FineTek SIS Technical manual

I

SIS Programmer Box

Operation Instruction

FineTek Co., Ltd.

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678

Tel: 886-2-22696789 Fax: 886-2-22686682

Website: http://www.fine-tek.com E-mail:[email protected]

08-SISPAXX-B1-EK,07/25/2019

II

Contents

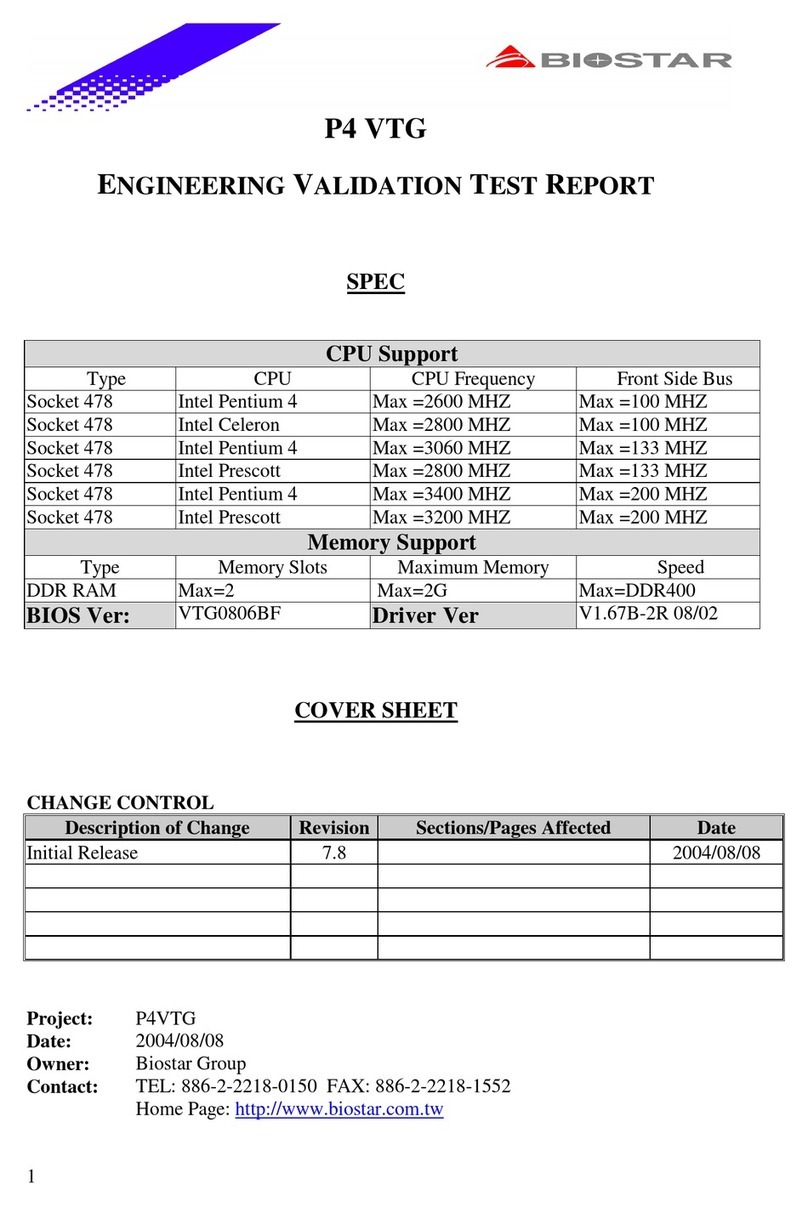

1. Reading Labels........................................................................................................3

1.1 Service Network........................................................................................4

2. Product Features.....................................................................................................5

3. Scope of Application...............................................................................................5

4. Ambient Conditions ................................................................................................5

5. Installation................................................................................................................6

5.1 System Requirements...............................................................................6

5.2 Program Installation..................................................................................6

5.3 Uninstall process.......................................................................................8

5.4 Electrical Connection................................................................................9

6. Operation................................................................................................................10

6.1 Buttons....................................................................................................10

6.2 Function Settings....................................................................................13

6.2.1Parameter Modification.........................................................................14

6.2.2Saving and Loading..............................................................................14

6.2.3Output Function Selection.....................................................................14

6.2.4Output Delay Time Setting....................................................................14

6.2.5Fault Alarm Output Setting....................................................................14

6.2.6Sensitivity Setting..................................................................................15

6.2.7Common Material Selection..................................................................15

6.3 Advanced Settings..................................................................................15

6.3.1Advanced Setting Buttons.....................................................................15

6.3.2Operating steps for advanced settings..................................................17

7. Simple Troubleshooting........................................................................................18

3

1. Reading Labels

Thanks for purchasing FineTek’s Product. This operation manual describes the product

features, working principles, operation and maintenance methods. It makes the user fully

understand how to use the product correctly, so as to prevent dangerous situations such as

device damage or operator injury.

Please read this operation manual completely and carefully before using the product.

Please contact the company if this operation manual can’t satisfy your demands.

The content of the operation manual is updated based on the version upgrade, which

will be uploaded to the website for the user to access.

Please don’t disassemble or repair the product on your own, as this will make you

disqualified from availing of the warranty service. Please send the product back to the

company for repair and calibration, or just contact the company.

Explanation of warning signs:

Danger→ It indicates that wrong operation will cause death or major disasters.

Note→ It indicates that wrong operation will cause injury and device damage to

some extent.

Electric shock→ It warns of possible electric shock.

Fire→ It warns of possible fire.

Prohibited→ It indicates the prohibited wrong behavior.

4

1.1 Service Network

Company

Address

Telephon

Fax

Taipei

Headquarters

(Taiwan)

No.16, Tzuchiang St., Tucheng

Industrial Park, New Taipei City

23678

+886 2 2269 6789

+886 2 2268 6682

Taichung

Sales office

(Taiwan)

+886 4 2465 2820

+886 4 2463 9926

Kaohsiung

Sales office

(Taiwan)

+886 7 333 6968

+886 7 536 8758

Fine automation

Co., Ltd.

(China)

No. 451, Duhui Road,

Zhuanqiao Township, Minhang

District, Shanghai City 201109

+86 021 64907260

+86 021 6490 7276

FineTek Pte Ltd.

(Singapore Branch)

37 Kaki Bukit Place, Level 4

Singapore 416215

+65 6452 6340

+65 6734 1878

FineTek GmbH

(Germany Branch)

Bei den Kämpen 26

21220 Seevetal-Ramelsloh,

Germany

+49 (0) 4185 8083 12

+49 (0) 4185 8083 80

FineTek Co., Ltd.

(Indonesia Branch)

Ruko Golden 8 Blok H No.38

Gading Serpong, Tangerang

Indonesia 15810

+62 (21) 2923 1688

+62 (21) 2923 1988

FineTek Co., Ltd.

(Malaysia Branch)

8-05, Plaza Azalea, Persiaran

Bandaraya,

Seksyen 14, 40000 Shah Alam,

Selangor, Malaysia

+603 5524 7168

+603 5524 7698

5

2. Product Features

The SIS Programmer Box is used to transfer sensor data to a PC for reading and

editing.Supporting our SIS Impedance Spectroscopy Level Sensor series for debugging

purposes, it includes the following functions:

Reading the current parameter settings of the sensor.

Changing the parameters of the sensor.

The current values of the sensor and further verification.

Attention! The hub is not suitable to be permanently connected as an monitoring device.

3. Scope of Application

SIS Sanitary Intelligent Level Switch parameter setting.

A multi-purpose, essential modulation kit for industrial level switches.

Sensor sensitivity adjustment for material replacement.

Sensor verification for equipment maintenance.

4. Ambient Conditions

Storage temperature: -40°C ~ 85°C (-40°F ~ 185°F).

Ambient temperature: -40°C ~ 85°C (-40°F ~ 185°F).

This product is not waterproof. Moisture intrusion must be prevented when it is being

operated.

Basic configuration: Programmer Box, PC, SIS Sanitary Intelligent Level Switch, cable.

6

5. Installation

5.1 System Requirements

Microsoft Windows XP/SP3 or newer is required.

At least one available USB 2.0 port.

The Programmer Box software.

5.2 Program Installation

You must have administrator privileges.

1. Insert the CD-ROM or USB into the drive or port to start the installation or download

from the website.

2. Click the file "SIS_****_**_**_**.exe" to start the installation as shown below.

3. Select your language from the drop-down menu and click "OK".

7

4. When the setup wizard pops up, click "Next".

5. Select the Destination Folder (C:\Program Files\SIS by default) and click "Install".

8

6. When the installation is complete, click "Finish" to start the program.

7. Install the driver by inserting the CD-ROM or USB or downloading from the website.

You can also use the Windows built-in wizard to find a on-line available driver to

complete the installation.

5.3 Uninstall process

To uninstall the program, process as follows:

1. Open the program folder (C:\Program Files\SIS by default), click "uninst.exe" to start

the uninstallation (shown as below).

9

2. Click "Yes (Y)" to uninstall (as shown below).

3. Click "OK" to complete the uninstallation (as shown below).

5.4 Electrical Connection

Connect the sensor and the SIS Programmer Box to the PC as shown below.

Connect the sensor to the SIS Programmer Box using the M12 connector (please use

the standard connector to ensure stable connection).

Connect the SIS Programmer Box to the computer using USB connector.

10

6. Operation

6.1 Buttons

a. Click the Production button to open the settings page (as shown below). The setting

functions are listed below.

b.

1

7

2

4

6

5

3

8

9

22

21

20

19

18

12

13

14

15

16

17

11

10

23

24

25

11

c. The functions are listed below:

Number

Item

Description

1

ID

ID has no function and can be ignored.

2

Communication

rate

BaudRate is set to38400 bps.

3

Port

Select the COM port for the connected device.

4

Hart interface

This item has no function and can be ignored.

5

Connection to

the sensor

Click "Link/stop" to connect to/disconnect from the sensor.

6

Real-time

information

"Stop Sync" means that the parameter information from the

sensor is reading every second. "Sync" means that the

parameter can be modified. (Synchronizing)

7

Exit

Exit the program.

8

Firmware

Version

The firmware version of the sensor.

9

Hardware

Version

The hardware version of the sensor.

10

Product Model

The product model of the sensor.

11

Sensitivity

The material sensitivity currently detected by the sensor.

12

Sensor output

state (1), (2)

The sensor output state (1) = OUT1, (2) = OUT2.

NORMAL_STATE means that the output is reset.

ACTIVE_STATE means that the output is active.

13

Overcurrent

indication (1),

(2)

Indicate whether overcurrent in the control circuit

(1) = OUT1, (2) = OUT2.

NORMAL_STATE means that the output current is under

normal condition.

ACTIVE_STATE means that the output current is

overloading and the protection mode is active.

14

Output function

selection (1), (2)

Select the method for detecting the material output (1) =

OUT1, (2) = OUT2.

Hysteresis NO: Hysteresis, normally open output.

Hysteresis NC: Hysteresis, normally closed output.

Window NO: Window, normally open output.

Window NC: Window, normally closed output.

15

Fault alarm

output (1), (2)

The state response of OUT1 and OUT2 outputs when a

fault occurs.

OFF: Only the green LED blinks and the output does not

12

change.

ON: The green LED blinks and the switch output is active

at the same time.

16

Start point

setting % (1), (2)

Start point setting (1) = OUT1, (2) = OUT2.

Between 2% and 98%, the minimum span is 1%.

17

Reset point

setting % (1), (2)

Reset point setting (1) = OUT1, (2) = OUT2.

Between 2% and 98%, the minimum span is 1%.

18

Start delay

setting (1), (2)

Reset delay time (1) = OUT1, (2) = OUT2.

The minimum is 0.5 sec, the maximum is 60 sec, the

minimum span is 0.1 sec.

19

Reset delay

time (1) =

OUT1, (2) =

OUT2.

The minimum is 0.5 sec, the maximum is 60 sec, the

minimum span is 0.1 sec.

20

Fault Delay

Time

The delay time setting of OUT1 and OUT2 output states

when a fault occurs.

21

Output type

(PNP/NPN)

Three-wire crystal output; select PNP or NPN as the switch

type.

22

Common

Material

Selection

Common material selection, built-in sensitivity setting.

23

Load Parameter

Load the previously saved function parameters.

24

Save Parameter

Save the current function parameter settings for future

applications.

25

Software

version

The current software version of the Programmer Box

13

6.2 Function Settings

Click the "SIS" program to open the window (as shown below). Click "Exit" to close the

program.

a. Configure the communication protocol; location, baud rate, COM port, etc. (for details,

see the previous section, Buttons).

b. To connect to the sensor, click the "Link" button to change it into "Stop" in the

"Production" page. To disconnect from the sensor, click the "Stop" button to change it

into "Link".

c. When the sensor is connected successfully, real-time data such as the firmware

version, hardware version, product model, and sensitivity of the sensor are showed in

the program.

d. No data is showed if the sensor does not have the appropriate communication protocol

or the connection is unsuccessful.

e. The Programmer Box is intended for parameter setting and debugging of the SIS

Sanitary Intelligent Level Switch only and not suitable to be permanently connected as

the control unit of a monitoring system. We cannot guarantee compatibility if it could be

connected to a sensor from other brands.

a

b

c、d

14

6.2.1 Parameter Modification

To modify the parameters of the sensor, refer to the following steps in the Production page.

1. Connect to the sensor (click "Link" to change the button into "Stop").

2. Stop syncing (click "Stop Sync" to change the button into "Sync").

3. Select the parameter or setting to be modified.

4. Start syncing (click "Sync" to change the button into "Stop Sync").

6.2.2 Saving and Loading

Refer to the following steps in the "Production" page.

Save Parameter: Click "Save Parameter" to select the path to be saved and enter the file

name. You can save the parameter data in the Production orAdvance item to a file.

Load Parameter: You can copy saved parameter data to the current settings page. Refer

to the following steps.

1. Connect to the sensor (click "Link" to change the button into "Stop").

2. Stop syncing (click "Stop Sync" to change the button into "Sync").

3. Load the file (click "Load Parameter" to select the file to be loaded).

4. Start syncing (click "Sync" to change the button into "Stop Sync").

6.2.3 Output Function Selection

Hysteresis: Output is active when the sensitivity ≧the "start point" setting, and reset

when the sensitivity ≦the "reset point" setting.

Window: Output is active when the sensitivity is between the "start point" and "reset

point" settings, and reset when >the "start point" or <the "reset point" setting.

6.2.4 Output Delay Time Setting

Start Point Delay Time: This setting does not change any state when material contact is

detected by the sensor, and changes the output and LED state after the specified delay time.

Reset Point Delay Time: This setting does not change any state when material separation is

detected by the sensor, and changes the output and LED state after the specified delay time.

6.2.5 Fault Alarm Output Setting

When a fault occurs, output is executed according to the mode specified.

OFF : The green LED light keeps flashing per second, and the output kept circuit

opening.

ON : The green LED light keeps flashing per second. OUT1 and OUT2 will be switched in

ON and OFF by “ but time of switching ON is always 0.5 second.

When a fault alarm occurs, the following situations are possible:

The detection signal of the sensor is out of range.

The internal parameter settings are incorrect.

15

6.2.6 Sensitivity Setting

The sensitivity is about 0% to 2% when the sensor is in the air (without contact with any

material), and increases depending on the material that it comes in contact with. The

minimum is 2%, the maximum is 98%, the minimum span is 1%.

6.2.7 Common Material Selection

Select the sensitivity using the built-in or a saved common material list.

1. Connect to the sensor (click "Link" to change the button into "Stop").

2. Stop syncing (click "Stop Sync" to change the button into "Sync").

3. Click the common material drop-down list. The sensitivity parameter setting will be

automatically applied after selection.

4. Start syncing (click "Sync" to change the button into "Stop Sync").

6.3 Advanced Settings

6.3.1 Advanced Setting Buttons

1

7

2

4

8

5

3

6

9

10

12

11

13

15

14

16

Click the "Advance" button to switch the page (as shown above). The setting functions are

listed below:

Number

Item

Description

1

Continuous

Monitoring

The connection button used to read the sensor data

characteristics. Click to connect and and click again to

disconnect.

2

Save

If the box is checked, data will be saved to a file when

clicking "Continuous Monitoring" to read the sensor

data characteristics.

3

Record 1,

Record 2

Click to capture the current characteristic curve.

4

Clear

Click to clear the characteristic curve record 1 and

record 2.

5

Sen.

The sensitivity.

6

Amp.

The peak value.

7

Trend chart

Show the characteristic curve of the current device.

8

OUT1、OUT2

Only one of them can be checked. Confirm the output

parameters currently being configured.

9

Reset Point

Sensitivity

The sensor reset point sensitivity setting

(corresponding to the selected OUTx).

10

Start Point

Sensitivity

The sensor start point sensitivity setting (corresponding

to the selected OUTx).

11

Amplitude

Action Point

An advanced setting for special purposes. The peak

setting of the amplitude action point.

(for details, see the next section).

12

Amplitude

Hysteresis

Point

An advanced setting for special purposes. The peak

setting of the amplitude hysteresis point

(for details, see the next section).

13

Rx、Tx

Check to display Rx and Tx graphs on the

characteristic curve screen.

Rx: Show the material characteristics.

Tx: Show the sensor signal characteristics.

14

Amplitude

Determination

Function

Correspond to the selected OUTx. Check/uncheck to

turn on/off this function.

15

Write

Parameter

Value

When all parameters are set, click this button to write

the parameter settings to the sensor.

17

6.3.2 Operating steps for advanced settings

A. Some material characteristics may be similar in terms of sensor attached and full

coverage sensitivity changes. Therefore, material characteristics can also be

determined by increasing the amplitude via advanced settings.

B. In general, materials that require the use of advanced settings are mainly for high

viscosity characteristics (such as catchup, chocolate syrup) and two-level detection

(such as oil/water).

C. To connect to the sensor, click the "Continuous Monitoring" button to change it into

" …… " on the advanced setting screen. When the material characteristic curve is

obtained, disconnect immediately (click the " …… " button to change it into

"Continuous Monitoring").

* Please note that parameter modification and configuration can only be done in

disconnected state. To modify, click "Write Parameter Value" to save the parameters

to the sensor.

D. Operating steps:

1. Attach some material to the sensor head after the sensor is installed.

2. Click Advance to open the page.

3. Click the "Continuous Monitoring" button. When the material characteristic curve

is obtained, click the " …… " button to exit.

4. Click "Record 1" to keep the characteristic curve when the sensor is attached to

the material on the screen, and record the amplitude peak (the value in the Amp

box in the upper right corner of the screen).

5. Add material so that it fully covers the probe of the sensor.

6. Click "Continuous Monitoring". In addition to the "Record 1" curve, the second

material characteristic curve appears on the screen, which is the curve when the

material fully covers the probe. Click again to exit.

7. Although the sensitivity is almost identical between the attached and fully covered

states, the amplitude peak of the signal is different. The amplitude peak of the

fully covered state is higher than that of the attached state.

8. If the amplitude peak of the fully covered state is 3300, the amplitude peak of the

attached state is 3000.Check the output port (OUTx) and "Amplitude

Determination Function" first, then drag the Y-axis determination line on the

screen to 3200 (or enter directly into the "Amplitude Action Point" field), and set

"Amplitude Hysteresis Point" to 100.

9. The recommended values in "Common Material Selection" can be used as the

sensitivity setting, including water, sugar-containing medium with low water

content or oil/powder.

10.Click "Write Parameter Value" in the lower right corner of the screen to write data.

A message pops up when succeeded.

18

7. Simple Troubleshooting

Anomaly

Cause

Solution

No LED is glowed

The USB connector is not

plugged in or loosen

Check the USB

connection and plug it in

properly.

The cable is damaged

Replace the USB cable.

The USB port is not

sufficiently powered.

Reinsert the USB or

change the computer.

Unable to connect to the

Programmer Box when

LEDs are normal

Invalid driver

Install the USB driver.

COM port error

Check and select the

correct COM port in

Device Manager.

Unable to connect to the

sensor when LEDs are

normal

The M12 connector is

damaged

Check and repair the

cable and the connector.

The connector is not

plugged in properly.

Check the connectors on

both sides and plug them

in properly.

All the solutions above did

not fix the problem.

The device is damaged

and cannot be used.

Contact your local sales

representative.

Other manuals for SIS

1

Table of contents

Popular Motherboard manuals by other brands

Intel

Intel BLKD915PGNL - LGA775 800FSB 4DDR Audio Lan SATA ATX... Technical product specification

ECS

ECS K7VTA3 manual

Acrosser Technology

Acrosser Technology AR-B1893 user guide

Microchip Technology

Microchip Technology SAM-IoT Wx v2 Hardware user's guide

ASROCK

ASROCK FM2A75M Pro4 user manual

Gigabyte

Gigabyte B360M HD3 user manual