Check the type and quantity of items before setting up.

1. For safety use ・・・・・・ 1

2. Outline of the product

2 - 1 Application ・・・・・・・・・・ 2

2 - 2 Specification ・・・・・・・・・・ 2

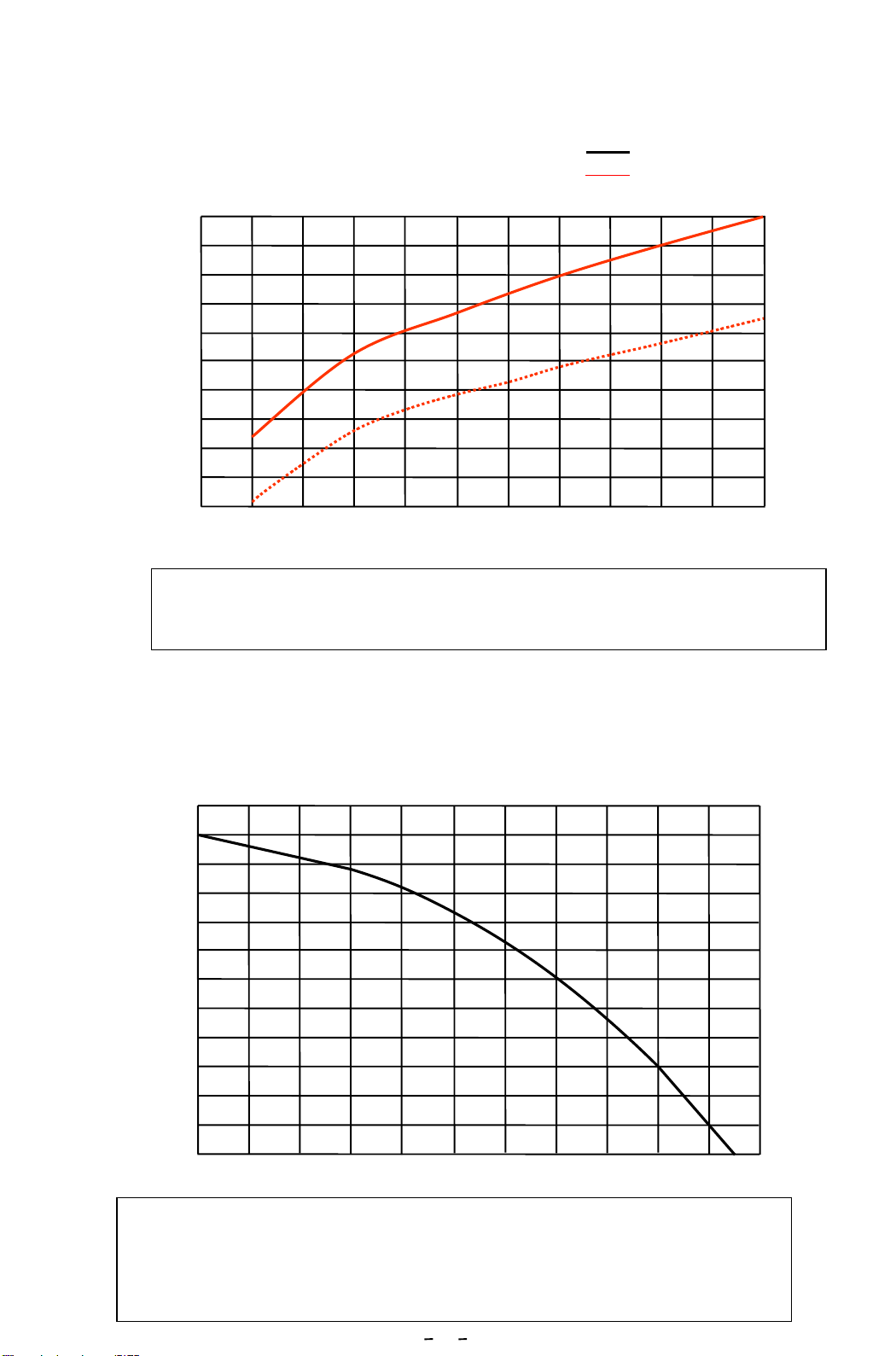

2 - 3 Cooling capability curve(Reference)・4

2 - 4 Circulation capability (Reference)・・・ 4

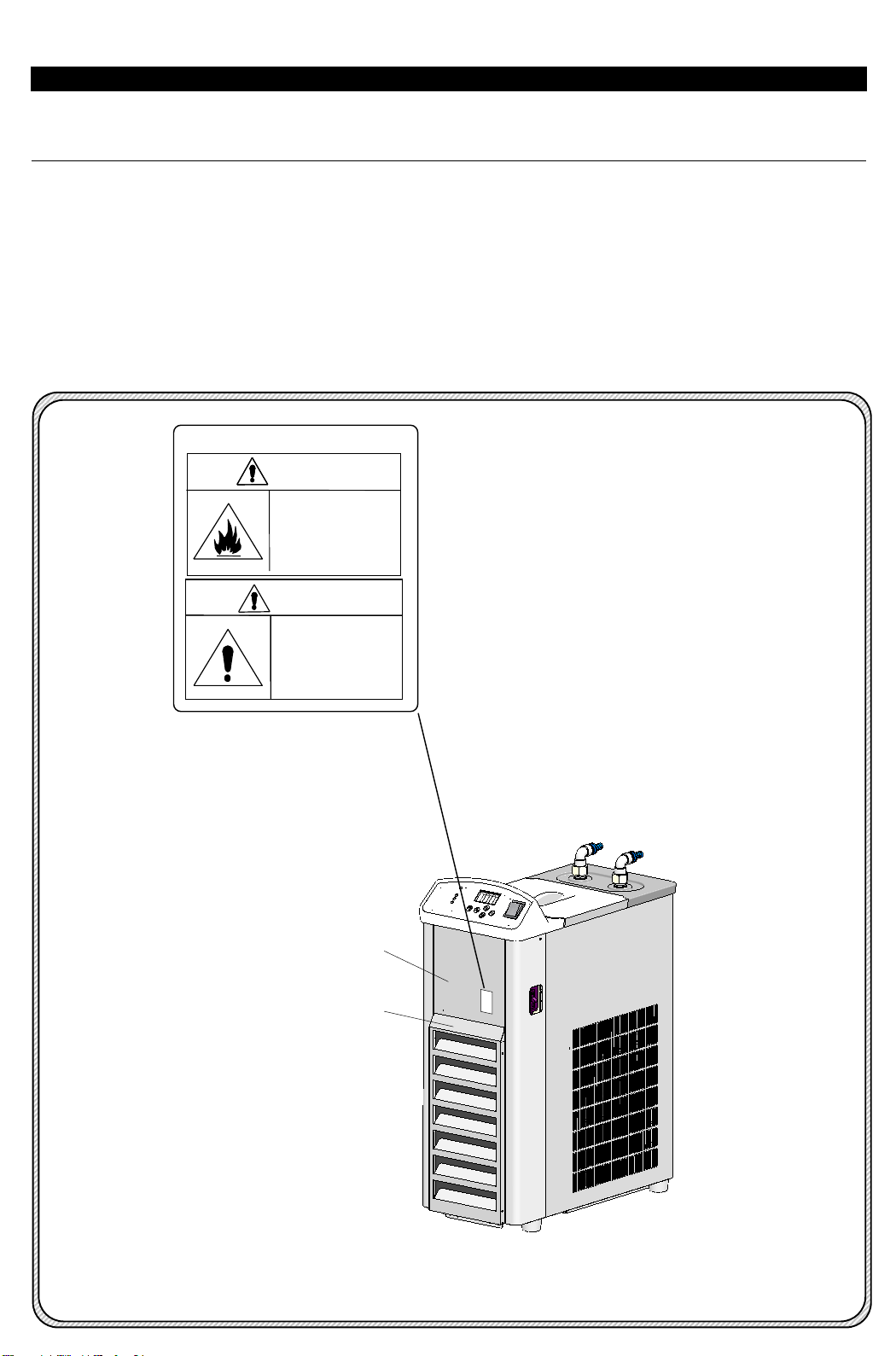

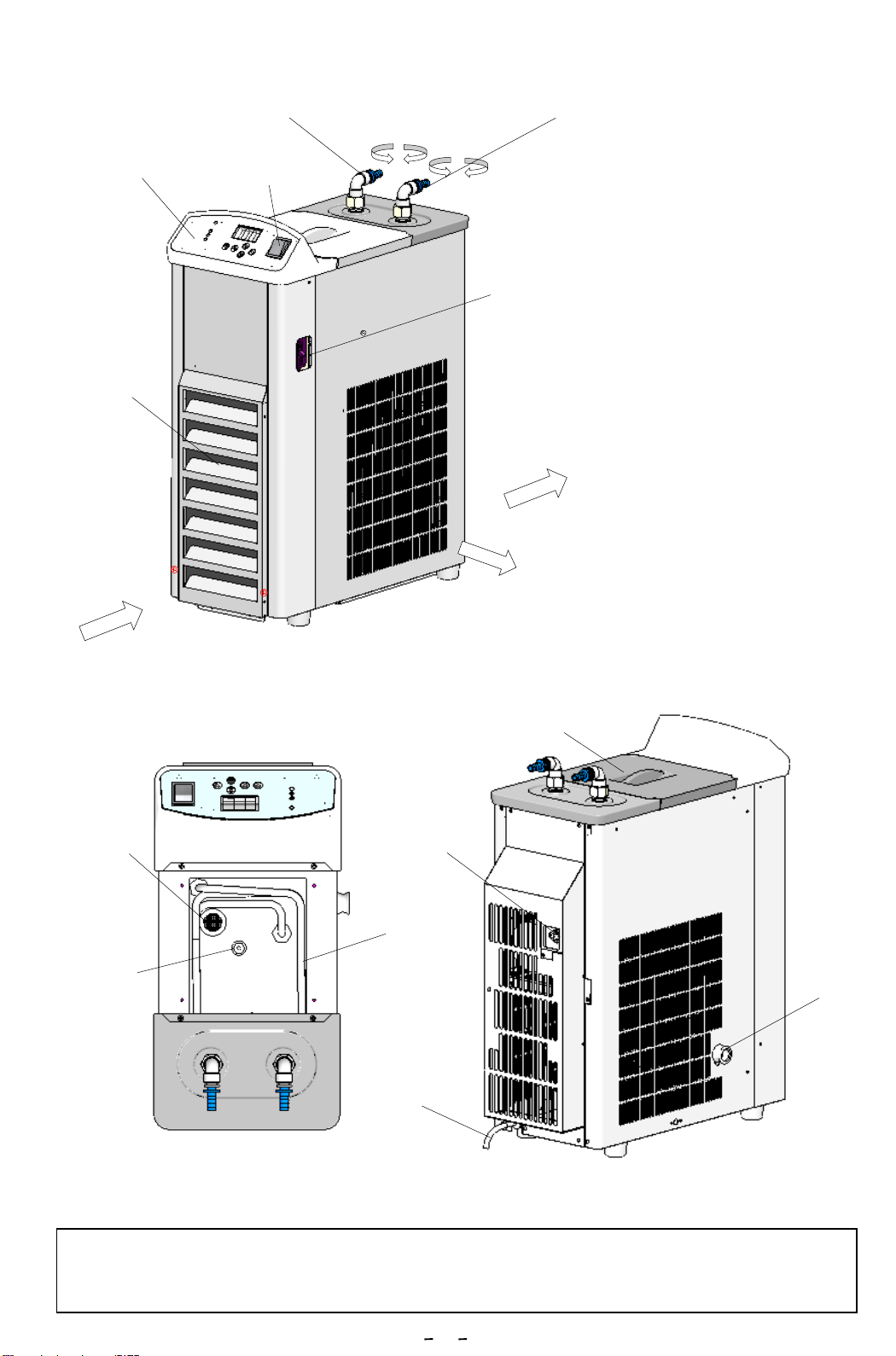

2 - 5 Description ・・・・・・・・・・ 5

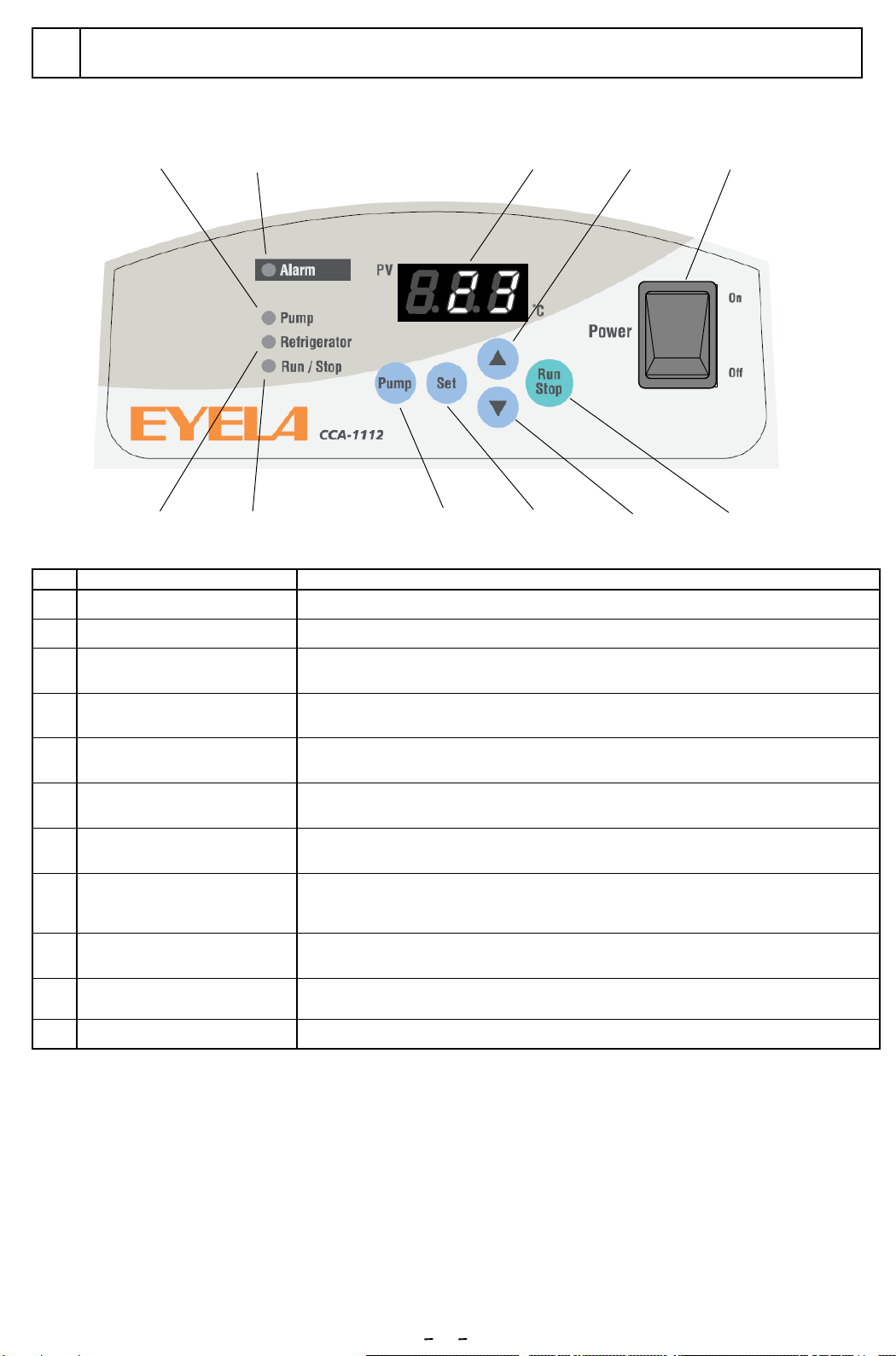

3.Names and functions of operating portion

3 - 1 Control panel ・・・・・・ 6

3 - 2 Safety・Alarm functions ・・・・・ 7

4.Installation

4 - 1 Environment・・・・・・・・・・・ 9

4 - 2 Conditions ・・・・・・・・・・・ 9

4 - 3 Utility connection ・・・・・・・ 10

5.Operation

5 - 1 Preparation ・・・・・・・・・・ 11

5 - 2 How to operate the unit・・・・・・ 13

5 - 3 How to use optional accessories ・15

6 Trouble shooting ・・・・・・ 18

Introduction

This manual describes the procedure of

installation, operation, troubleshooting,

maintenance, check-up

and disposal of Low Temperature Circulator,

CCA-11112A (220V, 60Hz)

Congratulations on your purchase of a

product.

7. Maintenance and checking

7 - 1 Operation test for residual current device ・・20

7 - 2 Caring and cleaning the product ・・20

8. Disposal of the product・・・・・・・・ 22

9.After-sales service ・・・・・・・・ 23

10.Consumable/spare part/optional

accessories ・・・・・・・・ 24

Table of contents

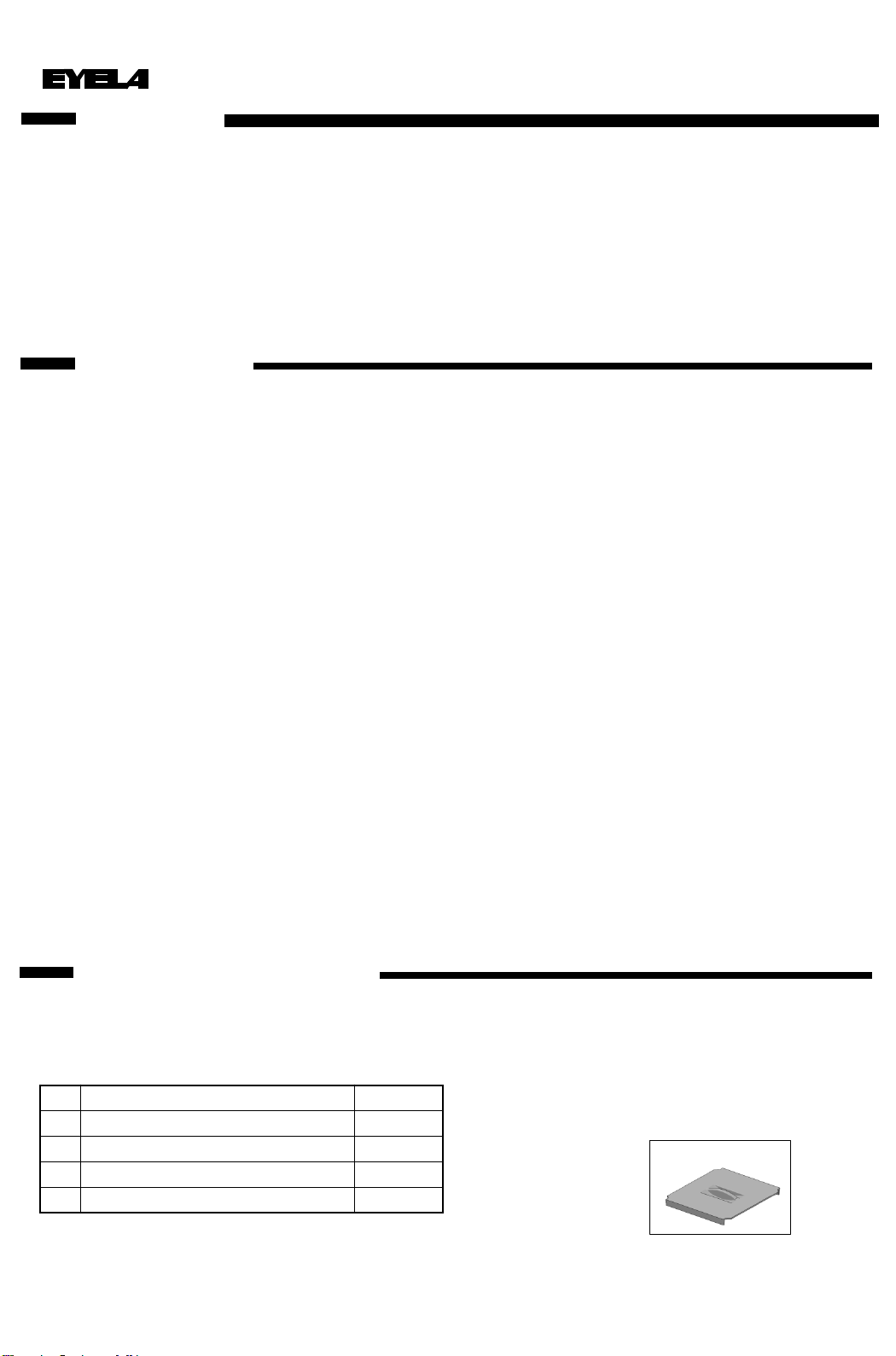

Items contained in your carton

No. Name QTY

1Main unit 1

2Tank cover 1

3Instruction Manual 1

4

Tank cover