4 5

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions including the following should always be

followed:

Read the complete instructions before operating this sewing machine.

DANGER - To reduce the risk of electric shock:

Unplug the power cord immediately after use and before cleaning.

WARNING - To reduce the risk of burns, re, electric shock or personal injury:

1. The sewing machine is not a toy. Increased caution is advised when the sewing machine is used

by or near children.

2. This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children must not play with the appliance. Cleaning and maintenance

must not be carried out by children without supervision.

3. This sewing machine may only be used for the intended purpose described in this operating

manual. Use only accessories recommended by the manufacturer and covered in these instruc-

tions.

4. Never use the sewing machine if the cables or plugs are damaged, the machine does not func-

tion properly, has fallen to the ground or been damaged, or has even fallen into water. In such

cases, take the sewing machine to the nearest dealer or service center for inspection, repair or

electronic or mechanical readjustment.

5. Use the sewing machine only when no ventilation openings of the machine and the foot control

are blocked and keep them free of lint, dust and fabric residues.

6. Never insert objects into openings in the sewing machine or allow them to fall inside the

machine.

7. Do not use the sewing machine outdoors.

8. In addition, do not use the sewing machine in places where propellant gas products (sprays) or

pure oxygen are used.

9. To turn o the machine, set the power switch to the "0" position and then disconnect the power

plug from the power outlet.

10. Always pull the plug and never the cord when disconnecting the machine from the power

supply.

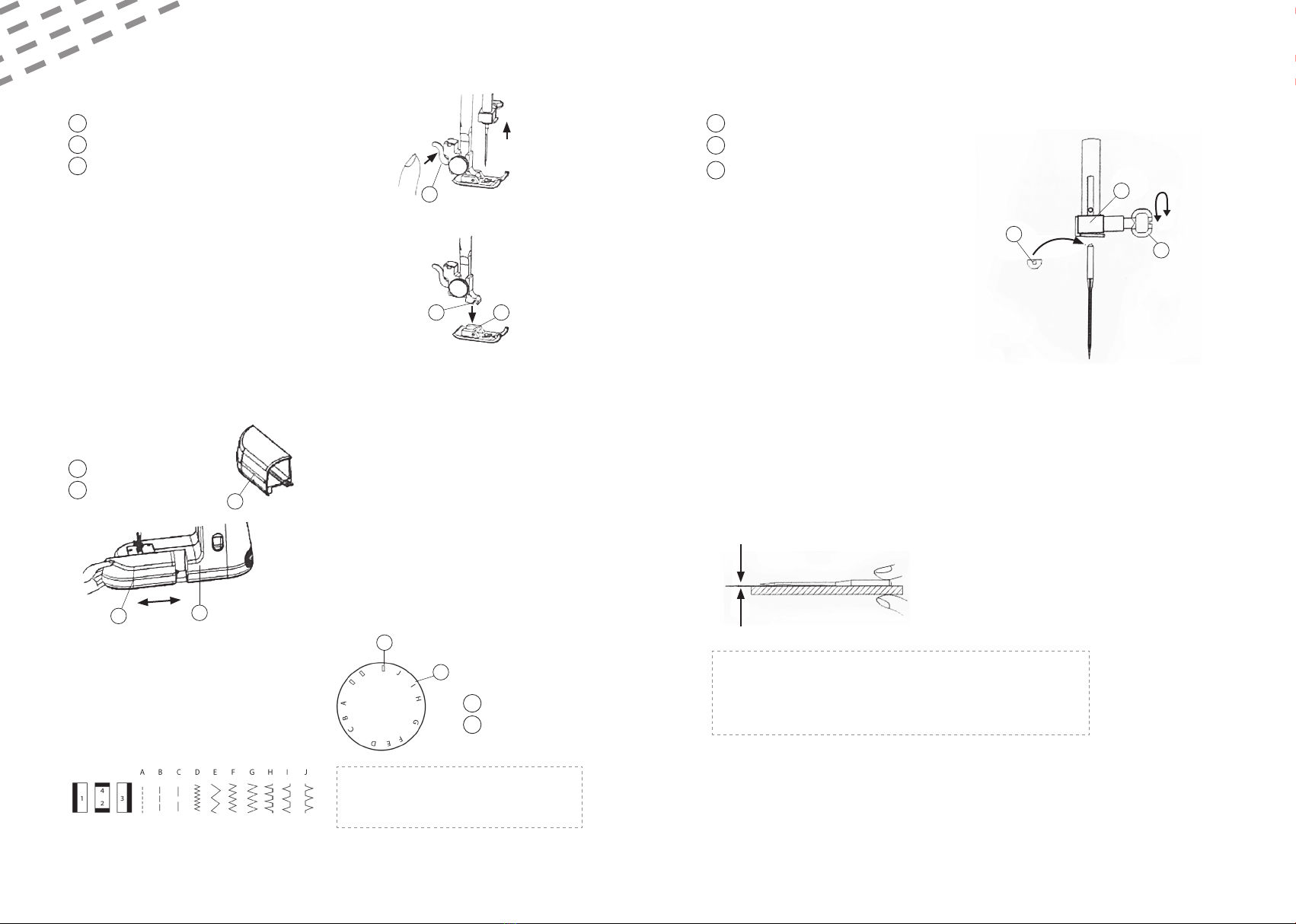

11. Keep your ngers away from all moving parts. Particular care must be taken in the area of the

sewing needle.

12. Always use the original needle plate. The use of an incorrect needle plate can cause the needle

to break.

13. Do not use bent needles.

14. Do not actively pull or push the fabric during sewing. This can lead to deection of the needle

and thus to needle breakage.

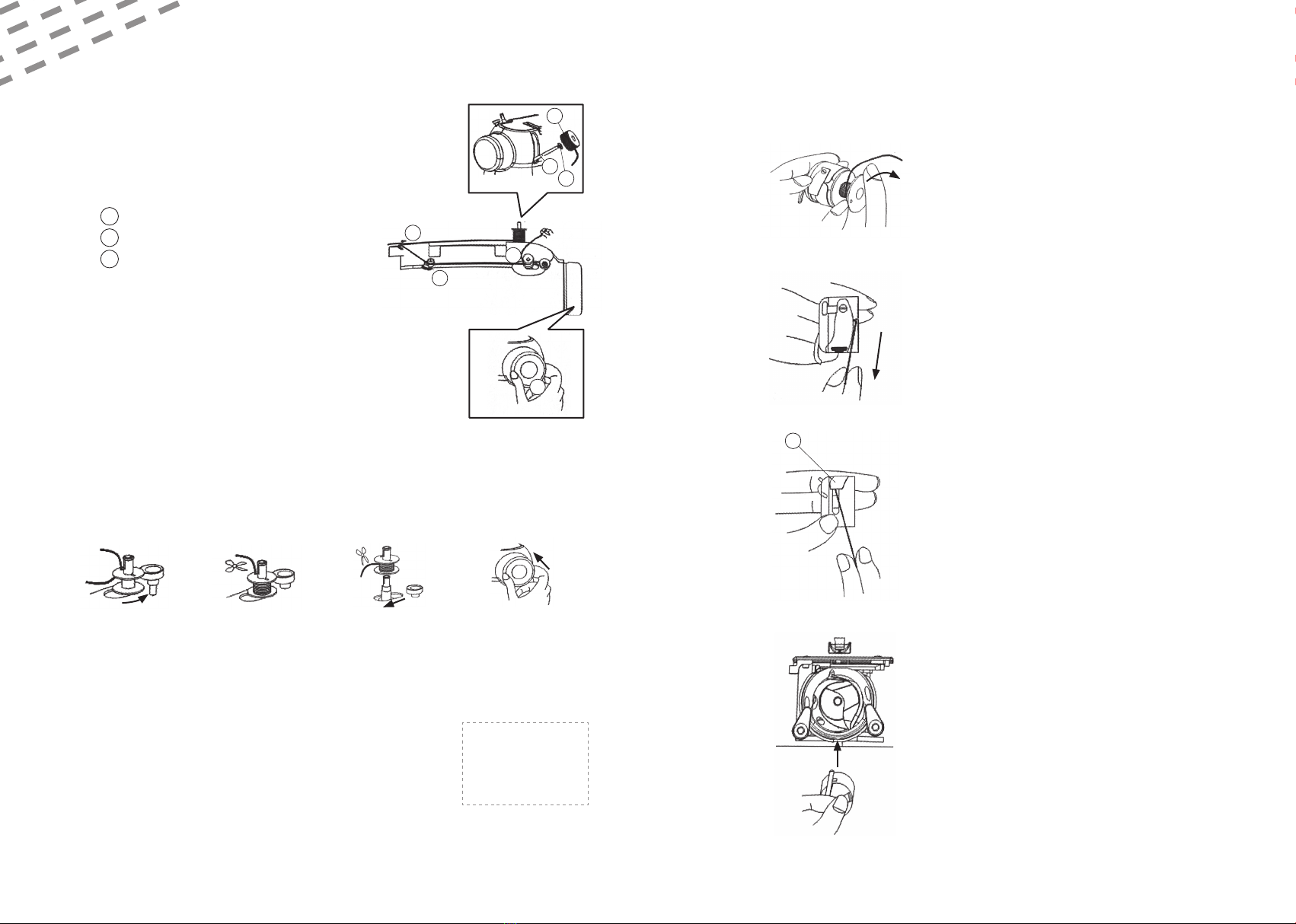

15. Switch o the machine (switch position "0") before you perform any activities in the needle

area, such as threading, changing the needle, changing the presser foot, and the like.

16. Always disconnect the sewing machine from the power supply before removing covers, oiling

the machine or any other oil the machine or carry out any other work intended to be performed

by the user and specied in this operating manual.

17. Observe the following to avoid injuries:

· Turn o the machine or unplug the power cord when leaving the machine unattended.

· Unplug the power cord before performing maintenance or replacing lamps.

CAUTION: Moving parts! To reduce the risk of injury, turn o the sewing machine before servicing.

Close the cover before operating the machine.

KEEP THIS INSTRUCTION

This product is intended for household or equivalent use.

This device complies with the EMC Directive 2014/30/EU for electromagnetic compatibility.

When disposing of this product, please note that it must be safely recycled in accordance

with the relevant national legislation relating to electrical/electronic products. If in doubt,

please contact your retailer for advice.

The design and specications are subject to change without notice.