Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

H8500A Hydraulic Impact Wrench, Drill and Screwdriver

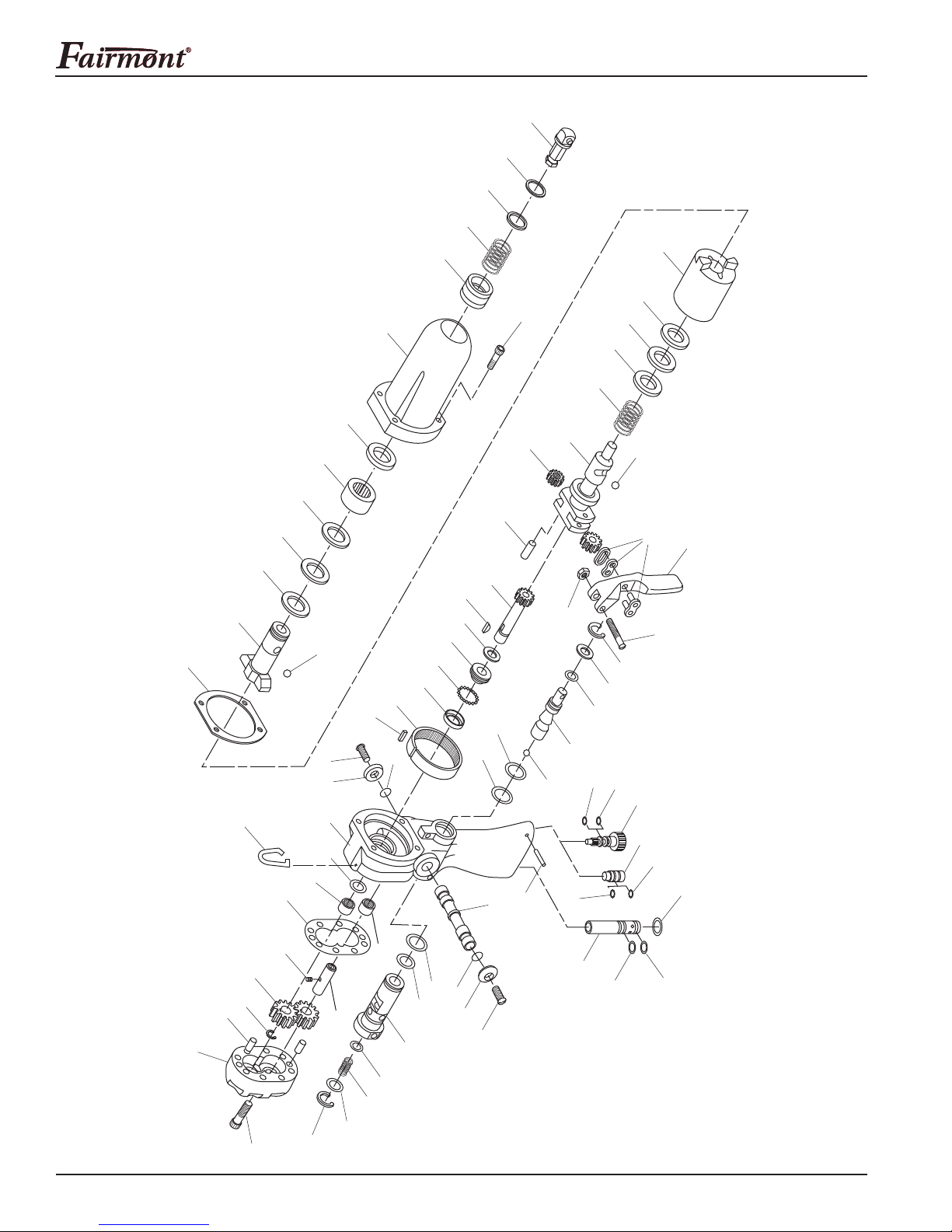

Disassembly

Complete disassembly of the tool is not recommended.

If a complete overhaul is necessary, return the tool to

your nearest Fairmont Authorized Service Center.

The disassembly procedure is divided into sections of

the tool. Disassemble only the section(s) necessary to

complete the repair.

Disassemble the tool on a at, clean surface. Take care

not to lose or damage any parts that may fall free during

disassembly.

Quick-Change Chuck

1.

Remove the adapter drive shank (73) from the chuck.

2. Remove the lock ring (72), ring (71), and spring (70).

Note: To prevent the loss of any steel balls, perform

the next step over a clean, empty container.

3. Slide the sleeve (69) off and remove the three steel

balls (68).

Case Components

1. Scribe a line across the case (63) and handle (1) to

align the parts correctly during assembly.

2. Remove four cap screws (67) and remove the case

(63) from the handle. Remove the gasket (66).

3. Remove the anvil (60), thrust bearing (61), and thrust

races (62) from the case. If necessary, press the

roller bearing (64) and seal (65) from the case.

4. Remove the hammer assembly (51–59) from the

handle assembly.

5. If the hammer assembly components require

disassembly, compress the hammer (55) and carrier

pinion (51) together in a vise or a press. Remove the

two steel balls (59). Release the assembly from the

vise or press.

6. Remove the hammer from the carrier pinion.

Remove the thrust races (57), thrust bearing (56),

and spring (58). Drive out the dowel pins (54) to

remove the gears (52).

7. Remove the ring gear (4) and the dowel pin (5) from

the handle assembly.

Motor

1. Scribe a line across the motor cap (47) and handle

(1) to align the parts correctly during assembly.

2. Remove eight cap screws (49) and the cap from the

handle. Remove the gasket (46) and, if necessary,

the dowel pins (45).

3. Pull the idler shaft (43) with gear (40) from the

handle. If necessary, remove the drive pin (44).

4. Remove the retaining ring (42), gear (40), and

Woodruff key (41) from the drive shaft (39). Pull the

drive shaft from the handle.

Note: To prevent the loss of any steel balls, perform

the next step over a clean, empty container.

5. Remove the inner race (38) and the 18 steel balls

(37) from the handle.

6. Use an O-ring tool to remove the O-ring (2) without

removing the needle bearing (3).

Trigger, Control Spool, and Super Spool™ Sleeve

1. Remove the retaining ring (25) and cap (24) from the

Super Spool sleeve (19). Remove the spring (29).

2. Remove the connecting link (33) from the trigger (32)

and control spool (26). Remove one nut (35) and one

machine screw (34) from the trigger (32). Remove

the trigger.

3. Remove the retaining ring (31) and washer (30).

Remove the control spool (26) from the Super Spool

sleeve (19). Remove the O-ring (27) from the control

spool (26). Remove the ball (28) from the control

spool.

4. Remove the external retaining ring (22) from the

Super Spool sleeve. Remove the sleeve from the

handle.

5.

Remove the O-rings (20, 21, 23) from the Super Spool

sleeve. Remove the O-ring (18) from the handle.

Directional Spool

1. Remove the cap screws (17) and buttons (16) from

the directional spool (14).

2. Slide the directional spool partially out of the handle

to expose either O-ring (15). Remove the exposed

O-ring. Remove the spool by pushing it back

through the handle. Remove the other O-ring.

Note: Attempting to force the directional spool

through the bore against the O-ring will damage the

O-ring and could allow particles of O-ring to get into

the motor.

Flow Control Cartridge

1. Remove the retaining ring (9). Remove the ow

control cartridge (6) from the handle.

2. Remove the O-rings (7, 8) from the cartridge.

Do not attempt to repair the ow control cartridge.

It contains no replaceable parts.

Failure to observe this warning can result in severe

injury or death.

Adjustable Torque Output Screw

or Non-Adjustable Torque Output Plug

1. Remove the roll pin (13) from the handle. Twist the

screw (10) or plug (74) counterclockwise to remove

it from the handle.

2. Remove the O-ring (11) and backup ring (12).