7

115G

Revised: September 1, 2006

TROUBLESHOOTING AN ABSORPTION FREEZER:

Absorption systems have the advantage of operating without electric power, and have a relatively silent

operation, as there is no compressor. Its refrigerant does not contain ozone-depleting substance. However, the system

is smoother and slower, and does not have the brute cooling down force of Freon. Many minor malfunctions or bad

installation, etc. can cause the freezer to not reach its desired -17C (0F) or colder temperature. Absorption is a slow

system. It will take longer to cool down than a compressor system. This appliance is not meant to be installed in a

public area (such as a restaurant) where the door would be open every few minutes.

All freezers are fully tested before leaving the factory, and have reached the desired temperature. The

following checkpoints should be followed if the freezer does not reach its desired temperature after transport and re-

installation in its new home.

1. Freezer must be level in all directions. There are 2 adjustable legs under the freezer to assist in levelling. Use a

"bubble" level to adjust legs. Installation on a weak floor could cause the freezer to become off level when fully

loaded. Check level after loading.

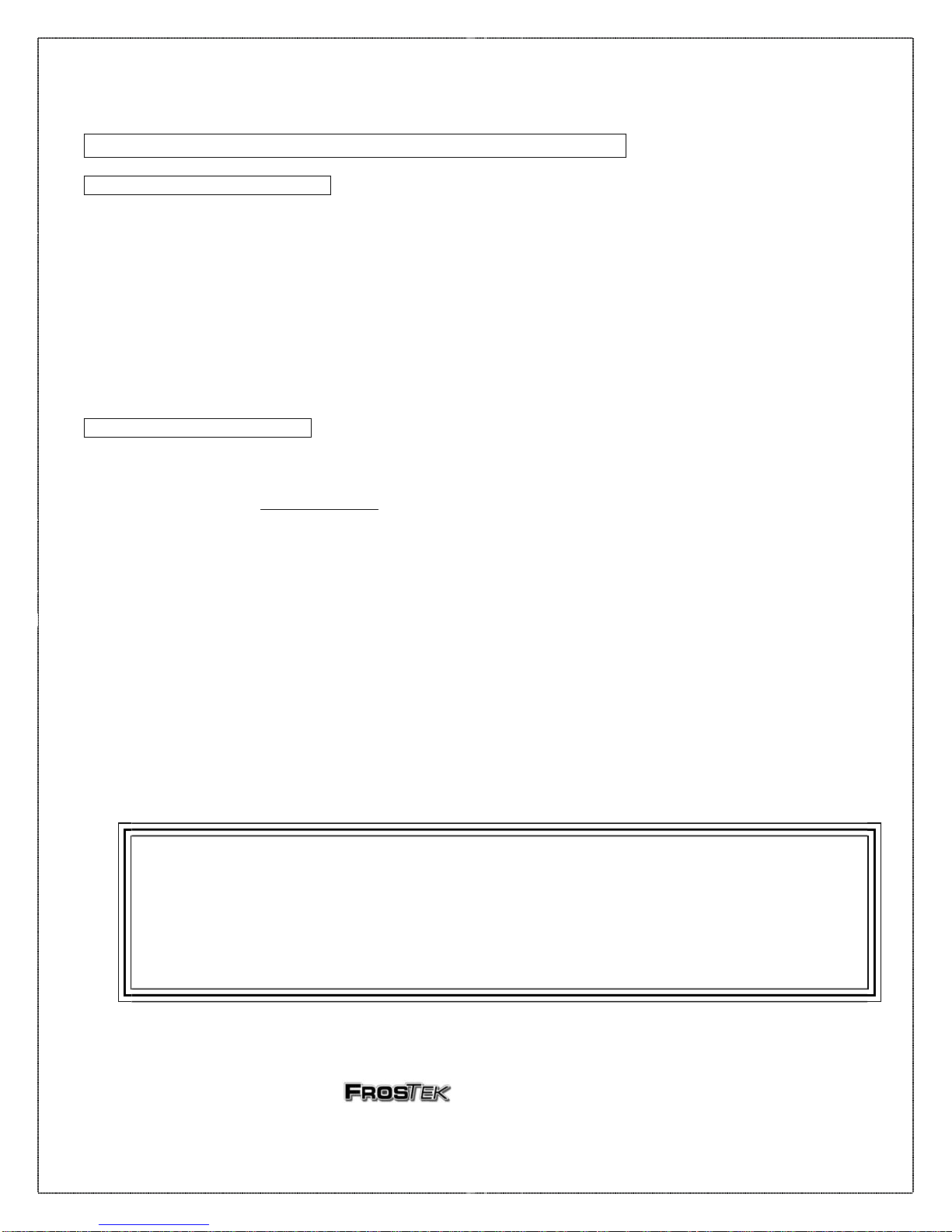

2. To operate, the refrigerant must flow down to the reservoir through gravity, after having returned to liquid inside

the evaporator pipe. The serpentine (coil) of pipes on the cooling unit (as shown in figure 1) must be of such a

position that the liquid will flow downward from left to right in the outside row of pipes, and from right to left in

the rows of pipe touching the back of the freezer. If these pipes are not as described above, the refrigerant will

remain in the pipes, and the system will eventually cease to operate.

3. The highest point of the system is point "A" (Figure 1), which must be higher than point "B". This little pipe

should be around the pipe "B", but not touching it.

4. When operating effectively, point "B" should be very warm to the touch. When putting your hand at point "B",

you will feel too much heat to leave it there... but it should not burn you. If the pipe is cold, or cool, the system

is not working, because of blockage or too low a source of heat.

When working well, the bottom 3 rows of the serpentine will be warmer than the 4 top rows.

5. To verify if the thermostat is functioning properly:

Make sure the setting of the thermostat is at "high" on the panel. With someone looking directly at the

flame, slowly reduce the thermostat setting: the flame should suddenly reduce in intensity if the thermostat is

functioning properly; then by slowly turning the thermostat higher, the flame should again increase. If the sensor

wire has been damaged (having leaked its gas or being kinked), the freezer would operate at its lowest setting

only.

6. Make sure no dirt, burnt paint, or insulation material fell on the burner. This would result in lack of heat at the

burner. Check that the burner did not come off the flue tube during transportation. Make sure the propane

pressure is 11" on the WC.

7. The freezer has a 0.34mm diameter orifice installed at the factory. When operating in very high altitude (on

mountains), a different, smaller orifice size will be required to compensate for the change in altitude pressure. In

certain cases, at very high altitudes, a new burner with a larger air hole may be required. INPUT RATINGS

ARE SHOWN IN BTU PER HOUR AND ARE FOR ELEVATIONS UP TO 2500 FEET. FOR

ELEVATIONS ABOVE 2500 FEET, INPUT SHOULD BE REDUCED 4 % FOR EACH 1000 FEET

ABOVE SEA LEVEL.

A new orifice will have to be ordered.

8. Check to make sure the baffle is inside the flue tube.