Flomec G Series User manual

G-SERIES TURBINES

(3-A High Temperature Sanitary Model )

(GSCPS)

11/2021 921977-02 Rev. G

2

To the owner…

Congratulations on receiving your FLOMEC® G-Series Sanitary Turbine.

We are pleased to provide you with a product designed to give you

maximum reliability and efficiency.

Our business is the design, manufacture, and marketing of liquid handling,

agricultural, and recreational products. We succeed because we provide

customers with innovative, reliable, safe, timely, and competitively priced

products. We pride ourselves in conducting our business with integrity and

professionalism.

We are proud to provide you with a quality product and the support you

need to obtain years of safe, depend- able service.

President

Great Plains Industries, Inc.

TABLE OF CONTENTS

General Information ---------------------------- 2

Installation ----------------------------------------- 4

Maintenance -------------------------------------- 5

Troubleshooting -------------------------------- 12

Troubleshooting Reference Guide --------- 15

Specifications ----------------------------------- 16

Service ------------------------------------------- 18

Warranty ----------------------------------------- 20

3

GENERAL INFORMATION

This manual will assist you in installing and maintaining your FLOMEC G-Series

Sanitary Turbine. For best results, take the time to fully acquaint yourself with all

information about all components of your G-Series Sanitary Turbine. If you need

assistance, contact the distributor from whom you purchased your turbine.

Product De cription

FLOMEC G-Series Sanitary Turbine flowmeters are volumetric flow measurement

devices. The moving fluid is used to turn a rotor, which is suspended in the flow

stream. The rotating speed of the rotor is proportional to the fluid velocity or

flowrate. As the blades from a spinning rotor pass by a magnetic sensor, an AC

voltage pulse is generated and transmitted to the readout instrument. Each pulse

is equal to a given volume of liquid; therefore “x” number of pulses are equal to a

gallon, litre, pound, barrel, etc.

Turbine Sizing

FLOMEC G-Series Sanitary Turbines are identified by the internal diameter of the

inlet and outlet.

Model 100 1 in. (6.7-67 GPM)

Model 100L 1 in. (6.7-67 GPM)

Model 150 1-1/2 in. (17.7-177 GPM)

Model 150L 1-1/2 in. (17.7-177 GPM)

Model 200 2 in. (33-330 GPM)

Model 200L 2 in. (33-330 GPM)

Turbine flowmeters should be sized in accordance to the actual flowrate and not

the process pipe size. For example, a process having a flowrate of 10-20 GPM in

a 1-1/2 in. process line requires Model 100 OR 100L turbine flowmeter.

Another important factor to take into consideration when sizing a turbine flowmeter

is instantaneous flowrate. This is extremely important when sizing a turbine

flowmeter where the volume is measured per hour or per day. For example, an

application where the total output is 500 barrels per day, occurring in a 5-hour

period; the recommended turbine flowmeter should be sized according to the

instantaneous flowrate:

(500 – 5) x 24 or 2,400 barrels per day

Thus, requiring a 1-1/2 inch turbine flowmeter.

4

INSTALLATION

Turbine flowmeters are affected by both upstream and downstream process

configurations. Turbine flowmeters should always be installed with a minimum of

10 pipe diameters upstream and 5 pipe diameters downstream. The only exception

is the placement of the pumps, valves, etc., on the upstream end. When this

occurs, 20 diameters of straight pipe should be used. The direction of flow is

indicated by the arrow on the turbine. All turbine flowmeters are designed to

measure flow in only one direction.

Check the items below once the turbine flowmeter is installed in the process line.

This will ensure a successful start-up.

1. Before installing the magnetic sensor, make sure that it is functioning properly.

This can be accomplished by checking the ohm resistance. Refer to Checking

Magnetic Pickup in the Troubleshooting section.

2. If a magnetic pickup enclosure is used on a sanitary turbine, discard the seal

cap that is included with the unit. If no enclosure is used, install the magnetic

pickup and slip the seal cap over the magnetic pickup and threads on the

adapter.

NOTE: This is not applicable for units that use a low profile adapter.

3. Check the interconnection cable between the turbine flowmeter and readout

device. Refer to Checking the Cable Assembly section.

4. Make sure that the new or correct K-factor is entered into the readout device.

NOTE: The K-factor is printed on the turbine body. The calibration report included

with the product provides several points along the flow curve.

Initial Start-Up

Turbine flowmeters can be installed in the horizontal or vertical position. When

installing a turbine flowmeter in the vertical position, it is important that the direction

of flow be up through the turbine flowmeter.

A spool should be installed in place of the turbine flowmeter during initial start-up

of a new process line. The process line should be purged, thus eliminating any

solids contained in the line. Once this is completed, the spool can be removed and

the turbine flowmeter installed.

Whenever possible, use 20 straight pipe diameters upstream and down- stream of

the turbine flowmeter. The length of straight pipe upstream and downstream of the

turbine flowmeter can be reduced with the use of flow straighteners or

straightening vanes. A minimum of 10 straight pipe diameters upstream and 5

downstream are required.

NOTE: Control valves should always be installed downstream of the turbine

flowmeter.

The turbine flowmeter should be installed in a location where the process line will

remain full of liquid at all times. Otherwise, when the process line becomes empty

and a valve is opened, the high velocity fluid hitting the turbine flowmeter rotor can

cause severe damage.

5

Reference:

3-A Accepted Practices for Permanently Installed

Product and Solution Pipelines and Cleaning Systems Used in

Milk and Milk Product Processing Plants, Number 605-XX as

amended for procedures and recommended flowrates.

When there is entrained air in the process line, an air eliminator should be used.

This entrained air causes air pockets and these air pockets will cause the rotor to

spin at a faster rate than liquid, thus resulting in in- correct readings, which results

in an overstatement of actual flowrate and volume. This condition can damage the

flowmeter.

In process lines where particulates are present, a filter/strainer should be used.

Refer to the table below for the recommended mesh size.

Turbine

Flowmeter Size Me h Size

1 inch 40

1-1/2 inch 18

2 inch 14

MAINTENANCE

Cleaning Procedure

G-Series Sanitary Turbines are designed to be compatible with commercially

accepted methods of both CIP (Cleaned-In-Place) mechanical cleaning as well as

intermittent SIP (Steam-In-Place) cleaning methods.

If CIP or SIP cleaning methods are not available, manual COP (Cleaning-Out-of-

Place) methods can be used.

Care must be taken during system start-up, chemical cleaning, air purge or steam-

cleaning processes to ensure that the turbine rotor does not over speed as damage

can result to the rotor and/or bearing. Maximum allowable over range for G-Series

Sanitary Turbines is 125% of maximum rated flowrate for intermittent periods.

A minimum fluid velocity of 5 foot per second (1.5 meter per second) must be

maintained during the CIP process to ensure adequate cleaning.

The following flowrates are recommended by the 3-A Recommended Practices

605-XX to achieve 5 FPS or 1.5 MPS in the respective Sanitary Tube size:

O.D. I.D. FLOWRATE

1.0 in.

2.5 cm

.875 in.

2.22 cm

9.4 GPM

35.6 LPM

1.5 in.

3.8 cm

1.375 in.

3.50 cm

24 GPM

90.8 LPM

2.0 in.

5.1 cm

1.875 in.

4.75 cm

43 GPM

163 LPM

WARNING

6

Temperature limit for SIP cleaning is primarily limited by the temperature rating on

the magnetic pickup. If the pickup temperature rating will be exceeded during SIP

cleaning, remove it during the cleaning process or a higher temperature rated

pickup should be specified. Internal components of the G-Series Sanitary Turbine

must be limited to less than 285° F (140° C). The temperature and pressure rating

of gaskets and clamps used in the installation must also be taken into

consideration when determining cleaning parameters.

Minimum requirements for effective sterilization with SIP cleaning are to maintain

250° F (121° C) at the coldest point in the system for a minimum of 30 minutes.

This requires a minimum of 15.3 psig (106 kPa) saturated steam pressure. Normal

recommended maximums for SIP cleaning on G-Series meters is 285° F (140° C)

and 39 psig (269 kPa) saturated steam pressure.

Di a embling the Turbine

1. Disconnect the turbine flowmeter cable from the magnetic pickup. (Refer to

Figure 1.)

2. Remove the magnetic pickup.

3. Ensure that the process line is depressurized and empty prior to removal of the

turbine flowmeter. Remove the turbine flowmeter from the process line.

4. Using a small screwdriver or similar tool, insert it into the radius notch of the

retaining ring on the outlet end, pull away from the groove and up, removing

the retaining ring from outlet end of the turbine flowmeter. This will allow the

rear support assembly and rotor to slide out of the turbine flowmeter body.

5. Remove the rear support assembly and rotor assembly before proceeding to

remove the front support.

NOTE: To remove the front support at the inlet end of the turbine flowmeter,

repeat the previous retaining ring and support removal operation.

6. Once the turbine flowmeter is taken apart, inspect the turbine flowmeter body

for signs of wear or defects. The body bore should be smooth and show no

evidence of wear.

NOTE: Do not install a new replacement kit into a turbine flowmeter body that

shows significant signs of wear.

7. Examine the rotor assembly for broken and/or bent blades. Remove any

foreign matter.

8. Examine the supports for signs of deterioration, such as wear marks and/or

burrs along the outer edge of the support vanes.

9. When the rotor assembly or the supports show any sign of deterioration, a new

replacement kit should be installed. Do not install a new replacement kit into a

defective turbine flowmeter body.

7

Replacement Kit

A replacement kit is comprised of all the internal component parts within the turbine

flowmeter. A replacement kit consists of the following:

FLOMEC Sanitary Turbine supports are not identical in design. The rear support

assembly has a shaft that supports the rotor; the front support does not.

Notice that the direction of flow is displayed on the body of the turbine flowmeter.

This is important when installing the supports and rotor and it also denotes the

direction in which the turbine flowmeter was calibrated.

1. Install the front support placing a vane between the notches in the turbine

flowmeter body. Install a retaining ring to keep the support in place.

2. Place the rotor assembly on the shaft of the uninstalled rear support assembly.

NOTE: FLOMEC Sanitary Turbine rotors are tapered on one end. The tapered end

should be installed facing the front support (see Figure 1).

Part De cription Quantity

Rotor Assembly 1

Support (Front) 1

Support Assembly (Rear) 1

Retaining Ring 2

Figure 1

8

3. Hold the turbine flowmeter body with the rear (outlet) end down, and slide the

rotor assembly and rear support assembly into the turbine flowmeter body.

Make sure the vane is placed between the notches.

4. Once the rear support assembly is in place, install the retaining ring.

5. Blow into the turbine flowmeter to ensure the rotor spins freely.

NOTE: Installation of the replacement kit is complete and the turbine flowmeter

can be reinstalled into the process line.

6. Install the magnetic pickup. HAND TIGHTEN ONLY.

NOTE: Be sure to use the proper magnetic pickup, cable and connector for the

application.

7. Enter the new K-factor supplied with the replacement kit into the electronic

readout device. (Refer to the calibration report.)

NOTE: All internal replacement kits are factory calibrated and are supplied with a

five point calibration certificate.

Single Post Design Replacement Kit for FLOMEC G-Series Sanitary Turbines

Figure 2

9

Replacement Kit for Sanitary Turbine Flowmeter (GSCPS)

Size Flow Range

(Gallon Per Minute)

Model Part No.

1 in. 6.7 - 67 GPM

GSCPS-100

GSCPS-100L 81008074

1-1/2 in. 17.7 - 177 GPM

GSCPS-150

GSCPS-150L 81508074

2 in. 33 - 330 GPM

GSCPS-200

GSCPS-200L 82008074

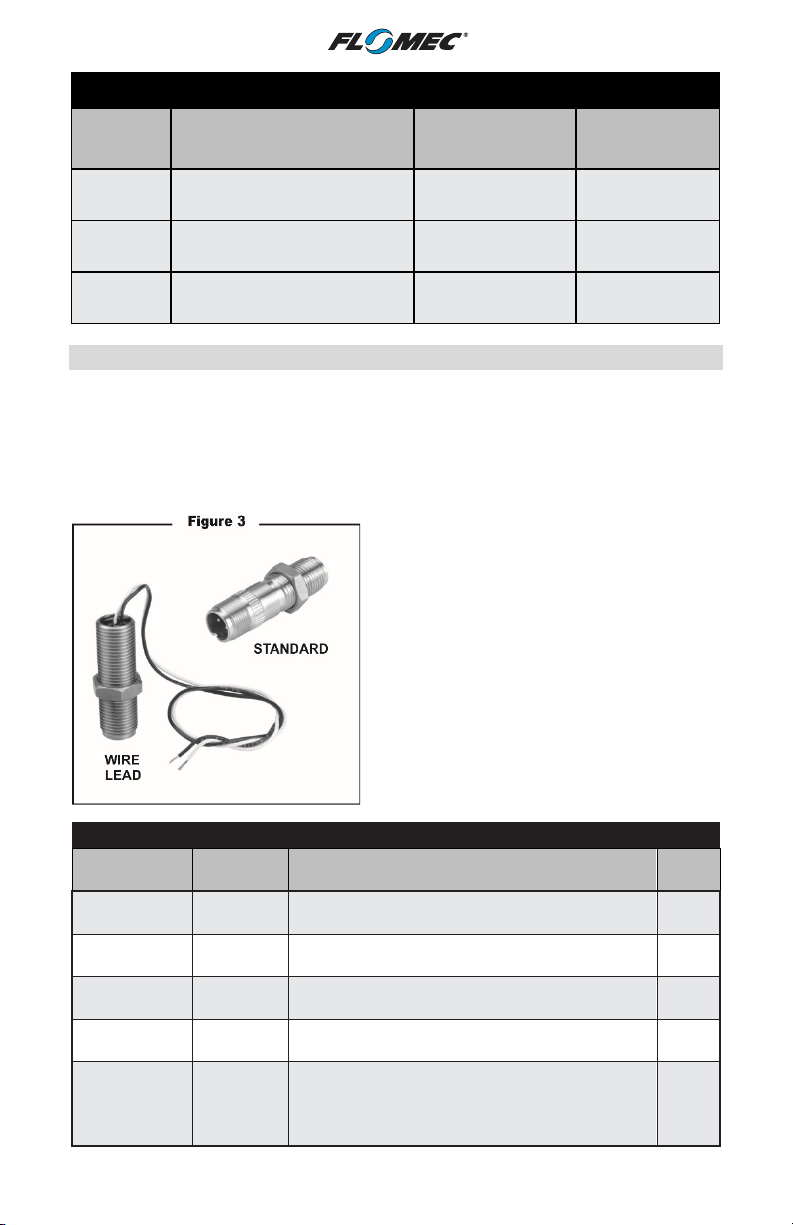

Magnetic Pickup

FLOMEC offers two types of magnetic pickups: Standard and Wire Lead. (See

Figure 3.)

When choosing a magnetic pickup, the turbine meter and electronics are generally

already known. Electronics can be either Local or Remote. Remote electronics

include FLOMEC Remote Displays or output to customer-supplied equipment.

Follow the next three steps when choosing a magnetic pickup.

1. Select your size: 1 in., 1-1/2 in., or 2 in.

2. Choose Local or Remote/Output.

•Local uses a wire lead pickup.

•Remote/Output requires a connector.

3. Choose either Sine Wave or Square

Wave as your signal type.

•Sine Wave does not require external

power for the sensor, and can be used

with battery powered displays.

•Square Wave requires external power

to power the sensor.

Selection Guide for 1 in. 1-1/2 in., 2 in. Turbine Meter

Magnetic

Pickup Type

Part No. Application

Cable

Type

Wire Lead

Standard 81003000 Meter mount electronics. Temperature

range: -100°F to +250°F. Sine wave output. None

Standard 81001000 Remote mount electronics. Temperature

range: -100°F to +250°F. Sine wave output. S

Herm/High

Temp. 81002000 Remote mount electronics. Temperature

range: -450°F to +258°F. Sine wave output. H or T

High Temp.

Standard 81007000 Remote mount electronics. Temperature

range: -450°F to +800°F. Sine wave output. H or T

Active Digital 81004000

Remote mount electronics. Temperature

range: -40°F to +248°F. Square wave, open

collector output, 5-32 VDC required. Signal

output: 0-10V, NPN.

D

10

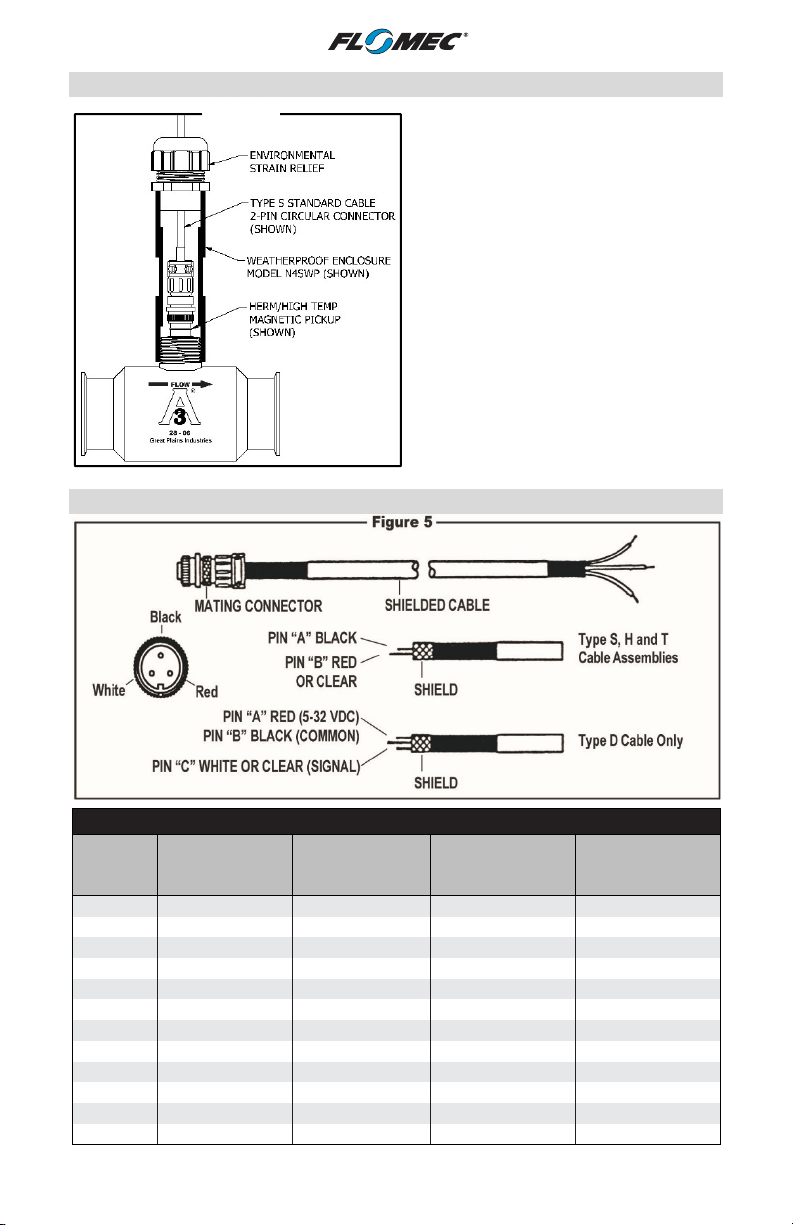

Magnetic Pickup Enclo ure

Pickup Enclosures are optional on G-

Series Sanitary Turbine Meters.

Choose from two versions of

weatherproof pickup enclosures (see

Figure 4):

•Model N4AWP - Part No. 80001101,

Zinc Plated Steel

•Model N4SWP - Part No. 80001105,

316 Stainless Steel

Cable A emblie (Connector Included)

Cable Length Selection Guide

Cable

Length

Type

“S”

Standard

(2 Conductor)

Type “D”

Digital or RF

(3 Conductor)

Type

“H”

Water Resistant

(2 Conductor)

Type

“T”

Hi-Temperature

(2 Conductor)

8

inch

83001001 83002001 83003001 83004001

5

feet

83001005 83002005 83003005 83004005

10

feet

83001010 83002010 83003010 83004010

15

feet

83001015 83002015 83003015 83004015

20

feet

83001020 83002020 83003020 83004020

25

feet

83001025 83002025 83003025 83004025

30

feet

83001030 83002030 83003030 83004030

40

feet

83001040 83002040 83003040 83004040

50

feet

83001050 83002050 83003050 83004050

75

feet

83001075 83002075 83003075 83004075

100

feet

83001100

125

feet

83001125

Figure 4

11

LOW RANGES

Size

Gallon

Per

Minute

Litre

Per

Minute

Frequency Output

Min. Max. Min. Max.

1 in.

6.7 67 25.2 252

100 - 1000 Hz

1-1/2 in.

17.7 177 67.0 670

100 - 1000 Hz

2 in.

33 330 124.9 1249

100 - 1000 Hz

DIMENSIONS

Size

Height Length

1 in.

2.75 3.562

1-1/2in.

3.00 4.594

2 in.

3.25 6.063

Dimensions are provided in inches.

(For optional low profile models, subtract 1 inch from height.)

12

TROUBLESHOOTING

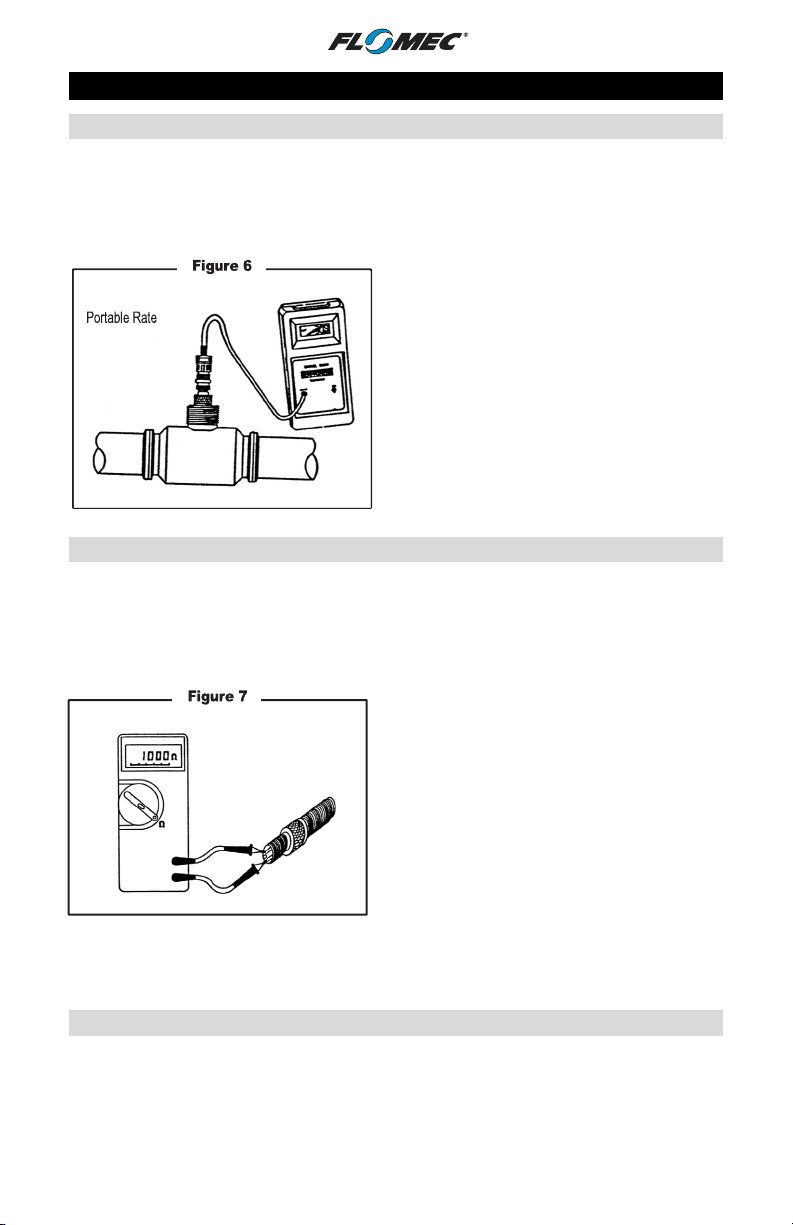

Locating the Problem

To determine the location of the problem, whether it is occurring at the turbine

flowmeter or at the electronic readout device, disconnect the cable assembly from

the magnetic pickup and connect the cable from the portable rate indicator onto

the magnetic pickup. (Refer to Figure 6.)

The portable rate indicator will display the

instantaneous rate of flow through the

turbine flowmeter. If the rate displayed is

equal to the rate of the process, then

both the magnetic pickup and the turbine

flowmeter are operational. The problem

will be located in either the cable

assembly or the electronic readout

device

When there is no rate displayed on the

portable rate indicator, the problem may

be caused by a defective magnetic pickup

or turbine flowmeter.

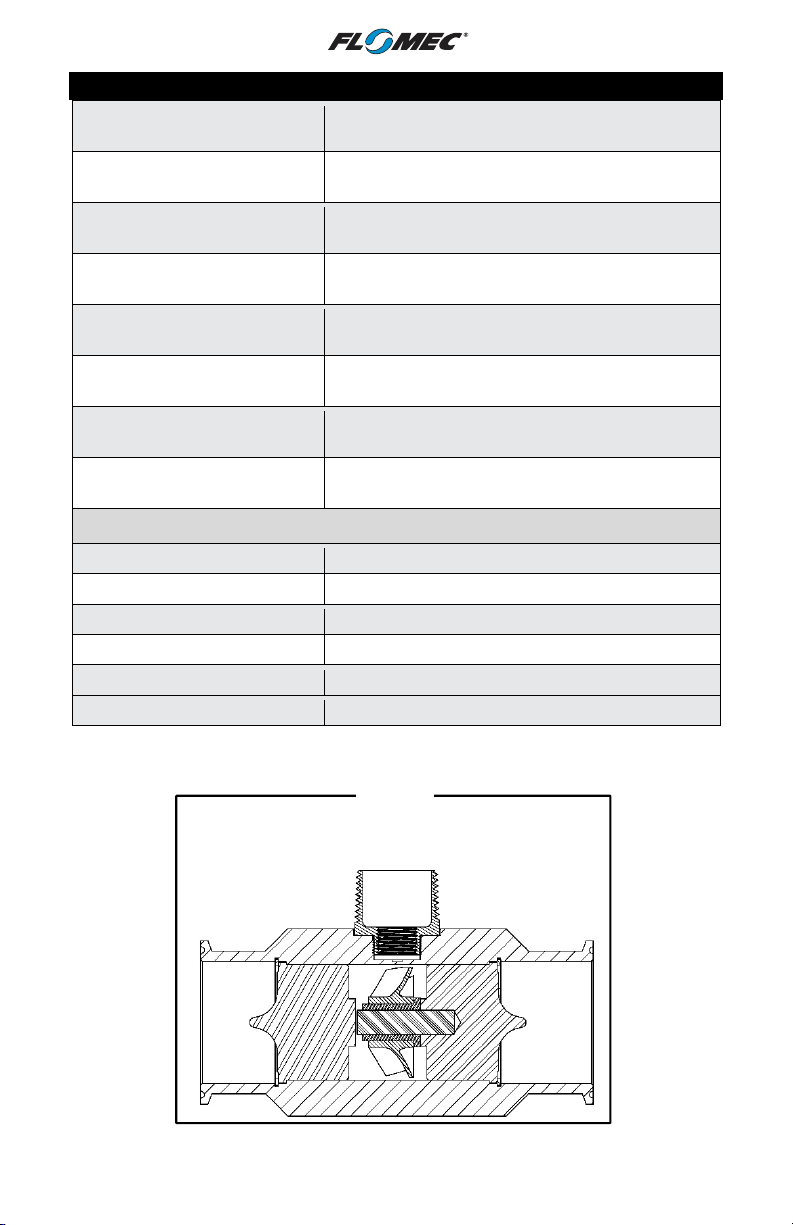

Checking the Magnetic Pickup

To determine the status of a hermetically sealed, two-wire lead, or standard

magnetic pickup, simply remove it from the turbine flowmeter, and using an ohm

meter, measure the ohm resistance by placing the leads of the ohm meter on each

pin of the magnetic pickup. (Refer to Figure 7.)

If the ohmmeter reads 1400 ohms ±20%,

then the magnetic pickup is good and

should NOT be replaced. If the ohmmeter

reads less than 1000 ohms, install a new

magnetic pickup. DO NOT throw the old

magnetic pickup away. Failure of the

magnetic pickup may have been caused

by moisture trapped inside. In some cases

when the magnetic pickup is allowed to

dry, it has become completely functional

and can be reused. When the ohmmeter

reads in excess of 1700 ohms, the

magnetic pickup is defective and should

be discarded.

NOTE: It is recommended that the ohm resistance be measured before installing

a used magnetic pickup.

Checking the Turbine Flowmeter

Once it has been determined that the magnetic pickup is functional and there is no

output displayed on the portable rate indicator, it can be concluded that the

problem lies within the turbine flowmeter. Remove the turbine flowmeter from the

process line. DO NOT remove the internals at this time.

Hand-held

Indicator

13

Visually inspect the internals of the turbine flowmeter. Check for particulates and/or

foreign objects, which may have lodged between the rotor and the body. In the

event an object is detected, simply remove the retaining ring on the outlet side of

the turbine flowmeter and remove the support and rotor assembly. Once the

turbine flowmeter parts are free from any foreign matter, reassemble.

NOTE: Always ensure that a support vane is installed between the indention marks

on the body.

Upon completion, verify the rotor spins freely, reinstall the turbine flowmeter into

the process line.

If there are no signs of particulates or any other foreign matter obstructing the rotor,

try blowing into the turbine flowmeter. If the rotor does not spin freely, insert a thin

screwdriver or similar tool, gently so as not to damage any of the rotor blades, and

turn the rotor.

There may be another cause for the rotor to drag or stop, such as incorrect bearing

material used for the application. For example, non-compatibility of the bearing

material with the process liquid, bearing material may not withstand the

temperature of the application, etc. When there is uncertainty with respect to the

selection of bearing material for a given application, contact GPI.

Before installing a new replacement kit, inspect the turbine flowmeter body for wear

and damage. By placing your finger inside the turbine flowmeter body, feel for any

signs of wear such as grooves, ridges, irregular spots. If such signs are evident, it

is a strong possibility that the turbine flowmeter body is damaged and the

installation of a new replacement kit is NOT recommended.

When a new replacement kit is installed inside a damaged turbine flowmeter body,

the internals will be ruined after a short period of operation and will have to be

discarded. In the event it is uncertain whether the turbine flowmeter body is

functional, it should be sent to GPI so the I.D. dimension of the turbine flowmeter

body bore can be checked. If it is found to be within tolerance, a new set of internals

will be installed. This will eliminate the possibility of using and/or discarding a

turbine flowmeter that shows signs of wear.

NOTE: A good turbine flowmeter body should have a smooth inner bore free of

wear signs.

If it is determined that the turbine flowmeter body is in good condition, install a

new replacement kit and reinstall the turbine flowmeter into the process line.

Checking the Cable A embly

This can be accomplished with the aid of a frequency oscillator. Simply plug the

cable assembly with the mating connector end that is located at the turbine

flowmeter into the frequency oscillator. The frequency oscillator will simulate the

output of a turbine flowmeter. If an output is displayed on the electronic readout

device, then the cable assembly is good.

In the event an output is not displayed, disconnect the frequency oscillator from

the cable assembly and connect the cable supplied with the frequency oscillator

directly to the electronic readout device, the same as you would a turbine

flowmeter cable assembly. (Refer to Figure 8.)

14

When the frequency oscillator is

connected and an output is displayed on

the electronic readout device, this

indicates that the turbine flowmeter cable

assembly is defective and should be

replaced. If no output is displayed, the

turbine flowmeter cable assembly is good

and the problem lies within the electronic

readout device.

Checking the Electronic

Using the frequency oscillator and the cable that is supplied, connect it to the

electronic readout device, the same as you would a turbine flowmeter cable

assembly. Once the frequency oscillator is connected, if no output is displayed on

the electronic readout device, check to ensure that the power is on, the fuses are

good, and the correct K-factor is dialed/programmed into the electronic readout

device. After verification of these items, if there is still no output displayed and/or

registered, then the manufacturer of the electronic readout device should be

consulted.

15

Trouble hooting Reference Guide

Symptom

Probable Cause

Solution

No output is

displayed or

registered

Defective magnetic pickup Refer to the Checking the

Magnetic Pickup section.

Foreign matter obstructing the

turbine flowmeter rotor

Refer to the Checking the

Turbine Flowmeter section.

Defective turbine flowmeter

internals

Refer to the Checking the

Turbine Flowmeter section.

Defective turbine flowmeter

cable assembly

Refer to the Checking the

Cable Assembly section.

Defective electronic/readout

device

Refer to the Checking the

Electronics section.

More volume/

output than

displayed or

registered.

Rotor may drag due to foreign

matter obstruction

Refer to the Checking the

Turbine Flowmeter section.

Magnetic pickup not screwed

down all the way into the

turbine flowmeter body,

causing it not to detect all the

rotor blades as they pass.

Screw the magnetic pickup all

the

way down into the turbine

flowmeter body. Hand-

tighten

only.

Turbine flowmeter installed

backwards.

Install the turbine flowmeter in

accordance with the process

flow direction.

Turbine flowmeter rotor

installed backwards.

Install the turbine flowmeter

rotor in accordance with the

process flow direction.

K-factor is too high in

electronic/readout device.

Verify K-factor used. K-factor

should be decreased.

Less volume/

output than

displayed or

registered.

Caused by entrained air in the

process line.

Install an air eliminator

upstream of turbine flowmeter.

K-factor is too low in

electronic/readout device.

Verify K-factor used. K-factor

should be increased.

16

SPECIFICATIONS

Accuracy *±0.5% of the true flow at any point within the

linear range of the turbine flowmeter.

Linearity *±0.5% of the mean K- factor throughout the

linear range.

Repeatability *±0.1% of the indicated flow throughout the

linear range.

Response Time:

1 in., 1-1/2 in. & 2 in 2-5 milliseconds for step change in flowrate.

Frequency Output:

1 in, 1-1/2 in. & 2 in. 100 - 1000 Hz (Over the linear range)

Voltage Output:

1 in., 1-1/2 in., & 2 in

Approx. 100 mV @ 100 Hz to

1.0 Volt (r.m.s.) @ 1000 Hz

Maximum Overage Up to 125% of maximum flowrate for

intermittent periods.

Operating Temperature -100° F to +225° F

(-70° C to +107° C)

Standard Material of Con truction

Housing 316 Stainless Steel

Rotor Nickel Plated CD4MCu Stainless Steel

Shaft 316 Stainless Steel

Rotor Supports 316 Stainless Steel

Sleeve/Thrust Bearing PEEK

Retaining Rings 300 Series Stainless Steel

* Data based on water calibration @ 77°F (25°C).

Materials of Construction

Figure 9

17

FLOW RELATED FORMULAS

BPH = Barrels Per Hour GPS = Gallons Per Second

BPD = Barrels Per Day GPD = Gallons Per Day

BPM = Barrels Per Minute GPM = Gallons Per Minute

CFM = Cubic Feet Per Minute

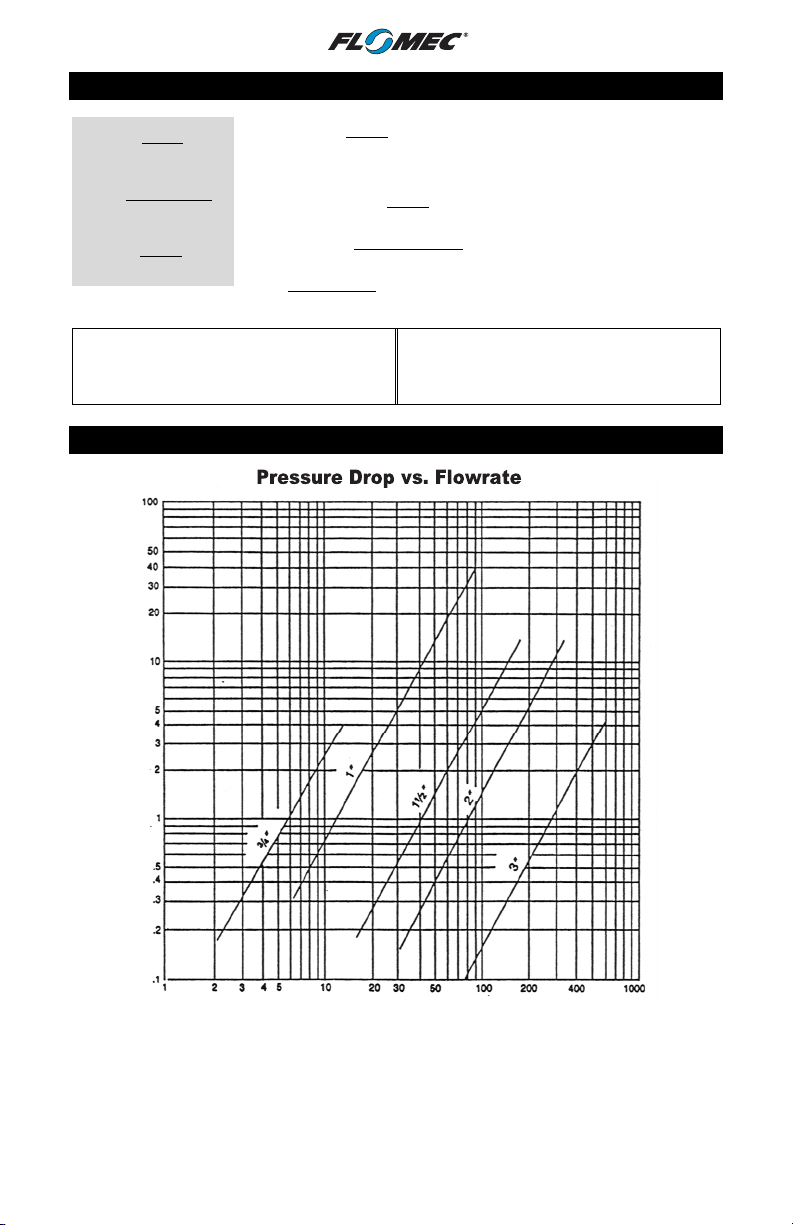

PRESSURE DROP v FLOWRATE

Flowrate Gallons Per Minute

For estimating pressure drops on liquids other than water, use the following formulas:

P = [ VIS ( PS) ] 1/4 x [ S.G. ] ¾ [ PH O ]

Where: PS = Absolute Viscosity in entipoise

SG = Specific Gravity

PH O = Pressure Drop at the Operating Flowrate from the hart

GPM =

Hz x 60

K-factor

Hz =

GPM x K

-

factor

60

K

-

factor =

Hz x 60

GPM

Pulses Per Litre = K-factor

3.785

Pulses Per Barrel = K-factor x 42

Pulses Per Cubic Meter = K-factor

. .003785

Pulses Per Pound = K-factor

Pounds Per Gallon

GPM = Pounds Per Hour

500 x S.G.

Pounds Per Hour = 500 x S.G. x GPM

Pounds Per Gallon = S.G. x 8.33 (Water)

BPH = GPM x 1.42857

BPD = GPM x 34.286

BPM = GPM x 0.238

GPS = GPM x .01666

GPD = GPM x 1440.0

GPM = BPD x .029167

GPM = BPH x 0.7

CFM = GPM x .13368

Pressure Drop PSI

18

SERVICE

For warranty consideration, contact your local distributor. If you need further

assistance, contact the GPI Customer Service Department at:

1-888-996-3837

You will need to:

•

Provide the model number of your turbine.

•

The serial number of your turbine.

•

Specific information about part numbers and descriptions.

For warranty work always be prepared with your original sales slip or other

evidence of purchase date.

RETURNING PARTS

Please contact the factory before returning any parts. It may be possible to

diagnose the trouble and identify needed parts in a telephone call. GPI can also

inform you of any special handling requirements you will need to follow covering

the transportation and handling of equipment that has been used to transfer

hazardous or flammable liquids.

CAUTION: Do not return turbines without specific authority from the GPI Customer

Service Department. Due to strict regulations governing transportation, handling,

and disposal of hazardous or flammable liquids, GPI will not accept turbines for

rework unless they are completely free of liquid residue.

CAUTION: Turbines not flushed before shipment can be refused and returned to

the sender.

19

NOTES

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

20

FLOMEC® TWO-YEAR LIMITED WARRANTY

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205, hereby

provides a limited warranty against defects in material and workmanship on all products

manufactured by Great Plains Industries, Inc. This product includes a 2-year warranty.

Manufacturer’s sole obligation under the foregoing warranties will be limited to either, at

Manufacturer’s option, replacing or repairing defective Goods (subject to limitations

hereinafter provided) or refunding the purchase price for such Goods theretofore paid by the

Buyer, and Buyer’s exclusive remedy for breach of any such warranties will be enforcement

of such obligations of Manufacturer. The warranty shall extend to the purchaser of this

product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of manufacture or on the date of purchase with

an original sales receipt. This warranty shall not apply if:

A. the product has been altered or modified outside the warrantor’s duly appointed

representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been

installed or operated other than in accordance with the manufacturer’s operating

instructions.

To make a claim against this warranty, or for technical assistance or repair, contact your

FLOMEC distributor or contact FLOMEC at one of the locations below.

In North or South America contact

Great Plains Industries, Inc.

5252 East 36

th

St. North

Wichita, KS 67220-3205

USA

888-996-3837

www.flomecmeters.com

(North America)

Outside North or South America contact

GPI Australia

(Trimec Industries Pty. Ltd.)

12/7-11 Parraweena Road

Caringbah NSW 2229

Australia

+61 02 9540 4433

www.flomec.com.au

The company will step you through a product troubleshooting process to determine

appropriate corrective actions.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY

FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN

THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any

particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from

U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702

(governs the resale availability of the warranty terms).

© 2021 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc. / 888-996-3837 / flomecmeters.com

11/2021 921977-02 Rev. G

Other manuals for G Series

2

This manual suits for next models

6

Table of contents