Excalibur Water Systems EWS SPREF24 User manual

1

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

TABLE OF CONTENTS

1) Installation ............................................................................................................................................ 2

1.1) Pre-installation instructions.......................................................................................................... 2

1.2) General Installation and Service Warnings................................................................................... 2

1.3) Site Requirements......................................................................................................................... 2

1.4) Installation Drawing ...................................................................................................................... 3

1.5) System Drawing ............................................................................................................................ 4

1.6) Plumbing Instructions ................................................................................................................... 4

1.7) Brine Line Connection................................................................................................................... 5

1.8) Overflow Line Connection............................................................................................................. 5

1.9) Drain Line ...................................................................................................................................... 5

1.10) Bypass Valve.............................................................................................................................. 6

1.11) Start Up Instructions ................................................................................................................. 7

2) Control Valve Programming.................................................................................................................. 8

2.1) Regeneration Screens ................................................................................................................... 8

2.2) Button Operation.......................................................................................................................... 8

2.3) Setting Time of Day....................................................................................................................... 9

2.4) User Displays................................................................................................................................. 9

2.5) Installer Display Settings ............................................................................................................. 10

2.6) Softener System Setup................................................................................................................ 11

3) Model Variable Components and Specifications................................................................................ 12

3.1) Flow Controls and Injectors ........................................................................................................ 12

3.2) Specifications ..............................................................................................................................12

4) Control Valve Cycles............................................................................................................................ 13

5) Components of Control Valve............................................................................................................. 15

5.1) Front Cover and PC Board...........................................................................................................15

5.2) Drive assembly, Piston and Spacer stack .................................................................................... 16

5.3) Injector Assembly........................................................................................................................ 17

5.4) Brine Tank Line Flow Control ...................................................................................................... 18

5.5) Drain Line Flow Control Assembly .............................................................................................. 19

5.6) Outlet Meter Assembly............................................................................................................... 20

5.7) Bypass Valve Components .......................................................................................................... 21

5.8) Installation Fitting Assemblies .................................................................................................... 22

6) Brine Tank Assembly........................................................................................................................... 24

7) Troubleshooting.................................................................................................................................. 25

7.1) Possible Error Codes ................................................................................................................... 25

7.2) Troubleshooting Procedures....................................................................................................... 26

8) Quick Reference Guide ....................................................................................................................... 29

9) Warranty ............................................................................................................................................. 31

2

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

1) INSTALLATION

1.1) Pre-installation instructions

The cycle times, sequence of cycles, salt dose refill time and exchange capacity are preset to by

Excalibur. The dealer must guide the installer to change the values according to the hardness, day

override and time of regeneration.

WATER TEST

Hardness gpg

Iron ppm

pH number

Nitrates ppm

Manganese ppm

Sulphur yes/no

Total Dissolved Solids

1.2) General Installation and Service Warnings

•The water conditioner is designed so that it can be installed easily with minor plumbing changes

on previous plumbing.

•The piping must be clamped properly and the weight of the plumbing must not be on the water

conditioner.

•Do not use any kind of lubricant including silicone. A silicone based lubricant can be only used on

black O-Rings but not necessary.

•Do not use pipe dope or other sealant on plastic nuts and caps. Teflon tape must be used only on

NPT threads.

•The nuts and caps can be fastened and unfastened by hand or the plastic service wrench. Do not

use pipe wrench to tighten the caps and nuts.

1.3) Site Requirements

•Water Pressure: - 40-110 psi

•Water Temperature: - 40-110°F (4.4-43°C)

•Electrical- 115/120 V, 60Hz Uninterrupted Outlet

•Current required is 0.5 Amperes with plug-in transformer (dry locations only).

•The tank should be on a firm level surface

4

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

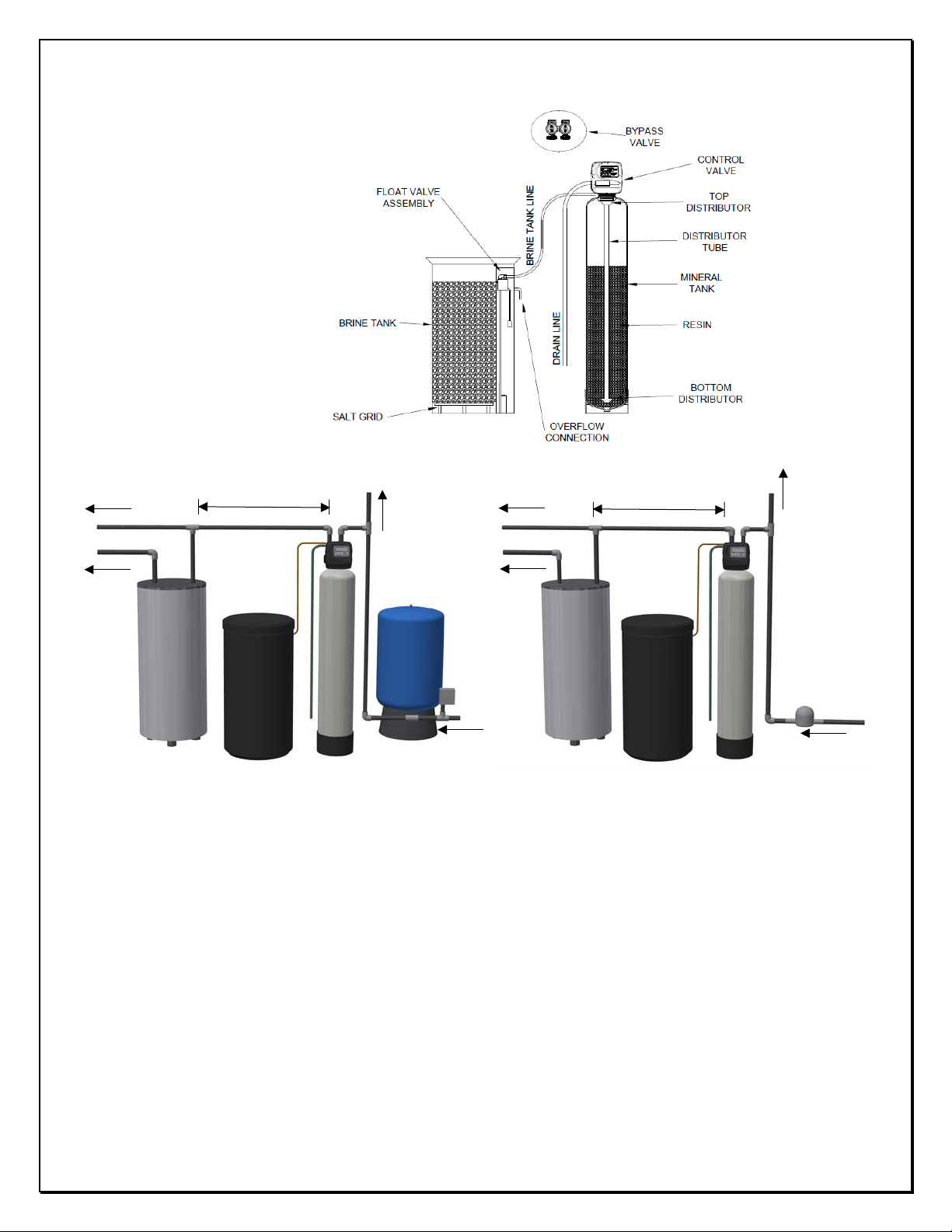

1.5) System Drawing

1.6) Plumbing Instructions

Well Water Installation Municipal Installation

1) The water conditioner must be located at the closest possible location to drain.

2) The water heater’s inlet must be at least 10ft away from water conditioner.

3) The unit including the drain must be located in a room temperature above 33° F.

4) If vacuum occurrence is expected, then the vacuum breaker must be installed at the inlet of the

water conditioner.

5) The bypass valve must be installed on the control valve.

6) The outside tap water if possible may be bypassed from the water conditioner.

7) The primer, solder or solder flux must not get on the O-rings while installation.

8) After soldering the lines must be cooled before installing the O-Rings, nuts and caps.

9) If the electrical system is grounded to the plumbing, then a copper strap must be connected

between inlet and outlet as shown in figure above.

10) The plumbing must be done by following the local plumbing codes.

Water

heater

Pressure

Tank

Minimum 10ft

Water

Meter

Minimum 10ft

Brine

Tank

Brine

Tank

Outside

Tap

Outside

Tap

Water

heater

Cold

Cold

Hot

Hot

5

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

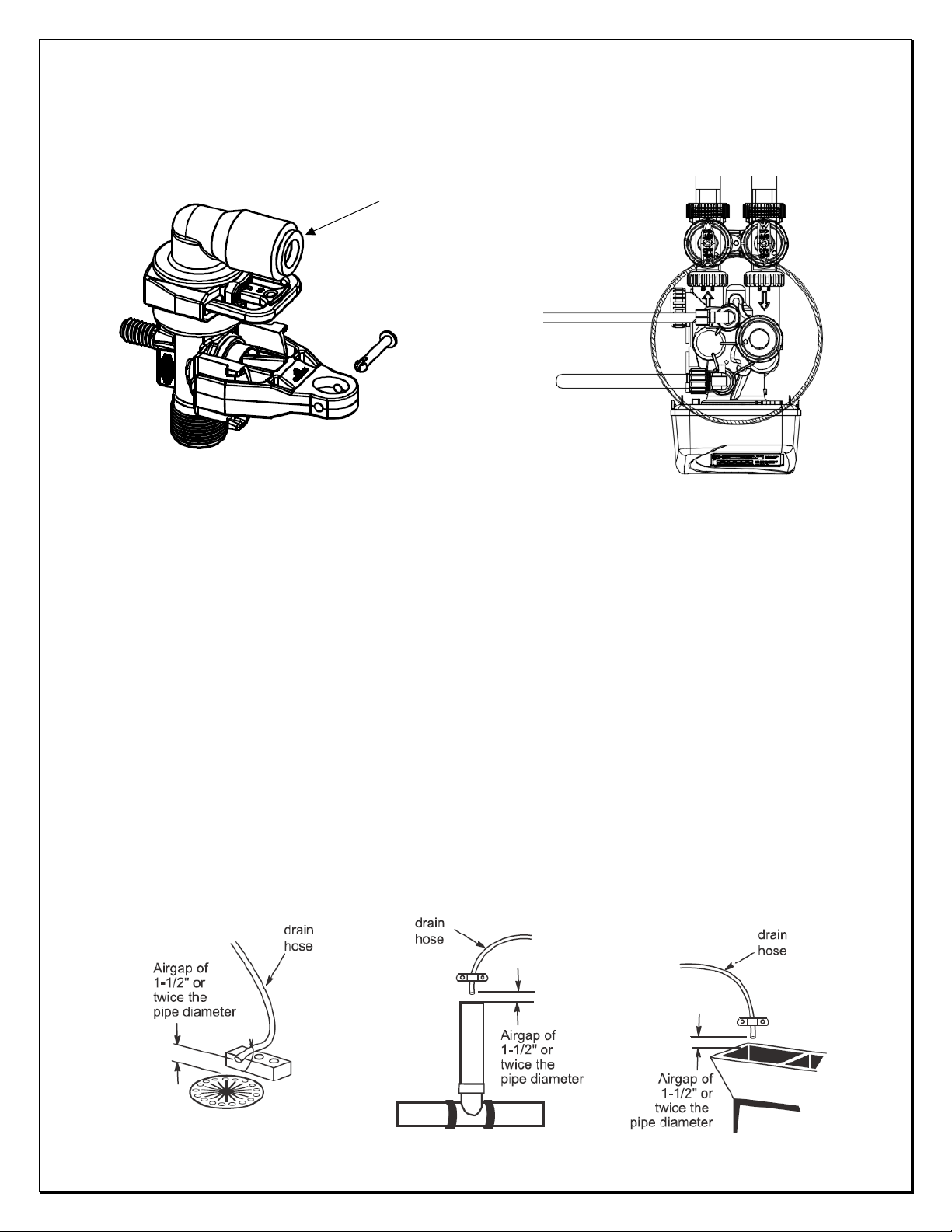

1.7) Brine Line Connection

Install 3/8” O.D. Polyethylene tube according to specification sheet from the brine tank to the control

valve.

1.8) Overflow Line Connection

•Only used where brine tank overflow water spillage can damage flooring or structure.

•Brine tank is equipped with safety float valve which prevents the overflow in case if control

valve fails to control the refill cycle.

•In case if safety float also fails to stop refill then only the water will come through overflow line

connection.

1.9) Drain Line

•The ½” tubing must be used for drain line.

•Leave minimum of 6” gap between flow control fitting and solder joints. The gap less than this

can damage the flow control.

•If the drain line is elevated and then emptied into the drain below the level the of control valve

then 7” loop should make at the end of drain line.

•The air gap between the drain and the end of the drain line must be twice the diameter of the

tube.

•The drain line must be clamped or strap tied at the end to secure in position.

Tank Brine Line

Connection

Brine Line

Drain Line

6

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

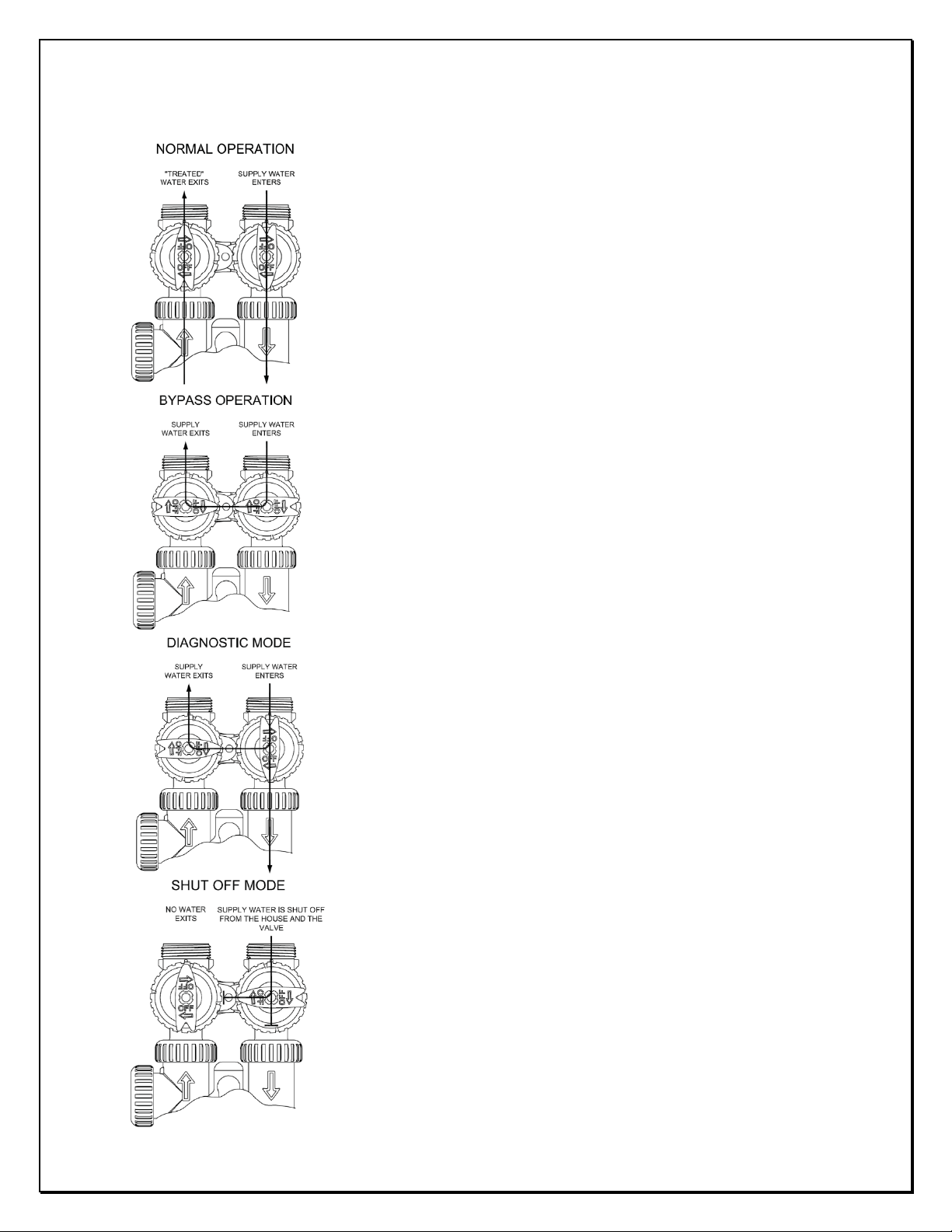

1.10) Bypass Valve

NORMAL OPERATION

The inlet and outlet handles of bypass valve should be pointing the

direction of flow indicated by the engraved arrows on the control valve.

Water flows through the control valve in normal operation as a water

conditioner.

BYPASS OPERATION

The inlet and outlet handles point to the center of the bypass valve.

The system is isolated from the water pressure in the plumbing

system. Untreated water is supplied to the house in this position.

DIAGNOSTIC MODE

The inlet handle points in the direction of flow and the outlet

handle points to the center of bypass valve, system water pressure

is allowed to the control valve and the plumbing system while not

allowing water to exit from the control valve to the plumbing.

Untreated water is supplied to the house in this position.

SHUT OFF MODE

The inlet handle points to the center of the bypass valve and the

outlet handle points in the direction of flow, the water is shut off

to the plumbing system. If water is available on the outlet side of

the Water Conditioner, it is an indication of water bypass around

the system.

7

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

1.11) Start Up Instructions

•Keep the bypass valve in bypass operation by moving both handles pointing towards the center

of bypass valve. Now the untreated water is being supplied to house. Open the faucet

downstream of the water conditioner until water comes clear out of it. The initial water can be

dirty because of installation debris. Now inspect the leaks in plumbing.

•Manually add approximate 6 inches of water to brine tank so that level reaches air check valve.

•Press and hold the “REGEN” button down for 5 seconds to start manual regeneration. The drive

motor will start to reach backwash cycle and countdown time begins. Turn the inlet bypass valve

handle halfway into the direction of diagnose operation. Once the steady water flows out of

drain then fully turn both handles of bypass valve into the direction of service operation.

Caution: - If water flow is too rapidly, there will be a loss of resin to drain.

•When the water become clear in drain line then press the regen button to advance the

regeneration to brine cycle. Lift off the brine tank lid to check if water is being drawn from brine

tank and shut off the faucet after confirming the brine draw flow.

•Press REGEN button to advance the regeneration to 2nd backwash cycle. Wait until the

countdown time starts.

•Press REGEN button again to advance the regeneration to rinse cycle with water coming through

the drain. Allow this process for the full amount of time during this cycle.

•The control valve will automatically advance the regeneration to the fill cycle. Allow to fill for the

full amount of time in this cycle. Once finished the control valve will automatically come to the

service position with the time of day being displayed.

•Add the salt to Brine Tank.

8

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

2) CONTROL VALVE PROGRAMMING

2.1) Regeneration Screens

2.2) Button Operation

Regen Screen

•Displays the time remaining in the current cycle.

•Displays the cycle name and sequence number.

•Pressing REGEN advances to the next cycle.

Scrolls to the next display.

•Pressing once and releasing will schedule a regeneration at the preset delayed regeneration time.

•Pressing again and releasing will cancel the delayed regeneration.

•Pressing and holding for 3 seconds will initiate an immediate regeneration

•Pressing while in regeneration will advance to the next cycle.

•Pressing in the program levels will go backwards to the previous screen

Change Variable being displayed.

Holding for 3 seconds initiates a control reset. The software version is displayed and the

piston returns to the home/service position, resynchronizing the valve.

•Sets time of day

•Save changes and Exit to user display from any programming screen

Regeneration occurs automatically if volume capacity drops below the reserve capacity

automatically predicted by Control Valve or the has control valve reached 14 number of days since

last regeneration.

9

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

2.3) Setting Time of Day

2.4) User Displays

When the system is operating, one of below given displays may be

shown. Pressing NEXT will alternate between the displays shown below.

User 1

This user display shows the volume capacity remaining.

User 2

Displays current time of the day.

−“SOFTENING” displays when the meter is registering the water.

−“REGEN TODAY” displays when the scheduled regeneration is to

occur at a scheduled time of day.

Push SET CLOCK button.

When hour flashes press ▲or ▼until the correct hour is displayed.

Then press NEXT.

The minutes will flash. Press ▲or ▼until the correct minute is

displayed. Press NEXT to return to the User Displays.

Time of day should only need to be set after power outages lasting

more than 8 hours, if the battery has been depleted and a power

outage occurs, or when daylight saving time begins or ends.

Return to User Display 1

10

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

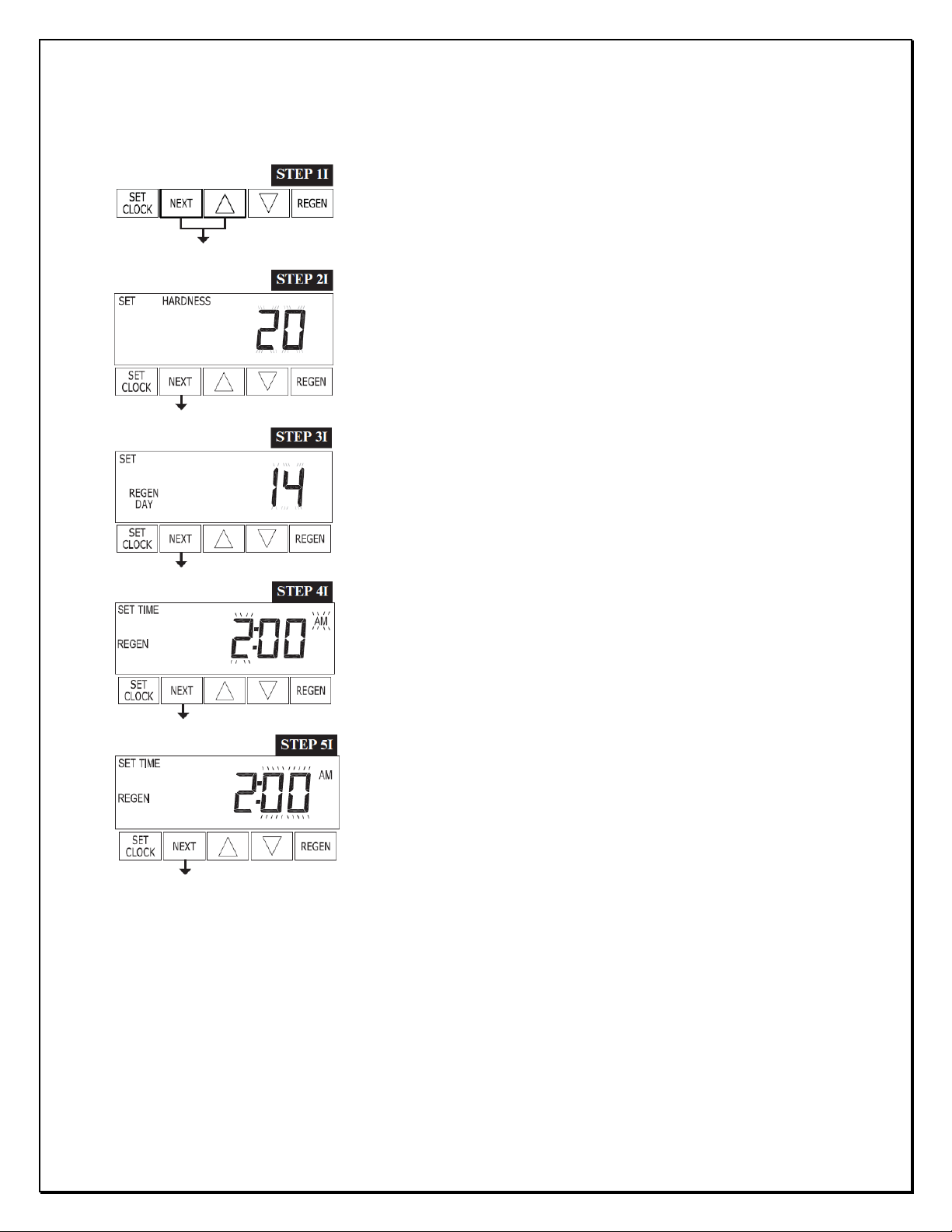

2.5) Installer Display Settings

Step 1I - To enter Installer Display press NEXT and ▲simultaneously

for about 5 seconds and release.

Step 2I – Hardness: Set the amount (gpg) of hardness using ▲or ▼.

Press NEXT to go to step 3I. Press REGEN to exit Installer Display

Settings.

Step 3I – Day Override: Set “14” the maximum number of days

between regenerations.

Press NEXT to go to step 4I. Press REGEN to return to previous step.

Step 4I – Next scheduled regeneration time (hour): Set the hour of

day for regeneration using ▲or ▼. (Usually 2:00AM or when the

predictable flow is minimum)

Press NEXT to go to step 5I. Press REGEN to return to previous step.

Step 5I – Next scheduled regeneration time (minutes): Set the

minutes of day for regeneration using ▲or ▼.

Press NEXT to exit Installer Display Settings. Press REGEN to return

to previous step.

EXIT INSTALLER DISPLAY SETTINGS

11

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

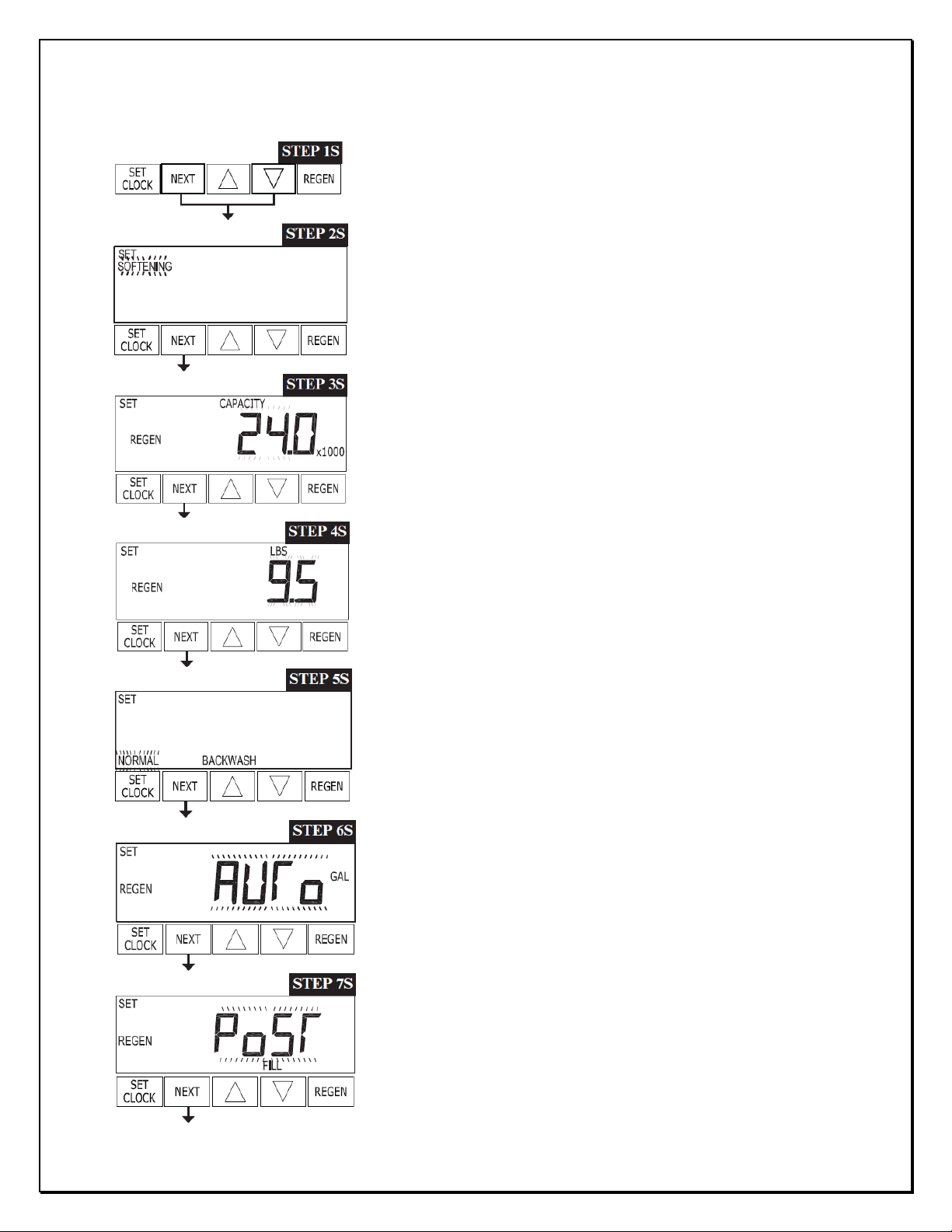

2.6) Softener System Setup

Step 1S - Press NEXT and ▼simultaneously for 5 seconds and

release.

Step 2S – Choose SOFTENING using ▲or ▼. Press NEXT to go to

Step 3S. Press REGEN to exit OEM Softener System Setup.

Step 3S – Enter the softening grains capacity given in specification

sheet according to the salt usage.

Step 4S – Enter the pounds of salt usage per regeneration. Press

NEXT to proceed to Step 5S or Press REGEN to return to previous

step.

Step 5S – Select “NORMAL” backwash length. Press NEXT to proceed

to Step 6S.

Step 6S –Set “AUTO” for estimating reserve volume capacity and

total volume capacity automatically.

Step 7S – Set “PoST” Refill location using ▲or ▼to refill the brine

tank immediately after the final rinse.

Press NEXT to go to Step 8S. Press REGEN to return to previous step.

12

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

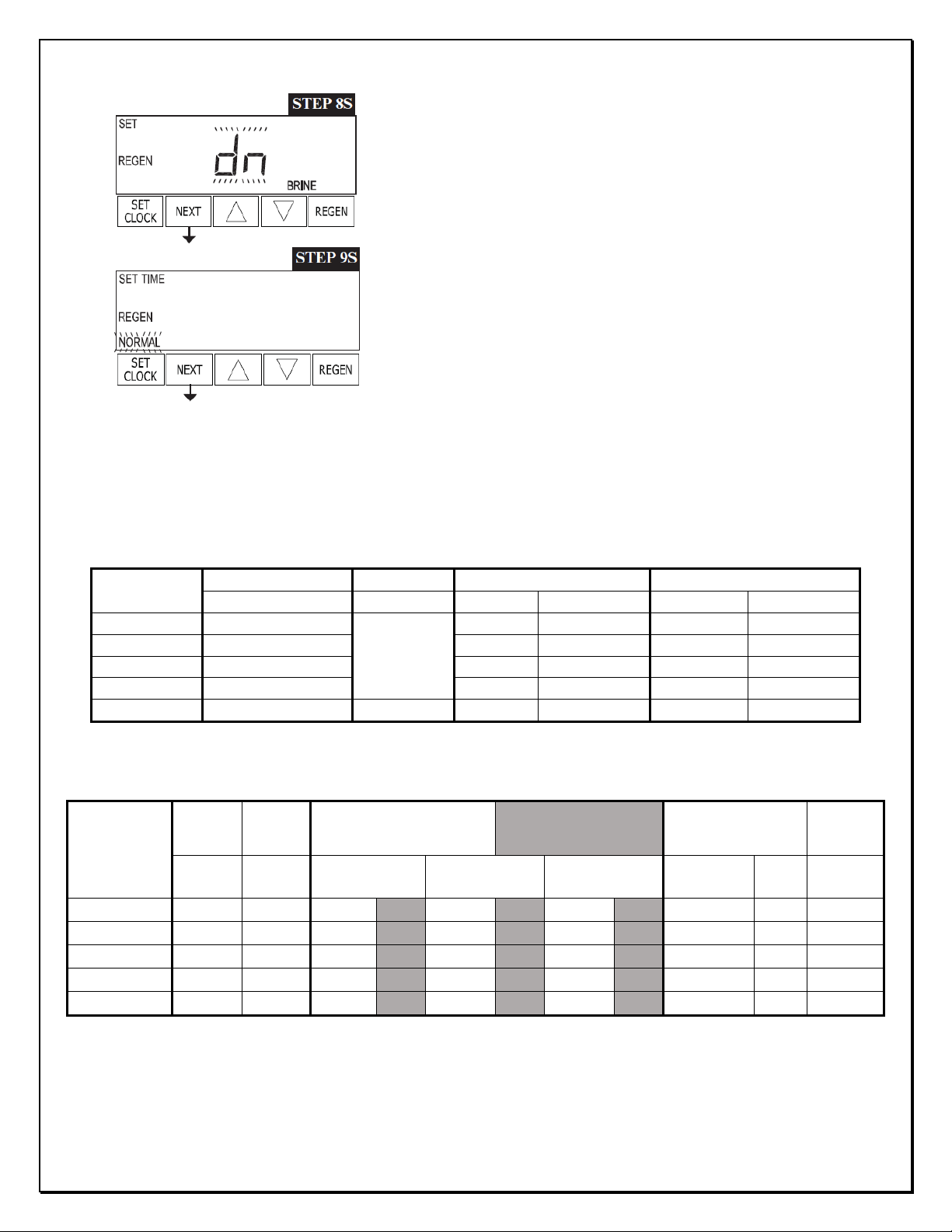

3) MODEL VARIABLE COMPONENTS AND SPECIFICATIONS

3.1) Flow Controls and Injectors

Model

Number

Mineral Tank

Brine Tank

Injector

Drain Flow Control

Dia X Height (Inch)

(Inch)

Color

Order #

Flow GPM

Order #

EWS SPREF24

9x48

18x33

Red

CLK V30101D

2.7

CLK V3162027

EWS SPREF32

9x48

Red

CLK V30101D

2.7

CLK V3162027

EWS SPREF42

10x54

White

CLK V30101E

3.2

CLK V3162032

EWS SPREF52

12x52

Blue

CLK V30101F

4.2

CLK V3162042

EWS SPREF62

13x54

18x40

Yellow

CLK V30101G

5.3

CLK V3162053

3.2) Specifications

*Excalibur Water Conditioners are factory programmed to 10lbs/ft3default settings

1Media contains 80% Softening Resin and 20% Coconut Shell Carbon Media

Model

Number

Mineral

Tank

Media1

Quantity

Grains Capacity Lbs Salt Setting Flow (GPM) Shipping

Weight

Dia X

Height

ft36lbs Salt/ft310lbs Salt/ft315lbs Salt/ft3Continuous Peak LBS

EWS SPREF24

9x48

1.00

16,000

5.0

22,000

8.0

24,000

12.0

4.0

6.4

74

EWS SPREF32

9x48

1.34

21,000

6.5

29,000

11.0

32,000

16.0

5.4

8.6

91

EWS SPREF42

10x54

1.75

28,000

8.5

38,000

14.0

42,000

21.0

7.0

11.2

114

EWS SPREF52

12x52

2.16

35,000

10.5

47,000

18.0

52,000

26.0

8.7

13.8

161

EWS SPREF62

13x54

2.59

41,000

13.0

56,000

21.0

62,000

31.0

10.4

16.6

183

Step 8S – Select “dn” for downflow brine cycle using ▲or ▼. Press

NEXT to go to Step 9S. Press REGEN to return to previous step.

Step 9S –Set “NORMAL” for the regeneration time. Press NEXT to

exit Softener System Setup or Press REGEN to return to previous

step.

EXIT SOFTENER SYSTEM SETUP

13

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

4) CONTROL VALVE CYCLES

In Service Cycle water flows through the upper basket

and flows down to the bottom distributor. In this

operation hardness of water is removed by resin.

In Backwash Cycle water flows in upflow direction, the

water enters the tank from bottom distributor and

collected by upper basket. This operation lifts the bed

and wash the resin. The water goes out through the

drain line.

Note: -Backwash, Brine and Rinse cycles bypass the

supply water to the demand.

14

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

In Brine Cycle water flows in downflow direction

which siphon the brine solution from brine tank and

slow rinse water goes to the drain.

In Rinse Cycle water flows rapidly in downflow

direction through the resin to the drain. This cycle

washes the excess sodium from the resin particles.

Fill Cycle (Not Shown): - The water flow same as

Service operation but water also flows to the brine

tank for refilling.

15

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

5) COMPONENTS OF CONTROL VALVE

5.1) Front Cover and PC Board

Drawing No.

Order No.

Description

Quantity

1

CLK V317501

WS1 Front Cover ASY

1

2

CLK V310701

WS1 Motor

1

3

CLK V310601

WS1 Drive Bracket & Spring Clip

1

4

CLK V310810BOARD

WS1 PCB XMEGA REPL

1

5

CLK V3110

WS1 Drive Reducing Gear 12x36

3

6

CLK V3109

WS1 Drive Gear Cover

1

Not Shown

CLK V3186

WS1 AC ADAPTER 120V-12V

1

CLK V3186EU

WS1 AC ADAPTER 220-240V-12V

CLK V3186UK

WS1 AC ADAPTER 220-240V-12V

CLK V318601

WS1 AC ADAPTER CORD ONLY

AC Adapter

U.S.

Supply Voltage

120 V AC

Supply

60 Hz

Output Voltage

12 V AC

Output Current

500 mA

Battery

Orientation

Battery Fully

Seated

Replacement

battery type 2032

16

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

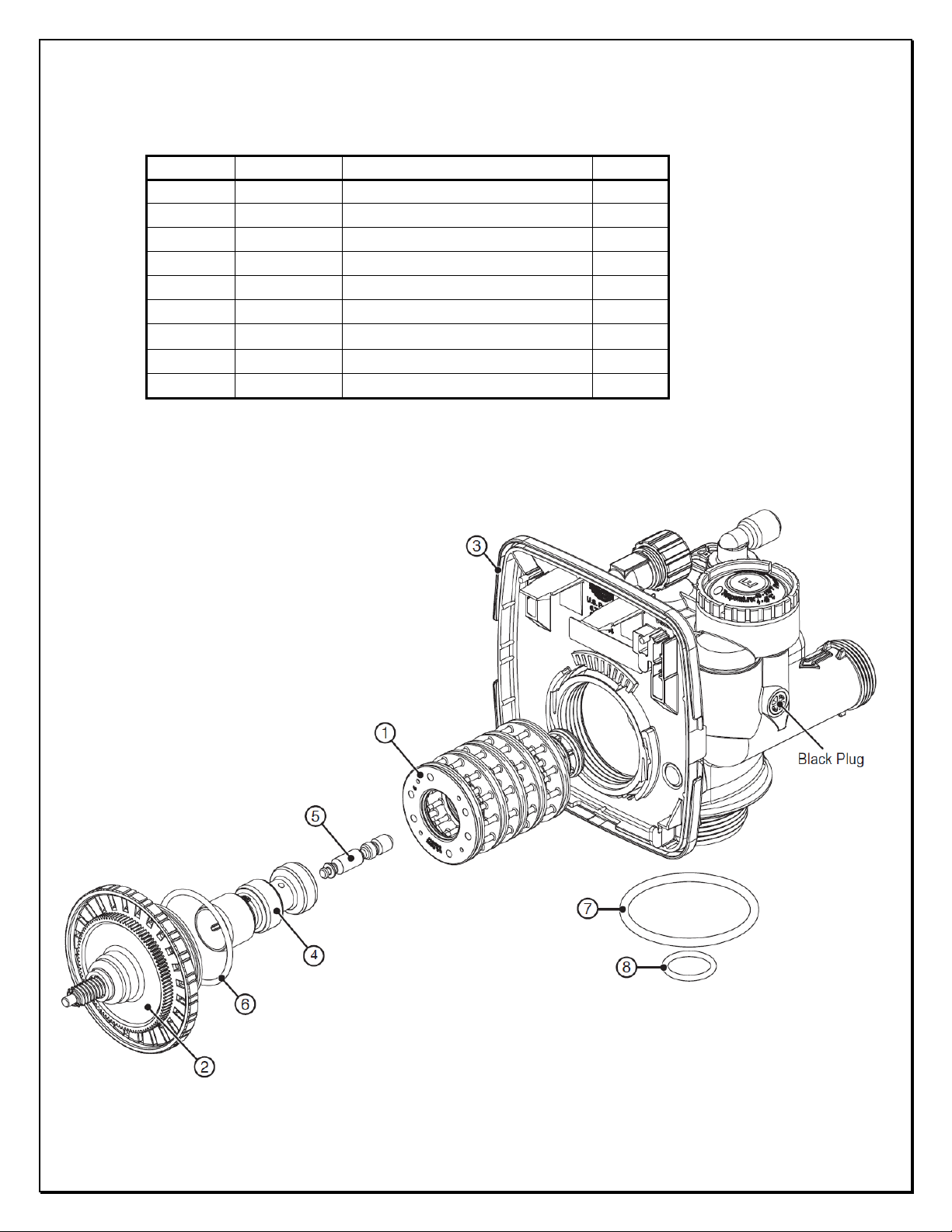

5.2) Drive assembly, Piston and Spacer stack

Drawing No.

Order No.

Description

Quantity

1

CLK V3005

WS1 Spacer Stack Assembly

1

2

CLK V3004

Drive Cap ASY

1

3

CLK V3178

WS1 Drive Back Plate

1

4

CLK V3011

WS1 Piston Downflow ASY

1

5

CLK V3174

WS1 Regenerant Piston

1

6

CLK V3135

O-ring 228

1

7

CLK V3180

O-ring 337

1

8

CLK V3105

O-ring 215 (Distributor Tube)

1

Not Shown

CLK V3001

WS1 Body ASY Downflow

1

17

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

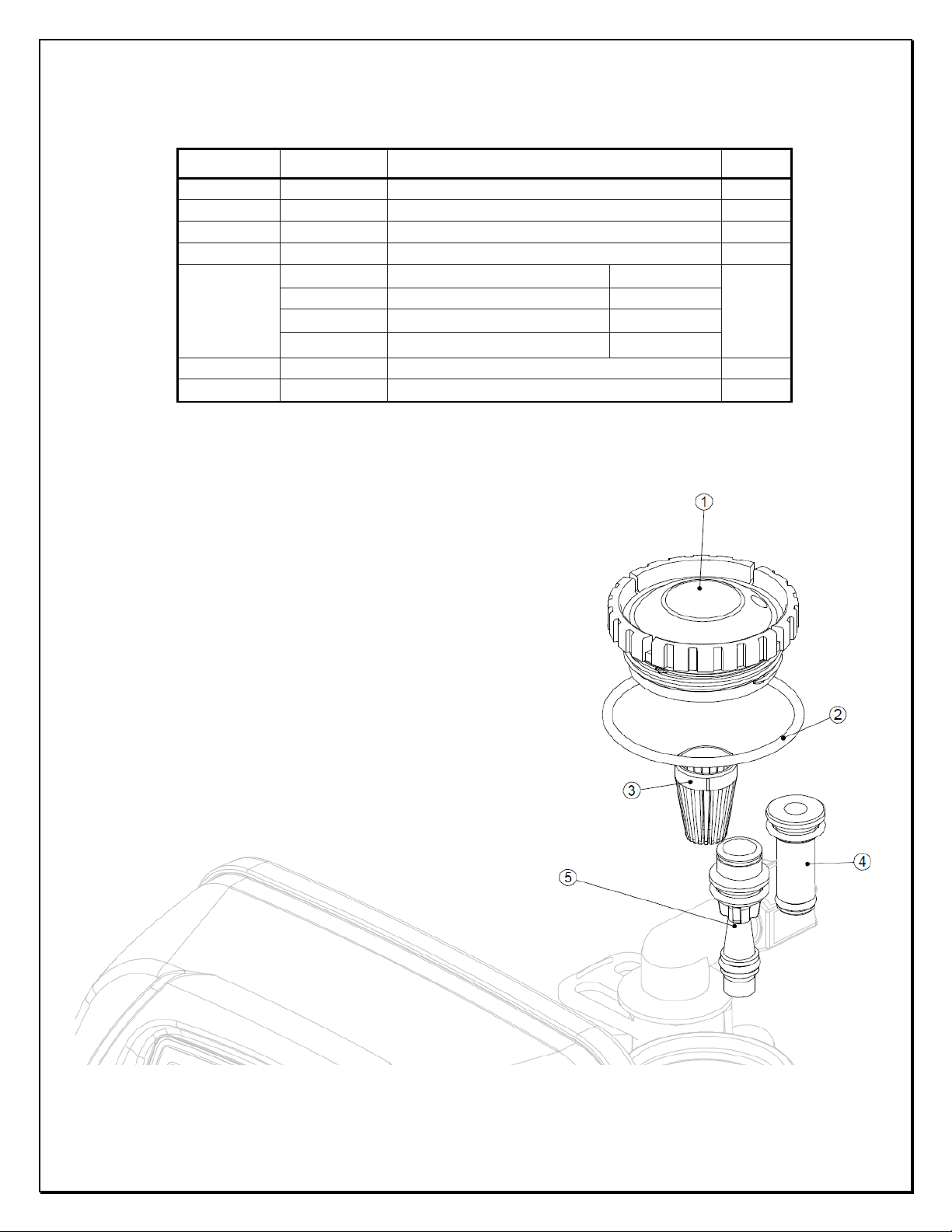

5.3) Injector Assembly

Drawing No. Order No. Description Quantity

1

CLK V3176

INJECTOR CAP

1

2

CLK V3152

O-RING 135

1

3

CLK V317701

INJECTOR SCREEN CAGE

1

4

CLK V30101Z

WS1 INJECTOR ASY Z PLUG

1

5

CLK V30101D

WS1 INJECTOR ASY D RED

For 9” Tank

1

CLK V30101E

WS1 INJECTOR ASY EWHITE

For 10” Tank

CLK V30101F

WS1 INJECTOR ASY F BLUE

For 12” Tank

CLK V30101G

WS1 INJECTOR ASY G YELLOW

For 13” Tank

Not Shown*

CLK V3170

O-RING 011

1

Not Shown*

CLK V3171

O-RING 013

1

* The injector plug and the injector each contain 011 (lower) and 013 (upper) O-ring.

18

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

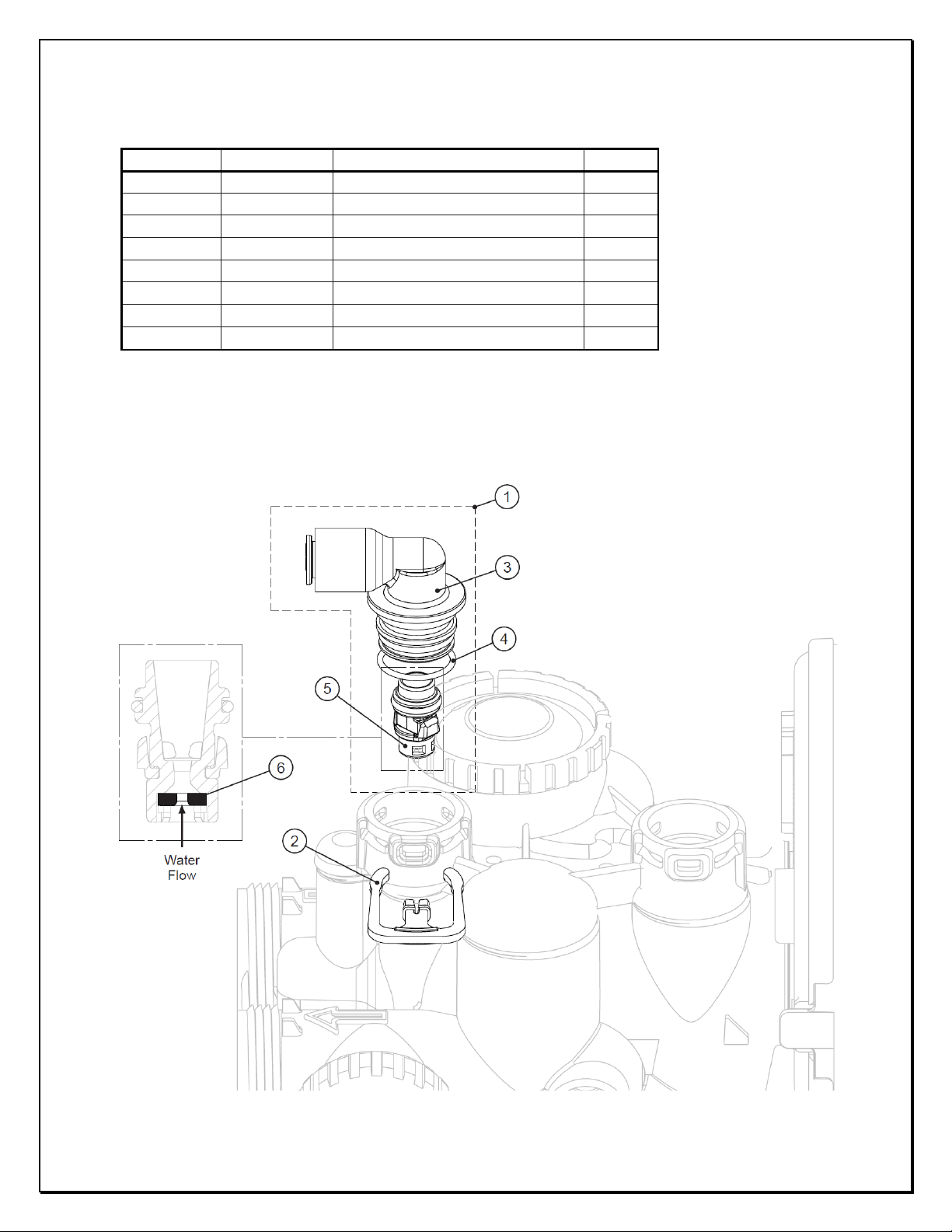

5.4) Brine Tank Line Flow Control

Drawing No.

Order No.

Description

Quantity

1

CLK V414401

Elbow 3/8 Liquifit Asy w/RFC

1

2

CLK H4615

Elbow Locking Clip

1

3

CLK H4628

Elbow 3/8” Liquifit

1

4

CLK V3163

0-ring 019

1

5

CLK V316501

WS1 RFC Retainer Asy (0.5 gpm)

1

6

CLK V3182

WS1 RFC

1

Not Shown

CLK V3552

WS1 Brine Elbow Asy w/RFC

Option

Not Shown

CLK H4650

Elbow ½” with nut and insert

Option

#5 - CLK V316501 Retainer Assembly includes #6 - CLK V3182 Refill flow control

19

WATER CONDITIONER INSTALLATION AND USER GUIDE

BARRIE • ONTARIO • CANADA 705.733.8900 WWW.EXCALIBURWATER.COM

5.5) Drain Line Flow Control Assembly

Drain Line ¾”

Drawing No.

Order No.

Description

Quantity

1

CLK H4615

Elbow Locking Clip

1

2

CLK PKP100TS8BULK

Polytube insert 5/8

Option

3

CLK V3192

WS1 Nut ¾ Drain Elbow

Option

4

CLK V315801

WS1 Drain Elbow ¾ Male

1

CLK V315802

WS1 Drain Elbow ¾ Male No

5

CLK V3163

O-ring 019

1

6

CLK V315901

WS1 DLFC Retainer ASY

1

7

CLK V3162017

WS1 DLFC 1.7 gpm

8” Tank

One DLFC

must

be used if ¾

fitting is used

CLK V3162022

WS1 DLFC 2.2 gpm

9” Tank

CLK V3162027

WS1 DLFC 2.7 gpm

10” Tank

CLK V3162032

WS1 DLFC 3.2 gpm

12” Tank

This manual suits for next models

4

Table of contents