The New Little Gracie II

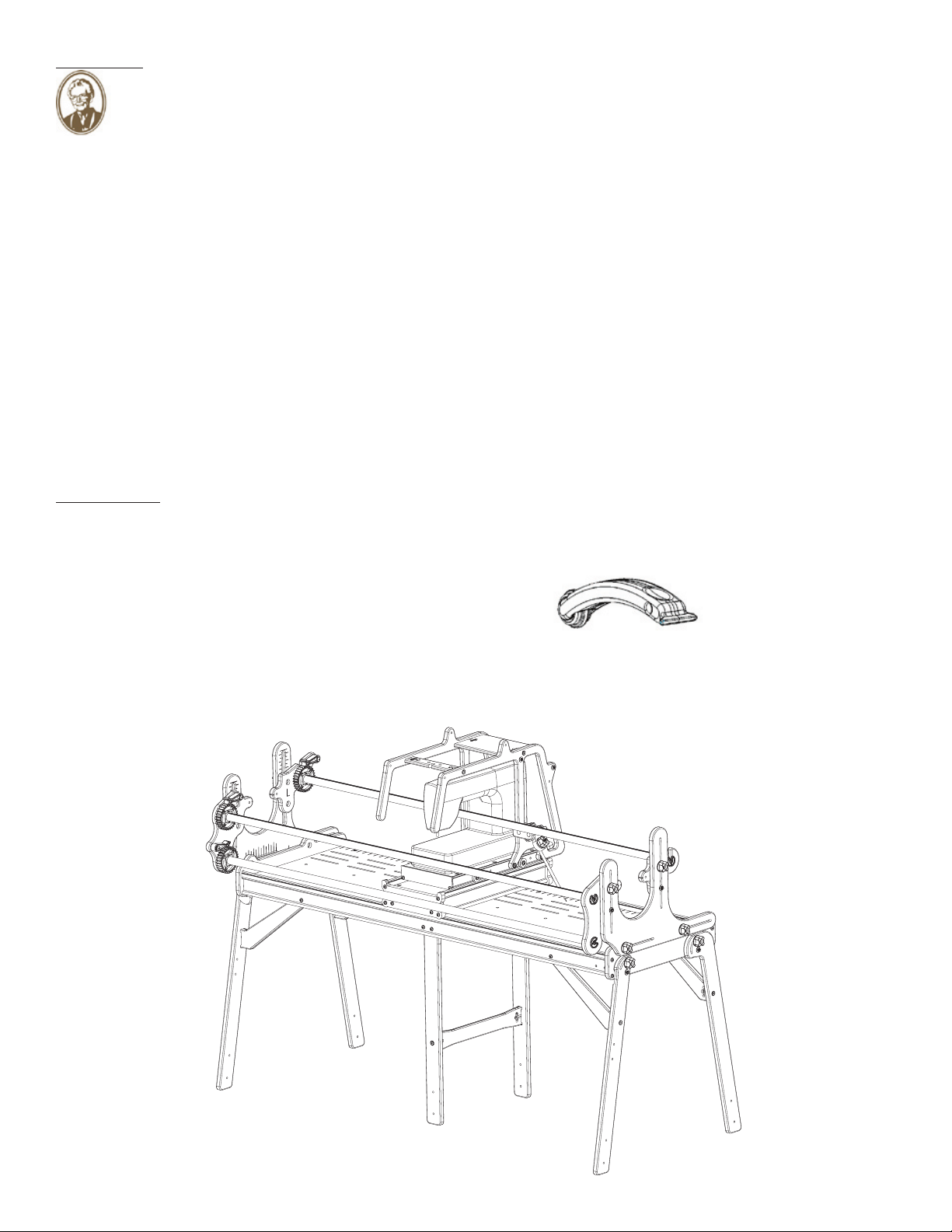

Home Machine Quilting System

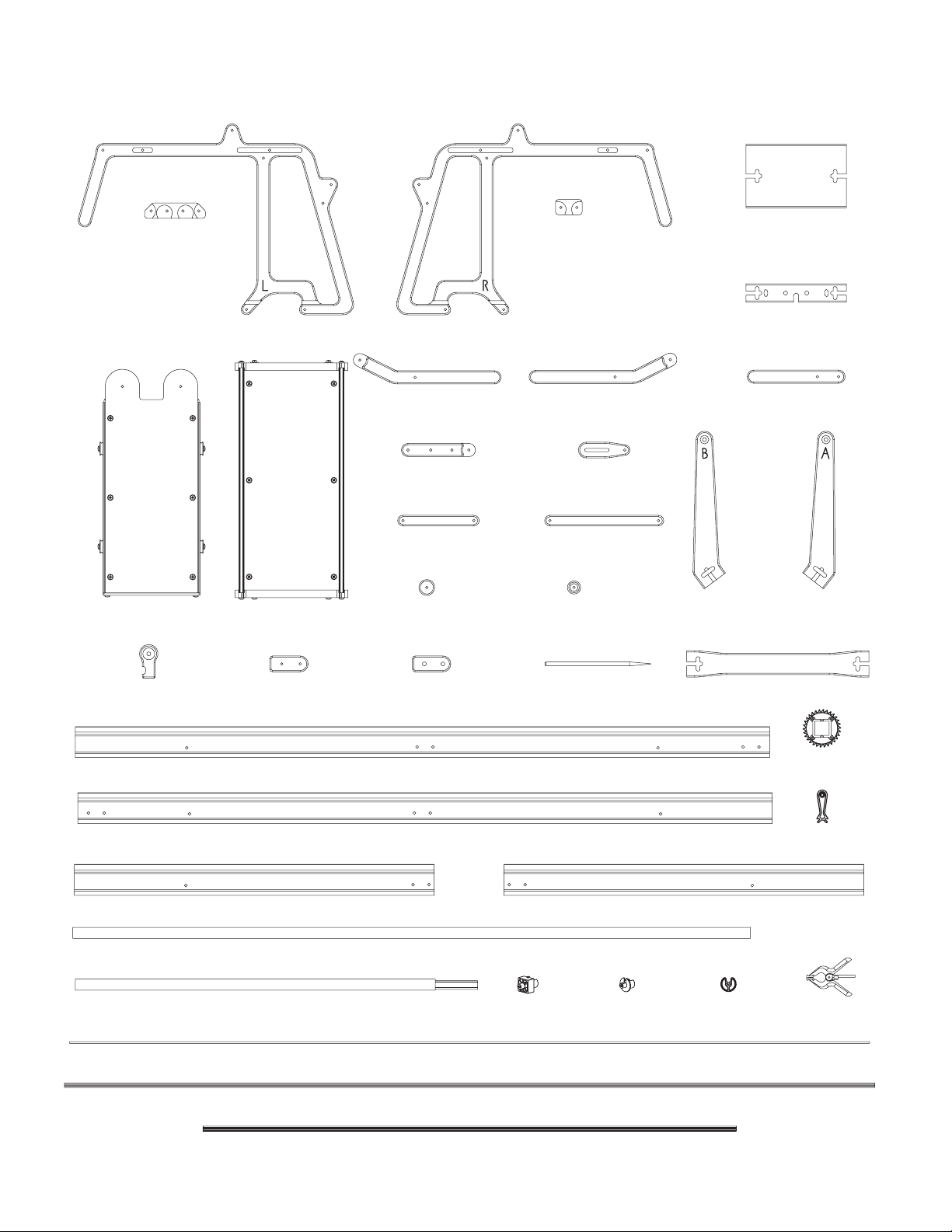

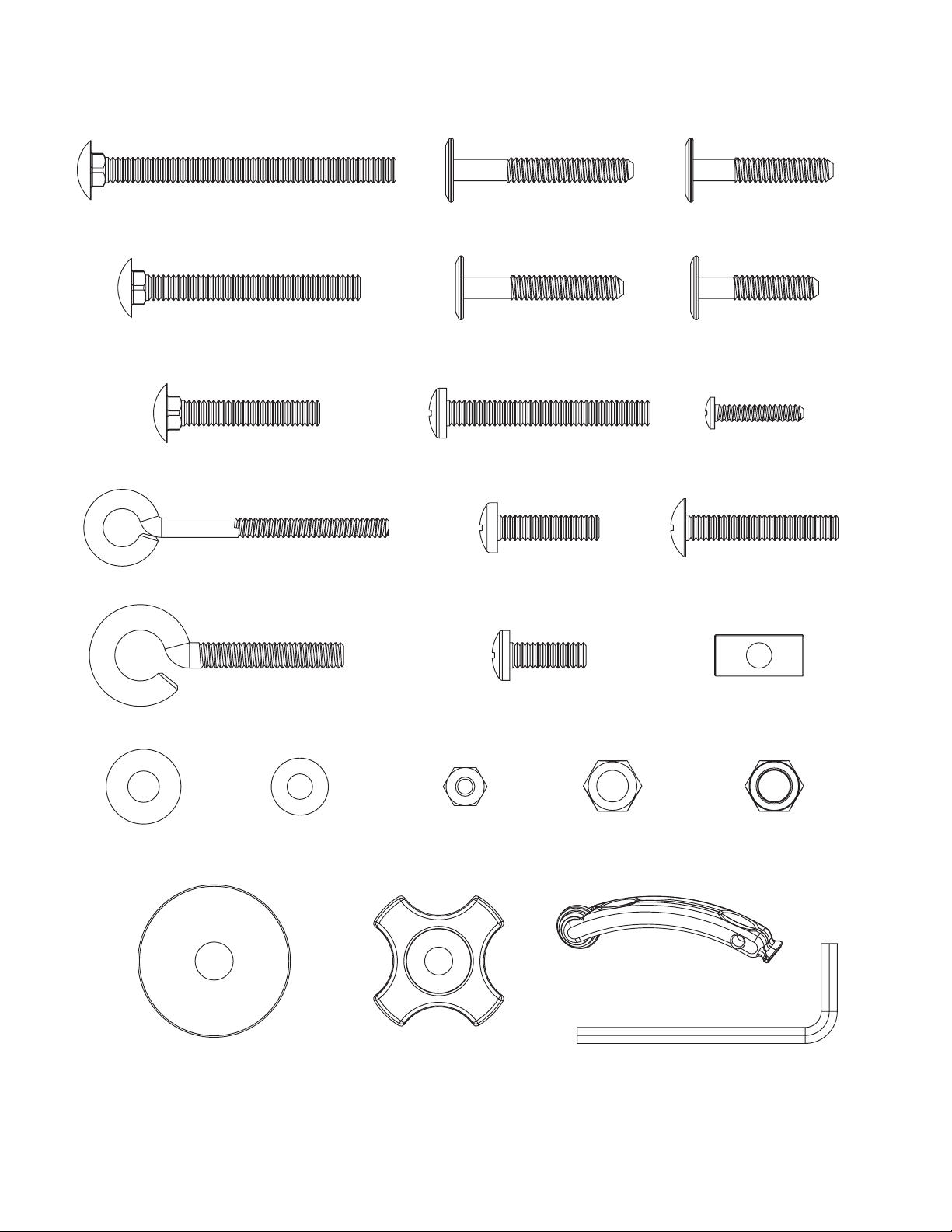

Parts List

Part List A............................................................................................................. 2

Part List B ............................................................................................................. 3

Part List C ............................................................................................................. 4

Care of Your Frame .............................................................................................. 5

Assembly Steps:

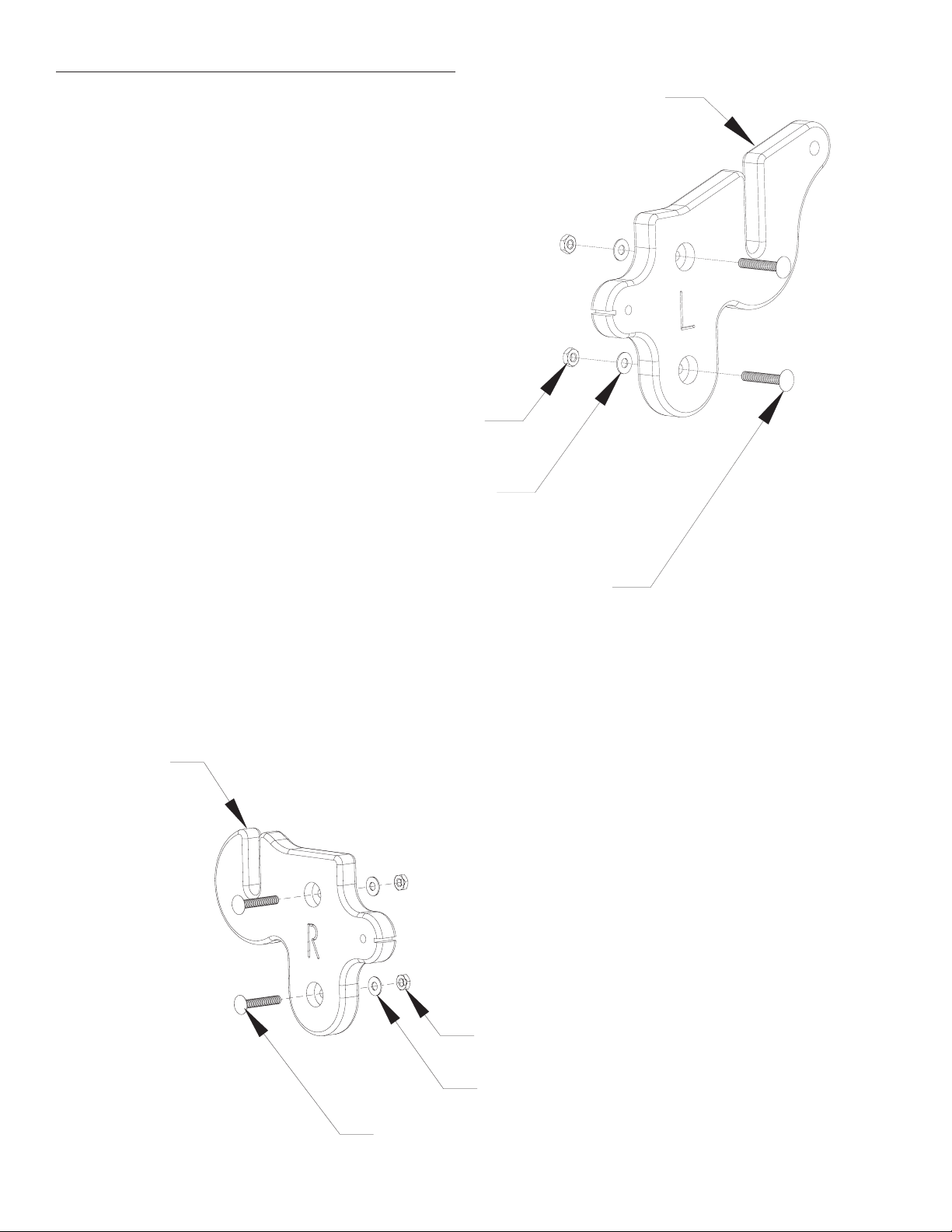

Step 1: Take Up Rail Mount End Assembly........................................................ 7

Step 2: Fabric Layer Rail Mount End Assembly................................................. 8

Step 3: Rail Mount End Assembly....................................................................... 9

Step 4: Frame End Hardware Assembly............................................................ 10

Step 5: Frame End Assembly............................................................................. 11

Step 6: Side Leg Brace “B” Assembly .............................................................. 11

Step 7: Side Leg Brace “A” Assembly .............................................................. 12

Step 8: Legs to Frame End Assembly................................................................ 13

Step 9: Table Assembly ..................................................................................... 14

Step 10: Middle Leg Spacer Assembly.............................................................. 15

Step 11: Track Installation................................................................................. 16

Step 12: Frame End to Table Assembly ............................................................ 16

Step 13: Middle Leg Installation........................................................................ 17

Step 14: Middle Leg Assembly.......................................................................... 18

Step 15: Rail Assembly...................................................................................... 19

Step 16: Ratchet Stop Assembly........................................................................ 19

Step 17: Carriage Handle Assembly.................................................................. 20

Step 18: Cross Brace Assembly......................................................................... 20

Step 19: Cone Thread Holder Assembly ........................................................... 20

Step 20: Cone Thread Guide Assembly............................................................. 21

Step 21: Lever to Carriage Assembly ................................................................ 21

Step 22: Lever Linkage to Handle Assembly .................................................... 22

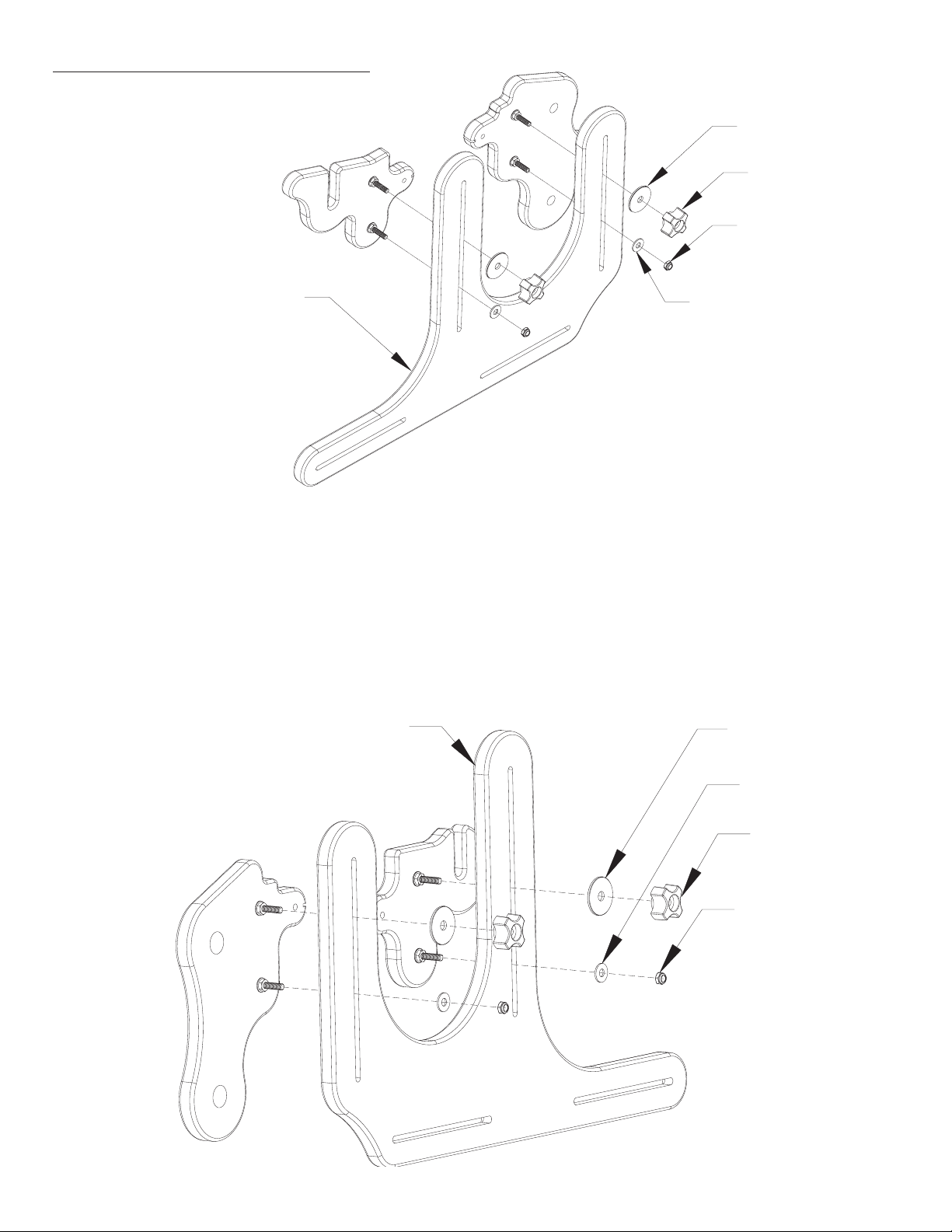

Step 23: Pedal Clamp to Handle Assembly ....................................................... 24

Step 24: Carriage to Frame Assembly ............................................................... 24

Step 25: Sewing Machine to Frame Assembly.................................................. 25

Step 26: Stylus Clamp Base Assembly.............................................................. 25

Step 27: Stylus Clamp Assembly....................................................................... 25

Step 28: Stylus Assembly .................................................................................. 25

Step 29: Stylus to Carriage Assembly ............................................................... 26

Step 30: Carriage Stop Assembly ...................................................................... 26

Optional 4th Pole.................................................................................................. 27

Fabric Installation............................................................................................. 28

Making Cloth Leaders......................................................................................... 29

Installing Your Fabric Layers to the Rails.......................................................... 30

Step 1: Quilt Backing to Second Rail ................................................................ 30

Step 2: Quilt Top to 3rd Rail.............................................................................. 30

Step 3: Batting.................................................................................................... 30

Step 4: Attaching Layers to the Take-Up Rail................................................... 31

Step 5: Putting Your Machine/ Carriages Onto Frame...................................... 31

Rolling Your Fabric ............................................................................................ 32

The Four-Inch Principle...................................................................................... 32

Bungee Clamp Assembly.................................................................................... 32

Copyright June 2005

Jim M. Bagley, GraceWood, Inc

(Reproduction Prohibited)