e

Wear

goggles

to

protect

the

eyes

from

lashing

"

ee

:

shrub

branches,

and

from

w

ind

and

sun

g

lar

e.

WHEN MAKING ADJUSTMENTS

• Do

not

attemp

t to

perform

repairs

on

your

vehicle

wt

engine

is

running.

•

Always

disconnect

spark

plug

wires

before

s

ervici

ng

:

part

of

the

engine

or

dr

i

ve

un

it.

TUNE

-UP

RAISING HOOD

1.

Pull

hood

lock

levers

up

to

release

hood

lat

ches

.

See

Fi

gur

e 6.

2.

Grasp

top

l

ouver

on

both

s

id

es

and

pull

up

and

forward

.

A

retainer

bar

will

prevent

hood

from

being

dama

ged

agains

t

the

front

bumper.

3. When

closin

g

hoo

d,

end

of

retainer

bar

mus

t

be

held

up

so

that

it

does

not

ca

tch

on

la

tch

.

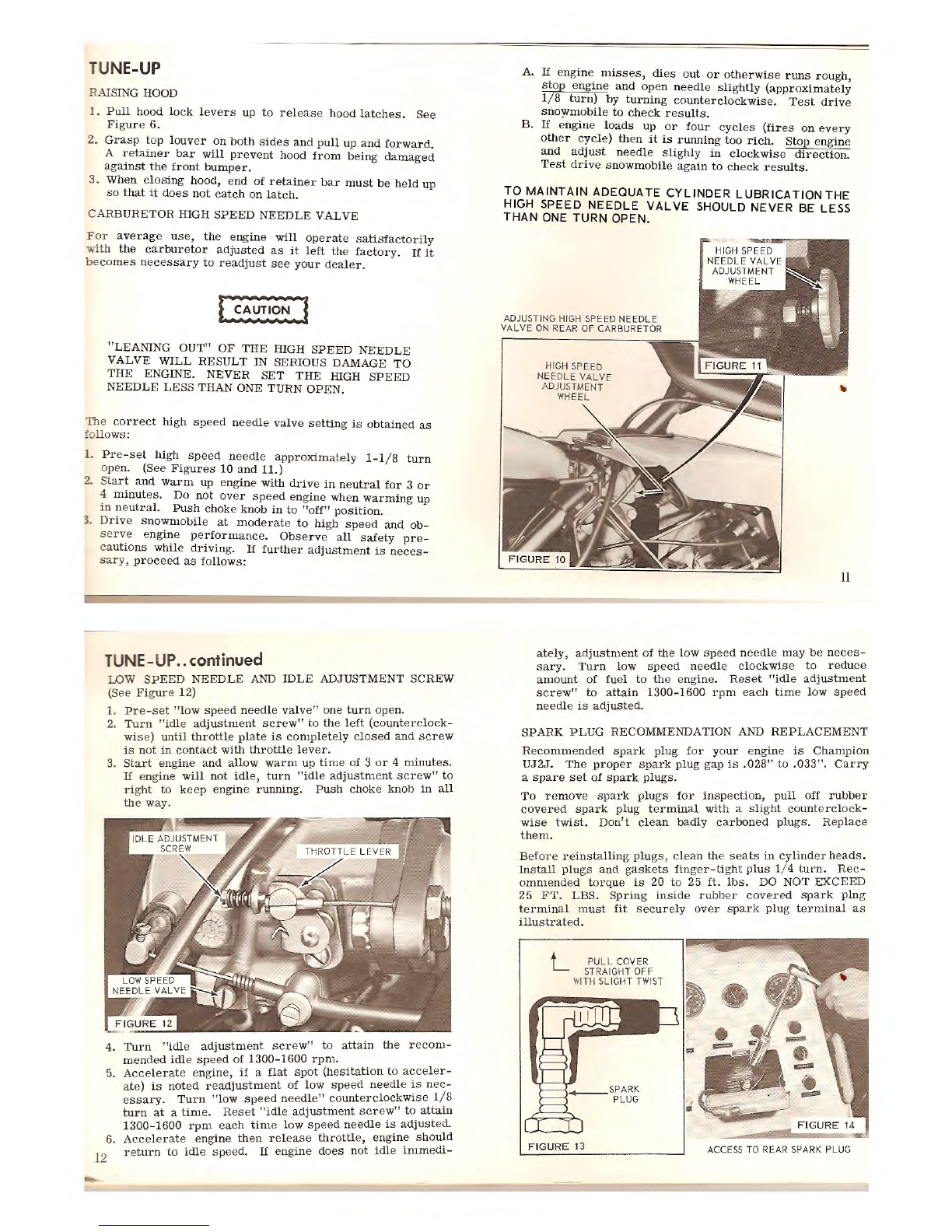

CA

RB

U

RETO

R HIGH S

PE

ED

NEED

LE

VALVE

For

average

us

e,

the

engine

w

ill

operate

satisfactorily

With

the

carb

uretor

adjusted

as

it

left

the

f

acto

r y.

If

it

bec

omes

n

ec

essar

y

to

readjust

see

yo

ur

dea

l

er.

"LEANING

OUT"

OF

THE

HIGH

SPEED

NEEDLE

VAL

VE

WILL

RESULT

IN SERIOUS DAMAGE

TO

THE

ENGINE. NEVER

SET

THE

HIGH

SPEED

N

EEDLE

LESS THAN ONE TURN

OPEN

.

The

correct

high

speed

n

eed

le

valve

setting

is

ob

t

ained

as

fo

llo

ws:

1. Pr e-

se

t

high

sp

eed

n

eedle

approximately

1-1

/ 8

turn

o

pen

. (See

Figures

10

and

11.)

2.

Sl

art

and

warm

up

engine

with

drive

in

ne

utr

al

for

3

or

4

min

ute

s.

Do

not

over

speed

engine

when

warm

ing

up

m ne

utral.

Push

choke

knob

in

to

"

off"

pos

ition.

3.

Dr

ive

snowm

ob

il

e

at

moderate

to

high

speed

and

ob-

se

rve

eng

in

e

performance.

Observe

all

safety

pre-

c

au

twns

wh

ile

dri

ving.

If

further

adjustment

is

neces-

sary,

p

roceed

as

follows:

TUNE-

UP

..

continued

LOW

SP

EED

NE

EDL

E

AND

IDLE

ADJUSTMENT SCREW

(

See

Fi

gur e

12

)

1. Pr e-s

et

"

low

speed

needl

e

va

lv

e"

one

turn

o

pen.

2.

Tu

r n "

idle

adjustment

screw

"

to

th

e

left

(counterc

l

ock

-

wi

se

) un

til

throttl

e

plate

is

completely

closed

and

screw

is

not

in

c

ontact

with

throttle

l

eve

r.

3.

Start

engine

and

allow

warm

up

tim

e

of

3

or

4

min

u

tes

.

If

engi

ne

will

not

idle,

tu

rn

"

id

le

adjustment

screw"

to

ri

ght

to

k

ee

p eng

in

e r unning.

Push

ch

oke

knob

in

a

ll

the

w

ay

.

4.

Turn

"idl

e

adj

us

tment

screw

"

to

attain

the

re

com-

mende

d

idle

speed

of

13

00

-1600

rpm.

5.

Accelerate

engi

ne,

if

a

flat

sp

ot

(hesitation

to a

cceler

-

ate)

is

noted

readjustme

nt

of

low

speed

ne

edle

is

nec-

essary

.

Turn

"l

ow

sp

e

ed

needle

"

counte

r

clo

c

kwis

e 1/ 8

turn

at

a

tim

e.

Reset

"idl

e

adjustm

e

nt

screw"

to at

tain

1300-

1600

rpm

each

tim

e low

speed

needle

is

adjusted.

6. Ac

celerate

engine

then

relea

se

throttle,

eng

in

e

should

r e

tu

r n to

idle

speed.

If

engine

does

not

idle

immedi

-

12

A.

If

engi

n

e.

misses,

dies

out

or

oth

er

wise

runs

ro

ug

h,

stop

engme a

nd

open

needl

e

slightly

(ap

pr

oximately

1/ 8 t

urn)

by

turnin

g

counter

c

lockwise

.

Test

drive

sno~mobile

to

check

r

esults.

B.

If

engine

load

s up

or

fo

ur

cy

cl

es

(fir

es

on

ev

ery

other

c

ycle)

then

it

is

runn

ing

to

o

rich.

Stop

e

ngine

and

adjust

n

ee

dl

e

slighly

in

clockwis

e

directio

n.

Test

d

ri

ve

snowmobile

ag

ain

to

ch

e

ck

resu

lts.

TO

MAINTAIN

ADEQUATE

CYLINDER

LUBRICATION

THE

HIGH SPEED

NEEDLE

VALVE

SHOULD

NEVER

BE

LESS

THAN ONE TURN OPEN.

ADJUST ING HI

GH

SPEED

NEEDL

E

VALV

E ON RE

AR

OF CARBURETOR

HI

GH

S

PEED

N

EE

DLE

VA

LVE

ADJUSTM

ENT

WHEEL

ll

ately

,

adjustment

of

th

e

low

sp

e

ed

needl

e

ma

y be n

ece

s-

sary.

Turn

low

sp

e

ed

need

le cl

ockw

i

se

to r

educe

amount

of

fuel

to

t

he

engine.

Rese

t "

idl

e

adjus

t

ment

screw"

to

atta

in 1300

-1

600

rpm

each

ti

me

lo

w

sp

ee

d

need

le

is

adjus

te

d.

SPARK

PLUG

RECOMMENDATION AND

REPLACE

M

ENT

Recommended

sp

ark

plug

for

yo

ur

e

ngine

is

Cham

p

ion

UJ2J

.

The

prop

er

spark

p

lu

g

ga

p

is

.

02

8" to

.033".

Ca

r ry

a

spare

set

of

spa

rk

plugs.

To

remove

spark

plugs

for

in

spe

ct

ion

,

pull

off

ru

bb

er

cov

er ed

spark

p

lu

g

te

r

minal

with

a

slight

count

e

rc

l

ock

-

wise

twist.

Don't

cl

e

an

bad

ly ca

rboned

plugs.

Repla

ce

t

hem.

Befor

e

reinstalling

plugs

,

cl

e

an

t

he

seats

in

cy

lind

er h

ead

s.

Install

pl

u

gs

and

ga

skets

fin

g

er

-tig

ht

plus

1/ 4

turn

. R

ec

-

omm

e

nd

ed

tor

que is

20

to 25 f

t.

lb

s. DO N

OT

E

XCEED

25

FT.

LBS.

Spri

ng

i

ns

i

de

r ubber co

ve

r ed

sp

a

rk

p

lu

g

te

rm

i

na

l mu

st

fit

s

ec

ur ely

over

sp

ar

k

plu

g

ter

min

al

as

illu

st

r

at

ed.

L PU

LL

COVER

STRAIGHT O

FF

WITH

SLIGHT

TW

IST

F I

GURE

13 ACCESS TO REAR SPARK

PL

UG

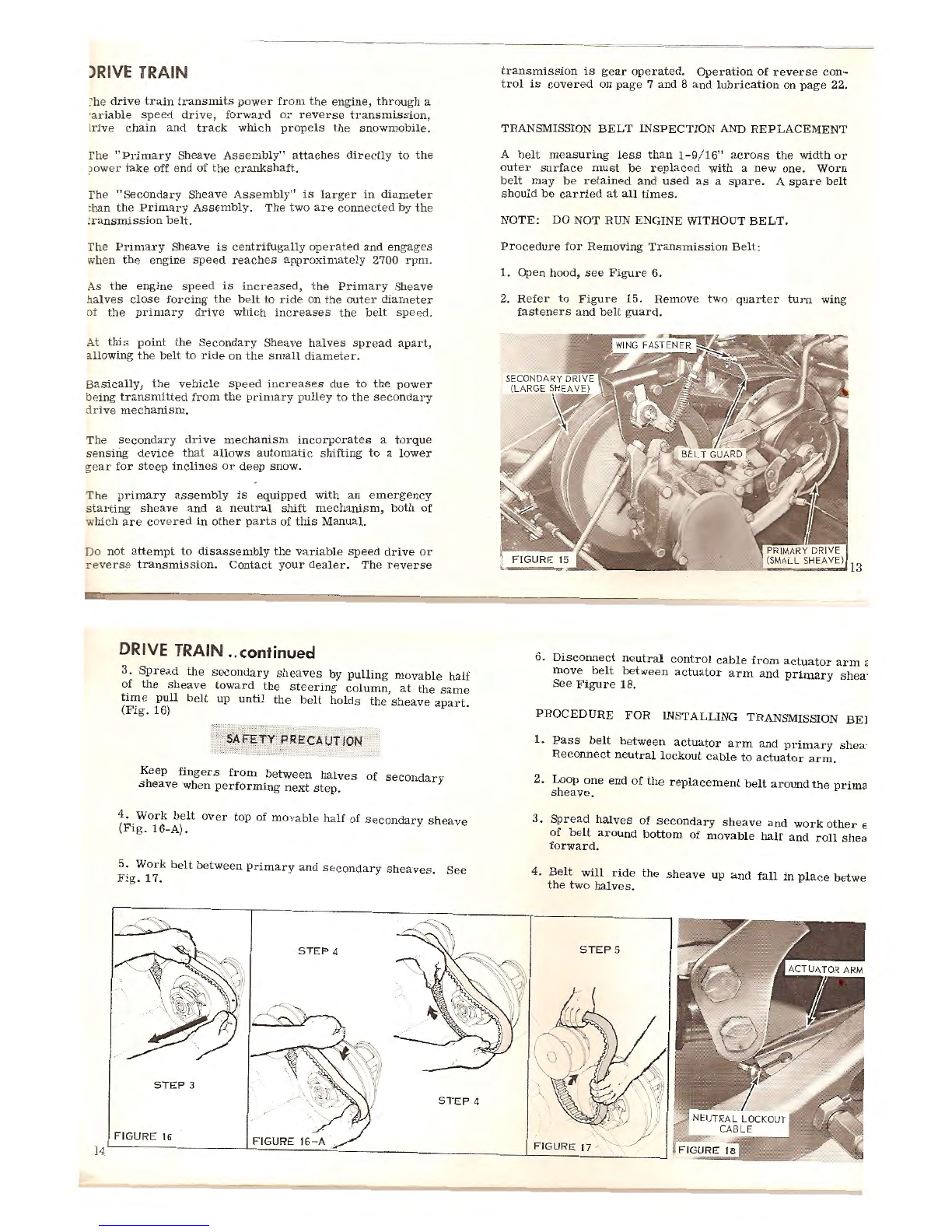

)RIVE TRAIN

~

he

drive

train

transmits

power

from

the

engine,

through

a

·a

riable

speed

drive,

forward

or

reverse

transmission,

!

rive

c

hain

and

track

which

propels

the

snowmobile

.

The

"Pr

i

mary

Sheave

Assembly

"

attaches

directly

to

the

?O

wer

take

off

end

of

the

crankshaft.

The

"Secondary

She

ave

Assembly"

is

larger

in

diameter

:han

the

Primary

Assembly.

The

two

are

connected

by

the

:

ransmiss

ion

belt

.

The

Pr

imary

Sheave

is

centrifugally

operated

and

engages

w

hen

the

engine

speed

reach

es

approximatel

y

2700

rpm

.

As

the

engine

speed

is

increased,

the

Primary

Sheave

h

alves

close

forcing

the

belt

to

ride

on

the

outer

d

iam

eter

of

the

primary

drive

which

increases

the

belt

sp

ee

d.

At

this

point

the

Secondary

Sheave

halves

spread

apar

t,

a

llowing

the

belt

to

ride

on

the

small

diam

e

ter.

Basically,

the

vehicle

speed

increases

due

to

the

power

b

eing

transmitted

from

the

primary

pulley

to

the

secondary

d

rive

mechanism.

The

secondary

drive

mechanism

incorporates

a

torq

ue

sens

ing

device

that

allows

automatic

shifting

to

a

lower

g

ear

for

steep

inclines

or

deep

snow.

Th

e

primary

assembly

is

eq

uipped

with

an

emergency

sta

rting

sheave

and

a

neutral

shift

mechanism,

both

of

w

hich

are

covered

in

o

ther

parts

of

this

Manual.

Do

n

ot

attempt

to

disassembly

the

variable

speed

drive

or

reve

rse

transmissi

on.

Contact

yo

ur

dealer

.

The

reverse

DRIVE TRAIN

..

continued

3.

Spread

the

secondary

sheaves

by

pulling

movable

half

of

the

sheave

toward

the

steering

column,

at

the

same

tlme

pull

belt

up

until

the

belt

hold

s

the

sheave

apart.

(F1g. 16)

SAFETY PRECAUTION

Ke

ep

fi

n

gers

from

between

halves

of

s

econda

ry

sh

eave

wh

en

performing

next

step.

4.

Work

belt

over

top

of

movable

h

alf

of

secondary

sheave

(Fig.

16-A).

5.

Work

belt

between

primary

and

secondary

sheaves

.

See

Fig.17.

transmission

is

gear

operated.

Operation

of

reverse

con-

trol

is

covered

on

page

7

and

8

and

l

ubrication

on

page

22.

TRANSMISSION

BELT

INSPECTION

AND

REPLACEMENT

A

belt

measuring

l

es

s

than

1-9

/16

"

across

the

width

or

o

ut

er

surface

must

be

replaced

with

a n

ew

one

.

Worn

belt

may

be

retain

ed

and

used

as

a

spare.

A

spare

belt

should

be

carried

at a

ll

times

.

NOTE:

DO

NOT

RUN ENGINE

WITHOUT

BELT.

Proced

ur

e

for

R

emo

ving

Tr

a

nsmission

Belt:

1.

Open

hood,

see

Figure

6.

2.

Refer

to

Figure

15.

Remove

two

quarter

turn

wing

fasteners

and

belt

guard.

6.

Disconnect

neutral

control

ca

ble

from

actuator

arm~

m

ove

belt

between

actuator

arm

and

primary

shea·

See

Figure

18.

PROCEDUR

E

FOR

INSTAL

LIN

G TRANSMISSION

BEl

1.

Pass

belt

between

actuator

arm

and

prim

ary

sh

ea·

Reconnect

neutral

l

ockout

cab

le

to

actuator

arm

.

2.

Loop

one

end

of

the

replacemen

t

belt

around

the

prim

3

sheave

.

3.

Spread

halv

es

of

secondary

she

av

e

and

work

other

e

of

belt

around

bottom

of

movabl

e

half

and

ro

ll

sh

ea

forward.

4.

Belt

will

ride

the

sheave

up

and

fa

ll

in

pl

ace

betwe

the

two

halves.

DRIVE TRAIN

..

continued

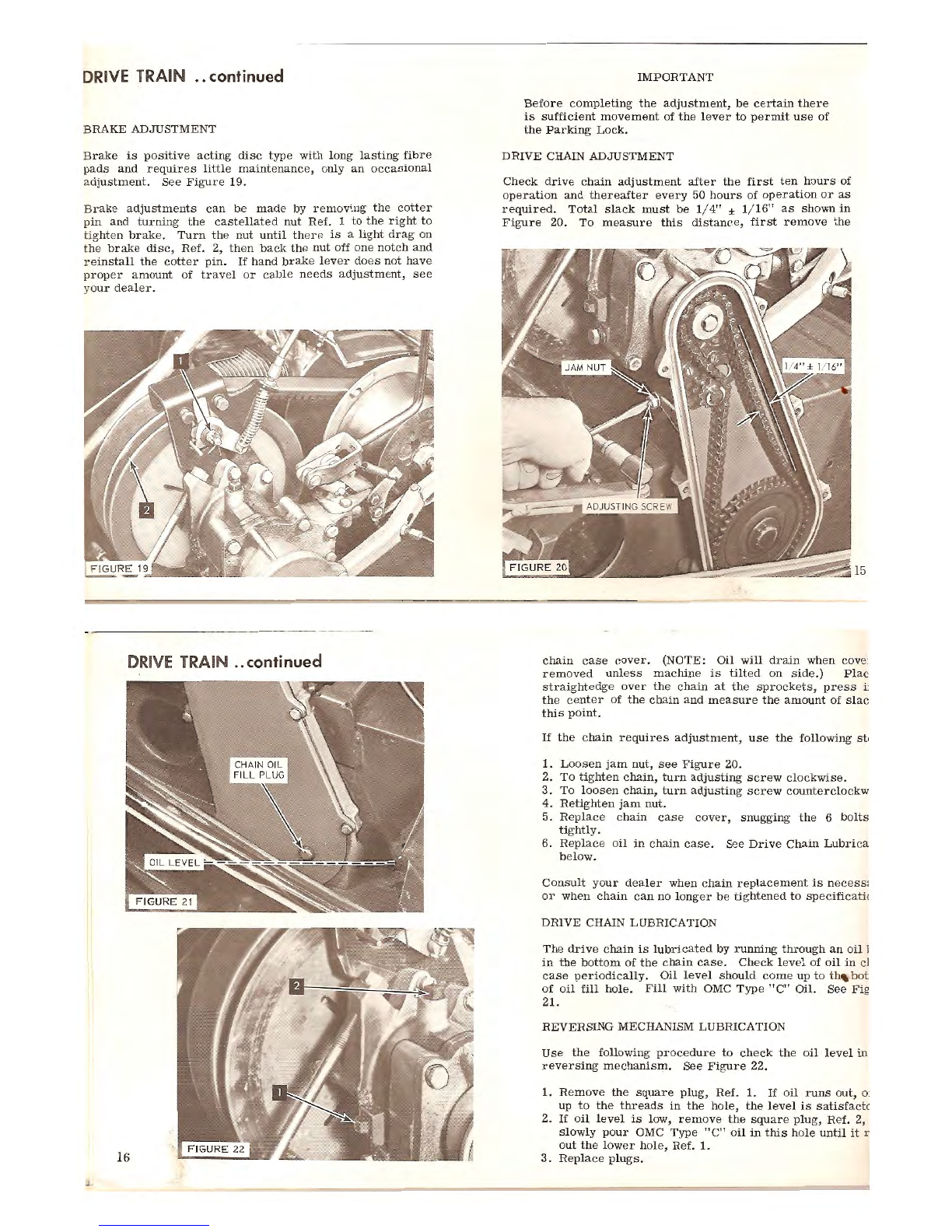

BRAKE ADJUSTMENT

Brake

is

positive

acting

disc

typ

e

with

l

ong

lasting

fibre

pads

and

re

quires

little

maintenance,

only

an

occas

ional

adj

ustment.

See

Figure

19.

Brake

adjustments

can

be

made

by

removing

the

cotter

pin

and

turning

the

castellated

nut

Ref.

1

to

the

right

to

tig

ht

en

brake.

Turn

the

nut

until

there

is

a

light

drag

on

the

brake

disc,

R

ef.

2,

then

back

th

e

nut

off

one

notch

and

re

install

the

cotter

pin.

If

hand

brake

lev

er

does

not

have

proper

amount

of

travel

or

cable

needs

adjustment,

see

y

our

dealer.

DRIVE TRAIN

..

continued

IMPORTANT

Before

comp

l

eting

the

adjustment,

be

certain

there

is

sufficient

movement

of

the

lever

to

permit

use

of

the

Parking

Lock.

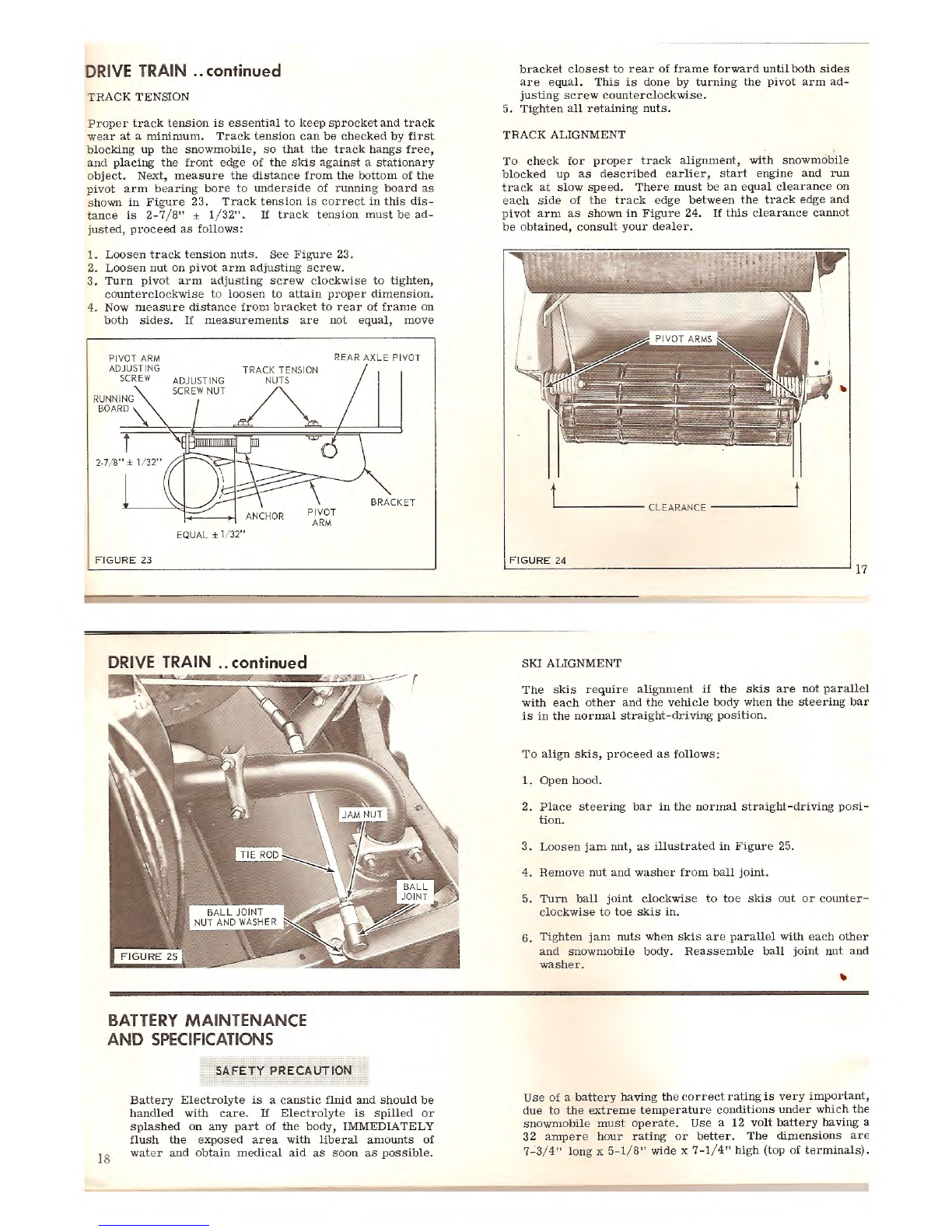

DRIVE CHAIN ADJUSTMENT

Check

drive

chain

adjustment

after

the

first

ten

hours

of

operation

and

thereafter

every

50

hours

of

operation

or

as

required.

Total

slack

must

be 1/

4"

± 1

/1

6"

as

shown

in

Figure

20.

To

measure

this

distance,

first

remove

the

chain

case

cover

. (NOTE:

Oil

will

drain

when

cove

removed

unless

machine

is

tilt

ed

on

side.)

Plac

straightedge

over

the

cha

in

at

the

sprockets,

press

i:

the

center

of

the

chain

and

measure

the

amou

nt

of

slac

this

point.

If

the

chain

requires

ad

justment,

use

the

following

st'

1.

Loosen

jam

nut,

see

Figure

20.

2.

To

t

ight

en

chain,

turn

ad

justing

screw

clockwise.

3.

To

loosen

chain,

turn

adjusting

screw

counterclockw

4.

Retighten

jam

nut.

5.

Replace

chain

case

cove

r,

snugging

the

6

bolts

tightly.

6.

Replace

oil

in

chai

n

case

. See

Drive

Chain

Lubric

a

below.

Consult

your

dealer

when

chain

replacement

is

necess

:

or

when

chain

can

no

lon

ger

be

tightened

to

specific

ati<

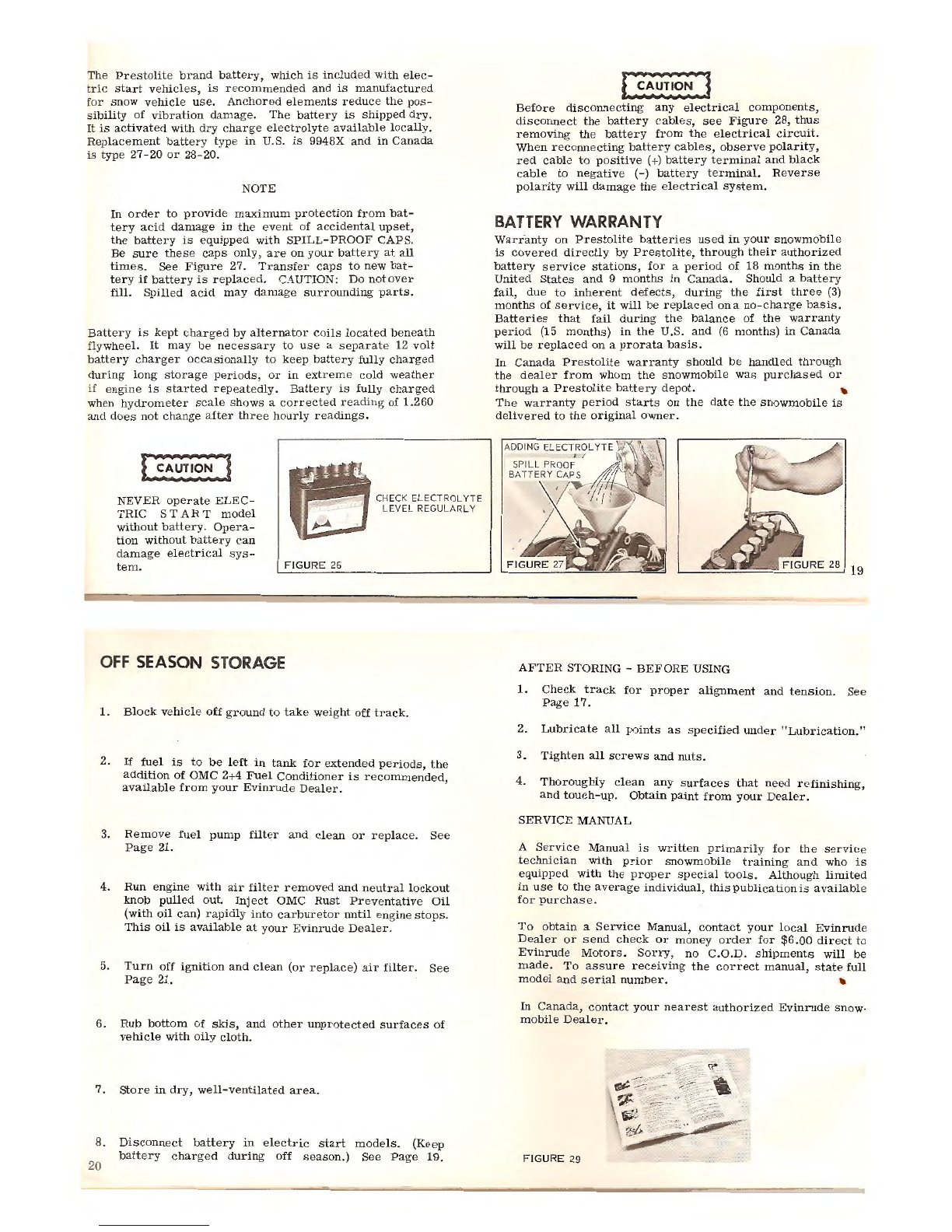

DRIVE CHAIN LUBRICATION

The

drive

chain

is

lubricat

ed

by

running

throu

gh

an

oill

in

the

bottom

of

the

chain

case

. Ch

eck

level

of

oil

in

cl

case

periodically

.

Oil

l

evel

should

come

up

to th

' b

ot

of

oil

fill

hol

e.

Fill

with

OMC

Type

"C"

Oil.

See Fig

21.

REVERSING MECHANISM LUBRICATION

Use

the

following

proced

ure

to

check

the

oil

level

in

r

eve

rsing

mechanism.

See

Figure

22.

1.

Remov

e

the

sq

uar

e

plug,

Ref.

1.

If

oil

runs

out,

o.

up

to

the

threads

in

the

hole,

the

l

evel

is

sat

i

sfact

c

2.

If

oil

le

vel

is

low,

remove

the

squar

e

plug,

Ref. 2,

slowly

pour

OMC

Type

"C

"

oil

in

this

hole

un

til

it

r

out

the l

ower

hol

e,

Ref.

1.

3.

Replac

e

plugs.

DRIVE

TRAI

N

..

co

ntinu

ed

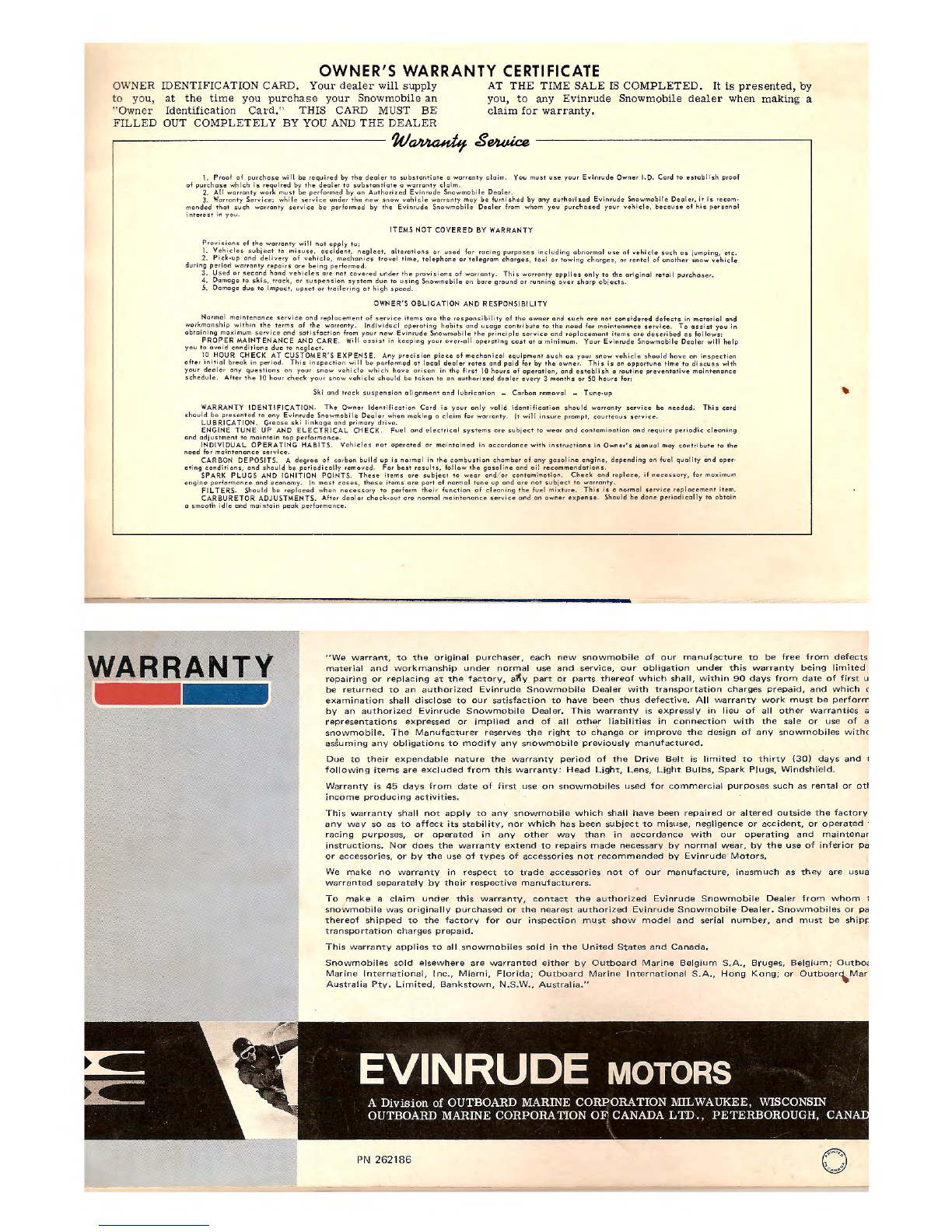

TR

ACK TENSION

Pr

oper

track

tension

is

essential

to

keep

sprocket

and

track

we

ar

at

a

minimum.

Track

tension

can

be

checked

by

first

b

locking

up

the

snowmobile,

so

that

the

track

hangs

free,

a

nd

placing

the

front

edge

of

the

skis

against

a

stationary

o

bject

.

Next,

measure

the

distance

from

the

bottom

of

the

p

ivot

arm

bearin

g

bore

to

underside

of

running

board

as

sh

own

in

Figure

23.

Track

tension

is

c

orrect

in

this

dis-

ta

nce

is

2-7

/

8"

± 1/ 32" .

If

track

tension

must

be

ad-

ju

s

ted,

proceed

as

follows:

1.

Loosen

track

tension

nuts

.

See

Figure

23.

2.

Loosen

nut

on

pivot

arm

adjusting

screw.

3.

Turn

pivot

arm

adjusting

scr

ew

clockwise

to

tighten,

counterclockwise

to

l

oo

sen

to

attain

proper

di

mens

ion.

4. Now

measure

distance

from

brack

et

to

rear

of

frame

on

both

sides

.

If

measurements

are

not

eq

u

al,

mov

e

PIVOT

AR

M

ADJ

US

TING

SC

REW

TRA

CK

TEN

SION

NUTS

R

EAR

AX

LE

PIVO

T

EQUAL

± l /

32"

F

IGURE

23

BATTERY

MAINTENANCE

AND

SPECIFICATIONS

18

SAFETY

PRECAUTION

Batte

ry

Electrolyte

is

a

caustic

fluid

and

should

be

handled

with

care.

If

Electrolyte

is

spilled

or

splashed

on

any

part

of

the

b

od

y,

IMMEDIATELY

flush

the

exposed

area

w

ith

lib

e

ral

amounts

of

w

ater

and

obtain

medical

aid

as

soon

as

possibl

e.

bracket

closest

to

r

ear

of

fram

e f

orward

until

both

si

de

s

are

equal.

This

is

done

by

turning

the

pivo

t

arm

ad

-

justing

screw

counterclo

c

kwise.

5.

Tighten

all

retaining

nu

ts

.

TRACK

ALIGNMENT

To

check

for

proper

track

alignment

,

with

snowmobile

bl

ocked

up

as

described

earlier,

start

en

gine

and

run

track

at

slow

speed

.

The

re

must

be

an

equal

clearance

on

each

side

of

the

track

edge

between

t

he

track

edge

and

pivot

arm

as

shown

in

Figure

24.

If

this

clearance

cannot

be

obtained

,

consult

your

dea

l

er.

FIGUR

E 24

L-~~~------

--------

----------------~17

SKl

ALIGNMENT

The

skis

require

alignmen

t

if

the

skis

are

not

parallel

with

each

other

and

th

e ve

hicle

bod

y

when

the

steering

bar

is

in

the

normal

straight

-

driving

position

.

To

align

skis,

pr

o

ceed

as

fo

llows:

1.

Open

hood

.

2.

Place

steering

bar

in

the

normal

straight

-dr

iving

po

si-

tion

.

3.

Loosen

jam

nut,

as

illustrated

in

Figure

25.

4.

Remove

nut

and

washer

from

ball

joint.

5.

Turn

ball

join

t

clock

w

ise

to

toe

skis

ou

t

or

cou

nter-

cl

oc

kwise

to

to

e

skis

in.

6.

Tig

ht

en j

am

nuts

w

hen

skis

ar e pa

rallel

with

each

ot

h

er

and

snow

mo

bile

body.

Reassem

b

le

ba

ll

join

t

nut

an

d

washer

.

Use

of a b

attery

having

the

correct

rating

is

very

importan

t,

due

to

the

e

xt

rem

e t

emperature

conditions

under

which

the

snowmo

b

ile

must

operate.

Use

a 12

volt

battery

having

a

32

amp

er e ho

ur

rating

or

better.

Th

e

dimensions

are

7~3

/

4"

long x 5-

1/

8"

wid

e x

7-1

/

4"

high (top

of

te

rmin

a

ls

).

The

Pres

tolit

e b

ra

nd

battery,

wh

ich

is

included

with

el

ec

-

t

ric

star

t

ve

hicl

es,

is

recommended

and

is

manufact

u

red

for

snow

vehicle

us

e.

Anchored

eleme

nts

reduce

the

pos

-

sib

ili

ty

of

v

ibr

at

ion

damage.

The

battery

is

ship

p

ed

dry.

It

is

act

ivated

w

ith

dry

c

har

ge

e

lectrolyte

available

l

oca

ll

y.

Replaceme

nt

battery

type

in

U.S. is 9948X

and

in

Canada

is

ty

pe

27-20

or

28

-20.

NOTE

In

order

to

prov

id

e

maximum

pro

t

ectio

n

from

bat

-

tery

acid

damage

in

th

e

event

of

accidental

ups

et,

the

battery

is

e

quipped

with

SP

ILL

-

PRO

OF

CAPS

.

Be

sure

thes

e

caps

only,

ar

e on yo

ur

batt

ery

at

all

times

. S

ee

Figure

27.

Transfer

caps

to

n

ew

bat

-

tery

if

battery

is r

eplaced.

CAUTION: Do

not

ove

r

fill.

Spi

ll

ed

ac

id

may

damage

surroundin

g

parts.

Ba

ttery

is

kept

ch

arged

by

alt

er

nat

or

coils

l

ocated

beneath

flywh

ee

l.

It

m

ay

be

necessa

ry

to

us e a

separate

12

volt

ba

ttery

charger

occasio

nall

y

to

keep

batt

er y

full

y

charged

d

uring

long

stora

ge

periods,

or

in

ext

r

eme

co

ld

weathe

r

if

engine

is

started

repeated

l

y.

Ba

tt

ery

is

fully

ch

arged

when hy

dromet

er

scale

shows

a

co

rr

ected

reading

of

1.260

an

d

does

not

ch

ange

a

ft

er

three

hourly

r

ea

din

gs.

NEVER

ope

rate ELEC-

TRIC

START

mo

del

witho

ut

b

attery.

Opera-

ti

on w

it

h

out

batt

ery

can

damage

el

ectrica

l

sys-

tem.

e

CHE

CK

ELECTROLYTE

LEV

EL REGULARLY

;...-4

F I

GURE

26

OFF

SEASON

STORAGE

1.

Block

vehi

cle

off

ground

to

take

wei

ght

o

ff

tr

ack

.

2.

If

fuel

is

to

be

left

in

tank

for

extended

per

i

ods,

the

addition

of

OMC 2+4

Fue

l Co

nditioner

is

recomme

nd

ed

ava

ilabl

e

from

yo

ur

Evinrude

Dealer.

'

3.

Remove

fuel

pump

filt

er and cl

ean

or

re

plac

e.

See

Page

21.

4.

Run

eng

in

e

with

air

filter

removed

and

neutral

l

oc

kout

knob

p

ull

ed

out

. Inj

ec

t OMC

Rust

Pr

eve

ntat

i

ve

O

il

(with

oil

ca

n)

rapid

ly

int

o

car

bur

et

or

until

eng

i

ne

stops

.

This

oil

is

ava

il

ab

le

at

your

Ev

i

nrude

Dea

l

er

.

5.

Turn

off ig

nition

a

nd

clean

(or

r

eplace)

air

filt

er.

See

Page

21.

6.

Rub

bott

om

of

skis,

and

ot

h

er

unprot

ected

su

rf

ac

es

of

vehic

le

with

oily

cl

oth.

7.

8.

20

store