Fastech Ezi-SERVOII EtherCAT TO User manual

Closed Loop Stepping System

EtherCAT Network

User Manual

•Ezi-SERVOII EtherCAT TO

FASTECH Co., Ltd.

Contents

Contents 2

Introduction 6

Before Operation ............................................ 6

Safety Precautions ........................................... 7

1 Product Specification 10

1.1 Model Naming .......................................... 11

1.2 Product Dimension ........................................ 12

1.3 EtherCAT Specifications ..................................... 13

1.4 Drive Specification ........................................ 14

2 Installation 15

2.1 Precautions of Installation .................................... 16

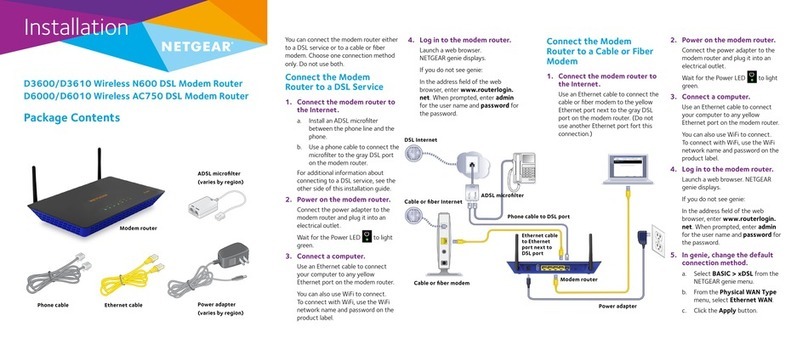

2.2 System Configuration ...................................... 17

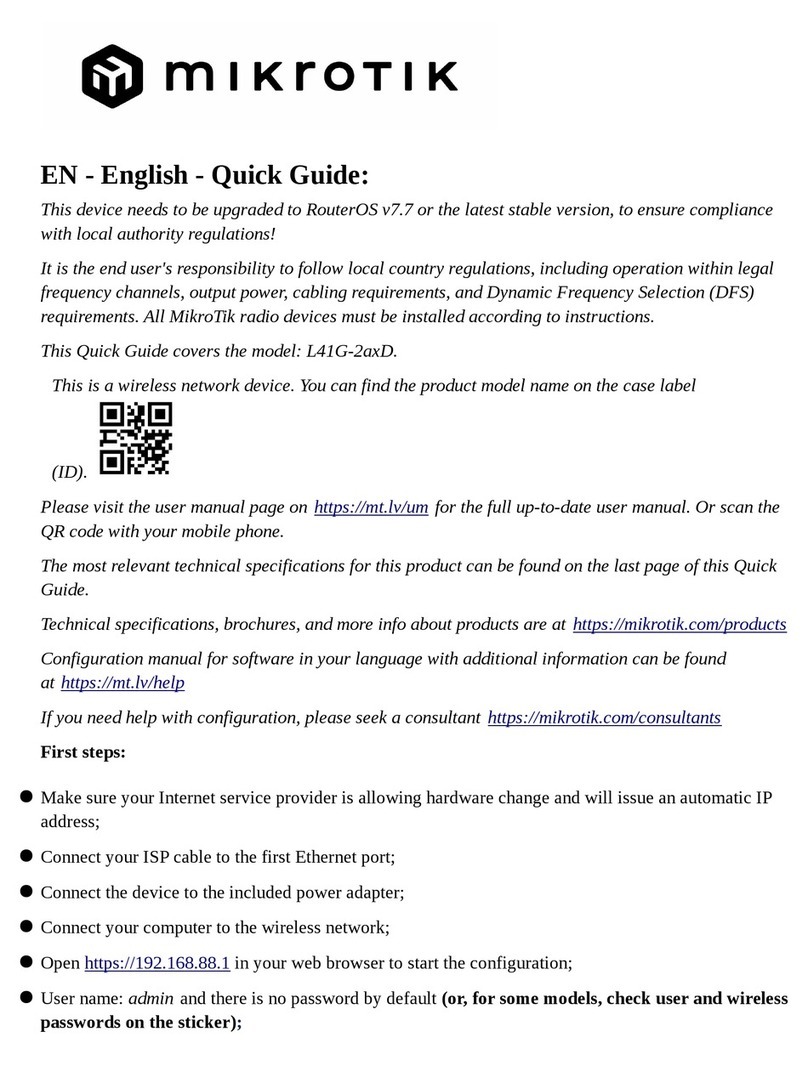

2.3 External Wiring Diagram ..................................... 18

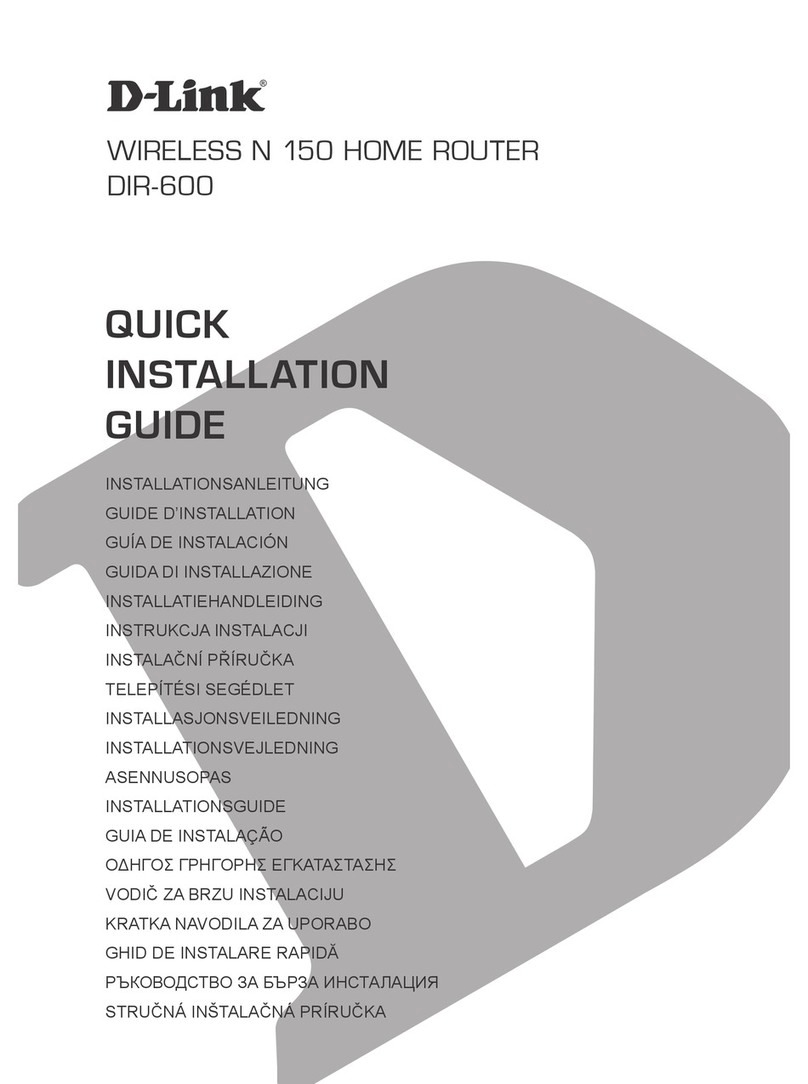

2.4 Appearance and Part Name ................................... 19

2.4.1 EtherCAT ID ....................................... 19

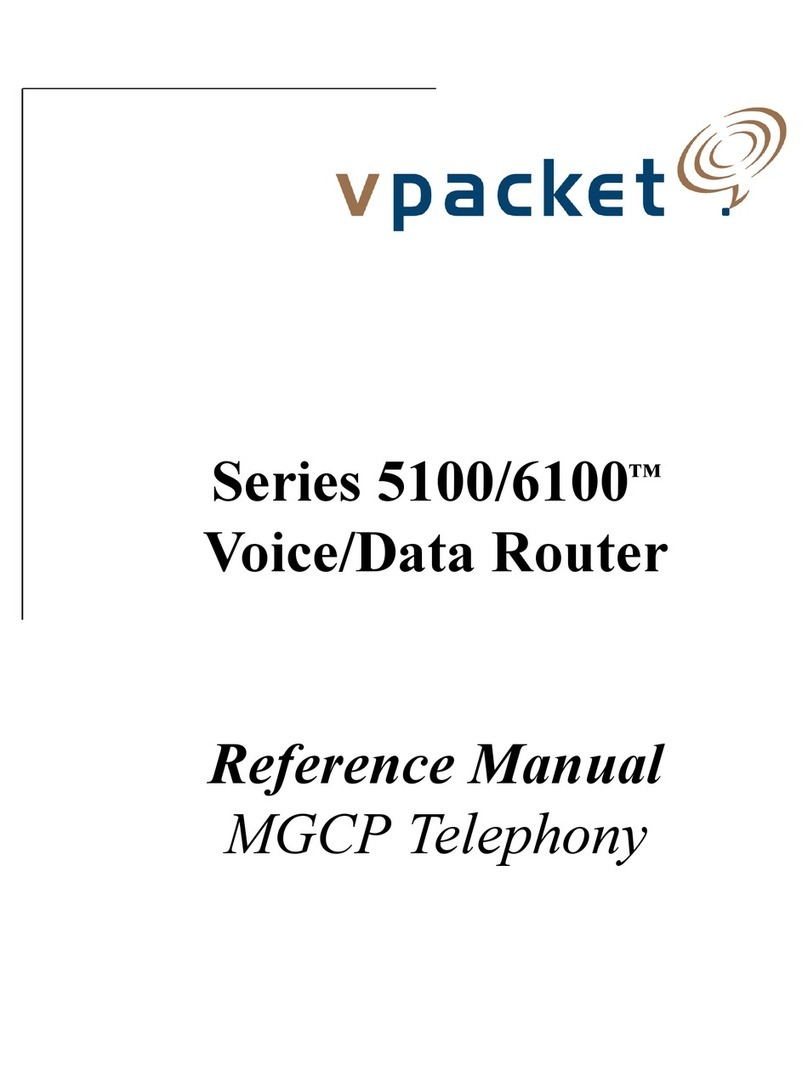

2.4.2 EtherCAT Status LED .................................. 20

2.4.3 EtherCAT Communication Connection ......................... 21

2.4.4 I/O Connector ...................................... 22

2.4.5 Encoder Connection Connector ............................. 23

2.4.6 Motor Connection Connector .............................. 23

2.4.7 Power Connection Connector .............................. 24

2.4.8 TQOFF Connector .................................... 25

2.4.9 USB Connector ...................................... 26

2.5 Appendix ............................................. 27

2.5.1 Extension Cable for Motor ................................ 27

2.5.2 Extension Cable for Encoder .............................. 27

2.5.3 Connector Specifications ................................ 28

3 EtherCAT Communication 29

3.1 CAN application protocol over EtherCAT ............................ 30

3.1.1 Object Dictionary ..................................... 30

3.1.2 Mailbox Communication ................................. 30

3.1.3 Process Data Communication ............................. 31

3.2 PDO Mapping ........................................... 31

3.2.1 PDO Mapping ...................................... 31

3.2.2 PDO Assign ....................................... 31

3.3 EtherCAT State Machine .................................... 32

3.4 Synchronization ......................................... 33

3.4.1 Free Run ......................................... 33

3.4.2 SM Event ......................................... 33

3.4.3 DC Sync Event ...................................... 33

3.5 EtherCAT Slave Information ................................... 34

4 CiA402 Drive Profile 35

Rev.37 FASTECH Co., Ltd. 2

4.1 Drive Status Control ....................................... 36

4.1.1 Control word ....................................... 38

4.1.2 Status word ........................................ 38

4.2 Error Code ............................................ 40

4.3 Mode of operation ........................................ 42

4.4 Cyclic Synchronous Position Mode ............................... 43

4.4.1 Definition ......................................... 43

4.4.2 Related Objects ..................................... 43

4.4.3 Control word and Status word .............................. 43

4.5 Profile Position Mode ...................................... 45

4.5.1 Definition ......................................... 45

4.5.2 Related Objects ..................................... 45

4.5.3 Control word and Status word .............................. 45

4.5.4 Position movement method ............................... 47

4.6 Homing Mode ........................................... 52

4.6.1 Definition ......................................... 52

4.6.2 Relative Objects ..................................... 52

4.6.3 Control word and Status word .............................. 52

4.6.4 Origin Search Method .................................. 53

4.7 Touch Probe ........................................... 60

4.7.1 Definition ......................................... 60

4.7.2 Related Objects ..................................... 60

4.7.3 Touch Probe Status and Control ............................ 60

4.8 Digital Input and Output ..................................... 62

4.8.1 Definition ......................................... 62

4.8.2 Related Objects ..................................... 62

4.8.3 User I/O .......................................... 62

4.8.4 ORIGIN and LIMIT Input ................................. 62

4.8.5 BRAKE Output ...................................... 63

4.9 Safety Function .......................................... 64

4.9.1 Operation of Safety Function .............................. 64

5 Operation 67

5.1 Operation Sequence ....................................... 68

5.2 Setting ............................................... 68

5.2.1 Installation ........................................ 68

5.2.2 Wiring ........................................... 68

5.2.3 Input Power ........................................ 68

5.2.4 PDO Mapping ...................................... 68

5.2.5 Set Communication Status ............................... 69

5.3 Operation ............................................. 69

5.3.1 Drive Status Control ................................... 69

5.3.2 Set Mode ......................................... 69

5.3.3 Set Operation ....................................... 69

5.3.4 Movement Command .................................. 69

5.3.5 Check Statues ...................................... 69

5.4 Drive Setting Adjustment .................................... 70

5.4.1 Change Rotation Direction ............................... 70

5.4.2 Change I/O Signal Level ................................. 70

6 EtherCAT Object Dictionary 71

6.1 Indication Type of Objects .................................... 72

6.1.1 Index and Sub-Index ................................... 72

6.1.2 Name ........................................... 72

6.1.3 Data Type ......................................... 72

6.1.4 Access .......................................... 73

6.1.5 SAVE ........................................... 73

6.1.6 PDO Mapping ...................................... 73

Rev.37 FASTECH Co., Ltd. 3

6.1.7 Constant Value ...................................... 73

6.1.8 Value Range ....................................... 73

6.1.9 Default Value ....................................... 73

6.2 Communication Object ...................................... 74

6.2.1 Object 1000h: Device type ............................... 74

6.2.2 Object 1001h: Error register ............................... 74

6.2.3 Object 1008h: Device name ............................... 74

6.2.4 Object 1009h: Hardware version ............................ 74

6.2.5 Object 100Ah: Software version ............................ 74

6.2.6 Object 1010h: Store parameters ............................ 75

6.2.7 Object 1011h: Restore default parameters ....................... 75

6.2.8 Object 1018h: Identity .................................. 76

6.2.9 Object 10F1h: Error settings .............................. 76

6.2.10 Object 10F3h: Diagnosis history ............................ 77

6.3 PDO Mapping Object ...................................... 79

6.3.1 Object 1600h: RxPDO-Map 0 .............................. 79

6.3.2 Object 1601h: RxPDO-Map 1 .............................. 79

6.3.3 Object 1A00h: TxPDO-Map 0 .............................. 79

6.3.4 Object 1A01h: TxPDO-Map 1 .............................. 80

6.3.5 Object 1C12h: RxPDO assign ............................. 80

6.3.6 Object 1C13h: TxPDO assign .............................. 80

6.4 Sync Manager Object ...................................... 81

6.4.1 Object 1C00h: Sync manager type ........................... 81

6.4.2 Object 1C32h: SM output parameter .......................... 81

6.4.3 Object 1C33h: SM input parameter ........................... 81

6.5 Drive Profile Object ........................................ 82

6.5.1 Object 603Fh: Error code ................................ 82

6.5.2 Object 6040h: Control word ............................... 82

6.5.3 Object 6041h: Status word ............................... 82

6.5.4 Object 605Ah: Quick stop option code ......................... 82

6.5.5 Object 605Bh: Shutdown option code ......................... 83

6.5.6 Object 605Ch: Disable operation option code ..................... 83

6.5.7 Object 605Dh: Halt option code ............................. 83

6.5.8 Object 605Eh: Fault reaction option code ....................... 84

6.5.9 Object 6060h: Mode of operation ............................ 84

6.5.10 Object 6061h: Mode of operation display ....................... 84

6.5.11 Object 6062h: Position demand value ......................... 84

6.5.12 Object 6064h: Position actual value .......................... 84

6.5.13 Object 6065h: Following error window ......................... 85

6.5.14 Object 6067h: Position window ............................. 85

6.5.15 Object 606Bh: Velocity demand value ......................... 85

6.5.16 Object 606Ch: Velocity actual value .......................... 85

6.5.17 Object 607Ah: Target position .............................. 85

6.5.18 Object 607Ch: Home offset ............................... 86

6.5.19 Object 607Dh: Software position limit ......................... 86

6.5.20 Object 607Eh: Polarity .................................. 86

6.5.21 Object 607Fh: Max profile velocity ........................... 87

6.5.22 Object 6081h: Profile velocity .............................. 87

6.5.23 Object 6083h: Profile acceleration ........................... 87

6.5.24 Object 6084h: Profile deceleration ........................... 87

6.5.25 Object 6098h: Homing method ............................. 87

6.5.26 Object 6099h: Homing speeds ............................. 88

6.5.27 Object 609Ah: Homing acceleration .......................... 88

6.5.28 Object 60B8h: Touch probe function .......................... 88

6.5.29 Object 60B9h: Touch probe status ........................... 89

6.5.30 Object 60BAh: Touch probe 1 positive value ..................... 90

6.5.31 Object 60BBh: Touch probe 1 negative value ..................... 90

6.5.32 Object 60BCh: Touch probe 2 positive value ..................... 90

Rev.37 FASTECH Co., Ltd. 4

6.5.33 Object 60BDh: Touch probe 2 negative value ..................... 90

6.5.34 Object 60C2h: Interpolation time period ........................ 91

6.5.35 Object 60D0h: Touch probe source ........................... 91

6.5.36 Object 60D5h: Touch probe 1 positive edge counter ................. 91

6.5.37 Object 60D6h: Touch probe 1 negative edge counter ................. 91

6.5.38 Object 60D7h: Touch probe 2 positive edge counter ................. 92

6.5.39 Object 60D8h: Touch probe 2 negative edge counter ................. 92

6.5.40 Object 60E3h: Supported homing methods ...................... 92

6.5.41 Object 60F4h: Following error actual value ...................... 92

6.5.42 Object 60FDh: Digital inputs .............................. 93

6.5.43 Object 60FEh: Digital outputs .............................. 93

6.5.44 Object 6502h: Supported drive modes ......................... 94

6.6 Manufacture specific Object ................................... 95

6.6.1 Object 2001h: Sensors logics .............................. 95

6.6.2 Object 2002h: Reverse limit direction ......................... 95

6.6.3 Object 2003h: Limit stop method ............................ 96

6.6.4 Object 2005h: Encoder resolution ........................... 96

6.6.5 Object 2006h: Start speed ............................... 96

6.6.6 Object 2007h: Run current ............................... 96

6.6.7 Object 2008h: Boost current .............................. 97

6.6.8 Object 2009h: Stop current ............................... 98

6.6.9 Object 200Ah: Motor number .............................. 98

6.6.10 Object 200Ch: Reference resolution .......................... 98

6.6.11 Object 200Dh: Position control gain .......................... 99

6.6.12 Object 200Eh: In-position mode ............................ 100

6.6.13 Object 200Fh: Encoder filter time ............................ 100

6.6.14 Object 2010h: Brake delay ............................... 101

6.6.15 Object 2011h: Digital input levels ............................ 101

6.6.16 Object 2012h: Digital output levels ........................... 101

6.6.17 Object 2014h: Homing Torque Ratio .......................... 101

6.6.18 Object 2018h: Internal Current Value .......................... 102

6.6.19 Object 201Ah: Push Mode ............................... 102

6.6.20 Object 201Bh: Limit Deceleration ............................ 102

6.6.21 Object 2020h: Error code history setting ........................ 102

6.6.22 Object 2021h: Error code history ............................ 103

6.6.23 Object 2025h: Lifetime Record ............................. 104

6.6.24 Object 2030h: Advanced settings ............................ 105

6.6.25 Object 2031h: Encoder count error ........................... 106

Changelog 107

Rev.37 FASTECH Co., Ltd. 5

Introduction

Before Operation

• Thank you for your purchasing Ezi-SERVOII EtherCAT TO.

• 32 Bit high-performance of ARM Processor on-board Ezi-SERVOII EtherCAT TO is motion con-

troller supports Field-network EtherCAT.

• This manual describes handling, safety instruction, diagnosis and troubleshooting of Ezi-SERVOII

EtherCAT TO.

• Before operating Ezi-SERVOII EtherCAT TO, thoroughly read this manual.

• After reading the manual, keep the manual near the product so that any user can read the manual

whenever needed.

Rev.37 FASTECH Co., Ltd. 6

Safety Precautions

General Precautions

• Contents of this manual are subject to change without prior notice for functional improvement,

change of specifications or user’s better understanding.

• When the manual is damaged or lost, please contact with Fastech’s agents or our company to get

a manual again.

• It is not responsible for Fastech to guarantee product randomly reconstructed because this kind of

improper action is out of range of guarantee.

Safety Precautions

Before installation, operation and repairing, thoroughly read the manual and fully understand the con-

tents. Also before operation, please understand the mechanical characteristics of the product and related

safety information and precautions.

User manual describes level of precaution for safety as Warning and Danger.

Warning

If user does not properly handle the product, the user may seriously or slightly injured and damages

may occur in the machine.

Danger

If user does not properly handle the product, a dangerous situation (such as an electric shock) may

occur resulting in deaths or serious injuries.

Information

Necessary Information and extra attentions for operation.

Although precaution is only a Warning, a serious result could be caused depending on the situation.

Rev.37 FASTECH Co., Ltd. 7

Check the product

Warning

Check the product is damaged or parts are missing. Otherwise, the machine may get damaged or

the user may get injured.

Installation

Warning

Carefully operate the product. Otherwise the product may get damaged or user’s foot may get

injured by dropping the product.

Use non-flammable materials such as metal in the place where the product is to be installed. Oth-

erwise, a fire may occur.

When installing several units of FASTECH Co., Ltd.’s products in a sealed place, install a cooling

fan to keep the ambient temperature as 50°C or lower. Otherwise a fire or other kinds of accidents

may occur due to overheating.

Danger

The process of installation, Connection, Operation, Checking and Repairing should be done with

qualified person.

Connect Cables

Warning

Keep the rated range of input voltage of the drive. Otherwise, a fire or other kinds of accidents may

occur.

Please follow the wiring diagram for cable connection. Otherwise, a fire or other kinds of accidents

may occur.

Danger

Before connecting cables, please check if input power is OFF. Otherwise, a fire or other kinds of

accidents may occur.

The case of Ezi-SERVOII EtherCAT TO is insulated from the ground of the internal circuit by the

condenser so please ground the product. Otherwise, an electric shock or a fire may occur.

Operation and Setting

Warning

If a protection function (alarm) occurs, firstly remove its cause and then release (alarm reset) the

protection function. If you operate continuously without removal of root cause, the machine may

get damaged or the user may get injured.

Make all input signals to OFF before supply input voltage to drive. Motor will run then the machine

may get damaged or the user may get injured.

All parameter values of Ezi-SERVOII EtherCAT TO are set by default factory setting value. Change

this value after reading this manual thoroughly. Otherwise, the machine may get damaged or other

kinds of accidents may occur.

Rev.37 FASTECH Co., Ltd. 8

Check and Repair

Danger

Stop to supply power to main circuit and wait for a while before checking or repairing the Ezi-

SERVOII EtherCAT TO. Electricity remains in the capacitor may cause danger as like electric shock.

Do not change cabling while power is being supplied. Otherwise, the user may get injured or the

product may get damaged.

Do not reconstruct the product. Otherwise, an electric shock may occur or the reconstructed product

can not get After Sales Service.

Rev.37 FASTECH Co., Ltd. 9

Chapter 1

Product Specification

Rev.37 FASTECH Co., Ltd. 10

1. Product Specification

1.1 Model Naming

Ezi-SERVOII-EC-TO-56 L-A-BK-PN05

Product Name

Drive Series Type

EC : EtherCAT

TO : Torque Off

Motor Flange Size

20 : 20mm

28 : 28mm

35 : 35mm

42 : 42mm

56 : 56mm

60 : 60mm

Motor Length

S : Small

M : Medium

L : Large

XL : Extra Large

Encoder Resolution

A : 10,000[ppr]

B : 20,000[ppr]

D : 16,000[ppr]

F : 4,000[ppr]

Reduction Gear Ratio

Blank – Without Gear

PN03 – 1:3

PN05 – 1:5

PN08 – 1:8

PN10 – 1:10

PN15 – 1:15

PN25 – 1:25

PN40 – 1:40

PN50 – 1:50

Brake

Blank : Without Brake

BK : Brake

Figure 1.1: Model Naming

Rev.37 FASTECH Co., Ltd. 11

1. Product Specification

1.2 Product Dimension

Figure 1.2: Dimensions

Rev.37 FASTECH Co., Ltd. 12

1. Product Specification

1.3 EtherCAT Specifications

Type of Communication EtherCAT

Physical Layer Ethernet - 100BASE-TX

Connector

RJ45 (shielded)

ECAT IN : EtherCAT Input

ECAT OUT : EtherCAT Output

ECAT Device ID Set Configured Station Alias by ECAT ID Switch : 1 ∼99

Set Physical Address at Master : 1 ∼65535

Topology Line (Structured by Products only)

Tree, Star (When use Junction products)

Support Protocol CoE (CANopen application protocol over EtherCAT)

FoE (File Access over EtherCAT)

Control Profile CiA402 drive profile (IEC61800-7)

Supported Operation Mode

Cyclic Synchronous Position Mode

Profile Position Mode

Homing Mode

Synchronization Free Run, SM Event, DC SYNC Event

(minimum cycle time: 250us)

Processing Data Configurable PDO Mapping

Table 1.1: Communication Specification

Rev.37 FASTECH Co., Ltd. 13

1. Product Specification

1.4 Drive Specification

Input Voltage 24VDC ±10%

Control Method Closed loop control with 32bit MCU

Current Consumption Max 500mA (Except motor current)

Operating

Condition

Ambient

Temperature

In Use : 0 ∼50°C

In Storage : -20 ∼70°C

Humidity In Use : 35 ∼85%RH (Non-Condensing)

In Storage : 10 ∼90%RH (Non-Condensing)

Vib. Resist. 0.5g

Function

Rotation Speed 0 ∼3,000 [rpm]

Resolution [ppr] 500 ∼100,000 pulse (Selectable by parameter)

Protection

Functions

Over Current Error, Over Speed Error, Position Tracking Error, Over

Load Error, Over Temperature Error, Over Regenerated Voltage Er-

ror, Motor Connect Error, Encoder Connect Error, In-Position Error,

ROM Error, Position Overflow Error

LED Display Power status, In-Position status, Servo On status, Alarm status

I/O Signal

Input Signals

3 dedicated input (LIMIT+, LIMIT-, ORIGIN)

6 user inputs (Photocoupler Input)

TQOFF Input

Output Signals

Brake

5 user outputs (Photocoupler Output)

TQMON Output

Table 1.2: Drive Specification

Rev.37 FASTECH Co., Ltd. 14

Chapter 2

Installation

Rev.37 FASTECH Co., Ltd. 15

2. Installation

2.1 Precautions of Installation

1. This product designed for indoor usage and the ambient temperature of the room should be 0 ∼

50°C.

2. If temperature of the case is 50°C, radiate the outside to cool down.

3. Do not install this product under direct rays or near magnetic or radioactive objects.

4. If more than 2 drives are installed in a line, keep the interval of 20mm or more vertically and 50mm

or more horizontally at least.

over 20mm

over 50mm

Rev.37 FASTECH Co., Ltd. 16

2. Installation

2.2 System Configuration

Figure 2.1: System Configuration Diagram

Rev.37 FASTECH Co., Ltd. 17

2. Installation

2.3 External Wiring Diagram

Figure 2.2: External Wiring Diagram

Rev.37 FASTECH Co., Ltd. 18

2. Installation

2.4 Appearance and Part Name

Main Power connection

(CN4)

Motor connection

(CN3)

Encoder connection

(CN2)

Digital I/O signal connection

(CN1)

Control Power connection

(CN5)

TQOFF connection

(CN6)

Drive status LED EtherCAT ID display

EtherCAT status LED

EtherCAT communication

(CN7)

EtherCAT communication

(CN8)

EtherCAT ID setting switch

(SW1, SW2)

USB connection

(CN9)

Figure 2.3: Appearance

2.4.1 EtherCAT ID

EtherCAT ID Display EtherCAT ID Set

Figure 2.4: EtherCAT ID

ID Setting

Change EtherCAT ID (Configured Alias ID) value by Rotary switch setting. Right switch indicates tens

and left switch indicates units.

Setting range is 0 ∼99.

Information

ID value (Configured Alias ID) set by Rotary switch applies when power of controller turns on.

ID Indication

7-Segment indicates Physical Address or EtherCAT ID (EtherCAT configured Alias) value. Conditions

for value indication as below.

• When Rotary Switch set all ‘0’, 7-Segment indicates EtherCAT Physical Address Value. Before

Physical Address assigned due to no connection between controller and master, It indicates 0.

Once Master assigns each controllers physical address, it indicates relevant value.

• If Rotary switch set as not 0 but other value, 7-Segment indicates relevant set value (EtherCAT

configured Alias).

• If 7-Segment of ID blinks, It indicates ID value as not applied yet. It can be applied once power

turn on again.

Rev.37 FASTECH Co., Ltd. 19

2. Installation

Error value indication

If error generates from controller (Fault Status), 7-Segment indicates Error value instead of EtherCAT ID

Value.

Error value is ‘E-000’ types then 2 digits will be indicated at 7-Segment.

1s 1s 1s 1s 1s

Figure 2.5: Error value indication (ex: E-015)

Please refer to 4.2 Error Code regarding indication value

2.4.2 EtherCAT Status LED

RUN / ERR Link / Activity

Figure 2.6: EtherCAT Status LED

This LED informs EtherCAT communication status. RUN LED, ERROR LED positions at the front side

of product and, Link/Activity LED individually positions at the top of right corner of EtherCAT ports..

Indication Color Status Description

RUN Green

OFF Init Status or Power OFF

Blinking Pre-Operational Status

Single Flash Safe-Operational Status

ON Operational Status

Flickering Bootstrap Status

ERR Red

OFF Non-error status or Power OFF

Blinking Extra Error

Single Flash Sync Error

Double Flash Watch-dog Error

Link/Activity Green

OFF Link not established in physical layer

ON Link established in physical layer

Flickering In operation after establishing link

Table 2.1: EtherCAT Status LED

EtherCAT LED Status Indication shown as picture as below to check visually.

Rev.37 FASTECH Co., Ltd. 20

This manual suits for next models

1

Table of contents