Exmark Ultra Vac QDS Frontrunner FRCK524 Manual

Page 1 of 7

109-6609 Rev. C

Loose Parts shipped inside Hopper:

109-6603 Dealer Pack

Part # Description Qty Use

103-1309 Warranty Registration Form 1 Fill out and return to Exmark

109-5606 Decal, Door Operation 1 Install on Lower ROPS Tube

109-3458 Pin, Chute Pivot 1 Used to retain discharge chute for side discharge

1-806003 Pin, Chute Pivot Hairpin 1 Retains chute pivot pin to deck

109-6474 Fill Sensor Harness Pack

Part # Description Qty Use

109-5340 Harness, Tractor Fill Sensor 1 Fill Sensor wiring harness with alarm attached

1-303335 Tie,7-15/16” Plastic 4 To retain Tractor Harness to tractor

109-5304-03 Bracket, Alarm Mtg 1 Bracket to hold Fill Sensor Alarm

109-2394

3290-357 U-bolt

3/8”-6 Whizlock Nut 1

2 To retain alarm bracket to ROPS

6x9 Hardware Bag

Part # Description Qty Use

323-9

3290-357

98-5975

Screw, 3/8-16 x 1-3/4” Hex

Nut, Whizlock 3/8

Washer, Spring Disc 3/8 4 To attach lower frame mount to frame

109-6604 Literature Pack

Part # Description Qty Use

-----------

----------- Manual, Operator’s

Manual, Parts 1

1 Read before operating machine

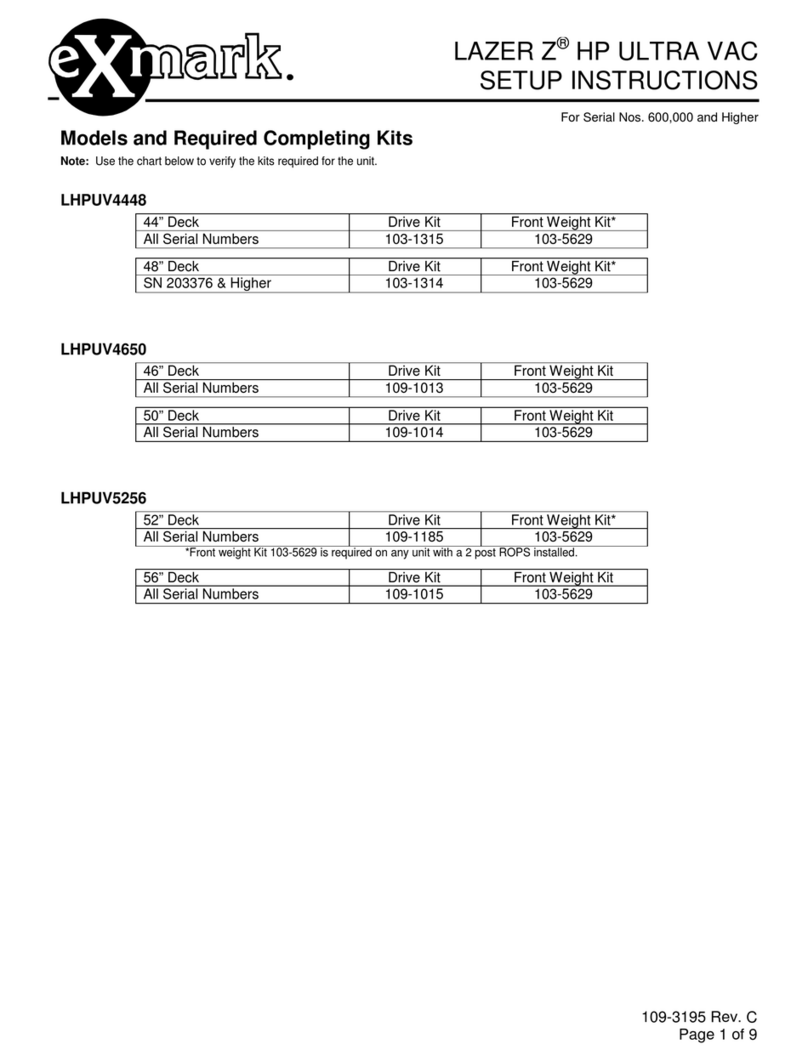

Model Numbers

FRUVD – Fits FrontRunner with 52”, 60” or 72” deck

FRCK524 – Completing kit for 52” deck

FRCK604 – Completing kit for 60” deck

FRCK724 – Completing kit for 72” deck

Note: Dual tail wheels are REQUIRED for maximum stability, clearance, and capacity.

FRDTWK – Complete kit to install dual tail wheels.

FRDTWA – Partial kit to install dual tail wheels, re-uses some components from single tailwheel.

FRONTRUNNER

®

ULTRA VAC

SETUP INSTRUCTIONS

For Serial Nos. 670,000 and Highe

r

Page 2 of 7

109-6609 Rev. C

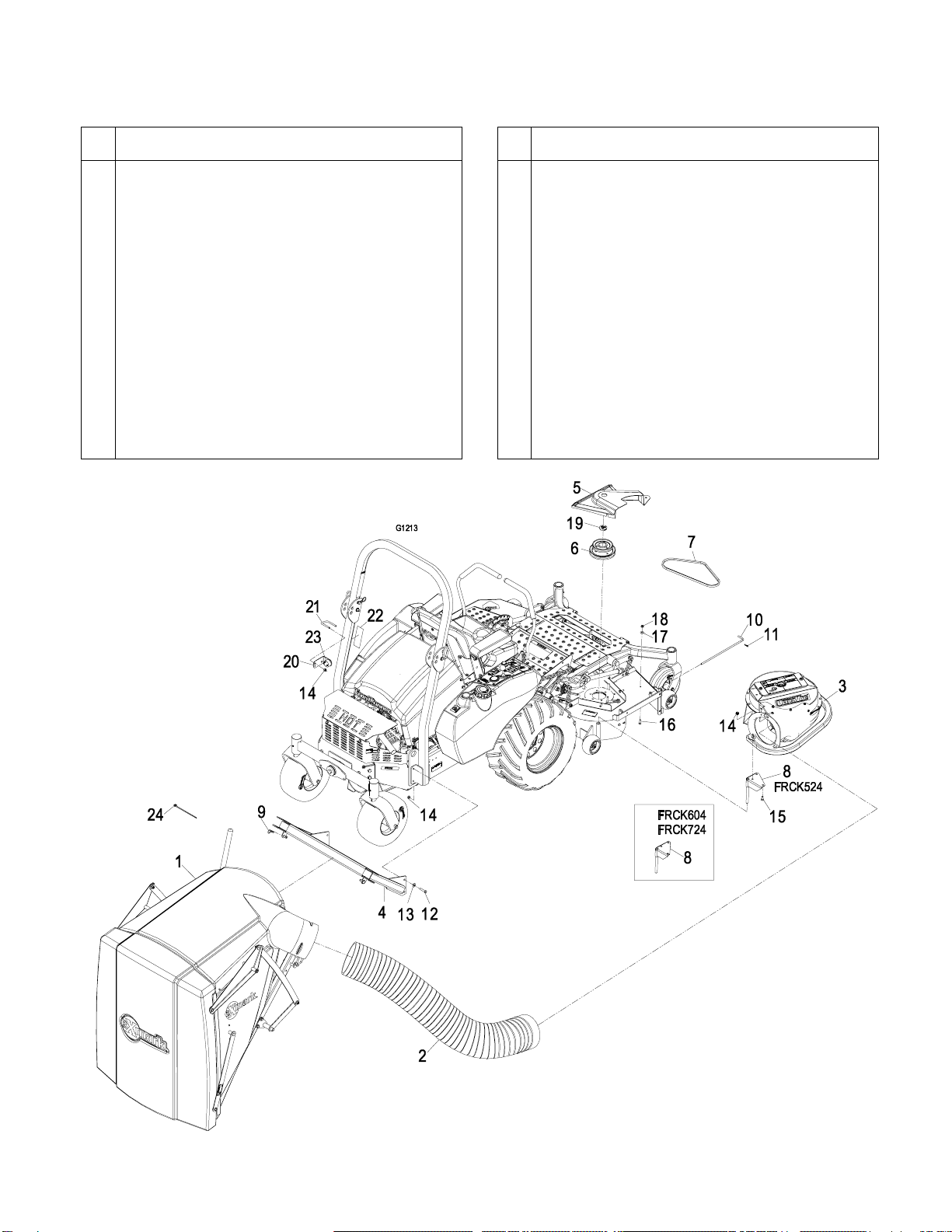

1. Assembly Instructions

Item

Part No.

Description

Qty.

1 ------------ Asm, Hopper..........................................1

2 ------------ Hose, FRUVD........................................1

3 ------------ Asm, Blower...........................................1

4 109-4748-03 Wld, Hopper Support..............................1

5 109-4846 Cover, Belt 52".......................................1

109-4847 Cover, Belt 60".......................................1

109-4848 Cover, Belt 72”.......................................1

6 103-2797 Jackshaft, 52" ........................................1

103-2792 Jackshaft, 60" ........................................1

109-2796 Jackshaft 72” .........................................1

7 109-4948 Belt, Blower Drive 52" ............................1

103-0866 Belt, Blower Drive 60" ............................1

103-0867 Belt, Blower Drive 72” ............................1

8 109-4841-03 Wld, Mount Pin 52" ................................1

103-0445-03 Wld, Mount Pin 60" & 72”.......................1

9 1-806005 Hairpin, Cotter (large).............................2

Item

Part No.

Description

Qty.

10 109-3458 Pin, Chute Pivot..................................... 1

11 1-806003 Pin, Hair (small).....................................1

12 323-9 Screw, HH 3/8-16 x 1 3/4....................... 4

13 98-5975 Washer, Spring Disk 3/8........................ 4

14 3290-357 Nut, Whizlock 3/8-16..............................9

15 323-4 Screw, HH 3/8-16 x 3/4..........................3

16 322-5 Screw, HH 5/16-18 x 1...........................1

17 3256-3 Washer, 5/16 Std................................... 1

18 32128-20 Nut, Whizlock 5/16-18............................ 1

19 103-1279 Plug.......................................................1

20 109-5304-03 Bracket, Alarm....................................... 1

21 109-2394 U-bolt..................................................... 1

22 109-5606 Decal, Door Operation........................... 1

23 ------------ Harness, Alarm...................................... 1

24 1-303335 Ties, Zip ................................................4

FIGURE 1

Page 3 of 7

109-6609 Rev. C

Safety

Safety Alert Symbol

This SAFETY ALERT SYMBOL is used

both in this instruction sheet and on the machine

to identify important safety messages which must

be followed to avoid accidents. This symbol

means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The safety alert symbol appears above information

which alerts you to unsafe actions or situations and

will be followed by the word DANGER, WARNING,

or CAUTION.

DANGER: White lettering / Red background.

Indicates an imminently hazardous situation which,

if not avoided, WILL result in death or serious injury.

WARNING: Black lettering / Orange background.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious

injury.

CAUTION: Black lettering / Yellow background.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

WARNING

POTENTIAL HAZARD

♦Using a single tailwheel may contact the

collection system and cause difficult

steering and reduce the machine stability.

WHAT CAN HAPPEN

♦The single tailwheel tire may contact the

bottom of the collection system causing

difficult steering.

♦A single tailwheel with a collection system

is less stable and a potential tip-over

could cause serious injury or death.

HOW TO AVOID THE HAZARD

♦Operate machine only with a dual

tailwheel installed.

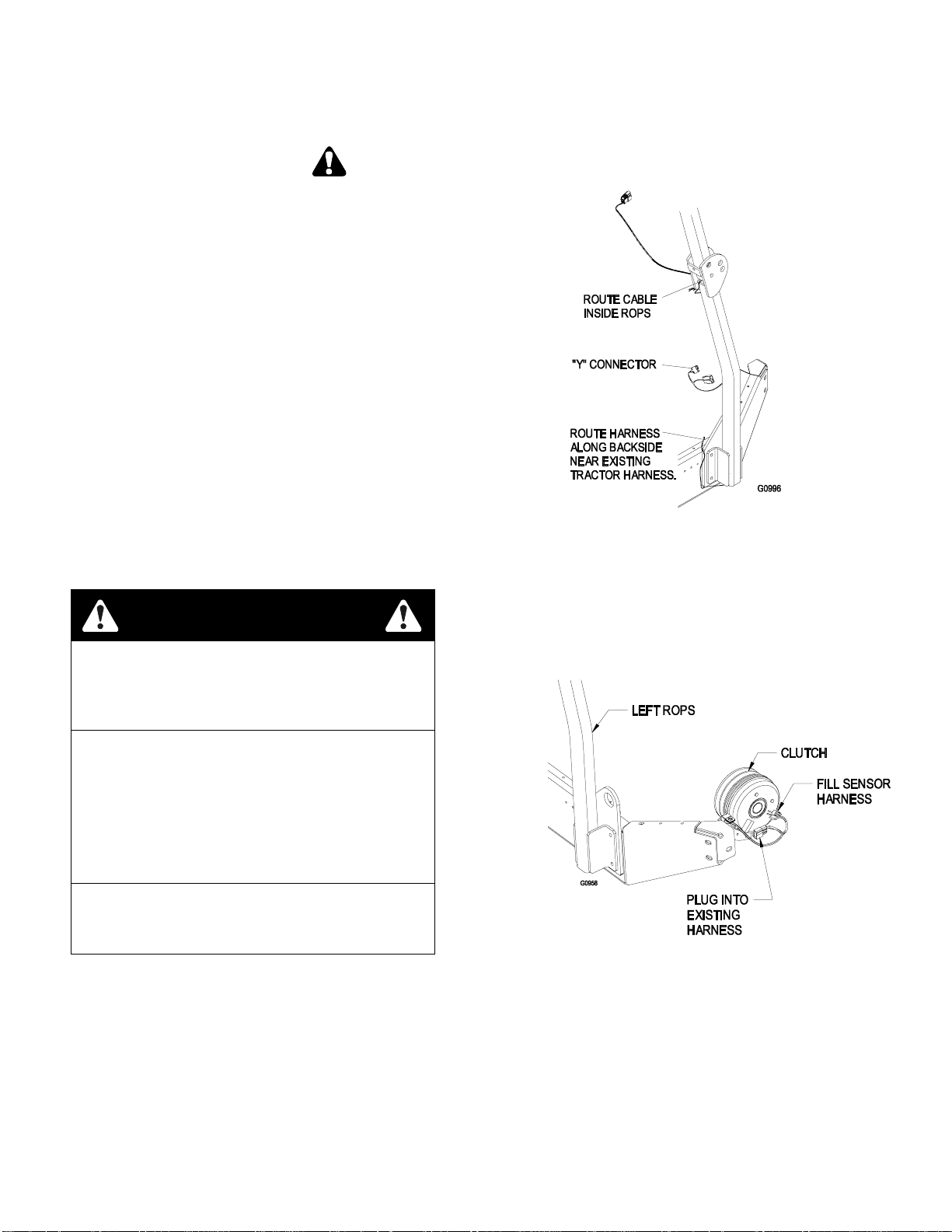

Route the Fill Sensor Wiring

1. Locate the wire harness for the fill sensor.

2. There is a “Y” connector on one end of the

harness. Snake this end down the inside of the

LH ROPS tube. See Figure 2.

FIGURE 2

3. Using the zipties provided, route wiring harness

along existing tractor harness to the rear of the

machine near the clutch.

4. At the back of the machine, unplug the tractor

harness from the clutch.

5. Connect the fill sensor harness between the

clutch and tractor harness as shown in Figure 3.

FIGURE 3

Page 4 of 7

109-6609 Rev. C

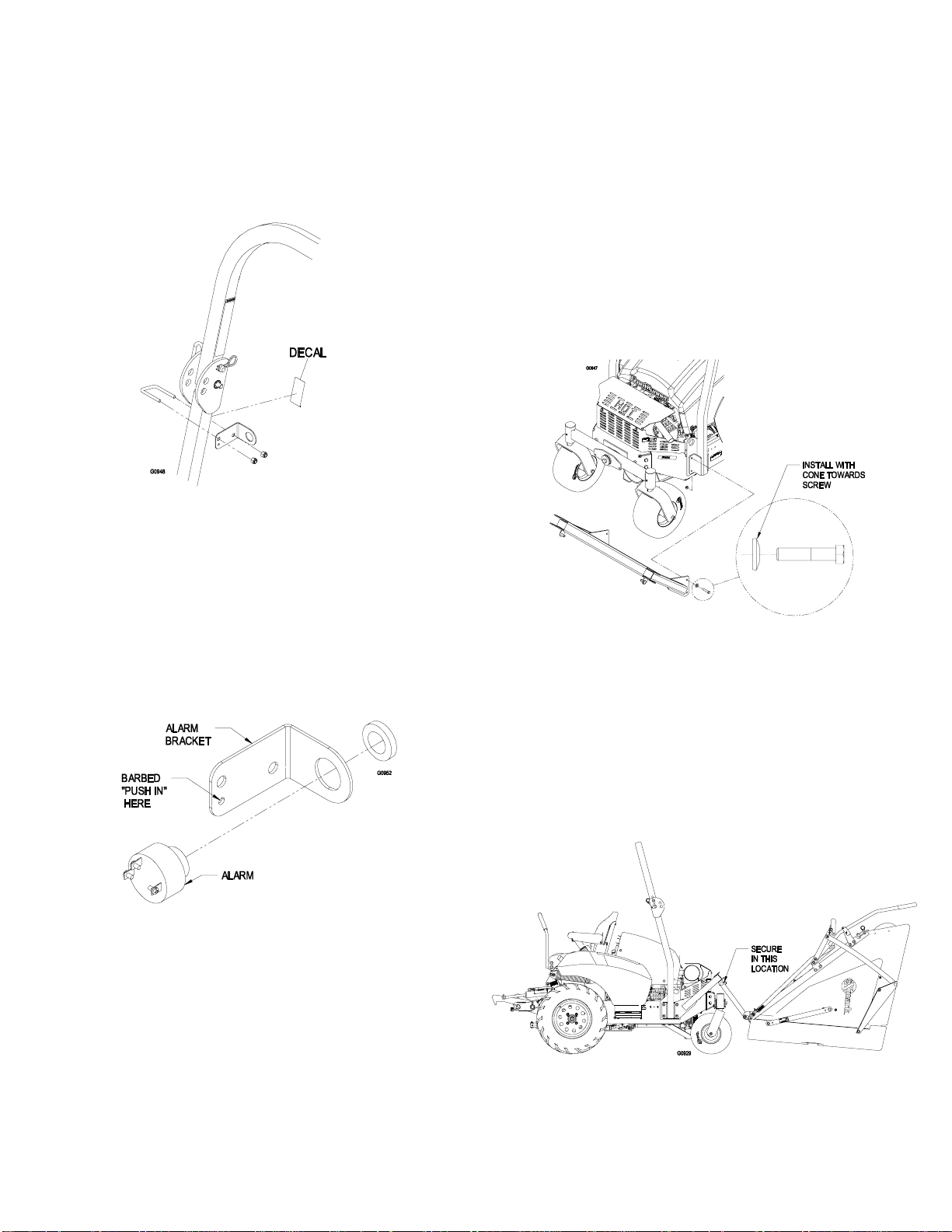

Assemble the Fill Sensor Alarm

Bracket

1. Apply the decal (109-5606) to the front of the LH

ROPS tube as shown in Figure 4. Locate the fill

sensor alarm bracket, u-bolt and hardware.

Assemble to top of LH ROPS tube.

FIGURE 4

Assemble the Fill Sensor Alarm

1. The fill sensor alarm is pre-assembled to the wiring

harness. Install alarm to bracket by unscrewing the

retaining ring, insert alarm through large hole in

bracket, and reinstall retaining ring hand tight. See

Figure 5.

2. Retain wire harness to alarm bracket by installing

the barbed “push in” into extra hole of alarm

bracket. See Figure 5.

FIGURE 5

Install Hopper Assembly

Note: Reference the previous assembly

diagrams for the Item numbers called out in the

installation instructions.

1. Remove the 2 bolts in the rear of the lower

ROPS tubes on each side to allow for

installation of the Ultra Vac.

2. Install the mount weldment (Item 4) loosely to

the rear of the machine using (4) 3/8-16 x 1.5”

screws, 3/8” spring disc washers and 3/8”

whizlock nuts provided. Make sure that the

raised portion of the spring disk washer faces

the head of the screw. (See Figure 6).

FIGURE 6

3. Loosen (but do not remove) the remaining 2

front screws on each side retaining the lower

ROPS tubes to the frame.

4. Apply a light coat of grease to the top surface of

the mount weldment. Install the hopper

assembly (Item 1) by laying the hopper

assembly back on the door, pivot the lower links

forward and slip the ends over the pins on the

mount weldment. Secure the assembly to the

mount using hairpins (Item 9). See Figure 7.

FIGURE 7

Page 5 of 7

109-6609 Rev. C

5. Lift the rear of the hopper assembly, pivoting it

upwards towards the ROPS. Using the pins

provided on the hopper assembly, pin the hopper

assembly to the ROPS plates. See Figure 8.

FIGURE 8

6. Torque all lower roll bar and mount hardware

attached to the machine frame to 30-35 ft-lbs

(41-47 N-m).

7. Plug wire harness into bulkhead connector on

hopper. (See Figure 9.)

FIGURE 9

Installation of Blower Assembly

1. Lower the deck fully. Remove the right hand belt

cover.

2. Remove the blade from the right spindle.

3. Insert special tool 109-2979 into splined end of

spindle shaft.

4. Remove the right sheave nut, spring disk washer,

and drive sheave from the spindle shaft– keep

hardware for re-use.

Use special tool 109-2979 to hold spindle from

rotating. Do not use the blade bolt to prevent

rotation.

5. Apply a light coat of Mobil HTS grease (or food

grade antiseize) to the top portion of the spindle

shaft where the sheave mounts.

6. Install the double sheave onto the right spindle

shaft. Install the spring disk washer and nut.

Make sure that the spring disk washer cone is

installed towards nut (See Figure 10). Torque

the sheave nut to 140-145 ft-lbs.

Use special tool 109-2979 to hold spindle

from rotating. Do not use the blade bolt to

prevent rotation.

FIGURE 10

Reinstall blade and torque 1/2-20x2 blade

bolt to 50-60 ft-lbs (75-81 N-m).

7. Reinstall the deck drive belt in the lower groove

of the double sheave. Install plug (Item 19) into

bore of double sheave.

8. Remove the discharge chute from the deck.

Discard the mounting hardware, but save the

discharge chute for use during side discharge

operation. The chute pivot pin (Item 10) and

hairpin (Item 11) may be stored in the pivot

holes on the discharge chute during bagging

operation.

9. Remove and discard existing hardware in deck

hole shown. Install the longer belt cover

mounting bolt (Item 16) into hole in deck as

shown in Figure 11.

FIGURE 11

Page 6 of 7

109-6609 Rev. C

10. Install the mounting pin weldment (Item 8) to the

blower assembly using the 3/8-16 x .75 bolts (Item

15) and whizlock nuts (Item 24). Maximum deck

clearance will be provided if the bolts are installed

from below the mounting pin. There are (2) different

mounting pin weldments, install as shown. (See

Figure 12).

FIGURE 12

11. Install the belt (Item 7) onto the blower by working it

around the impeller sheave.

12. Mount the blower on the deck by sliding the

mounting pin into the tube at the rear right corner of

the deck. Swing the blower closed. Adjust the

position of the front pin to engage the slot in the

front of the deck. Use the latch to lock the blower in

this position. Adjust the tension on the latch to hold

the blower up to the deck, yet allow for release by

hand.

13. Pull the spring loaded idler back and slip the belt

over the top deck spindle sheave.

14. Install the plastic belt cover (Item 5). The rear of the

cover is slotted and can slip between the knob and

deck reinforcement plate. The knob retaining the

front of the original steel belt cover must be reused

and installed after the new plastic cover has been

positioned.

Assemble the Tube

1. The hopper inlet has ribs to engage the spiral

reinforcement of the flexible tube. Using a marker or

paint pen, mark the flexible tube approximately 4”

from the end. Insert the end of the tube into the

hopper inlet, and rotate clockwise to engage.

Rotate and thread the tube into the hopper inlet

up to the 4” mark. It may be easier to “push” the

tube into the inlet rather than rotating. (See

Figure 13.)

FIGURE 13

1. Orient hose adapter flange on tube with hose

adapter flange on blower housing (it only goes

on one way). Engage shoulder bolts through

keyholes in adapter flange on blower and rotate

to lock. Insert lock pin in small hole in top of

flange to lock in place. See Figure 14.

FIGURE 14

Operation

Pre-Start

1. Read the operator’s manual for the mower and

Ultra Vac to familiarize yourself with all controls

before operating the machine. Make sure that

you understand the controls, their locations,

their functions, and their safety requirements.

2. Ensure the blower, belt cover, flexible tube and

hopper assembly are in good condition, properly

attached, and latched.

Run In

1. Verify that the blower drive operates correctly

prior to delivery to customer.

2. The Ultra Vac blower operates when deck drive

is engaged. Be sure that all persons are clear

of the mower deck and blower before engaging

the cutting blades. Set the throttle to “midway”

Page 7 of 7

109-6609 Rev. C

position. Pull outward on the PTO switch to the

“ROTATE” position.

3. To disengage the deck drive and blower, set the

throttle to “midway” position. Push in on the PTO

switch to the “STOP” position to stop the cutting

blades and blower. The cutting blades will require a

slightly longer amount of time to come to a complete

stop when the blower is installed on the deck.

Fill Sensor

The fill sensor is located at the front of the hopper, and is

wired into the PTO circuit. When grass fills the hopper

enough to block one or both sensors, an alarm will sound.

The fill sensor testing must be made with the PTO

engaged, but the engine does not have to be running.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake. Unlatch the door

and pull the door handle engagement pin to raise the

door to the top of the hopper (see Figure 15.)

FIGURE 15

2. Reach into the hopper and place a piece of masking or

duct tape over the LH sensor. It may be helpful to

remove the screen as shown in Figure 15.

3. Close the door.

4. Sit in the seat and turn the key to the RUN position, but

DO NOT START the unit.

5. Pull up on the PTO switch to engage power to the

clutch; you should hear a click from the clutch.

6. There is a split second delay before the fill sensor

alarm will sound.

7. Repeat steps 1-3 to remove the tape from the sensor.

Adjustments

The FrontRunner Ultra Vac was adjusted at the factory

to operate properly. However, there are three basic

adjustments that can be made, should your unit require

them:

1. Fill sensors: Located inside the hopper, they

sound an alarm when the hopper is full. They

can be adjusted for varying grass conditions that

fill the hopper differently (see Figure 16).

FIGURE 16

Moving the LH sensor up works better in wetter

conditions.

Moving the LH sensor down works better in

dryer conditions.

2. Latches: The latches (Figure 17) can be

adjusted. With the door closed, the latch plate

should be set so that the latch cams completely

engage and contact the latch plates bolted to

the door.

FIGURE 17

3. Latch handle link: The latch handle needs to

be able to snap over-center to keep the latch

cams tight against the door latch plates and the

door pulled shut. The length of the latch linkage

is controlled by the two whizlock nuts on either

side of the latch link (Figure 17). The whizlock

nuts should be adjusted so that reasonable

force on the handle is required to over-center

and latch the door. Do not adjust so that the

over-center spring collapses completely when

the door is fully latched.

This manual suits for next models

5

Other Exmark Vacuum Cleaner manuals