feedback 45134 User manual

45134 03/2017

7

VARIABLE SPEED POLISHER

C

ALIFORNIA PROPOSITION 65

W

ARNING: You can create dust

w

hen you cut, sand, drill or grind

m

aterials such as wood, paint,

m

etal, concrete, cement, or other

m

asonry. This dust often contains

ch

emicals known to cause cancer,

b

irth defects, or other reproductive

h

arm. Wear protective gear.

W

ARNING: This product or its

p

ower cord may contain

ch

emicals, including lead, known

t

o the State of California to cause

ca

ncer and birth defects or other

r

eproductive harm. Wash hands

a

fter handling.

I

mportant!

W

hen using equipment, a few safety

p

recautions must be observed to

av

oid injuries and damage. Please

r

ead the complete operating manual

w

ith due care. Keep this manual in a

s

afe place, so that the information is

av

ailable at all times. If you give the

eq

uipment to any other person, give

t

hem these operating instructions as

w

ell. We accept no liability for

d

amage or accidents which arise due

t

o non-observance of these

i

nstructions and the safety information

h

erein.

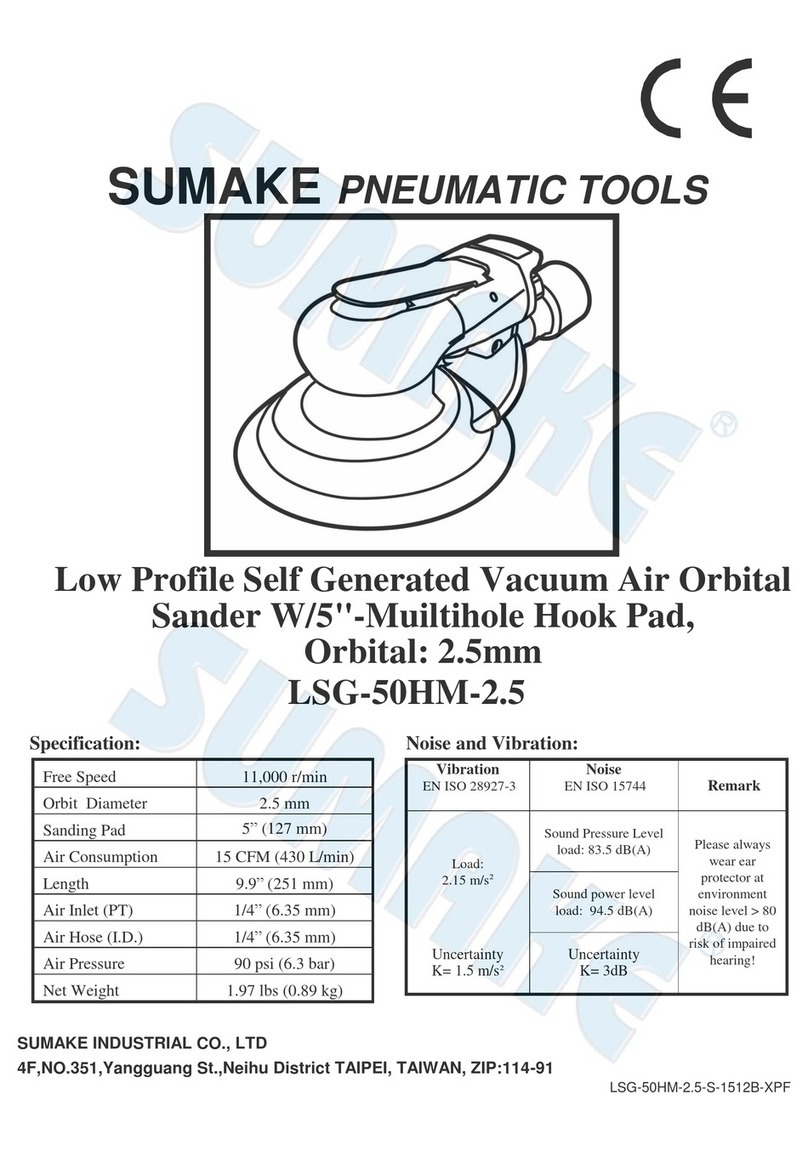

SPECIFICATIONS

Motor: 120V ~ 60Hz, 9.2 Amp

No-Load Speed: 200 - 3,350 RPM

Buffing Diameter: 7

Keep this manual and receipt in

a safe and dry place for future

reference.

GENERAL SAFETY RULES

WORK AREA

KEEP THE WORK AREA CLEAN

AND WELL LIT. Cluttered benches

and dark areas increases the risk

of injury.

DO NOT OPERATE THE TOOL

IN EXPLOSIVE ATMOSPHERES,

such as in the presence of

flammable liquids, gases, or dust.

The tool may create a spark that

could ignite flammable liquids,

gases, or dust.

KEEP VISITORS AWAY. Do not

let visitors handle the tool. All

visitors should be kept safely

away from the work area.

NEVER ENGAGE IN

HORSEPLAY WITH THE TOOL.

Respect the tool as a working

implement.

PERSONAL SAFETY

OPERATORS AND OTHERS IN

WORK AREA MUST WEAR

SAFETY GLASSES WITH SIDE

SHIELDS. Safety glasses must

conform to ANSI Z87.1

specifications.

Models: 45134

For Customer Service, please call 1-800-348-5004 or

email feedback@natitools.com

Please carefully read and save these instructions before attempting to assemble, maintain, install, or operate this

product. Observe all safety information to protect yourself and others. Failure to observe the instructions may

result in property damage and/or personal injury. Please keep instructions for future reference.

Important Operating Instructions

For warranty purchases, please keep your dated proof of purchase. File or attach to the manual for safe keeping.

1

2

ALWAYS WEAR EAR AND

HEAD PROTECTION. Wear ear

protection to protect your ears

from loud noises. Wear head

protection to protect your head

from flying objects.

USE SAFETY EQUIPMENT. A

dust mask, non-skid safety shoes,

and a hard hat must be used for

the applicable conditions. Wear a

full face shield if you are

producing metal filings or wood

chips.

DRESS PROPERLY. Do not

wear loose clothing or jewelry.

Contain long hair. Keep hair,

clothing, and gloves away from

moving parts. Loose clothes,

jewelry, or long hair can be caught

in moving parts and increase the

risk of injury.

STAY ALERT, WATCH WHAT

YOU ARE DOING AND USE

COMMON SENSE WHEN

OPERATING A POWER TOOL.

Do not use tool while tired or

under the influence of drugs,

alcohol, or medication. A moment

of inattention while operating the

tool may cause serious injury.

AVOID UNINTENTIONAL

STARTING. Keepfingers away

from trigger when not in use.

DO NOT OVERREACH. Keep

proper footing and balance at all

times. Proper footing and balance

enables better control of the tool in

unexpected situations.

REMOVE ANY ADJUSTING KEY

OR WRENCH BEFORE

TURNING THE POWER TOOL

ON. A wrench or key left attached

to a rotating part of the power tool

may result in personal injury.

ELECTRICAL SAFETY

POWER TOOL PLUGS MUST

MATCH THE OUTLET. Do not use

any adapter plugs with grounded

power tools. Unmodified plugs and

matching outlets will reduce the risk

of electric shock.

VOID BODY CONTACT WITH

GROUNDED SURFACES SUCH

AS PIPES, RADIATORS, RANGES,

AND REFRIGERATORS. There is

an increase in electric shock if your

body is grounded.

DO NOT EXPOSE POWER

TOOLS TO RAIN OR WET

CONDITIONS. Water entering a

power tool will increase the chance

for electric shock.

DO NOT ABUSE THE CORD.

Never use the cord for carrying,

pulling or unplugging the power tool.

Keep cord away from heat, oil,

sharp edges, or moving parts.

Damaged or entangled cords

increase the risk of electric shock.

WHEN OPERATING A POWER

TOOL OUTDOORS, Using a cord

suitable for outdoor use reduces the

risk of electric shock.

IF OPERATING A POWER TOOL

IN A DAMP LOCATION IS

UNAVOIDABLE, use a Ground

Fault Circuit Interrupter (GFCI)

protected supply. Use of a GFCI

reduces the risk of electric shock.

TOOL USE AND CARE

DO NOT FORCE THE POWER

TOOL. Use the correct power tool

for your application. The correct

power tool will do the job better

and safer at the rate for which it

was designed.

DO NOT USE THE POWER

TOOL IF THE SWITCH DOES

NOT TURN IT ON AND OFF. Any

power tool that cannot be

controlled with the switch is

dangerous and must be repaired.

NEVER MODIFY OR ALTER

THE TOOL. Doing so may cause

the tool to malfunction and

personal injuries may result.

KNOW THIS TOOL. Read

manual carefully; learn its

applications and limitations, as

well as the specific potential

hazards related to this tool.

CHECK FOR MISALIGNMENT

OR BINDING OF MOVING

PARTS, BREAKAGE OF PARTS,

OR ANY OTHER CONDITION

THAT MAY AFFECT THE

TOOL S OPERATION. If

damaged, have the tool serviced

by an authorized technician

before using. Many accidents are

caused by poorly maintained

tools.

MAINTAIN TOOLS WITH CARE.

Keep the tool clean for better and

safer performance.

NEVER CARRY THE TOOL BY

THE POWER CORD.

STORE TOOLS OUT OF THE

REACH OF CHILDREN AND

UNTRAINED PEOPLE. Tools are

dangerous in the hands of

untrained users.

f

eedback@natitools.com 1-800-348-5004

3

DISCONNECT THE PLUG FROM

THE POWER SOURCE BEFORE

MAKING ANY ADJUSTMENTS,

CHANGING ACCESSORIES, OR

STORING THE POWER TOOL. This

will reduce the risk of accidental

starting.

USE THE POWER TOOL THE

WAY IT WAS INTENDED. Use of

the power tool for operations

different could result in a hazardous

situation.

WARNING: The warnings,

precautions, and instructions

discussed in this instruction manual

cannot cover all possible conditions

and situations that may occur. It

must be understood by the operator

that common sense and caution are

factors which cannot be built into

this product, but must be supplied by

the operator.

KICKBACK

Kickback is a sudden reaction to a

pinched or snagged rotating wheel,

backing pad, brush or any other

accessory. Pinching or snagging

causes rapid stalling of the rotating

accessory which in turn causes the

uncontrolled power tool to be forced

in the direction opposite of the

accessory s rotation at the point of

binding.

1. Maintain a firm grip on the power

tool and position your body and arm

to allow you to resist kickback

forces. Always use auxiliary handle,

if provided, for maximum control

over kickback or torque reaction

during start-up. The operator can

control torque reactions or kickback

forces, if proper precautions are

taken.

2. Never place your hand near the

rotating accessory.

3. Do not position your body in the

area where the power tool will move

if kickback occurs. Kickback will

propel the tool in direction opposite

to the wheel s movement at the

point of snagging.

4. Use special care when working

corners, sharp edges, etc. Avoid

bouncing and snagging the

accessory. Corners, sharp edges,

or bouncing have a tendency to

snag the rotating accessory and

cause loss of control or kickback.

5. Do not allow any loose portion of

the polishing bonnet or its

attachment strings to spin freely.

Tuck away or trim any loose

attachment strings. Loose and

spinning attachment strings can

entangle your fingers or snag on the

workpiece.

VIBRATION SAFETY

This tool vibrates during use.

Repeated or long-term exposure to

vibration may cause temporary or

permanent physical injury,

particularly to the hands, arms, and

shoulders. To reduce the risk of

vibration-related injury:

1. Anyone using vibrating tools

regularly or for an extended period

should first be examined by a doctor

and then have regular medical

check-ups to ensure medical

problems are not being caused or

worsenedfrom use. Pregnant

women or people who have

impaired blood circulation to the

hand, past hand injuries, nervous

system disorders,

diabetes, or Raynaud s Disease

should not use this tool. If you feel

any medical or physical symptoms

related to vibration (such as

tingling, numbness, and white or

blue fingers), seek medical advice

as soon as possible.

2. Do not smoke during use.

Nicotine reduces the blood supply

to the hands andfingers,

increasing the risk of vibration-

related injury.

3. Wear suitable gloves to reduce

the vibration effects on the user.

4. Use tools with the lowest

vibration when there is a choice

between different processes.

5. Include vibration-free periods

each day of work.

6. Grip tool as lightly as possible

(while still keeping safe control of

it). Let the tool do the work.

7. To reduce vibration, maintain

the tool as explained in this

manual. If any abnormal vibration

occurs, stop use immediately.

TOOL SERVICE

USE ONLY ACCESSORIES

THAT ARE IDENTIFIED BY THE

MANUFACTURER FOR THE

SPECIFIC TOOL MODEL.

USE OF UNAUTHORIZED

PARTS OR FAILURE TO

FOLLOW MAINTENANCE

INSTRUCTIONS MAY CREATE A

RISK OF INJURY.

TOOL SERVICE MUST ONLY

BE PERFORMED BY A

QUALIFIED REPAIR

PERSONNEL.

f

eedback@natitools.com 1-800-348-5004

4

SETUP

Installing the Auxiliary Handles

WARNING: To prevent serious

injury: Do not operate this tool

without the auxiliary handle properly

installed.

The D-Handle (included) may be

installed for either right-hand or left-

hand use.

OPTION 1: Using the D-Handle

Attach the D-Handle to the sides of

the front cover, using the hex key

and two hex head bolts.

NOTE: Slide the hex key through

the hole in the handle to access the

bolt on the long side of the handle

OPTION 2: Using with a side

handle (side handle not included)

This tool can be used with many

standard angle grinder side handles

which can be installed on either

side.

Installing the Backing Pad/Foam

Pad

1. The accessory MUST be:

in diameter

5/8 x 11 TPI

2. Press in and hold the Spindle

Lock Button to prevent the Spindle

from turning.

3. Thread the backing pad onto the

spindle until firmly secured in place.

Workpiece and Work area set

up

1. Designate a work area that is

clean and well-lit. The work area

must be accessible by children or

pets to prevent distraction and

injury.

2. Route the power cord along a

safe route to reach the work area

without creating a tripping hazard

or exposing the power cord to

possible damage. The power cord

must reach the work area with

enough extra length to allow free

movement while working.

3. Secure loose workpieces using

a vise or clamps (not included) to

prevent movement while working.

4. There must not be hazardous

objects, such as utility lines or

foreign objects nearby that will

present a hazard while working.

OPERATION

Polishing

1. Make sure the surface to polish

has been thoroughly washed, and

is free of dust, dirt, oil, grease,

etc.

2. Place a clean foam pad (sold

separately) securely onto the

backing pad.

3. Apply 2 tablespoons of wax

(not included) evenly on the foam

pad.

Caution: Do not apply the wax

directly to the surface of the

vehicle. The amount of wax

needed will vary according to the

size of the vehicle being waxed.

f

eedback@natitools.com 1-800-348-5004

5

8. Begin using the polisher to apply

wax to the vehicle. Apply the wax to

all the flat surfaces with broad,

sweeping strokes in a crisscross

pattern. Apply the wax evenly over

the surface of the vehicle.

9. Add additional wax to the

polishing pad as needed. To add

additional wax:

a. Stop the tool and allow the

polisher to come to a complete stop.

b. Add a small amount of wax

evenly over the pad surface.

c. Avoid using too much wax. For

additional applications of wax to the

foam pad, reduce the amount of

wax. The foam pad will not absorb

as much wax in subsequent

applications.

d. Resume operation.

Note: The most common error

when waxing/polishing a vehicle is

applying too mush wax. If the foam

pad becomes saturated with wax,

applying wax will be more difficult

and will take longer. Applying too

much wax may also reduce the life

of the foam pad. If the foam pad

continually comes off the backing

pad during use, too much wax may

have been applied.

10. After the wax has been applied

to

the vehicle s surface, turn off the

polisher. Unplug the power cord from

the electrical source.

11. Remove the foam pad from the

backing pad and with your hand and

the foam pad, apply wax to any hard

to reach areas of the vehicles such

as around lights, door handles, unde

r

bumpers, etc.

12. Allow sufficient time for the wax

to dry.

13. Place a clean polishing bonnet

(sold separately) securely onto the

backing pad.

Note: Tightly pull the string to secure

the polishing bonnet. Secure the

string and keep it out of the way by

tying several knots.

Note: Start and stop the polisher

only while it is held firmly against the

surface of the vehicle. Failure to do

so may result in the bonnet being

thrownfrom the backing pad.

14. Start the polisher and begin

buffing off the dried wax.

15. When you have removed as

much wax as you can with the

polisher, turn off and unplug the

polisher.

16. Remove the polishing bonnet

from the backing pad. Using the

polishing bonnet, remove the wax

from all the hard to reach areas of

the vehicle.

4. Rotate the speed dial to select the

desired speed between 1 & 4.

Caution: Only use the slower

speeds (1 through 4) for polishing.

Otherwise, damage may occur to the

paint being polished. NATI is not

responsible for damage to the

vehicle s finish due to improper use

of this Polisher.

5. Plug the power cord into an

electrical extension cord (not

included). Then, plug the extension

cord into a grounded, GFCI-

protected, 120 Volt electrical outlet.

WARNING: To prevent electrical

shock, keep cord connection off the

ground.

Note: Always start and stop the

polisher while it is held firmly against

the surface of the vehicle. Failure to

do so may result in the foam pad or

polishing bonnet being thrown from

the polishing pad.

6. To start, position the unit on the

area to be polished, grip the polisher

firmly with both hands and press the

trigger. Release the trigger to stop.

To use the lock on button, while

holding in the trigger, press the lock

on button, then release the trigger.

The polisher will stay on. Press and

release the trigger to stop.

7. Keep pressure off of the polisher

when operating. The foam pad

should LIGHTLY contact the

polishing surface.

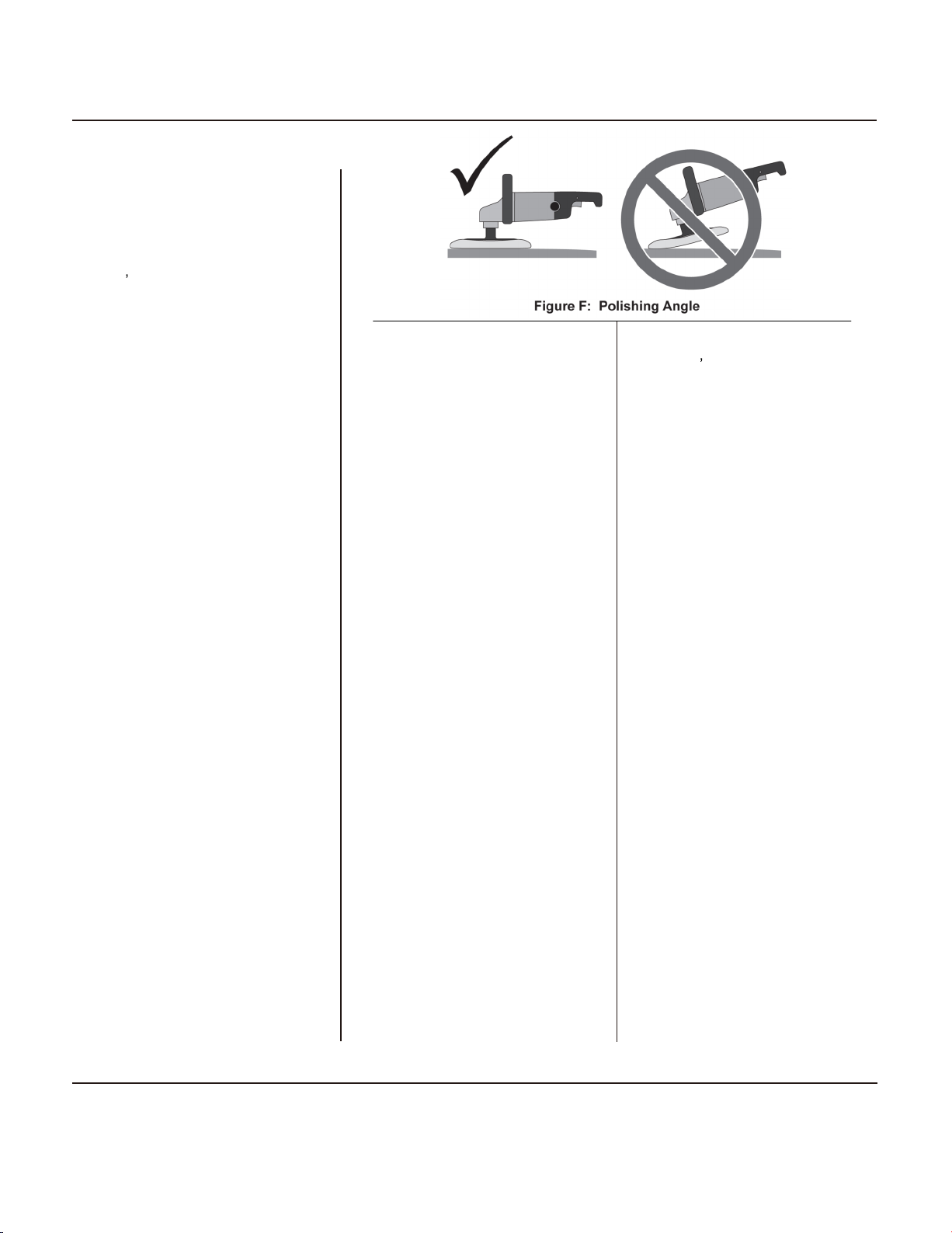

Caution: To prevent damage to the

foam pad, polishing bonnet, and

vehicle finish: Only apply the

pad/bonnet flat against the surface,

see Figure F.

f

eedback@natitools.com 1-800-348-5004

6

CLEANING, MAINTENANCE, &

LUBRICATION

1. Before each use, inspect the

general condition of the tool. Check

for:

parts

its safe operation

2. After use, wipe external surfaces

of the tool with a clean cloth.

3. Periodically blow dust and grit out

of the motor vents using dry

compressed air. Wear ANSI-

approved safety goggles and

NIOSH-approved breathing

protection while doing this.

4. Periodically recheck all nuts,

bolts, and screws for tightness.

5. Remove foam pad from backing

pad when polisher is not in use.

This will allow backing pad to dry

and retain its original shape. Wash

with mild soap and water before

storing.

6. The polishing bonnet may be

machine washed in cold water with

mild detergent. Do not put in the

dryer.

7. Use only a clean cloth and mild

detergent to clean the body of the

polisher. Do not use solvents. Do

not immerse any part of the tool in

liquid.

8. Carbon Brush Maintenance. The

carbon brush may require

maintenance when the motor

performance of the tool decreases

or stops working completely. To

maintain the brushes:

a. Remove the carbon brush cover

on each side of the motor housing.

b. Remove the carbon brushes

from the housing. Keeptrack of

which orientation the old carbon

brushes were in to prevent

needless wear if they will be

reinstalled.

c. If either carbon brush is worn

down by more than 1/2, replace

them both.

d. To clean old carbon brushes

before reusing them, rub the

contact areas with a pencil eraser.

e. Reinsert the old carbon brushes

in the same orientation to reduce

wear.

f. When installing, make sure the

carbon portions of the brushes

contact the motor armature, and

that the springs face away from the

motor. Also, make sure the springs

operate freely.

g. Replace the carbon brush

covers. Do not over-tighten.

Note: New carbon brushes tend to

spark whenfirst used until they

wear and conform to the motor s

armature.

WARNING: If the supply cord of

this power tool is damaged, it must

be replaced only by a qualified

service technician.

f

eedback@natitools.com 1-800-348-5004

45134 03/2017

FUNCTIONAL DESCRIPTION AND SPECIFICATIONS

WARNING: Disconnect the toolfrom the power source before making any adjustments, changing accessories or storing the tool.

Such precautionary safety measures reduce the risk of unintentionaltool operation.

7

For Customer Service, please call 1-800-348-5004or

email feedback@natitools.com

7 VARIABLE SPEED CAR POLISHER

Model: 45134

8

Symptom Possible Cause(s) Corrective Action

Tool will not start

Cord not connected Check that the cord is plugged in

No power at outlet

Check power at outlet. If outlet is

unpowered, turn off tool and check circuit

breaker. If breaker is tripped, make sure the

circuit isright capacityfor tool and circuit has

no other loads.

Internal Damage or wearReplace carbon brushes and/or have

technician service tool

Tool operates slowly

Excess pressure applied to workpiece. Decrease pressure, allow tool to do the

work.

Power being reduced by long or small

diameter extension cord.

Eliminate use of extension cord. If an

extension cord is needed, use one with the

proper diameter for its length and load.

Performance decreases

over time Carbon brushes worn or damaged Replace brushes

Excessive noise or

rattling Internal damage or wear Have technician service tool

Overheating

Forcing tool to work too fast. Allow tool to work at its own rate

Blocked motor housing vents.

Wear ANSI-approved safety goggles and

NIOSH-approved dust mask/respirator while

blowing dust out of motor using compressed

air.

Motor being strained by long or small

diameter extension cord.

Eliminate use of extension cord. If an

extension cord is needed, use one with the

proper diameter for its length and load.

Tool does not sand or

polish effectively

Disc or accessory may be loose on spindle Be sure disc accessory arbor is correct and

outer flange/arbor nut is tight.

Disc accessory may be damaged, worn, or

wrong type for the material

Check condition and type of disc accessory.

Use only proper type of disc accessory in

good condition.

Wax sprays off polishing pad Reduce RPM to minimum setting

Troubleshooting Guide

feedback@natitools.com 1-800-348-5004

9

North American Tool Industries (NATI) makes every effort to ensure that this product meets high quality

and durability standards. NATI warrants to the original retail consumer a 1-year limited warranty from the

date the product was purchased at retail and each product is free from defects in materials. Warranty

does not apply to defects due directly or indirectly to misuse, abuse, negligence, or accidents, repairs or

alterations, or a lack of maintenance. NATI shall in no event be liable for death, injuries to persons or

property, or for incidental, special, or consequential damages arising from the use of our products. To

receive service under warranty, the original manufacturer part must be returned for examination by an

authorized service center. Shipping and handling charges may apply. If a defect is found, NATI will

either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Email: feedback@natitools.com or Call 1-800-348-5004

feedback@natitools.com 1-800-348-5004

45134 03/2017

7 VARIABLE SPEED CAR POLISHER

10

For Customer Service, please call 1-800-348-5004 or

email feedback@natitools.com

Model: 45134

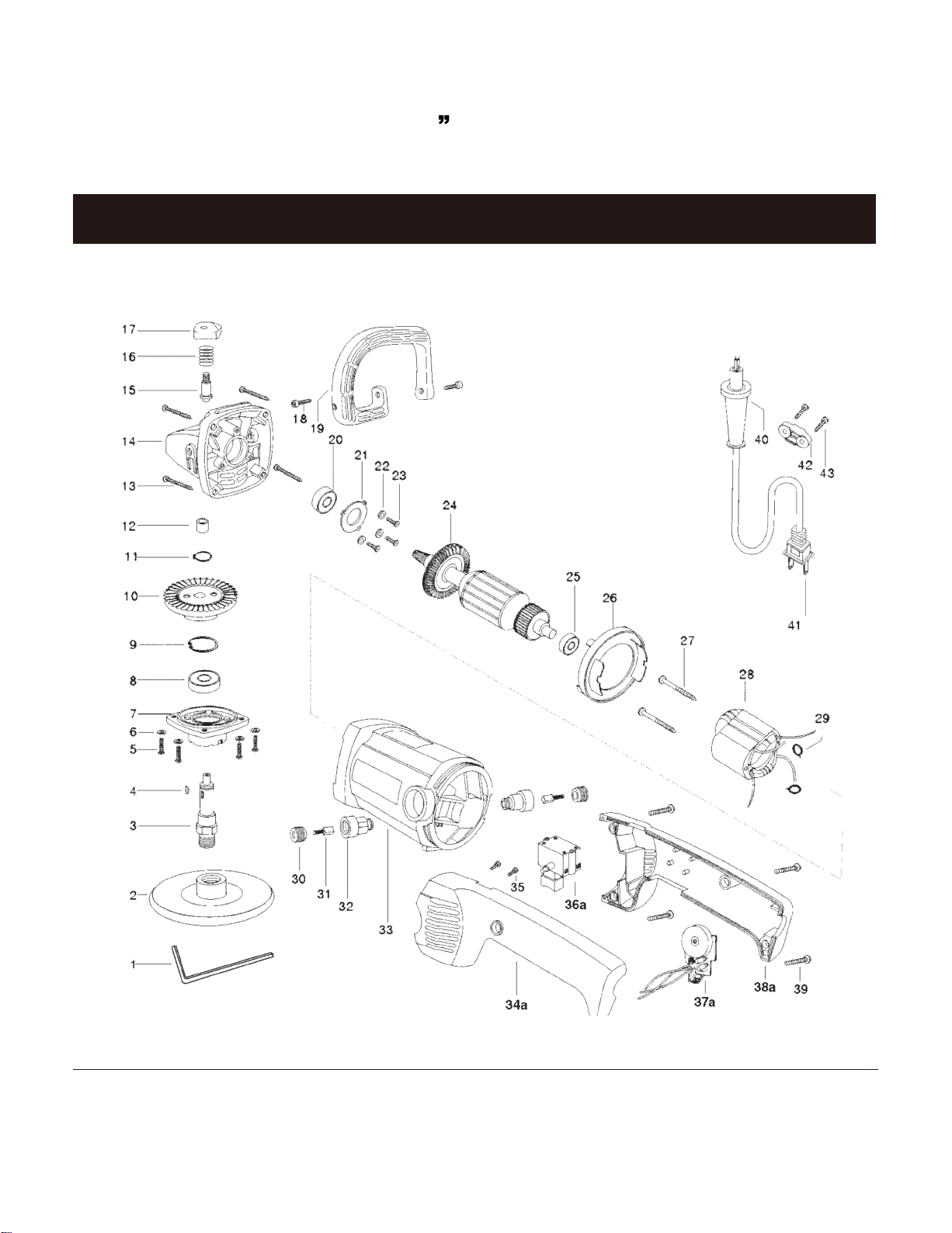

Parts List

11

feedback@natitools.com

# Description QTY. # Description QTY.

1 Hex Key 1 23 Screw (4x10) 3

2 Backing Pad 1 24 Armature 1

3 Spindle 1 25 Bearing (#18) 1

4 Half Circle Key (4x13) 1 26 Wind Shield Ring 1

5 Screw (5x16) 4 27 Tap Screw (5x55) 2

6 Spring Washer 4 28 Stator 1

7 Front Cover 1 29 Spring (#110) 2

8 Bearing (#201) 1 30 Brush Holder Cover 2

9Fender Ring (32) 1 31 Carbon Brush (#4100) 2

10 Large Gear 1 32 Brush Holder (#4100) 2

11 Fender Ring (12) 1 33 Motor Housing 1

12 Steel Sleeve (115B, 12x8x10) 1 34 Upper Back Cover 1

13 Tap Screw (5x30) 4 35 Tap Screw (3x10) 2

14 Front Cover 1 36 Trigger 1

15 Lock Pin 1 37 Speed Adjustment 1

16 Lock Spring 1 38 Lower Black Cover 1

17 Spindle Lock Cap 1 39 Screw (4x20) 4

18 Hex Head Screw (8x16) 2 40 Sheath (#125) 1

19 Handle 1 41 Power Cord 1

20 Bearing (#101) 1 42 Press Cable Board 1

21 Triangle Press Cover 1 43 Tap Screw (4x14) 2

22 Spring Washer(4) 3

feedback@natitools.com 1-800-348-5004

Table of contents

Popular Sander manuals by other brands

Flex

Flex XFE 7-12 80 user manual

RIDGID

RIDGID 535 Manual Chuck manual

Bosch

Bosch GSS 140 A Professional Original instructions

Bosch

Bosch EasyCurvSander 12 Original instructions

Bosch

Bosch GSS 230 A PROFESSIONAL operating instructions

Ingersoll-Rand

Ingersoll-Rand 99S Operation and maintenance manual