Foley 622 User manual

- ORIGINAL INSTRUCTIONS -

622

AUTO - INDEX

SPIN / RELIEF

REEL MOWER GRINDER

Patent No. 5,321,912

6,010,394 & 6,290,581

6,685,544 & 6,699,103

SERVICE MANUAL

55013 (11-21)

2

- ORIGINAL INSTRUCTIONS -

As manufacturers of sharpening equipment, we want to conrm to you, our customers, our concern for

safety. We also want to remind you about the simple, basic, and common sense rules of safety when using

this equipment. Failure to follow these rules can result in severe injury or death to operators or bystanders.

It is essenal that everyone involved in the assembly, operaon, transport, maintenance, and storage of this

equipment be aware, concerned, prudent, and properly trained in safety. Always use proper shielding and

personal protecve equipment as specied by the manufacturer.

Our current producon machines include, as standard equipment, guards or shields for the grinding wheel,

safety signs, and operator's and service manuals. Never bypass or operate the machine with any of the

guards or safety devices removed or without the proper personal safety equipment.

Operator's Manual

Before operang this grinder, an operator must read and understand all of the informaon in the

Operator's Manual and understand all of the safety signs aached to the product. A person who has not read

or understood the Operator's Manual and safety signs is not qualied to operate the unit. Accidents oen

occur on machines that are used by someone who has not read the Operator's Manual and is not familiar

with the equipment. If you do not have an Operator's Manual or current producon safety signs, contact the

manufacturer or your dealer immediately.

The equipment is designed for one-man operaon. Never operate the equipment with anyone near, or

in contact with, any part of the grinder. Be sure no one else, including bystanders, is near you when you

operate this product.

Following these simple, basic safety rules, as well as others:

• Find and understand all safety signs in the Operator's Manual and on the equipment. This will help

minimize the possibility of accidents and increase your producvity in using this product.

• Be careful and make sure that everyone who operates the grinder knows and understands that it is a very

powerful piece of machinery, and if used improperly, serious injury or death may result.

• The nal responsibility for safety rests with the operator of this machine.

3

- ORIGINAL INSTRUCTIONS -

Safety Message......................................................................................................... 2

Safety Instrucons.................................................................................................... 3 -6

Service Data and Adjustments ................................................................................. 7 -21

Trouble Shoong ...................................................................................................... 22 -39

Parts Diagram ........................................................................................................... 40 - 71

Wiring Diagram ........................................................................................................ 72 - 73

Wiring Schemac...................................................................................................... 74

Read the Operator's Manual before operang this equipment. Keep this manual handy for ready

reference. Require all operators to read this manual carefully and to become acquainted with all

adjustments and operang procedures before aempng to operate the equipment. Replacement

manuals can be obtained from your selling dealer or the manufacturer.

The equipment you have purchased has been carefully engineered and manufactured to provide

dependable and sasfactory use. Like all mechanical products, it will require cleaning and upkeep.

Lubricate and clean the unit as specied in the Operator's Manual. Please observe all safety

informaon in this manual, the Operator's Manual and the safety decals on the equipment.

4

- ORIGINAL INSTRUCTIONS -

13. Follow

instrucons in Service Manual for lubricaon and

prevenve maintenance.

14. or

when changing the grinding wheel.

15.

Make sure the switch is OFF before plugging in the

Grinder.

16. Consult the

manual for recommended accessories. Using improper

accessories may cause risk of personal injury.

17. A guard or other part

that is damaged or will not perform its intended

funcon should be properly repaired or replaced.

18.

Do not leave grinder unl it

comes to a complete stop.

19. Read this manual

carefully. Learn its applicaon and limitaons as well

as specic potenal hazards.

20.

If safety decals become damaged or illegible for any

reason, replace immediately. Refer to replacement

parts illustraons in Service Manual for the proper

locaon and part numbers of safety decals.

21.

1. and in working order.

2.

3.

4. .

Don't use grinder in damp or wet locaons. Machine

is for indoor use only. Keep work area well it.

5. . All visitors should be

kept a safe distance from work area.

6. with padlocks or

master switches.

7. It will do the job

beer and safer if used as specied in this manual.

8. Don't force the Grinder

or an aachment to do a job for which it was not

designed.

9. Wear no loose clothing,

gloves, neckes, or jewelry which may get caught in

moving parts. Nonslip footwear is recommended.

Wear protecve hair covering to contain long hair.

Wear respirator or lter mask where appropriate.

Wear protecve gloves.

10. .

11. Make certain that the

cung unit is securely fastened with the clamps

provided before operang.

12. Keep proper foong and

balance at all mes.

5

- ORIGINAL INSTRUCTIONS -

DO

1. DO always wheels in a

manner.

2. all wheels before

mounng for possible damage.

3. against the

established maximum safe operang speed

marked on wheel.

4. for equal

and correct diameter.

5. when supplied

with wheels.

6. DO be sure is properly adjusted.

7. DO always at

least one-half of the grinding wheel.

8. DO allow to run

at operang speed, with guard in place, for at

least one minute before grinding.

9. DO always or some

type of eye protecon when grinding.

DON'T

1. DON'T use a cracked wheel or one that

or has become damaged.

2. a wheel onto the machine OR

the size of the mounng hole - if wheel won't

t the machine, get one that will.

3. DON'T ever

established for the wheel.

4. DON'T use mounng anges on which the bearing

surfaces

5. the mounng nut excessively.

6. DON'T grind on the (see

Safety Code B7.2 for excepon).

7. DON'T start the machine unl the

8. work into the wheel.

9. of a grinding

wheel whenever a grinder is started.

10. so that motor slows

noceably or work gets hot.

generated by grinding and cung operaons. Exposure to dust may cause

respiratory ailments. Use approved NIOSH or MSHA respirators, safety glasses or face shields, and protecve

clothing. Provide adequate venlaon to eliminate dust, or to maintain dust level below the Threshold Limit

Value for nuisance dust as classied by OSHA.

6

- ORIGINAL INSTRUCTIONS -

IMPORTANT GROUNDING INSTRUCTIONS

MANUAL

This is the Electrical Hazard Symbol. It indicates that

inside the

enclosure of this product. TO REDUCE THE RISK OF

FIRE OR ELECTRIC SHOCK, do not aempt to open the

enclosure or gain access to areas where you are not

instructed to do so.

7

- ORIGINAL INSTRUCTIONS -

This Service Manual is designed for technicians who have the necessary mechanical and electrical knowledge and skills

to reliably test and repair the 622 Spin/Relief Grinder. For those without the background, service can be arranged

through your local distributor.

This secon presumes that you are already familiar with the normal operaon of the grinder. If not, you should read

the Operator's Manual or do the servicing in conjuncon with someone who is familiar with its operaon.

Persons without the necessary knowledge and skills should not remove any panels or shields, or aempt any internal

troubleshoong, adjustments, or parts replacement.

If you have quesons not answered in this manual, please contact your distributor.

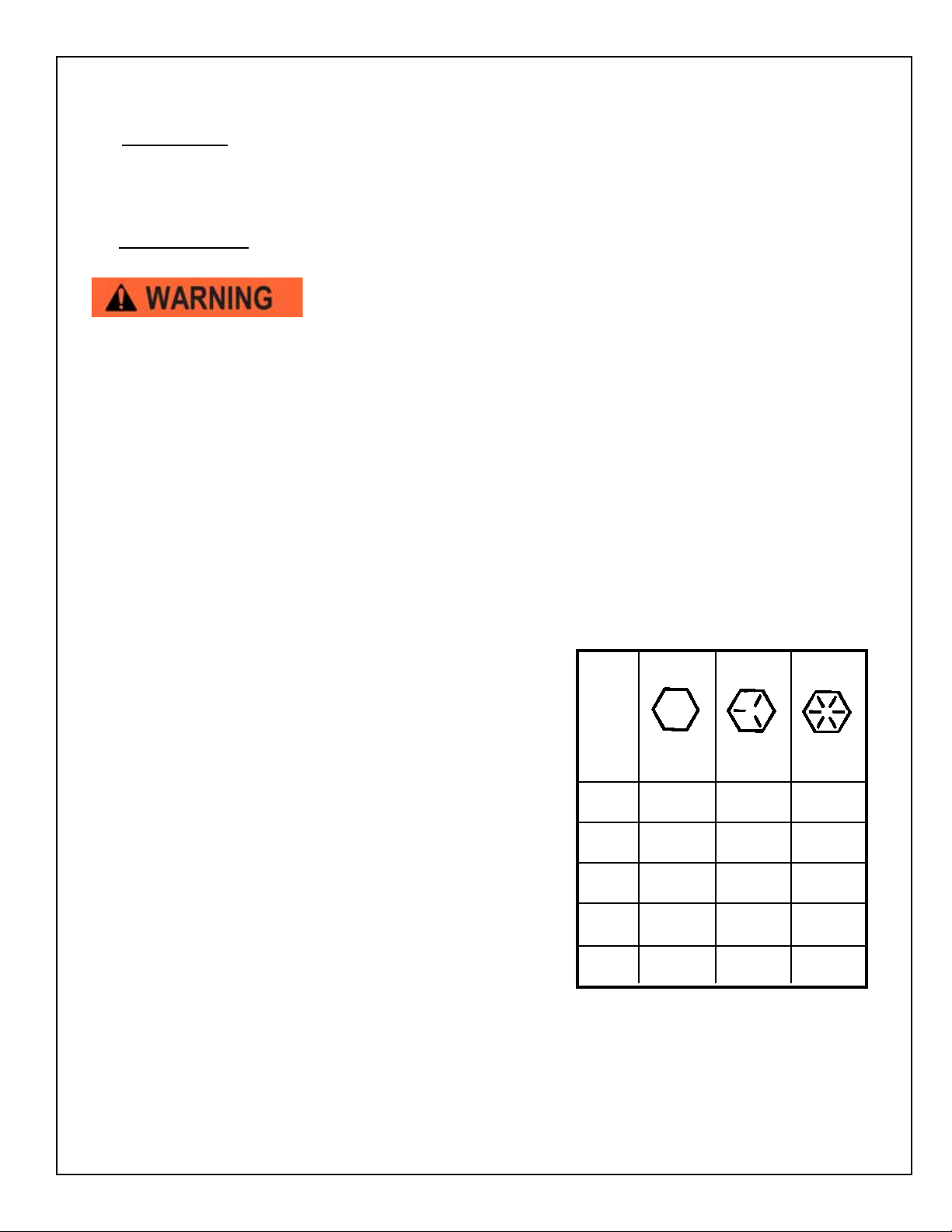

Throughout this manual we refer to torque requirements

as "rmly ghten" or the like. For more specic torque

values, refer to the informaon below.

Refer to the table at the right.

Use the Grade 2 values in the table at the right.

Use the Grade 8 values in the table at the right.

No. 6 screws: 11 in.- lbs (0.125kg - m)

No. 8 screws: 20 in. - lbs (0.23 kg - m)

No. 10 screws: 32 in. - lbs (0.37 kg - m)

6 -lbs 9 -lbs 13 -lbs

thread (0.8 kg-m) (1.25 kg-m) (1.8 kg-m)

11 -lbs 18 -lbs 28 -lbs

thread (1.5 kg-m) (2.5 kg-m) (3.9 kg-m)

19 -lbs 31 -lbs 46 -lbs

thread (2.6 kg-m) (4.3 kg-m) (6.4 kg-m)

30 -lbs 50 -lbs 75 -lbs

thread (4.1 kg-m) (6.9 kg-m) (10.4 kg-m)

45 -lbs 75 -lbs 115 -lbs

thread (6.2 kg-m) (10.4 kg-m) (15.9 kg-m)

8

- ORIGINAL INSTRUCTIONS -

DAILY MAINTENANCE IS SPECIFIED ON PAGE

7 OF THE OPERATOR'S MANUAL AND IS TO BE

PERFORMED BY THE OPERATOR.

LISTED BELOW ARE PERIODIC MAINTENANCE

ITEMS TO BE PERFORMED BY YOUR COMPANY'S

MAINTENANCE DEPARTMENT:

1. Clean the dust tray located under the grinding

wheel area. Use a vacuum or a small broom and

dust pan to clean.

2. Inspect the Poly-V belt on the grinding motor

for cracking and make any necessary adjustments

every three months.

3. Wipe o and lubricate, with never-seize, the

vercal adjustment shas every six months. Run

the arms up and down to coat the working areas of

the sha.

4. Inspect the traverse cog belt for cracking and

defects every three months. Remove any grit or

dust that may aect the funcon of the belt. Adjust

tension if necessary per procedures called out in

the adjustment secon.

5. Clean and lubricate the grinding sha and

traverse shas every 2 to 4 weeks. Follow the

procedure on the next page.

6. Lubricate grinding sha bearing with one shot

of grease once every 2 years. See FIG 2.

9

- ORIGINAL INSTRUCTIONS -

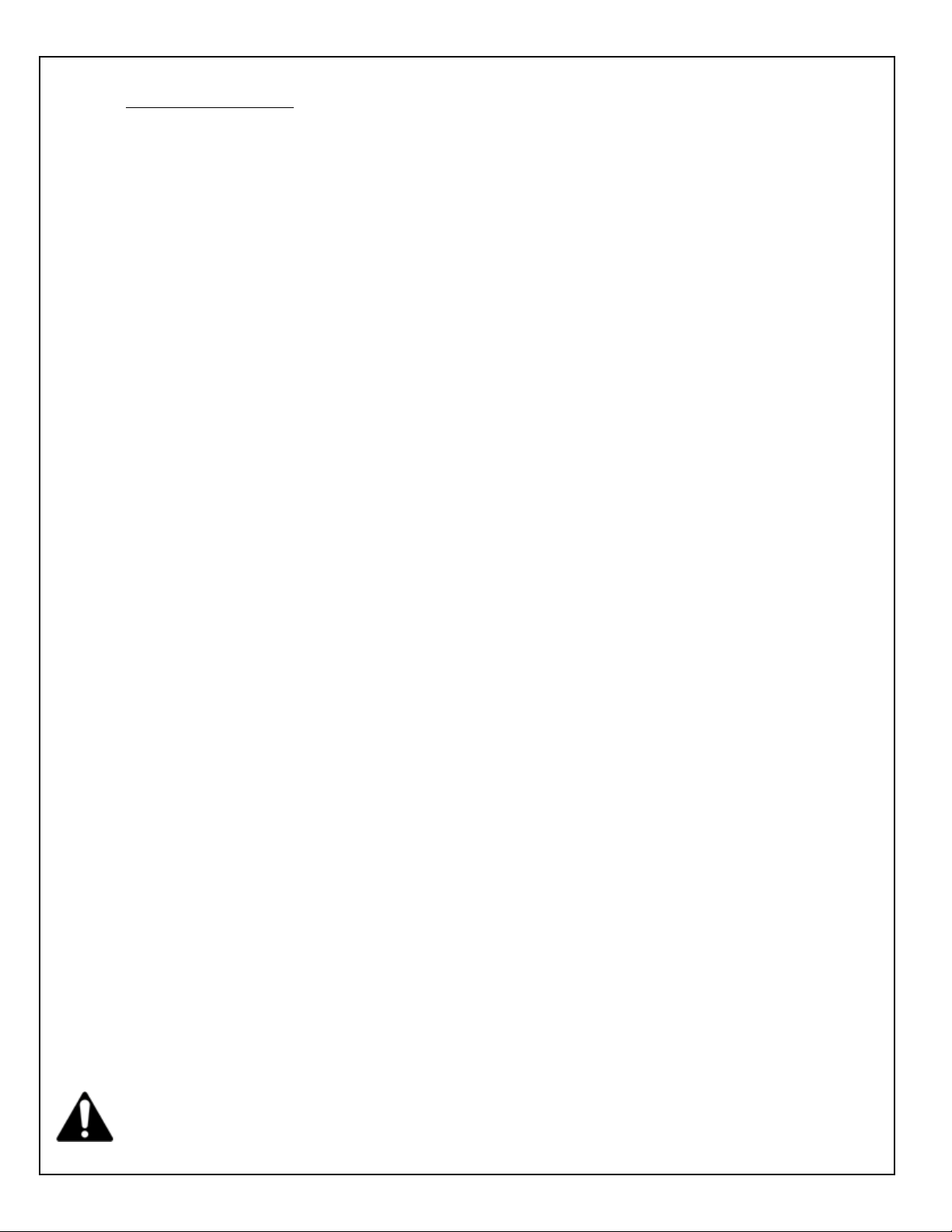

LUBRICATION

STEP 1 – Thoroughly clean all three shas.

STEP 2 – Flood spray all three shas with CRC 3-36 unl the lubricant is dripping o the shas. Do not use

Then run the grinding head assemblies back and forth through their full range

of travel. This will remove the dust and deposits from inside the wheel anges. Repeat if necessary unl

lubricaon is clear of deposits. Clean keyways located on the grinding sha with so brush.

STEP 3 – With a clean rag, wipe o the excess amount of lubricant from the shas. Run the grinding

assemblies through their range of travel and wipe the shas aer each traverse. Repeat unl the shas are

dry to the feel. This completes the lubricaon process.

IMPORTANT:

If the unit will be shut down for an extended period of me, more than four weeks, then the shas and other

appropriate parts of the unit should be ooded with lubricant and that lubricant le in place unl the unit is

brought back into service. When the unit is brought back into service the full lubricaon procedure as stated

above should be repeated.

FIG. 3

TRAVERSE

SHAFTS

GRINDING SHAFT

COG BELT

GRINDING SHAFT

BEARING

POLY-V BELT

GRINDING SHAFT

BEARING

10

- ORIGINAL INSTRUCTIONS -

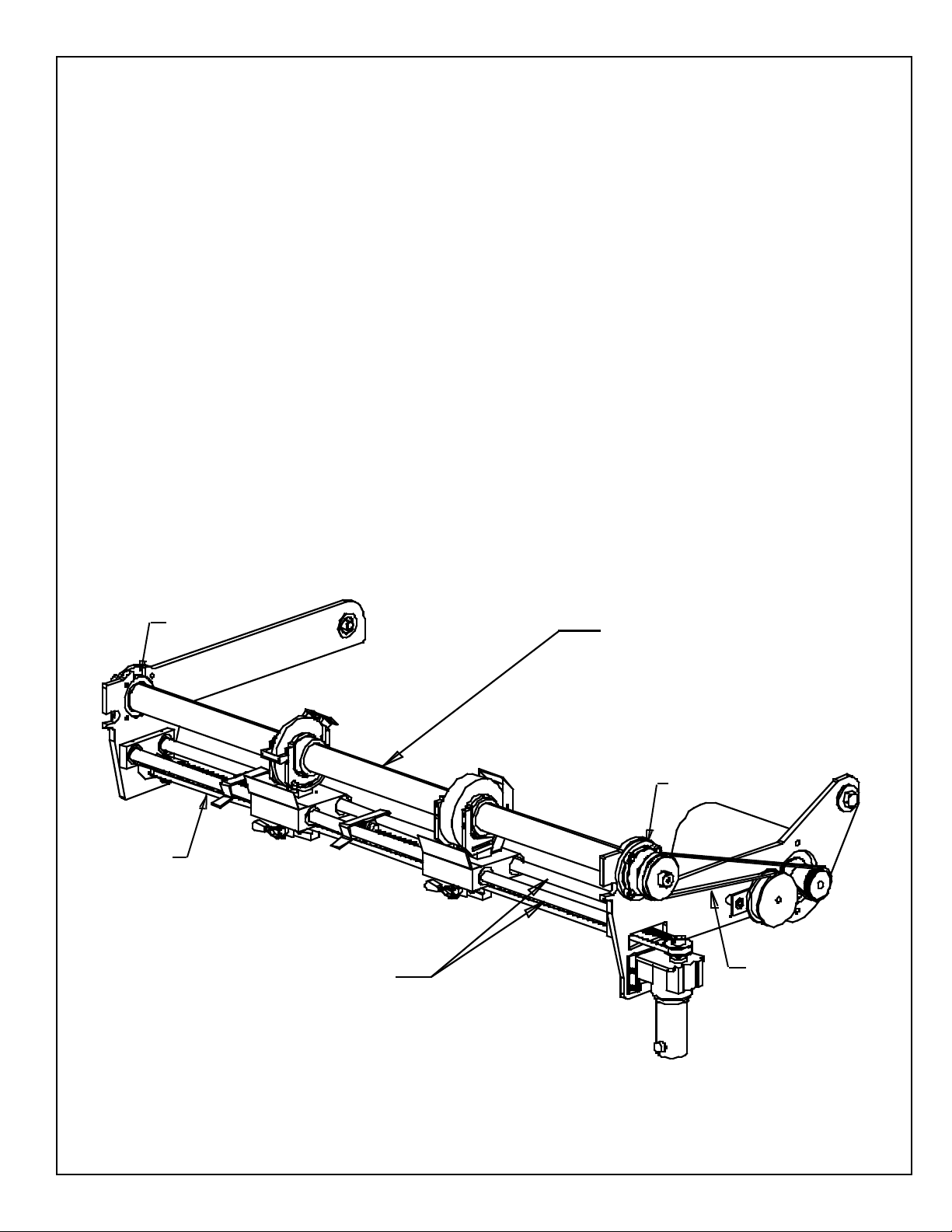

To replace the wheel lower the le side of the

grinding sha and raise the right side.

To remove the le side bearing: rst, loosen the

setscrews on the bearing collar, then remove the four

screws that hold the bearing to the le arm.

Slide the grinding wheel hub assembly(s) o the

sha, taking note of what side the nut is on. Use the

spanner wrench to remove and replace the grinding

wheel(s).

Place the grinding wheel hub assembly(s) back

on the grinding sha. Verify that the spin hub is

located between the spin drive yoke assembly before

lowering the grinding sha.

Reinstall the bearing on the le side of the grinding

sha making sure to t the pilot on the bearing into

arm. Tighten the four mounng screws, and then

ghten the setscrews to the sha.

FIG. 4

BEARING

SPIN NUT

SPIN WHEEL

SPIN FLANGE

11

- ORIGINAL INSTRUCTIONS -

To replace or inspect the grinding motor belt,

remove the right side cover panel. To remove the

belt, pull down on the tensioner pulley.

For the belt to funcon properly the grinding

sha pulley and the grinding motor pulley must

be in line with the tensioner pulley. To adjust the

pulley posion, loosen the setscrews on the pulley.

Locate the belt in the center of the idler pulley.

Measure from the arm to the edge of the belt at

the idler pulley. Adjust the two other pulleys unl

the same measurement is achieved and ghten the

pulley setscrews.

Reinstall the right side cover panel, then run

the grind motor to assure that the belt is not

misaligned. The belt will walk o the pulley if the

system is not aligned properly.

To replace the traverse belt, loosen the nuts on

the le side ulley that are used to tension the belt.

Loosen the screws holding the traverse motor and

lt the boom of the motor out, releasing any

remaining tension on the belt. On the le side

remove the nut from the boom belt tensioning

screw. This will allow the belt to be removed.

Place a new belt on the le pulley, making sure it

is seated properly in the cogged teeth, and replace

the locknut. Feed the new belt through the slot on

the right arm and place on motor pulley. Use the

motor as a lever to apply tension to the new belt.

Tighten motor screws and adjust the tension in

the belt as specied in the BELT TENSION secon.

Adjust the height of the motor pulley if necessary

so the belt is located in the center of the traverse

belt clamp.

Reinstall the le side and right side cover panels,

then test the traverse motor.

FIG. 7

FIG. 6

12

- ORIGINAL INSTRUCTIONS -

CLEANING AND MAINTENANCE GUIDELINES FOR POLYCARBONATE

WINDOWS

Wash polycarbonate windows with a mild dish washing liquid detergent and lukewarm water, using a clean

so sponge or a so cloth. Rinse well with clean water. Dry thoroughly with a moist cellulose sponge to

prevent water spots. Do not scrub or use brushes on these windows. Also, do not use butyl cellosolve in

direct sunlight.

Fresh paint splashes and grease can be removed easily before drying by rubbing lightly with a good grade

of VM&P naphtha or isopropyl alcohol. Aerward, a warm nal wash should be made, using a mild dish

washing liquid detergent soluon and ending with a thorough rinsing with clean water.

Scratches and minor abrasions can be minimized by using a mild automobile polish. Three such products

that tend to polish and ll scratches are Johnson paste Wax, Novus Plasc Polish #1 and #2, and Mirror Glaze

plasc polish (M.G. M10). It is suggested that a test be made on a corner of the polycarbonate window with

the product selected following the polish manufacturer's instrucons.

• DO NOT use abrasive or highly alkaline cleaners on the polycarbonate windows.

• Never scrape polycarbonate windows with squeegees, razor blades or other sharp instruments.

• Benzene, gasoline, acetone or carbon tetrachloride should be used on polycarbonate windows.

• DO NOT clean polycarbonate windows in hot sun or at elevated temperatures.

• Butyl cellosolve, (for removal of paints, marking pen inks, lipsck, etc.)

• The use of masking tape, adhesive tape or lint removal tools works well for liing o old weathered

paints.

• To remove labels, sckers, etc., the use of kerosene, VM&P naphtha or petroleum spirits is generally

eecve. When the solvent will not penetrate scker material, apply heat (hair dryer) to soen the

adhesive and promote removal.

13

- ORIGINAL INSTRUCTIONS -

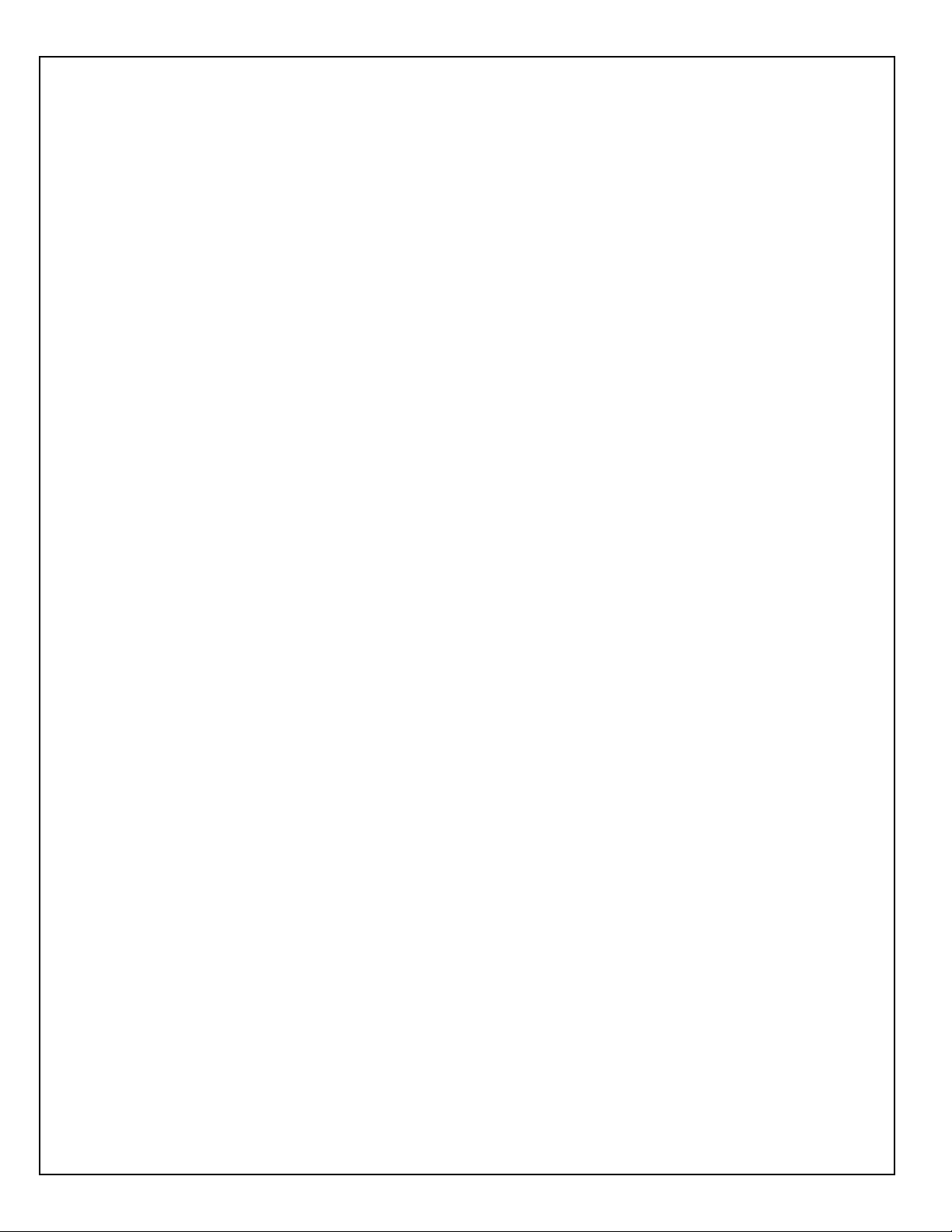

For the proximity switch to perform properly

and reverse the direcon of the grinding head

assembly, the sensor end of the prox must face

toward the head assembly that is in use, and must

be mounted such that it is located past the edge of

the prox holder.

NOTE: The light on the proximity switch acvates

when metal is approximately 3/16" [4.6 mm] from

front of proximity switch.

FIG. 9

14

- ORIGINAL INSTRUCTIONS -

If the spin drive motor is moving during operaon, or

does not move freely into posion, adjust the tension

of the 2 T-Handles. See FIG. 25.

FIG. 25

T-HANDLES

To adjust the tension on the traverse belt, ghten the

screws and nuts located at the le side of the traverse

belt. Tighten the nuts unl the compression springs

measure 3/4" [19mm]. See FIG. 26. If the springs are

not tensioned equally, uneven loading on the traverse

system may cause parts to fail.

DO NOT OVERTIGHTEN. OVERTIGHTENING COULD

DAMAGE THE BELT OR TRAVERSE DRIVE SYSTEM.

If the traverse clamp is slipping during regular

operaon it may be necessary to ghten the clamp. To

ghten, loosen the jam nut on the clamp p. Screw

the p out so there is .10" gap between the p and

the Clamp Support Block. See FIG 27. Lock in place by

ghtening the jam nut against the clamp being careful

not to move the p. Verify the distance between the

clamp p and block is sll .10". The .10" seng allows

slippage in a jam situaon and damage can occur if this

adjustment is set to narrow.

CAUTION SHOULD BE USED AS ADJUSTING THE TIP

WILL AFFECT THE SLIP LOAD AND COULD DAMAGE

THE CLAMP TIP, BELT OR TRAVERSE DRIVE SYSTEM.

FIG. 26

FIG. 27

14

- ORIGINAL INSTRUCTIONS -

ADJUSTMENTS

SPIN MOTOR ADJUSTMENT

If the spin drive motor is moving during operaon, or

does not move freely into posion, adjust the tension

of the 2 T-Handles. See FIG. 25.

FIG. 25

T-HANDLES

TRAVERSE BELT TENSION

To adjust the tension on the traverse belt, ghten the

screws and nuts located at the le side of the traverse

belt. Tighten the nuts unl the comprension springs

measure 3/4" [19mm]. See FIG. 26. If the springs are

not tensioned equally, uneven loading on the traverse

system may cause parts to fail.

DO NOT OVERTIGHTEN. OVERTIGHTENING COULD

DAMAGE THE BELT OR TRAVERSE DRIVE SYSTEM.

TRAVERSE CLAMP FORCE

If the traverse clamp is slipping during regular

operaon it may be necessary to ghten the clamp. To

ghten, loosen the jam nut on the clamp p. Screw

the p out so there is .10" gap between the p and

the Clamp Support Block. See FIG 27. Lock in place by

ghtening the jam nut against the clamp being careful

not to move the p. Verify the distance between the

clamp p and block is sll .10". The .10" seng allows

slippage in a jam situaon and damage can occur if this

adjustment is set to narrow.

CAUTION SHOULD BE USED AS ADJUSTING THE TIP

WILL AFFECT THE SLIP LOAD AND COULD DAMAGE

THE CLAMP TIP, BELT OR TRAVERSE DRIVE SYSTEM.

FIG. 26

FIG. 27

14

- ORIGINAL INSTRUCTIONS -

ADJUSTMENTS

SPIN MOTOR ADJUSTMENT

If the spin drive motor is moving during operaon, or

does not move freely into posion, adjust the tension

of the 2 T-Handles. See FIG. 25.

FIG. 25

T-HANDLES

TRAVERSE BELT TENSION

To adjust the tension on the traverse belt, ghten the

screws and nuts located at the le side of the traverse

belt. Tighten the nuts unl the comprension springs

measure 3/4" [19mm]. See FIG. 26. If the springs are

not tensioned equally, uneven loading on the traverse

system may cause parts to fail.

DO NOT OVERTIGHTEN. OVERTIGHTENING COULD

DAMAGE THE BELT OR TRAVERSE DRIVE SYSTEM.

TRAVERSE CLAMP FORCE

If the traverse clamp is slipping during regular

operaon it may be necessary to ghten the clamp. To

ghten, loosen the jam nut on the clamp p. Screw

the p out so there is .10" gap between the p and

the Clamp Support Block. See FIG 27. Lock in place by

ghtening the jam nut against the clamp being careful

not to move the p. Verify the distance between the

clamp p and block is sll .10". The .10" seng allows

slippage in a jam situaon and damage can occur if this

adjustment is set to narrow.

CAUTION SHOULD BE USED AS ADJUSTING THE TIP

WILL AFFECT THE SLIP LOAD AND COULD DAMAGE

THE CLAMP TIP, BELT OR TRAVERSE DRIVE SYSTEM.

FIG. 26

FIG. 27

14

- ORIGINAL INSTRUCTIONS -

ADJUSTMENTS

SPIN MOTOR ADJUSTMENT

If the spin drive motor is moving during operaon, or

does not move freely into posion, adjust the tension

of the 2 T-Handles. See FIG. 25.

FIG. 25

T-HANDLES

TRAVERSE BELT TENSION

To adjust the tension on the traverse belt, ghten the

screws and nuts located at the le side of the traverse

belt. Tighten the nuts unl the comprension springs

measure 3/4" [19mm]. See FIG. 26. If the springs are

not tensioned equally, uneven loading on the traverse

system may cause parts to fail.

DO NOT OVERTIGHTEN. OVERTIGHTENING COULD

DAMAGE THE BELT OR TRAVERSE DRIVE SYSTEM.

TRAVERSE CLAMP FORCE

If the traverse clamp is slipping during regular

operaon it may be necessary to ghten the clamp. To

ghten, loosen the jam nut on the clamp p. Screw

the p out so there is .10" gap between the p and

the Clamp Support Block. See FIG 27. Lock in place by

ghtening the jam nut against the clamp being careful

not to move the p. Verify the distance between the

clamp p and block is sll .10". The .10" seng allows

slippage in a jam situaon and damage can occur if this

adjustment is set to narrow.

CAUTION SHOULD BE USED AS ADJUSTING THE TIP

WILL AFFECT THE SLIP LOAD AND COULD DAMAGE

THE CLAMP TIP, BELT OR TRAVERSE DRIVE SYSTEM.

FIG. 26

FIG. 27

15

- ORIGINAL INSTRUCTIONS -

FIG. 23

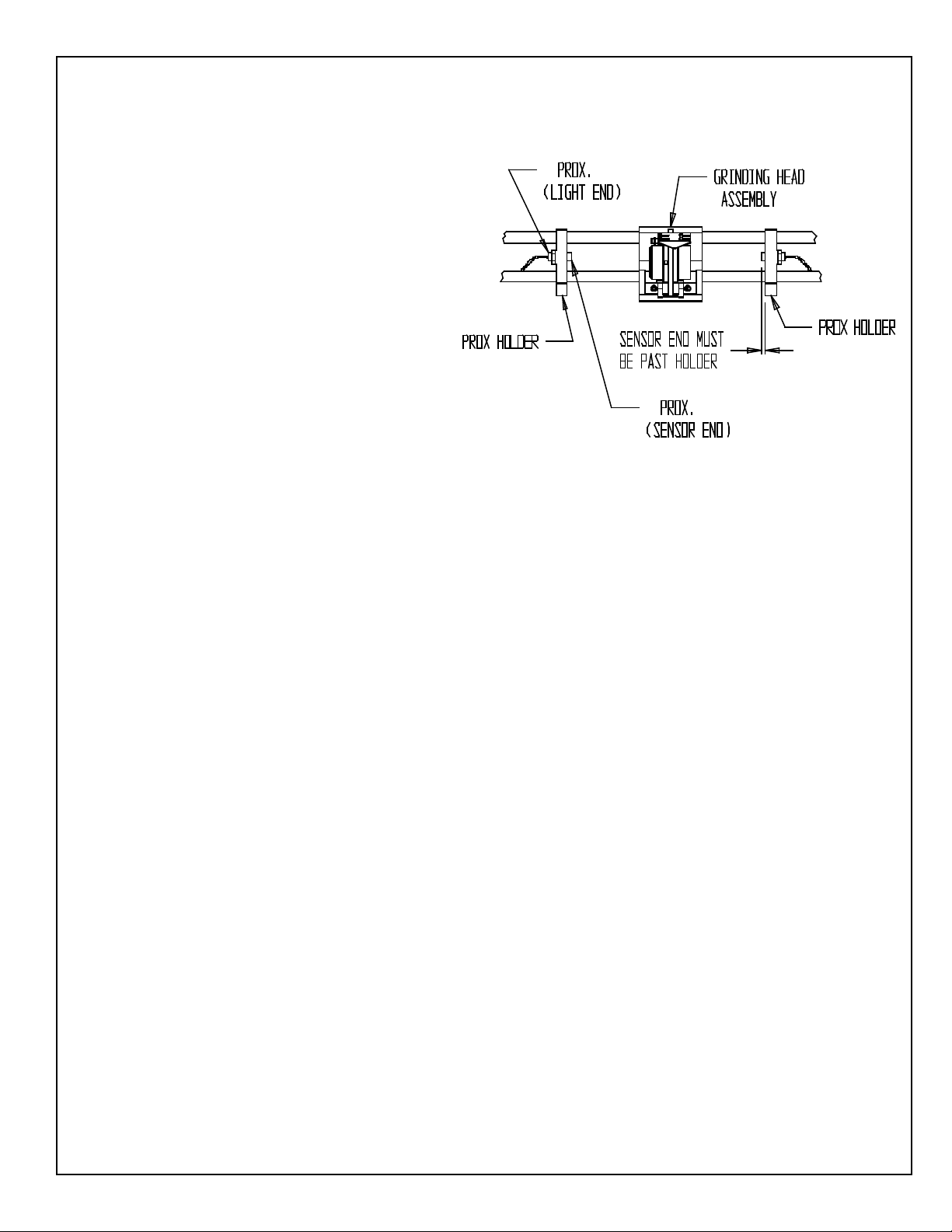

The Traverse Drive Control Board has nine

potenometers and four switches as shown

on drawing 6524511 which is included. These

potenometers and switches have been set at the

factory to the posions shown on the drawing.

Also see FIG. 23 and FIG. 24.

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion. This posion

turns the Acceleraon/Deceleraon o for this

applicaon.

The maximum speed potenometer is preset to

posion for 90 Volts DC output to the traverse motor

at terminals A1 and A2.

The IR Comp control is preset to 3:00 posion. Never

adjust past the 4:30 posion.

Regulaon of the traverse motor may be improved by

slight adjustment of the IR COMP trim pot clockwise

from its factory set posion. Overcompensaon

causes the motor to oscillate or to increase speed

when fully loaded. If you reach such a point, turn

the IR COMP trim pot counterclockwise unl the

symptoms just disappear.

The Reverse Torque seng determines the maximum

current limit for driving the motor in the reverse

direcon. The potenometer is preset to the 10:30

posion. It should not require adjustment.

The Forward Torque seng determines the

maximum current limit for driving the motor in the

forward direcon. The potenometer is preset to

the 10:30 posion. It should not require adjustment.

This motor control board has a potenometer which

must be set for 50 HZ or 60 HZ operaon. For 60 HZ

set to 3:00 posion. For 50 HZ set to 9:00 posion.

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion.

The tach potenometer is not used in this

applicaon. It should be a the factory seng of 8:30.

This switch is factory preset to the 90 posion for a

90 VDC motor..

This switch is factory preset to the ARM posion.

The lower control board has two switches. Both

switches are factory preset to 115 for 115 VAC

operaon.

Potenometer

Clock Orientaon

Terminal ends (Feet) are always at the 6:00 posion,

no maer how the potenometer is orientated on the board.

FIG. 24

15

- ORIGINAL INSTRUCTIONS -

CONTROL BOARD POTENTIOMETER ADJUSTMENTS

FIG. 23

TRAVERSE DRIVE CONTROL BOARD (TDC)

The Traverse Drive Control Board has nine

potenometers and four switches as shown

on drawing 6524511 which is included. These

potenometers and switches have been set at the

factory to the posions shown on the drawing.

Also see FIG. 23 and FIG. 24.

Fwd Accel & Rev Accel---FWD ACC & REV ACC

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion. This posion

turns the Acceleraon/Deceleraon o for this

applicaon.

Maximum Speed---MAX SPD

The maximum speed potenometer is preset to

posion for 90 Volts DC output to the traverse motor

at terminals A1 and A2.

IR Compensaon---IR COMP

The IR Comp control is preset to 3:00 posion. Never

adjust past the 4:30 posion.

Regulaon of the traverse motor may be improved by

slight adjustment of the IR COMP trim pot clockwise

from its factory set posion. Overcompensaon

causes the motor to oscillate or to increase speed

when fully loaded. If you reach such a point, turn

the IR COMP trim pot counterclockwise unl the

symptoms just disappear.

Rev Torque---REV TQ

The Reverse Torque seng determines the maximum

current limit for driving the motor in the reverse

direcon. The potenometer is preset to the 10:30

posion. It should not require adjustment.

Fwd Torque---FWD TQ

The Forward Torque seng determines the

maximum current limit for driving the motor in the

forward direcon. The potenometer is preset to

the 10:30 posion. It should not require adjustment.

Deadband---DB

This motor control board has a potenometer which

must be set for 50 HZ or 60 HZ operaon. For 60 HZ

set to 3:00 posion. For 50 HZ set to 9:00 posion.

Minimum Speed---MIN SPD

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion.

Tach---TACH

The tach potenometer is not used in this

applicaon. It should be a the factory seng of 8:30.

Armature Switch---ARMATURE 90-180

This switch is factory preset to the 90 posion for a

90 VDC motor..

Feedback Switch--- FEEDBACK ARM-TACH

This switch is factory preset to the ARM posion.

The lower control board has two switches. Both

switches are factory preset to 115 for 115 VAC

operaon.

Potenometer

Clock Orientaon

Terminal ends (Feet) are always at the 6:00 posion,

no maer how the potenometer is orientated on the board.

FIG. 24

15

- ORIGINAL INSTRUCTIONS -

CONTROL BOARD POTENTIOMETER ADJUSTMENTS

FIG. 23

TRAVERSE DRIVE CONTROL BOARD (TDC)

The Traverse Drive Control Board has nine

potenometers and four switches as shown

on drawing 6524511 which is included. These

potenometers and switches have been set at the

factory to the posions shown on the drawing.

Also see FIG. 23 and FIG. 24.

Fwd Accel & Rev Accel---FWD ACC & REV ACC

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion. This posion

turns the Acceleraon/Deceleraon o for this

applicaon.

Maximum Speed---MAX SPD

The maximum speed potenometer is preset to

posion for 90 Volts DC output to the traverse motor

at terminals A1 and A2.

IR Compensaon---IR COMP

The IR Comp control is preset to 3:00 posion. Never

adjust past the 4:30 posion.

Regulaon of the traverse motor may be improved by

slight adjustment of the IR COMP trim pot clockwise

from its factory set posion. Overcompensaon

causes the motor to oscillate or to increase speed

when fully loaded. If you reach such a point, turn

the IR COMP trim pot counterclockwise unl the

symptoms just disappear.

Rev Torque---REV TQ

The Reverse Torque seng determines the maximum

current limit for driving the motor in the reverse

direcon. The potenometer is preset to the 10:30

posion. It should not require adjustment.

Fwd Torque---FWD TQ

The Forward Torque seng determines the

maximum current limit for driving the motor in the

forward direcon. The potenometer is preset to

the 10:30 posion. It should not require adjustment.

Deadband---DB

This motor control board has a potenometer which

must be set for 50 HZ or 60 HZ operaon. For 60 HZ

set to 3:00 posion. For 50 HZ set to 9:00 posion.

Minimum Speed---MIN SPD

The potenometer is factory preset to the minimum

full counterclockwise 8:30 posion.

Tach---TACH

The tach potenometer is not used in this

applicaon. It should be a the factory seng of 8:30.

Armature Switch---ARMATURE 90-180

This switch is factory preset to the 90 posion for a

90 VDC motor..

Feedback Switch--- FEEDBACK ARM-TACH

This switch is factory preset to the ARM posion.

The lower control board has two switches. Both

switches are factory preset to 115 for 115 VAC

operaon.

Potenometer

Clock Orientaon

Terminal ends (Feet) are always at the 6:00 posion,

no maer how the potenometer is orientated on the board.

FIG. 24

16

- ORIGINAL INSTRUCTIONS -

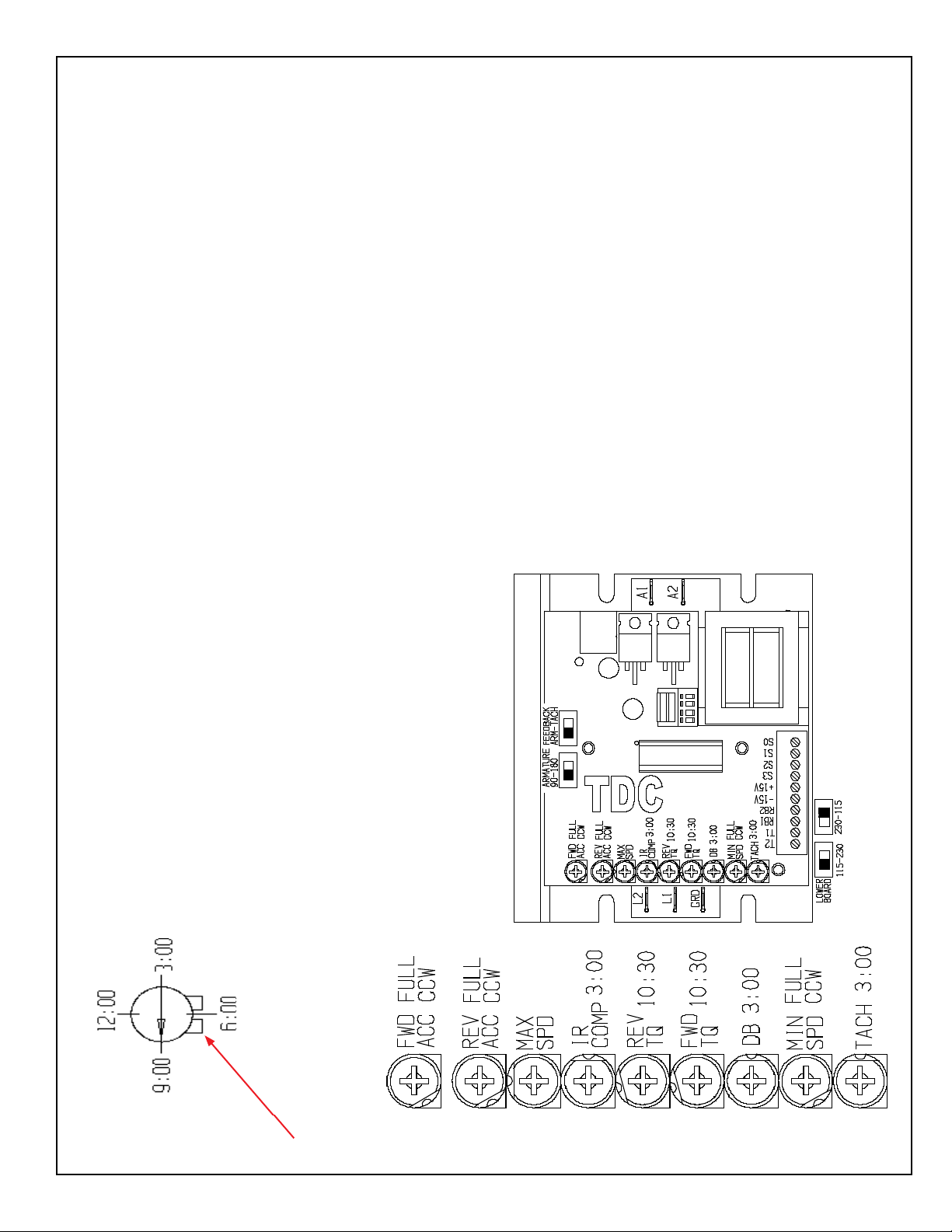

FIG. 18

SPIN TORQUE POT

(TORQ) 2:00

IR COMP

POT

9:00

IDLE TORQUE

POT (ITP)

10:00

RELIEF SPEED

POT (SPEED) 12:00

SWITCH 1

SET TO OFF

DELAY SET

TO 1

Potenometer Clock

Orientaon

SPIN DRIVE CONTROL BOARD (SDC)

The Spin Drive Control Board has four potenometers, two switches and one dial as shown on FIG. 17. These

potenometers,switches and dial have been set at the factory to the posions shown on FIG. 17.

I

The Spin Torque Potenometer (STP) and the Spin Speed Pot (SSP) interact with each other. The (STP) is

located on the spin board as remote torque preset at 2:00 for torque seng. See FIG. 17. The (SSP) is located

on the control panel and is for spin speed adjustment.

Spin Torque Pot (STP) controls maximum torque allowable in the spin grinding cycle only. This should never

be adjusted past the 3:00 posion. If the reel does not turn, check that the reel is free turning by hand

spinning with the power OFF and the spin drive disconnected.

The Spin Speed Pot (SSP) controls reel spin speed, adjust as required. This controls the spin drive speed for

spinning the reel.

The IR Compensaon Pot is factory set at 9:00. Regulaon of the spin or relief grind spin motor

may be improved by a slight adjustment of the IR COMP Pot clockwise from its factory-set posion.

Overcompensaon causes the motor to oscillate or to increase speed when fully loaded. If you reach such a

point, turn the IR COMP Pot counterclockwise unl symptoms just disappear.

17

- ORIGINAL INSTRUCTIONS -

This Electrical Troubleshoong secon is designed for technicians who have the necessary electrical

knowledge and skills to reliably test and repair the ACCU-Touch electrical system. For those without that

background, service can be arranged through your local distributor.

This manual presumes that you are already familiar with the normal operaon of the grinder. If not, you

should read the Operator's Manual, or do the servicing in conjuncon with someone who is familiar with its

operaon.

Persons without the necessary knowledge and skills should not remove the control box cover or aempt any

internal troubleshoong, adjustments, or parts replacement.

If you have any queson not answered in this manual, please call your distributor. They will contact the

manufacturer if necessary.

All wires on the ACCU-Master have a wire label at each end for assembly and troubleshoong. The wire

label has a code which tells you wiring informaon. The rst set of two or three numbers are the Foley wire

number. The next group of leers or numbers are the code for the component to which the wire aaches.

Example: RT1 for Relay Terminal 1. The last set of numbers or leers is the name of the terminal on the

component to which the wire aaches.

To insert or remove a wire from the terminal block, insert a small

screw driver into the square hole. Then insert or remove wire

from the round hole. Remove screwdriver to lock the wire in

place.

Note the square hole can also be used when checking for voltages.

The probe p of the mulmeter can be inserted into the square

hole to take readings.

FIG. 28

18

18

4

12

91

13

5

8

7

10

14

4

32

11

6

- ORIGINAL INSTRUCTIONS -

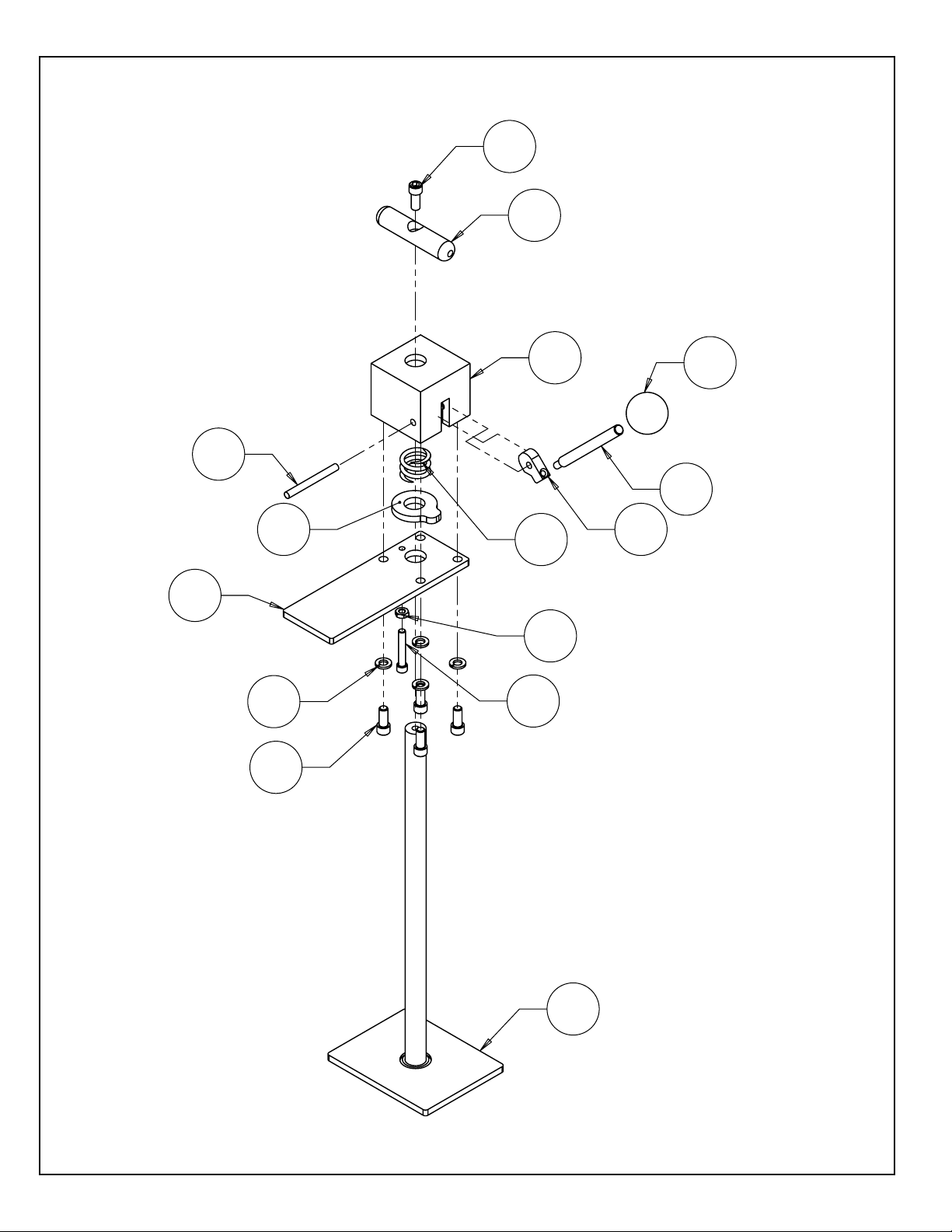

6339541 REAR CLAMP ASSEMBLY

- ORIGINAL INSTRUCTIONS -

19

- ORIGINAL INSTRUCTIONS -

1..................... 09351......................... KNOB - BALL 1.18 OD x 3/8-16F (B27)

2..................... B252431..................... 1/4-28 x 1.5 SOCKET HEAD CAP SCREW FULL THREAD

3..................... K311501..................... 5/16 LOCKWASHER SPLIT

4..................... B311211..................... 5/16-18 x 3/4 SOCKET HEAD CAP SCREW

5..................... H252807 .................... PIN - DRIV LOC .25 D x 1.75 LG

6..................... J252100 ..................... JAM NUT 1/4-28

7..................... 3706207..................... COMPR SPRING .84 ID X .88 LG

8..................... 6339160..................... CLAMP BAR

9..................... 6339161..................... CLAMP HOUSING

10................... 6339163..................... CLAMP RING

11................... 6339164..................... LEVER HANDLE

12................... 6339165..................... BASE HANDLE

13................... 6339212..................... CAM LOCK

14................... 6339540..................... REAR CLAMP WELDMENT

20

20

3

4

10

10

18

18

26

26

39

43

55

63

60

27

27

57

66

8

66

25

4

13

20

16

26

12

17

26

30

44

46

47

48

58

61

62

4

24

25

42

52

41

18

59

45

22

2

23

4

33

15

1

23

14

5

21

24

25 31

32

3437

38

50

54

5

25

36

28

35

51

27 9

11

53

28 35

28

27

19

53

64

65

67

23

15

23

67

56

3

18

4

33

45

- ORIGINAL INSTRUCTIONS -

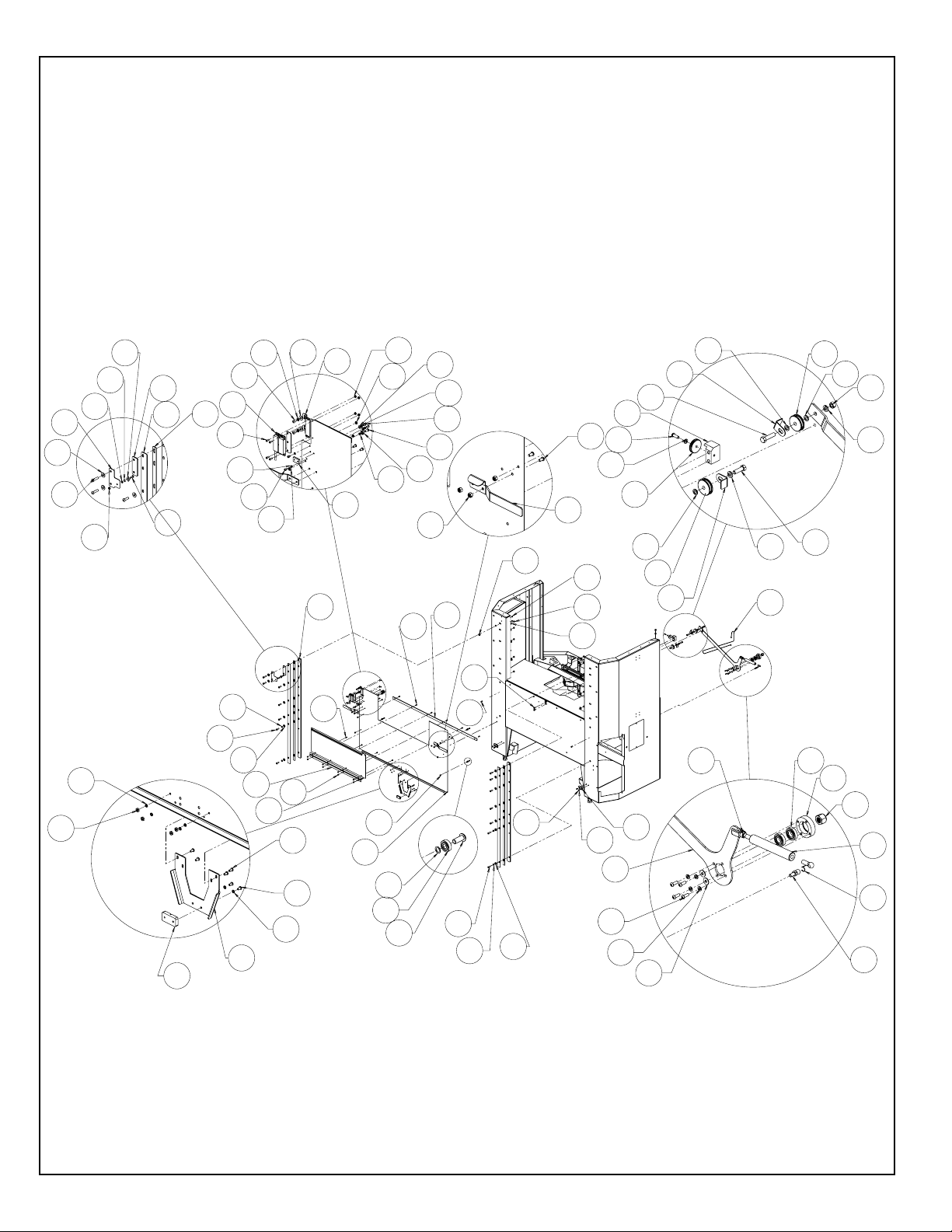

6339545 REAR GUARD DOOR ASSY.

- ORIGINAL INSTRUCTIONS -

Popular Lawn Mower manuals by other brands

Gude

Gude Big Wheeler 560 MEGA Translation of the original instructions

Country Clipper

Country Clipper 1800M Safety instructions and operation manual

SaMASZ

SaMASZ KDTC 260 Operator's manual

VITO GARDEN

VITO GARDEN VIMR1400 instruction manual

McCulloch

McCulloch M55H53HW instruction manual

Husqvarna

Husqvarna TC 242 Euro instruction manual