1.0 INTRODUCTION AND GENERAL INFORMATION

Safety first, WWW! (Who, Where and When can fly it)

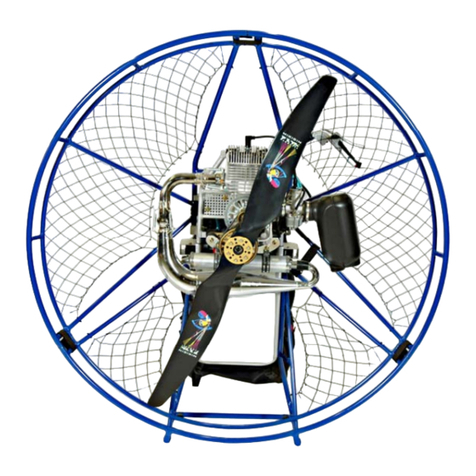

To fly with Trike is the most exciting, less expensive, safest, and most accessible form of aviation

available! However, it is still aviation, and it brings with it all the inherent potential dangers of

aviation. People can, and do, get hurt, and even killed, in any form of aviation, including to fly with

Trike. For that reason it is imperative that before flying with this Trike you must receive proper

training from qualified instructors and obtain a valid license, an then to respect all aviation deserves,

respect weather and conditions, and realize that in the end, it is the pilot himself that is fully responsible

for his own safety and the safety of fellow pilots and bystanders.

Depending on every national regulations, the flights with Trike may only be operated in authorized

areas and flights within controlled airspace usually needs a permission given by radio.

Additional requirements like a valid insurance must be fulfilled.

To fly with Trike is an extremely demanding sport that requires exceptional levels of attention,

judgment, maturity, self-discipline, and attention to detail. It is unlikely that you will be able to

participate in it safely unless you make a conscious and continual commitment to your own safety.

Due to the inherent risks in flying this or any Trike, no warranty of any kind can be made against

accidents, bodily injury, equipment failure, and/or death.

This Trike is not covered by product liability insurance. Do not start it or fly it unless you are

willing to assume all risks inherent in the sport of Powered Paragliding and all responsibility for

any property damage, injury, or death which may result from the use of this product.

Please read and be sure you thoroughly understand this Operator’s Manual before

starting or flying your XENIT PLUS. It contains information critical to the safe

operation of the Trike.

Notation used

Certain special terms (NOTE, CAUTION, WARNING) will be used throughout this manual. Their usage

is defined below.

A NOTE provides supplemental information to help clarify a point being made in the text. Generally, a

“note” is provided to help assembly, use, or maintenance of the product. Disregarding a “note” could

cause inconvenience, but would not cause damage or personal injury.

A CAUTION provides supplemental information to help clarify an area where equipment damage

could occur. Disregarding a “caution” could result in permanent and significant mechanical damage,

however personal injury is unlikely.

A WARNING provides supplemental information to help clarify an area where personal injury or death

could occur from negligence. Disregarding a warning” could result in serious injury or death.