FISCHBEIN F User manual

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

1

Manufactured and Assembled by:

Fischbein Company

151 Walker Road – Statesville, NC 28687

USA

Imported and serviced by:

Fischbein sa

Paepsem Business Park

Boulevard Paepsem,18b – 1070 Brussels

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

2

FISCHBEIN

Model F

PORTABLE BAG CLOSER

USERS MANUAL

SERIAL NUMBER : ....................

WEIGHT :..........................5,8 kg

NOISE LEVEL : ...... 79 dB

VIBRATIONS : ..........18 m / sec²

EDITION : ....................10 / 2001

Manufactured and assembled by : Fischbein Company

151 Walker Road

Statesville , NC 28687

USA

Imported and serviced by : Fischbein S.A.

Paepsem Business Park

Boulevard Paepsem,18b, B - 1070

Brussels - Belgium

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

3

FOREWORD

The contents of this manual are considered to be proprietary and

confidential to FISCHBEIN and should not be reproduced without the

prior written permission of FISCHBEIN .

Nothing contained in this document is intended to extend any

promise , warranty or representation , expressed or implied , regarding

the FISCHBEIN products described herein .

Any such warranties or other terms and conditions of products shall be

in accordance with the standard terms and conditions of sale for such

products , which are available upon request .

FISCHBEIN reserves the right to make changes and improvements

to products without notice and without incurring any obligation to make

such changes or add such improvements to products sold previously .

The use of repair parts other than those included within the

FISCHBEIN approved parts list may create hazardous conditions over

which FISCHBEIN has no control .

Therefore FISCHBEIN cannot be held responsible for equipment in

which non-approved repair parts are installed .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

4

MACHINE SPECIFICATIONS

Model: F

Stitch length: approximately 7 mm

Maximum thickness of sewn material: 6,5 mm

Sewing speed: approximately 13,6 m / min (charge)

Weight: 5,8 kg ,with electric cord and 200gr

cone.

Vibration level: 18,62 m / sec²

Noise level: 79 dB.

Motor voltage: 24 , 110 , 230 VAC, 12 VDC

dependent on option .

Power options: electric or air motor options.

Seam: single thread chain stitch.

Needle: D5 , REF: 13050

Thread: 20/4 Polyester, 200 gr cone

good for approximately 250 meters

seam

GENERAL GUIDELINES FOR TORQUE APPLIED TO F HARDWARE .

Cover screws 2,5 - 2,9 Nm

Needle bar guard and other covers , 2,5 - 2,9 Nm

Retaining collars ( internal or external ) , 2,5 - 2,9 Nm

Looper holder and cam follower clamp screws , 2,5 - 2,9 Nm

All other set screws , 2,5 - 2,9 Nm

All other hardware fasteners not specified . 2,5 - 2,9 Nm

Needle bar clamp 2,9 - 3,5 Nm

Looper Cam set screws not exceed 0,14Nm

Eccentric set screws 2,9 - 3,5 Nm

Slide bar button head screws ( 4 ) 2,1 - 2,3 Nm

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

5

TABLE OF CONTENTS .

Foreword page : 02

Machine specifications page : 03

Service page : 05

Recommendations page : 05-06

How to use the machine? page : 07

How to handle a paper bag before closing it? page : 08

Treading and tension adjustment page : 09-10

How to open a sewn bag? page : 11

MAINTENANCE

Daily maintenance page : 12

Cleaning of the machine page : 12-13

Weekly maintenance page : 13-14

PARTS REPLACEMENT - GENERAL RECOMMENDATION

Bottom view of key components page : 15

How to replace a needle? page : 16-17

How to replace a looper? page : 18-19

How to replace a feed dog? page : 20

How to replace the knives? page : 20

Screws and hardware page : 21

How to replace the belt? page : 22

ADJUSTMENTS OF THE MACHINE

Looper stroke adjustments page : 23

Height adjustment of the needle versus looper page : 24

Adjustment of looper clearance page : 25

Motor instructions page : 26

Trouble shooting page : 27

Spare Parts and accessories page: 28

SPARE PARTS LIST AND DRAWINGS

Plate A : housing - needle lever - presser foot page : 30-32

Plate B : mainshaft and looper assembly page : 33-34

Plate C : handle and electric drive page : 35-36

Plate D : motor page : 37-38

Numerical parts list page : 39-40

Placement stickers and add guards page : 41-42

Safely disposing page : 43

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

6

SERVICE .

Should your machine require factory service or maintenance

please contact any of the Fischbein authorized distributors or

Fischbein Brussels . Return the warranty card with details concerning your

problems for warranty justification .

They can also give you the best advice on utilization ,oil ,thread and

spare parts .

RECOMMENDATIONS FOR MAX. PERFORMANCE .

Work area.

The MODEL F machine should be operated in an area that allows freedom

of motion for the operator and the unit. The machine’s input end at the feed

dog works quickly and the output end near the thread knife is very sharp.

Other operators should keep out of arm’s reach from the area in which the

machine works. Operators should always wear proper eye protection when

operating the machine and not wear loose clothing or jewelry. Long hair

should be pulled back and tied to avoid getting caught in the machine.

Before you start the machine .

1. Make sure your machine is well connected to an adequate power

supply as indicated on the motor.

The motor is double insulated , so there is no grounding required .

2. Verify that all guards are in place .

3. No special installation is required , but we may recommend you to

place something on the ground to set the machine on when not in use.

4. The machine is shipped to you with some examples of sewn test strips

Examine these carefully to see how proper chain form should look.

5. Use of the Fischbein model 1550 suspension and balancing unit is

recommended. This will allow the machine to be suspended at any

convenient height , ready for use .

6. You may want to try the machine on some empty bags or pieces of

paper to get a feel of how to use it , before you start with filled bags .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

7

As you sew with the Fischbein model F .

1. Do not use the machine in very humid environment.

2. Machine mechanism will carry the bag automatically through;

therefore do not either pull , push , or turn the machine .

3. Keep hands and fingers away from the bag moving mechanisms.

( feed dog , presser foot )

4. Only use the machine to close bags of specific thickness. It is not

desined for clothing or very thin plastic bags , (see page 3 , machine

specifications) .

5. A minimum of paper bag strength is required. For plastic bags, a

minimal thickness of 120 µ ( microns ) is necessary , depending on

quality of PE used .

Maintenance .

1. Always use genuine Fischbein parts .

2. Do not use screws other than those indicated in the parts list .

Hardware items on the Fischbein model F systems are not metric .

3. Always use original Fischbein D5 needles .

4. Use a 20 / 4 Fischbein 100 % polyester thread to get the best results .

5. Fischbein Premium Thread ( N° 25010.. ) is an excellent product ,and

available in various colors . With a full 200 gr cone you will sew

around 250 bags ( depending of bag widthness ) .

6. We also recommend that you use other Fischbein products such as :

cleaning agents and crepe paper ( tape ) ; these products were

selected to avoid problems and allow the for maximum efficiency of

the machine .

7. Proper settings for all internal components are made at the factory ,

any change to these settings could cause damage to the machine

mechanism .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

8

HOW TO USE THE FISCHBEIN PORTABLE BAG CLOSER ?

1. Take the machine in your right hand and place your finger over the

start switch placed on the underside of the handle .

2. The switch engages and dis-engages with a positive “ click “ .

Pressing and holding it in will start the machine running , releasing

it will stop the machine .

3. It is recommended that bag top “ gussets “ be formed before sewing

the bag . This will make a stronger and more durable closure .

See fig : 1-3 .

4. Take the top of the bag in your left hand at the right side of the bag .

5. Feed the top of the bag between the presser foot and the throat plate .

6. Press on the switch so that the machine starts running . During the

closing operation , the bag will carried through the sewing gap

correctly by the action of the feeding mechanism .

There is no need to push the machine or pull the bag .

7. When the bag is in the machine , it may be usefull to shift your

left hand to the other end of the bag top to support the bag and

achieve a straight seam .

8. When you reach the end of the bag , let the machine run for a little

to form a short “ chain “ and then gently turn the machine to the

left , enabling the knives to cut the thread .

WARNING !!!!

Keep always your hand away from the presser foot to avoid the danger that

your hand could be caught by the feed dog .

NOTE .

Important to check is the free space available between the top

of the bagged product and the sewing line .

The free space must be sufficient the whole width of the bag to allow

enough material to sew .

When closing net bags or jute bags , a free space between the top of the

product and the sewing line of 10 cm is recommended .

For paper bags , not less than 5 cm is suitable .

Experiment with each type of product and bag material to see how

much space needs to be left , to avoid tearing of the bag .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

9

HOW TO HANDLE A BAG BEFORE CLOSING IT ?

Fig 1 : When the bag is filled in and ready

to be closed , you must manually

reform the bag top including the

recommended gussets .

Fig 2 : After reforming operation , fold

the bag top as close as possible

to the product and than bring

the bag in its original vertical

position as shown on

Fig : 2 and 3 .

Fig 3 : You can now start the closing

operation remembering to leave

sufficient free space between the

top of the product and the sewing

line .

Fig : 4 When handling a jute bag with

thick bag edges , do not intro -

duce this edge directly into the

mechanism but shift the edge

gently before introduction and

starting the closing operation .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

10

METHOD OF THREADING , ADJUSTMENT AND TENSION .

WARNING !!!

Always disconnect the machine from it’s power source

before threading or adjustment .

Threading .

To thread the machine follow the thread path indicated in Fig:5.1 &5.2 .

1. Pass the thread through the first

and second eyelet ( 11109 ) .

2.Take the thread around the

tensioner stud inserting it between

the two tension discs (11114 ) .

3. Pass it through the thirth eyelet

( 11109 ) close to the needle bar

guarding ( 11101 ) .

4. It should then be passed through the

slotted opening in the needle bar

guard , through the needle bar

( 11500 ) and finally through the

opposite side of the needle bar

guard .

5. Then push the thread through the

eyelet ( 11109 ), to reach the needle

front side .

6. Push the thread through the needle

eye from the front side and pull it

through for about 8 cm .

7. Take a bag or small test piece and

introduce it between the throat plate

and the presser foot , making sure

that the needle is up . Start the

machine and sew it through . This

will provide a “ thread chain “ .

8. The machine is now ready to be

used .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

11

Thread cone replacement .

To install a new cone of thread :

1. Unscrew the wing nut (11805) at the base of the thread stand .

2. Remove the thread clamping bolt (11804) .

3. Take a new cone of thread , place it on the thread clamping bolt

and put it on the thread stand (11815) .

4. Re - attaching the wing nut and tightening it sufficiently. The

cone must not be able to rotate or wobble on the thread stand

Thread tension adjustment .

It should not typically be necessary to change the thread tension unless

you change to a much different thread or are sewing a special type of

material . Consult your dealer or a Fischbein service representative for

questions concerning special thread applications .

-The spring (11115) determines

the tension on the thread when

pulled through the two discs

(11114) .

-By turning the nuts of the

tension discs clockwise , you

will get more thread tension , by

turning in the opposite direction

you will reduce that tension .

-The first nut (11117) , close to the spring (11115) is there to adjust the tension,

the second nut (11116) and the washer spring (11655) , serve to lock the

adjustment .

- The screw (F64038) prevents eventual loss of the nuts (11116&11117) and

has no adjustment purpose .

- Start with minimum tension initially and examine the stitch . If it appears

too loose , gradually tighten the tensioning nut until a proper stitch is

achieved . Be sure to tighten the locking nut when the proper setting is reached.

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

12

HOW TO OPEN A SEWN BAG?

1.A: Thread chain along the

front side of the bag .

B: Thread chain along the

rear side of the bag .

C: Simply cut the thread

chain .

2 . Remove the thread from

the front side of the bag .

3 . Pull off that thread to

open the bag .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

13

MAINTENANCE AND SMALL REPAIRS .

WARNING !!!!

Always unplug the machine before starting work .

DAILY MAINTENANCE .

Lubricating the machine in operation .

1. Before closing your first bag be certain to see that the lubrication

mechanism is functioning properly .

2. To speed oil through the machine mechanism you must simply press

the oil pump button 2 or 3 times in succession . You will see the oil

flowing through the feeder tube

as you do . This should be

performed every 2 hours of

machine usage . The wicking

inside the housing carries the

dispensed oil to other moving parts

near the looper and needle bar. Do

not remove the wicking from the

MODEL F. If the wicking (11508)

becomes worn and thin, replace it

immediately.

3. Check the level of the oil pump

regularly . Always fill it genuine

Fischbein machine oil (12800) .

4. Always replace the oil reservoir cap to avoid contaminating the

lubricant.

This could cause the oil lines to plug and prevent lubrication of the

machine parts .

5. We recommend pushing the oil pump while the machine is running to

give better oil distribution inside the machine .

Cleaning of the machine .

Each day , clean the machine of any dust or accumulated debris .

This can easily be done by blowing out the machine cavities with

compressed air or by using a dry bristle brush .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

14

Sticking particles must be removed by using a small brush .

Do not forget to clean arround the bottom of the machine , especially

around the looper and the knives .

If you are working in a very dusty environment , we recommend this

cleaning operation twice a day . To do that , simply slide open the looper

cover (11102) . Blow out the inside with compressed air . Close the

looper cover and tighten the cover pivot screw (11108) if necessary .

By doing these operations daily , you will increase the life of your

machine .

WEEKLY MAINTENANCE .

WARNING!!!!

Always disconnect the machine from the electrical power

source before performing any maintenance or adjustment

Clean the machine weekly , for a few minutes in a cleaning oil bath .

How to proceed ?

1. Fill in a small tank with cleaning oil

up to 6 cm maximum .

2. Remove looper cover located at the

bottom of the machine and the belt -

pulley cover and handle .

3. Plunge the machine vertically into

the oil so that it is immersed to the

level of the throat plate .

4. Turn the machine manually at the

pulley so the moving parts are

cleaned in the cleaning oil bath .

5. Remove the machine from the bath

and drain any excess of oil from the

mechanism .

6. Your machine is now free of dirt and parts are cleaned up .

7. If necessary you may want to loosen any stubborn dirt or grit with a small

brush and rinse the machine again .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

15

8. Afterwards you may want to clean the outside parts by using a small oiled

brush . Wipe the machine off with a soft , absorbent cloth .

CAUTION !!!!

For a good job , always use Fischbein cleaning oil (12802) .

Never use benzene or similar aggressive or volatile products . Such products

could dry the oil from critical moving parts and cause extensive damage to the

machine or melt some of the plastic components .

Volatile solvent fumes could present a fire hazard if the machine is run where

such vapors exist .

Check the motor brushes each week to be sure that they are of sufficient

length . When the brushes become too short they may damage the motor.

They should be 6 mm in length at minimum .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

16

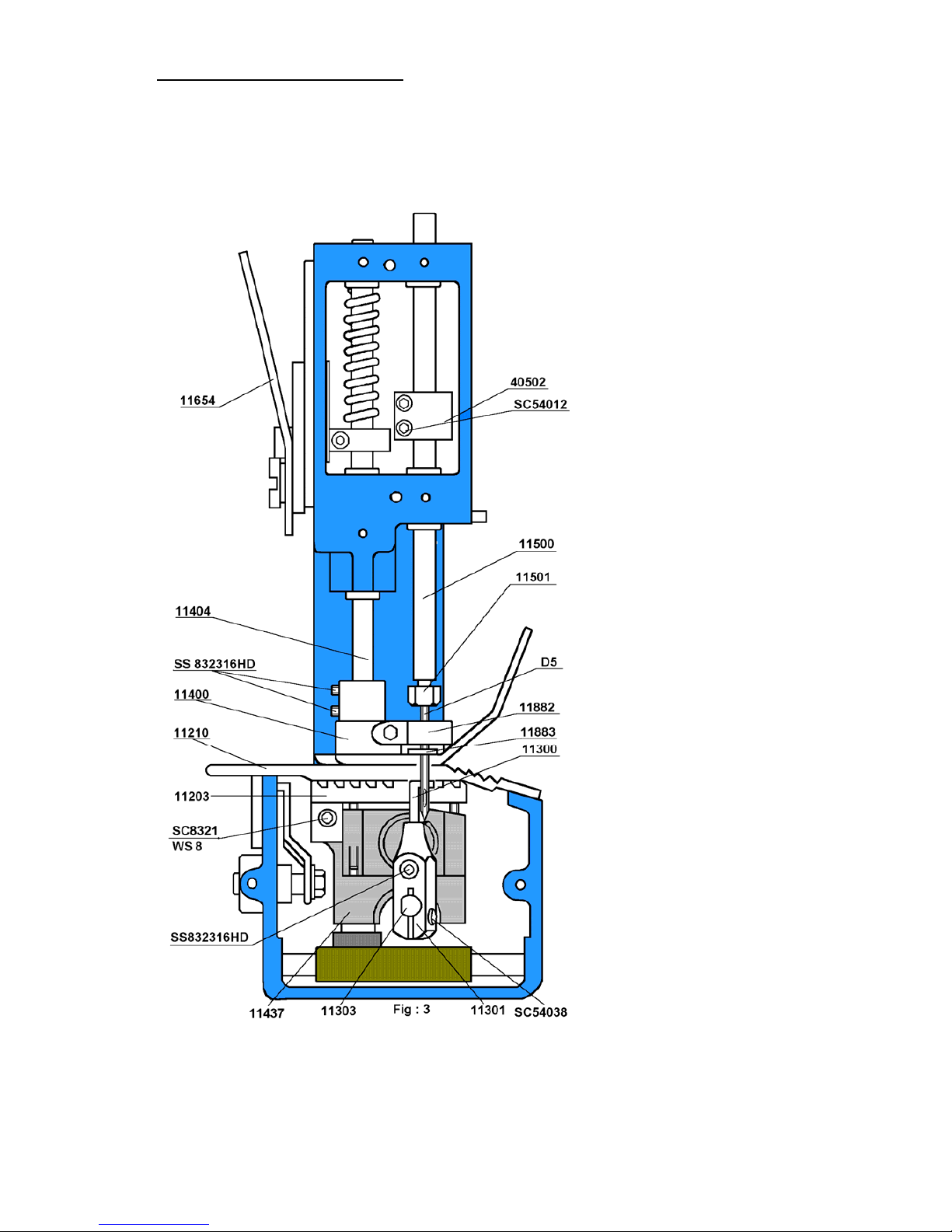

BOTTOM SIDE VIEW OF THE F PORTABLE BAG CLOSER .

After removing needle bar guard (11101) , looper cover (11102) and

knife guard (11125) .

.

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

17

REPLACEMENT OF PARTS : HOW TO PROCEED ?

Placement of the machine for parts replacement .

Place the machine so that it rests on

the motor and the machine handle is flat

against the table .

It should be sitting so that you are

looking into the looper cavity and

at the needle bar guard .

How to replace a needle ?

The needle is held in the needle bar

by using the special nut (11501) .

The nut should be adjusted with a

3/8 open end wrench or suitable

adjustable tool (11645) .

Be careful not to strip the threads or

the hex surface .

Do not use pliers .

1. Unplug the machine .

2. Remove the pulley guard (11801) .

3. Raise the presser foot to it’s detent

position and rotate the machine

manually until the needle bar is at

it’s highest position .

4. Loosen the needle bar clamping

screw (11501) with the wrench

provided with the machine (11645) .

5. Remove the needle .(D5)

6. Place the new needle in the needle bar making sure that it is fully inserted and

that the long grove faces you and the needle scarf is to the back .

The groove lips should match the base of the machine as close as possible and

the eye should be facing you .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

18

7. Tighten the screw to clamp the

needle in place .

The nut is designed so that it

does not require excessive

force to tighten , a firm torque

will be sufficient .

8. Lower the presser foot .

9. Check to see if the needle is

passing through the middle of

the needle guard . (11883)

See also Fig : 5A .

10.Replace the pulley guard .

11.Re - thread the machine .

12.Use always genuine Fischbein

D5 needles .

CAUTION !!!

Keep always your fingers

away from under the

needle .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

19

How to replace the looper , 11300 ?

1. Unplug the machine .

2. Place the machine in the

position described above .

3. Raise the presser foot to

it’s detent position .

See Fig : 6 .

4. Remove the pulley guard

(11801) and rotate the

machine manually until the

feed dog is at it’s lowest

position .

5. It’s advisable to remove the

needle (D5) for safety

purposes .

6. Remove the looper cover

(11102) by unscrewing screw ( 11108) .

7. Remove the throat plate

(11210) by unscrewing

the 3 screws ( F64038) .

8. Remove the feed dog

(11203) by removing

screw (SC8321) and the

washer ( WS8) .

9. Remove the looper

(11300) from the looper

holder (11301) by loos-

ening the set screw

(SS832316HD) .

10.Install the new looper

(11300) into the looper

holder (11301) . Make

sure that : the flat side of the

looper is faces the set screw (SS832316HD) The looper is inserted

completely to the bottom of the looper holder (11301) .This is very

important for the adjustment of the machine .

FISCHBEINCOMPANY

The Leader in Bag Closing Technology

REF : 14810F-GB

ED.A10/2001

20

11. Tighten the looper set

screw (SS832316HD) .

12. Replace the needle as per

the previous procedure .

13. Now is a good time to

check the machine timing

(see timing procedure ,

page : 28 ) .

14. Replace the feed dog

making sure that it is set

correctly on the height

adjustment screws .

15. Replace the throat plate .

16. Replace the looper cover

and check to see that all

screws are tight .

17. Replace the pulley guard.

Table of contents