UNDERSTANDING THE PODIUM RC2

•Body

!Large diameter 6061-T6 smooth bore seamless aluminum body allows for greater damping force

capability while allowing the shock to run at lower overall temperatures.

!Increased oil volume allows for reduced fade and increased durability.

!Genuine Kashima Coating for less friction and reduced heat.

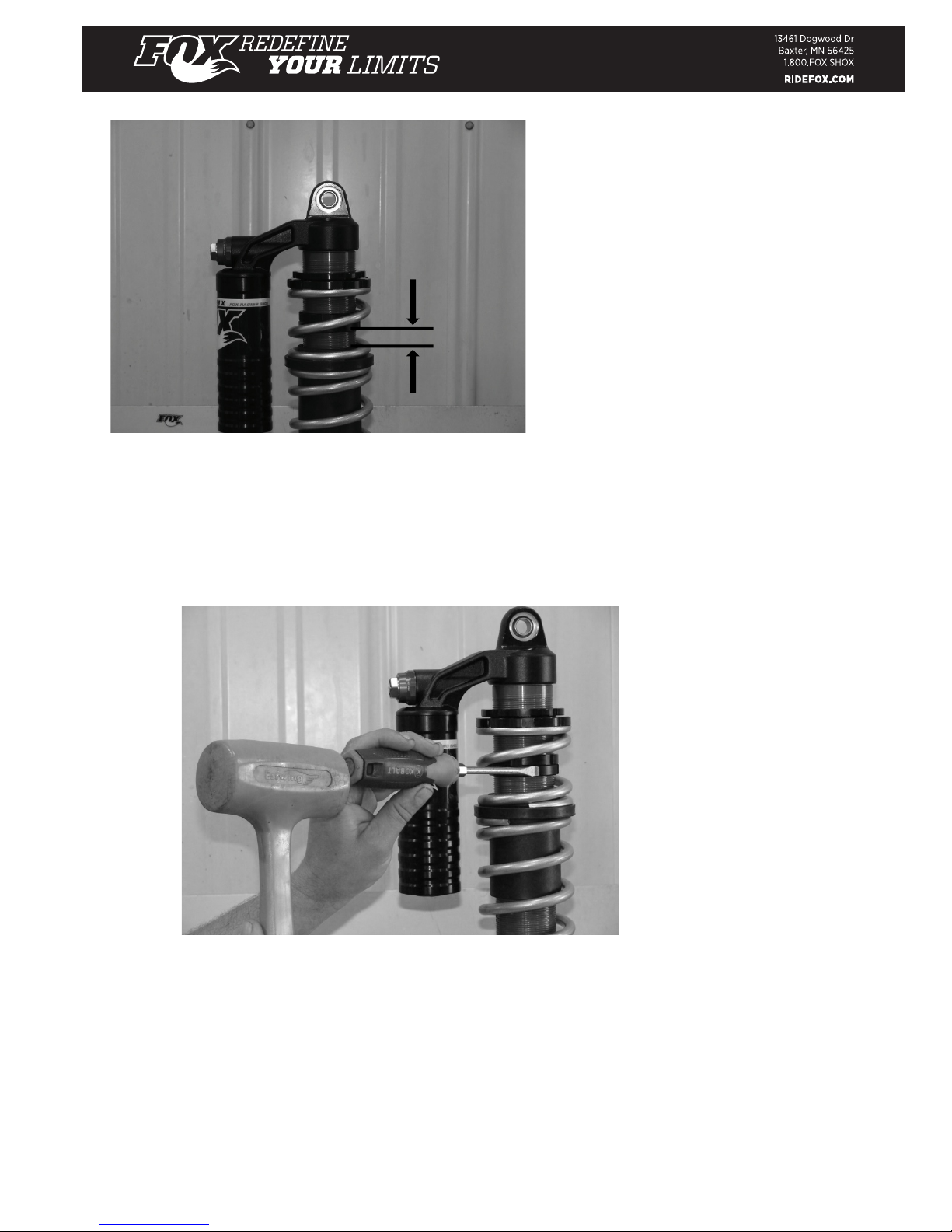

•Spring Adjustment

oPreload adjustment

oCrossover ring adjustment

•High-Speed Compression Adjuster (22 position)

oThe high-speed compression (HSC) adjuster mainly affects compression damping

during medium-to-fast suspension movements such as steep jump faces, harsh flat

landings and aggressive whoops. The goal is to run as little high-speed compression

damping as possible without bottoming.

•Low-Speed Compression Adjuster (24 position)

oThe low-speed compression (LSC) adjuster primarily affects compression damping

during slow suspension movements such as G-outs or smooth jump landings. It also

affects wheel traction and the harshness or plushness of the vehicle (note that low-

speed has nothing to do with the speed of the vehicle). Choose an LSC setting that

gives good body control without causing excessive harshness or loss of traction.

•Rebound damping Adjustment (22 position)

oRebound damping controls the rate at which the shock returns after it has been compressed.

The proper rebound setting is a personal preference and changes with rider weight, riding style and

conditions.

•Teflon-Lined, Heat-Treated, Alloy Steel Spherical Bearings

•Hard-Chrome-Plated Alloy Steel Shaft

•Bottom-Out Control Technology:

oBottom-out cup provides additional end-of-stroke compression damping for those really

hard hits.

!Offers up to 30 percent more damping at the final 25 percent of travel.

This allows the shocks to be tuned to give improved small- bump compliance in the upper

portion of the stroke while still maintaining the ability to absorb huge impacts effectively.