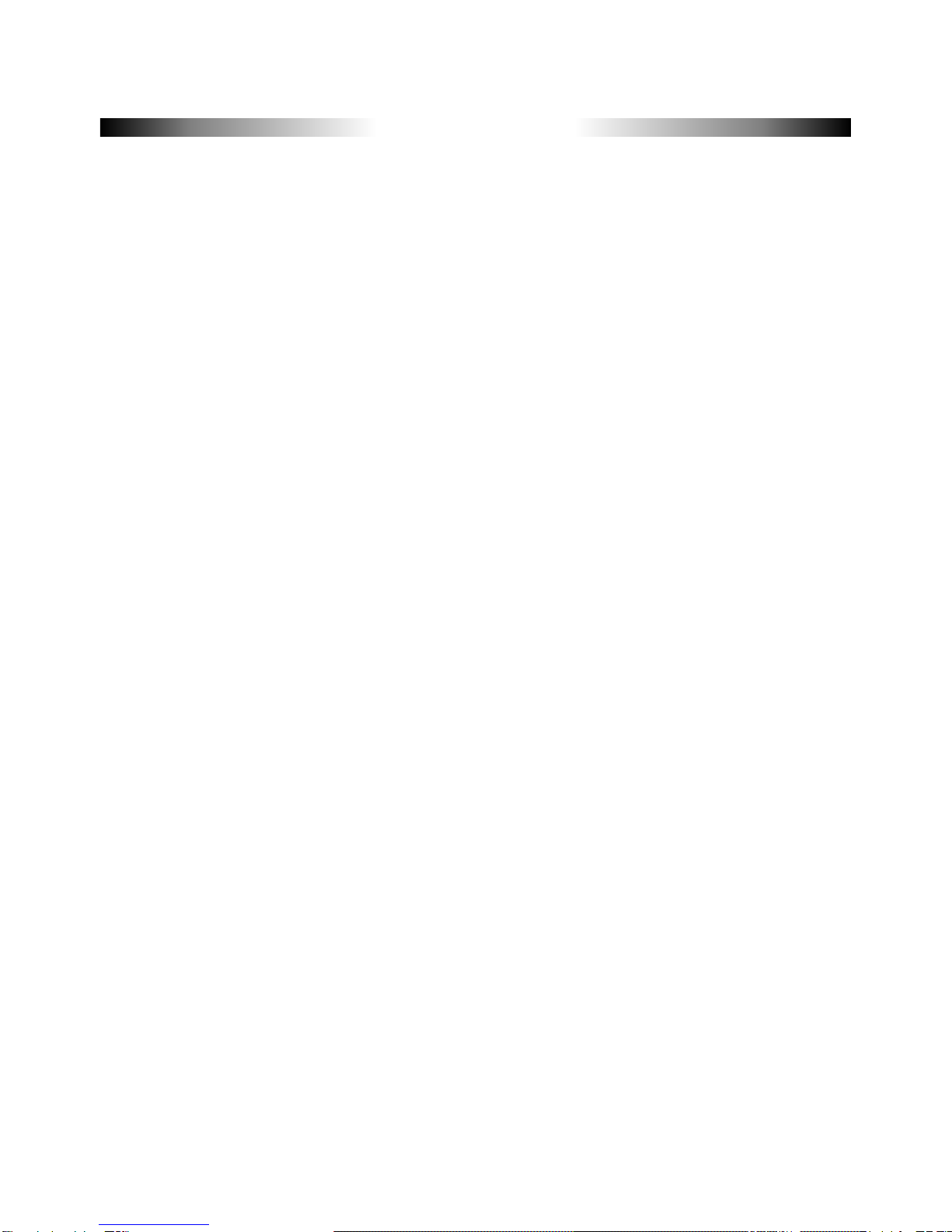

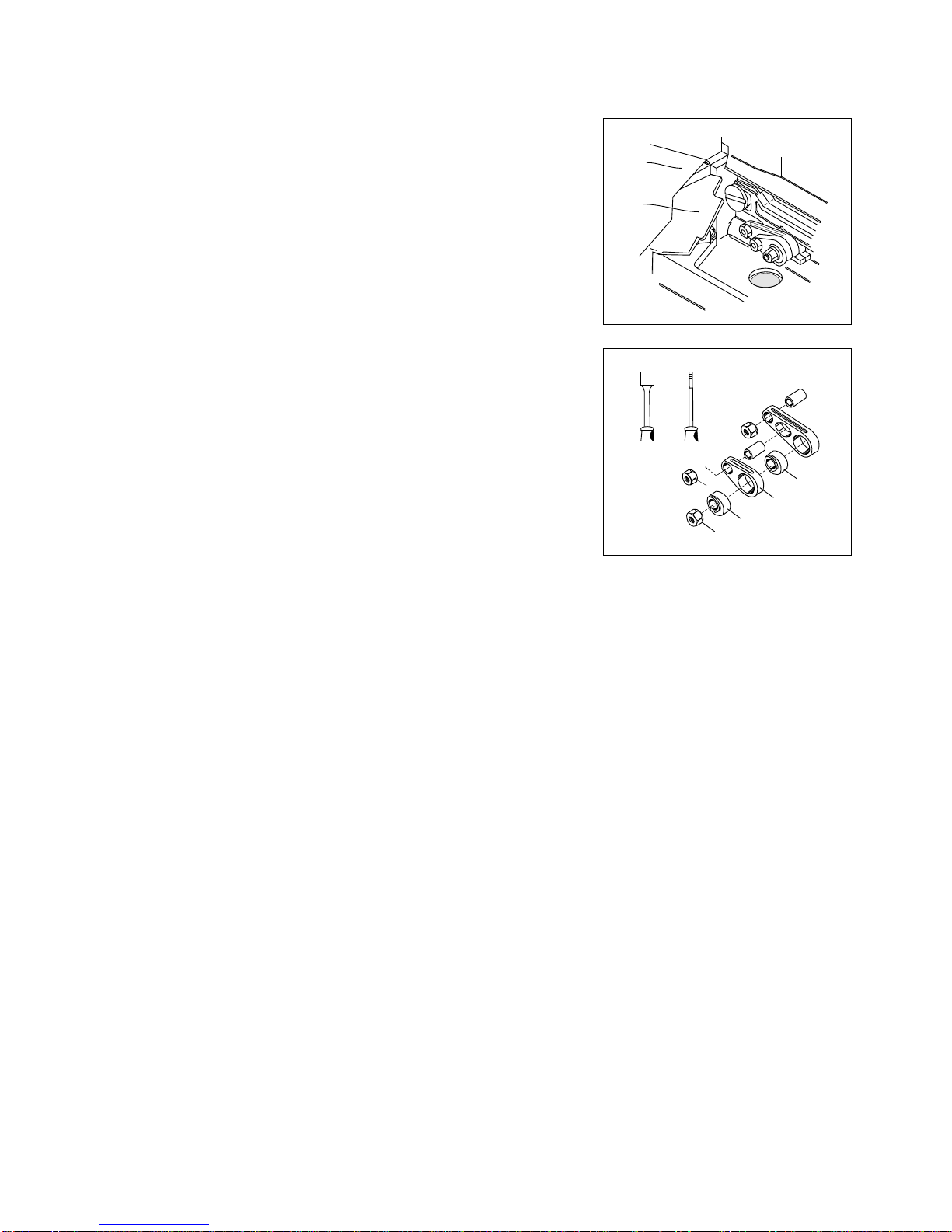

ADJUSTING OF FOOT LIFTER LEVER

Adjust Pressure Foot to Start to lift from the top face of stitch Plate turning

Adjusting Screw (E) when the Foot Lifter Lever (F) is lowered in 3 mm from the

end of Adjusting Screw (E) for Foot Lifter Lever Stopper (D). When Presser Foot

is raised to its highest position, adjust the bottom face of it to be 4mm. from top

face of Stitch Plate.

At this moment Loosen Nut (I) and turn Stop Screw for Presser Foot (H) then

adjust the Screw to touch with Arm of the machine.

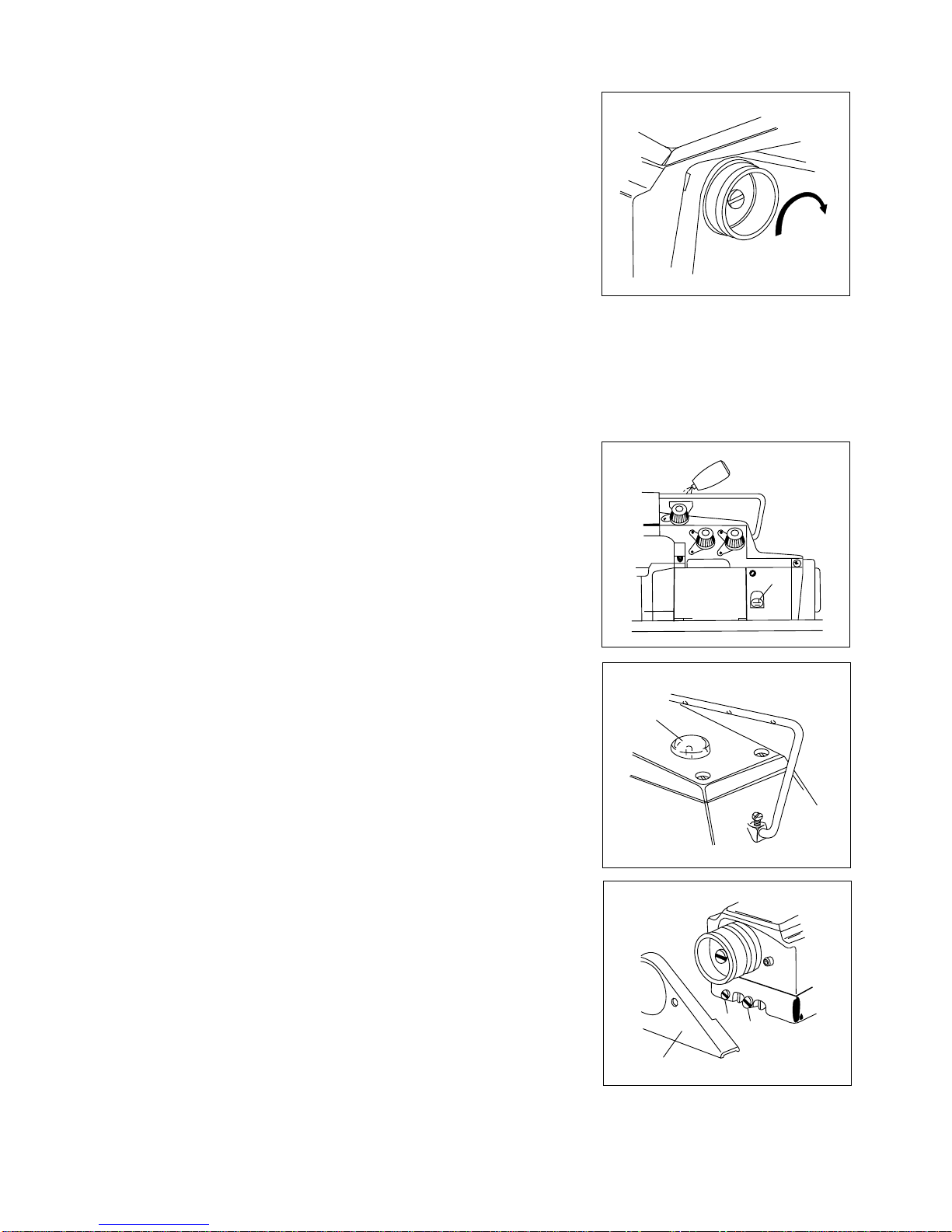

ADJUSTING OF WIDTH OF OVEREDGE SEAM

Towidenthewidth;

Loosen Screw (A) for upper Knife Holder and move the Holder to the

Direction (X) According to the necessity and tighten Screw (A) again.

Subsequently loosen Screw (B) for Lower Knife Holder. Then Lower Knife

Holder will move to the direction (X) by pressure of the spring inside,

consequentlyLowerKnifewilladherecloselytoUpperKnife(D)withsuitable

strength.And,tightenScrew(B)again.]

Tonarrowthewidth

Loosen Screw (B) for Lower Knife Holder and Move the Holder to the

direction (Y) according to the necessity and tighten Screw (B) softly.

Subsequently,loosenScrew(B)forLowerKnifeagainandmadeLowerKnife

(C) adhere closely to Upper Knife (D) by the pressure of spring. Then,

retightenScrew(B).

Note : For adjusting width of the overedge seam, make the blade of Upper

KnifebehigherthanifofLowerKnifein0-1mm.

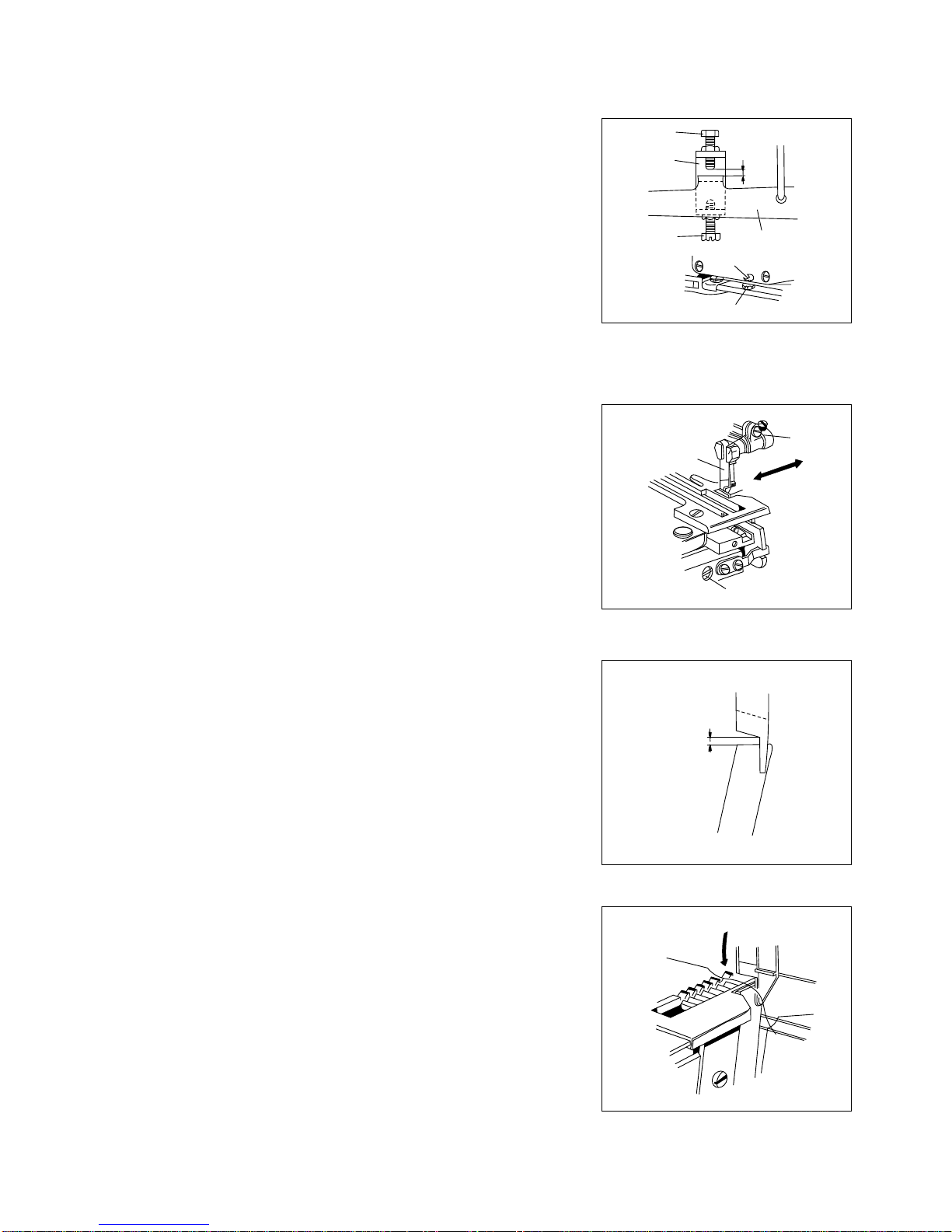

SharpnessofKnives

Check the sharpness of knives turning Pulley manually with a thread put

between Upper and Lower Knives, after adjusting the seam of overedge

seam.

Note : When it may be necessary to sharpen knives please refer to

"SharpeningofknivesforFabricCutting"onPage14.

(1)

(2)

(3)

0 ~ 1mm

I

E

D

G F

H

3mm

Thread

A

B

C

Y

X

D

5