Forest CKS User manual

78

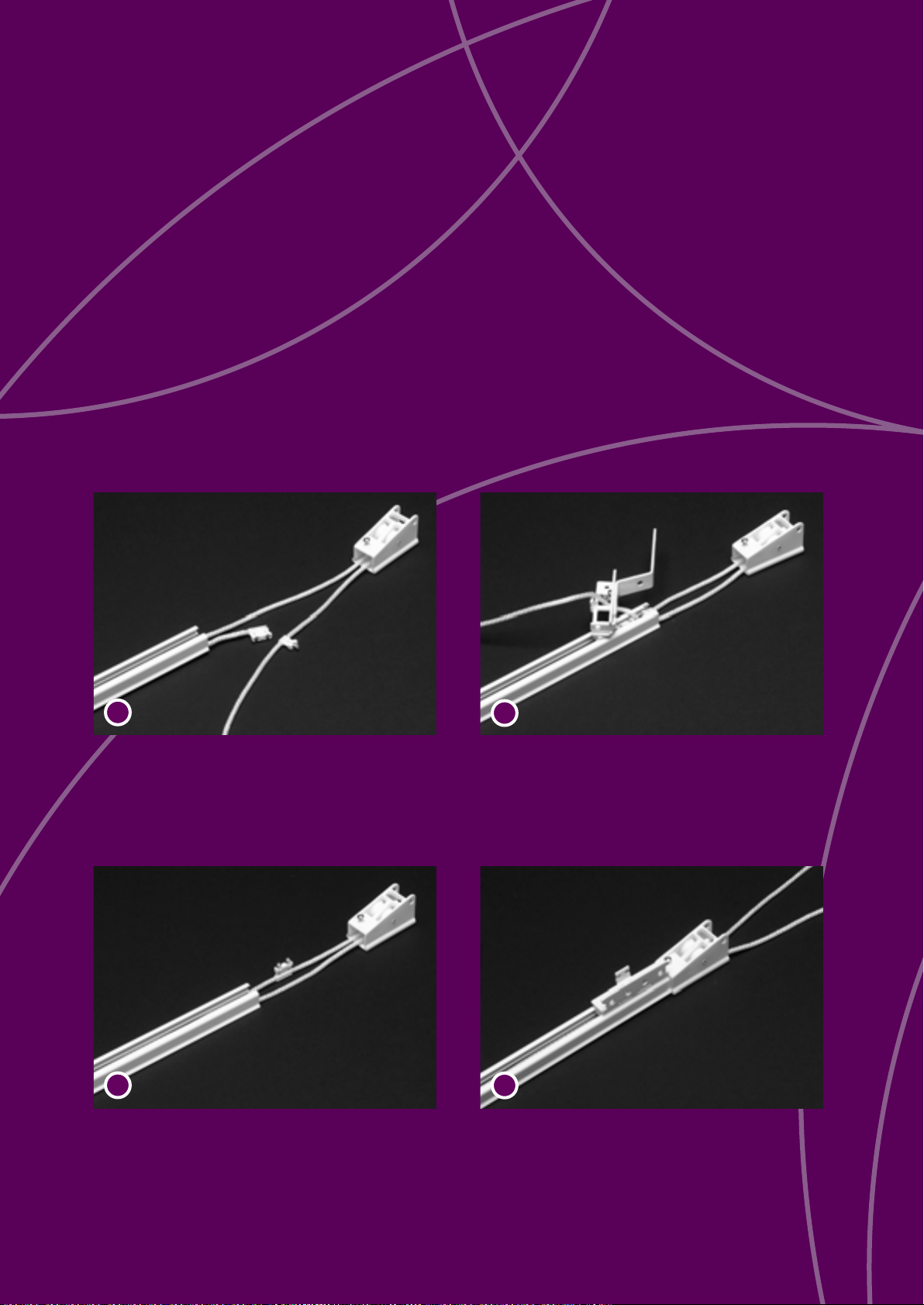

Determine the cord length by pulling the cord. Pull at

the end to reduce the drop height, pull at the loop to

increase the drop height. Screw the half cord connector

tight to position the cord drop height (with CCS®:

the second cord connector in the double construction).

If necessary, cut the cord by heating it and make a knot

at the end of the cord. Tight this on the extension in

the middle of the master carrier overlap. This creates

a strong construction.

56

By pulling the cord through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

Ensure that the cord runs behind the metal pin in

the pulley. This avoids slack in the mechanism during

operation.

CKS®& CCS®Assemblage

Tips & Suggestions:

• The maximum length for cording / chaining CCS®is as follow:

6,10 mtr (20 Ft.) and for CKS®is 6 mtr (19.7 Ft.).

• The above sizes are without the pulleys! With pulleys, the sizes are as follow:

centredraw one-way draw

CCS®6,18 mtr (20.27’) 6,17 mtr (20.24’)

CKS®6,08 mtr (20’) 6,08 mtr. (20’)

Fix one cord connector onto the end of the cord

(CCS®facing outside, CKS®to the middle of the track).

Slide the half cord connector on the other end of the

cord (with CCS®, use a normal CCS cord connector),

but do not screw it.

Slide the master carrier, together with the two cord

connectors into the cord channel of the track.

The cord is lifting out of the track, through the first

gap of the master carrier overlap.

Fix the second cord connector on the opposite cord,

(CCS®facing outside, CKS®towards the middle of the

track).

Slide the master carrier underlap, together with the cord

connector into the cord channel of the track and fix the

second pulley onto the track.

1

34

CCS®& CKS®Assembly – cord adjustability.

Instructions for assembling CCS®& CKS®, with cord adjustability.

This application can be made for CCS®, as well for CKS®. The advantage is that the requested drop height can be deter-

mined at a later stage. This feature makes the system very suitable for pre-assembling. This application is also possible

for one-way draw. Start, repeating the first two steps of the instructions with cord and continue with the steps below.

Necessary items: Articlenumber:

CCS-track 30010.. ……

Nylon cord 1030401000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

CKS Cord Connector 3030301000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

Nylon cord 1030401000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

CKS Cord Connector 1530301000

CKS Cord Connector (half) 1530311000

Drill with bit 1

Lighter (for heathen the nylon cord)

2

03-2006

assemblageCKSCCSEng_210306 21-03-2006 13:47 Page 4

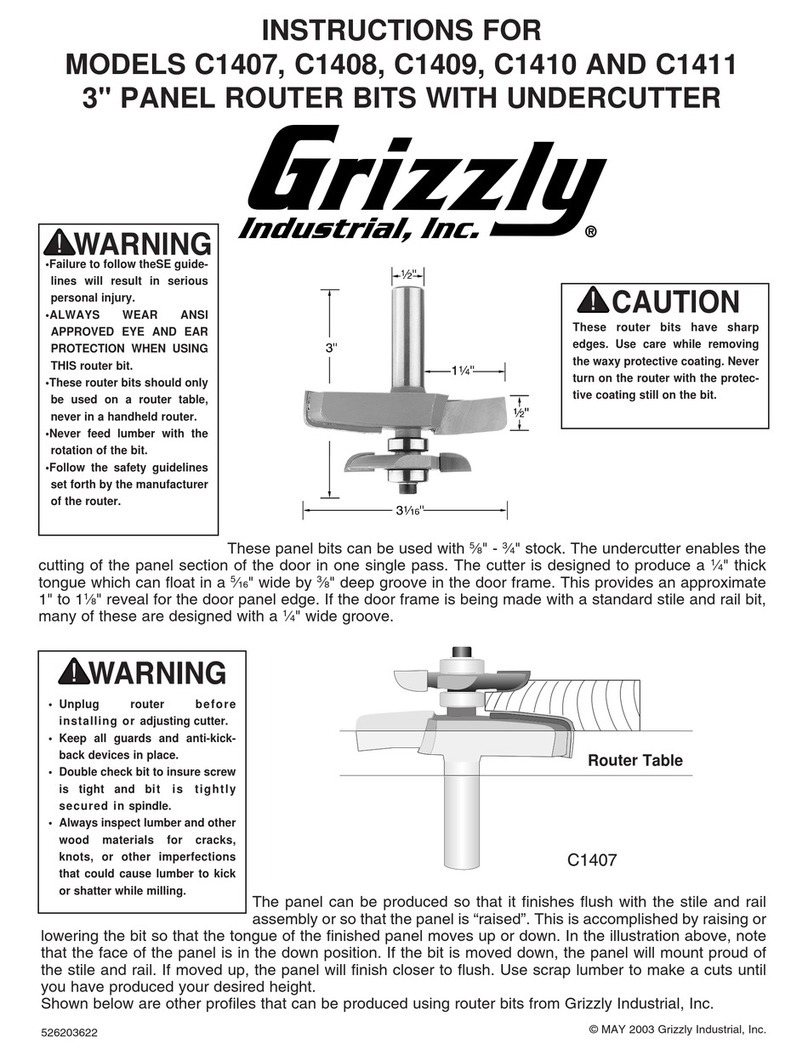

Pull one end of the cord through the holes of the first

pulley and slide the pulley over the track, like picture

shows. With one way draw of CCS®, the Small Pulley

has to be used.

Fix the pulley onto the track and continue next steps

on the other side of the track.

Fix the cord half into the cord connector. Ensure, with

CCS®that the gap of the cord connector is facing

outwards the track and with CKS®, the gap is facing

towards the middle of the track. The fixing is easy by

making a slide movement of the cord trough the gap

of the cord connector.

Pull the other end of the cord through the second

pulley and connect it into the other side of the first

cord connector.

12

34

CCS®& CKS®- Assemblage - cord

Instructions for assembling CCS®& CKS®center- and one-way draw, with cord.

Necessary items: Articlenumber:

CCS-track 30010.. ……

Nylon cord 1030401000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

CKS Cord Connector 3030301000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

Nylon cord 1030401000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

CKS Cord Connector 1530301000

Drill with bit 1

Lighter (for heathen the nylon cord)

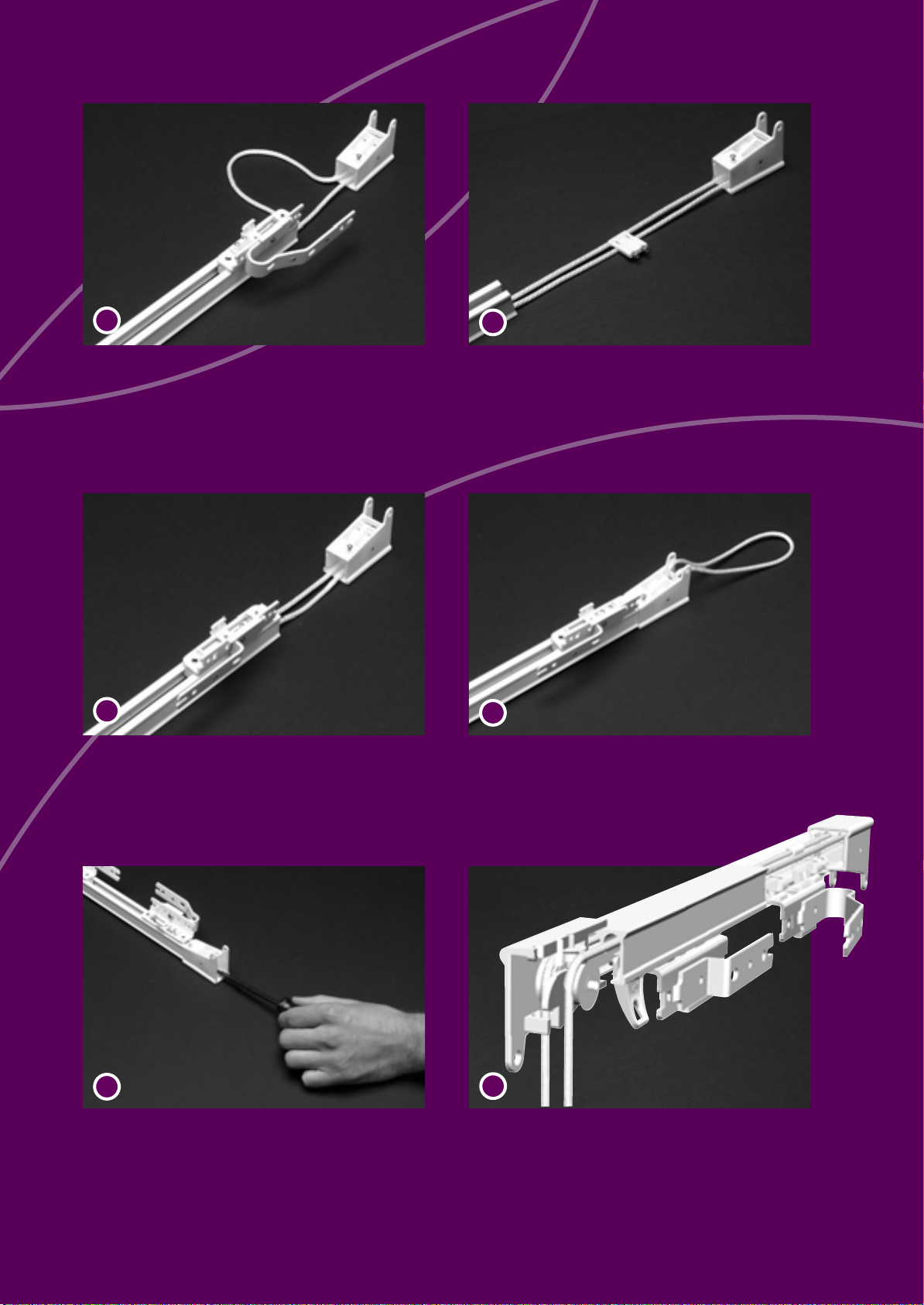

By pulling the cord, the side of operation can be deter-

mined. Slide the master carriers wide from each other

and screw the cord connectors tight. Now, the system

is balanced.

Ensure that the cord runs behind the metal pin in

the pulley. This avoids slack in the mechanism during

operation.

78

Slide the master carrier overlap, together with the cord

connector into the cord channel of the track.

Fix the second cord connector on the opposite cord,

(CCS®facing outside, CKS®to the middle of the track).

56

9

By pulling the cord through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

Slide this construction into the cord channels of the

track, against the first pulley. Leave seven balls out

of the cord channel, lifting up through the master

carrier. Now, determine side of operation.

Slide the second pulley onto the track (don’t screw it)

and mark the first ball on the opposite chain beside the

pulley. This must be done on the other side of the side

of operation! Take off the pulley and count eight balls

(with CCS®: nine balls) from the marked one. Cut the

chain after the ninth ball.

Fix the master carrier overlap on the chain by following

exactly the same procedure as described above.

Slide the master carriers wide from each other to check

that the system is balanced. For a solid construction,

use a tie rip on the extension of the master carrier.

By pulling the chain through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

1

34

Slide the master carrier underlap, together with the

second cord connector into the cord channel of the

track and fix the second pulley onto the track. Use the

screwdriver.

CCS®& CKS®Assembly - chain.

Instructions for assembling CCS®& CKS®, center- and one-way draw, with chain.

The system with chain is recommended in situations with one or more curves in the track. Steps 1 and 2 of the cord

instructions can be followed. Read ‘chain’ instead of cord.

On this page, the difference in assembling will be explained.

Necessary items: Articlenumber:

CCS-track 30010.. ……

BS Chain 4.5 x 6 3535501000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

BS Chain 4.5 x 6 3535501000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

Drill with bit 1

Lighter (for heathen the nylon cord)

Determining track-length: CKS®minus 8 cm (3,2" for

center closing and one-way draw), CCS®minus 8 cm

(center closing) and minus 6,5 cm (one-way draw).

Determining cord-length: 2 times track length + 2 times

the desired drop height of the cord. Cut the nylon cord

by heating it with the lighter.

2

Remove the metal pins inside the both pulleys.

Pull the chain trough the second pulley and cross the

two ends of the chain through the master carrier under-

lap (overlap, when it’s a one-way draw). Leave two

balls space after the extension of the master carrier

and glue the last balls onto each other.

10

assemblageCKSCCSEng_210306 21-03-2006 13:47 Page 1

Pull one end of the cord through the holes of the first

pulley and slide the pulley over the track, like picture

shows. With one way draw of CCS®, the Small Pulley

has to be used.

Fix the pulley onto the track and continue next steps

on the other side of the track.

Fix the cord half into the cord connector. Ensure, with

CCS®that the gap of the cord connector is facing

outwards the track and with CKS®, the gap is facing

towards the middle of the track. The fixing is easy by

making a slide movement of the cord trough the gap

of the cord connector.

Pull the other end of the cord through the second

pulley and connect it into the other side of the first

cord connector.

12

34

CCS®& CKS®- Assemblage - cord

Instructions for assembling CCS®& CKS®center- and one-way draw, with cord.

Necessary items: Articlenumber:

CCS-track 30010.. ……

Nylon cord 1030401000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

CKS Cord Connector 3030301000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

Nylon cord 1030401000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

CKS Cord Connector 1530301000

Drill with bit 1

Lighter (for heathen the nylon cord)

By pulling the cord, the side of operation can be deter-

mined. Slide the master carriers wide from each other

and screw the cord connectors tight. Now, the system

is balanced.

Ensure that the cord runs behind the metal pin in

the pulley. This avoids slack in the mechanism during

operation.

78

Slide the master carrier overlap, together with the cord

connector into the cord channel of the track.

Fix the second cord connector on the opposite cord,

(CCS®facing outside, CKS®to the middle of the track).

56

9

By pulling the cord through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

Slide this construction into the cord channels of the

track, against the first pulley. Leave seven balls out

of the cord channel, lifting up through the master

carrier. Now, determine side of operation.

Slide the second pulley onto the track (don’t screw it)

and mark the first ball on the opposite chain beside the

pulley. This must be done on the other side of the side

of operation! Take off the pulley and count eight balls

(with CCS®: nine balls) from the marked one. Cut the

chain after the ninth ball.

Fix the master carrier overlap on the chain by following

exactly the same procedure as described above.

Slide the master carriers wide from each other to check

that the system is balanced. For a solid construction,

use a tie rip on the extension of the master carrier.

By pulling the chain through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

1

34

Slide the master carrier underlap, together with the

second cord connector into the cord channel of the

track and fix the second pulley onto the track. Use the

screwdriver.

CCS®& CKS®Assembly - chain.

Instructions for assembling CCS®& CKS®, center- and one-way draw, with chain.

The system with chain is recommended in situations with one or more curves in the track. Steps 1 and 2 of the cord

instructions can be followed. Read ‘chain’ instead of cord.

On this page, the difference in assembling will be explained.

Necessary items: Articlenumber:

CCS-track 30010.. ……

BS Chain 4.5 x 6 3535501000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

BS Chain 4.5 x 6 3535501000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

Drill with bit 1

Lighter (for heathen the nylon cord)

Determining track-length: CKS®minus 8 cm (3,2" for

center closing and one-way draw), CCS®minus 8 cm

(center closing) and minus 6,5 cm (one-way draw).

Determining cord-length: 2 times track length + 2 times

the desired drop height of the cord. Cut the nylon cord

by heating it with the lighter.

2

Remove the metal pins inside the both pulleys.

Pull the chain trough the second pulley and cross the

two ends of the chain through the master carrier under-

lap (overlap, when it’s a one-way draw). Leave two

balls space after the extension of the master carrier

and glue the last balls onto each other.

10

assemblageCKSCCSEng_210306 21-03-2006 13:47 Page 1

78

Determine the cord length by pulling the cord. Pull at

the end to reduce the drop height, pull at the loop to

increase the drop height. Screw the half cord connector

tight to position the cord drop height (with CCS®:

the second cord connector in the double construction).

If necessary, cut the cord by heating it and make a knot

at the end of the cord. Tight this on the extension in

the middle of the master carrier overlap. This creates

a strong construction.

56

By pulling the cord through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

Ensure that the cord runs behind the metal pin in

the pulley. This avoids slack in the mechanism during

operation.

CKS®& CCS®Assemblage

Tips & Suggestions:

• The maximum length for cording / chaining CCS®is as follow:

6,10 mtr (20 Ft.) and for CKS®is 6 mtr (19.7 Ft.).

• The above sizes are without the pulleys! With pulleys, the sizes are as follow:

centredraw one-way draw

CCS®6,18 mtr (20.27’) 6,17 mtr (20.24’)

CKS®6,08 mtr (20’) 6,08 mtr. (20’)

Fix one cord connector onto the end of the cord

(CCS®facing outside, CKS®to the middle of the track).

Slide the half cord connector on the other end of the

cord (with CCS®, use a normal CCS cord connector),

but do not screw it.

Slide the master carrier, together with the two cord

connectors into the cord channel of the track.

The cord is lifting out of the track, through the first

gap of the master carrier overlap.

Fix the second cord connector on the opposite cord,

(CCS®facing outside, CKS®towards the middle of the

track).

Slide the master carrier underlap, together with the cord

connector into the cord channel of the track and fix the

second pulley onto the track.

1

34

CCS®& CKS®Assembly – cord adjustability.

Instructions for assembling CCS®& CKS®, with cord adjustability.

This application can be made for CCS®, as well for CKS®. The advantage is that the requested drop height can be deter-

mined at a later stage. This feature makes the system very suitable for pre-assembling. This application is also possible

for one-way draw. Start, repeating the first two steps of the instructions with cord and continue with the steps below.

Necessary items: Articlenumber:

CCS-track 30010.. ……

Nylon cord 1030401000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

CKS Cord Connector 3030301000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

Nylon cord 1030401000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

CKS Cord Connector 1530301000

CKS Cord Connector (half) 1530311000

Drill with bit 1

Lighter (for heathen the nylon cord)

2

03-2006

assemblageCKSCCSEng_210306 21-03-2006 13:47 Page 4

78

Determine the cord length by pulling the cord. Pull at

the end to reduce the drop height, pull at the loop to

increase the drop height. Screw the half cord connector

tight to position the cord drop height (with CCS®:

the second cord connector in the double construction).

If necessary, cut the cord by heating it and make a knot

at the end of the cord. Tight this on the extension in

the middle of the master carrier overlap. This creates

a strong construction.

56

By pulling the cord through the big gap of the pulley,

it will hang straight down the curtain and a good

operation is guaranteed.

Ensure that the cord runs behind the metal pin in

the pulley. This avoids slack in the mechanism during

operation.

CKS®& CCS®Assemblage

Tips & Suggestions:

• The maximum length for cording / chaining CCS®is as follow:

6,10 mtr (20 Ft.) and for CKS®is 6 mtr (19.7 Ft.).

• The above sizes are without the pulleys! With pulleys, the sizes are as follow:

centredraw one-way draw

CCS®6,18 mtr (20.27’) 6,17 mtr (20.24’)

CKS®6,08 mtr (20’) 6,08 mtr. (20’)

Fix one cord connector onto the end of the cord

(CCS®facing outside, CKS®to the middle of the track).

Slide the half cord connector on the other end of the

cord (with CCS®, use a normal CCS cord connector),

but do not screw it.

Slide the master carrier, together with the two cord

connectors into the cord channel of the track.

The cord is lifting out of the track, through the first

gap of the master carrier overlap.

Fix the second cord connector on the opposite cord,

(CCS®facing outside, CKS®towards the middle of the

track).

Slide the master carrier underlap, together with the cord

connector into the cord channel of the track and fix the

second pulley onto the track.

1

34

CCS®& CKS®Assembly – cord adjustability.

Instructions for assembling CCS®& CKS®, with cord adjustability.

This application can be made for CCS®, as well for CKS®. The advantage is that the requested drop height can be deter-

mined at a later stage. This feature makes the system very suitable for pre-assembling. This application is also possible

for one-way draw. Start, repeating the first two steps of the instructions with cord and continue with the steps below.

Necessary items: Articlenumber:

CCS-track 30010.. ……

Nylon cord 1030401000

CCS Master Carrier Overlap R/L 30157…000

CCS Master Carrier Underlap R/L 30156…000

CCS End Pulley 30301…000

CCS End Pulley Small 30302…000

CKS Cord Connector 3030301000

Drill with bit 1

Lighter (for heathen the nylon cord)

Necessary items: Articlenumber:

CKS-track 1501001…..

Nylon cord 1030401000

CKS Master Carrier Overlap R/L 1515701000

CKS Master Carrier Underlap R/L 1515601000

CKS Pulley 1530101000

CKS Cord Connector 1530301000

CKS Cord Connector (half) 1530311000

Drill with bit 1

Lighter (for heathen the nylon cord)

2

03-2006

assemblageCKSCCSEng_210306 21-03-2006 13:47 Page 4

This manual suits for next models

1

Table of contents