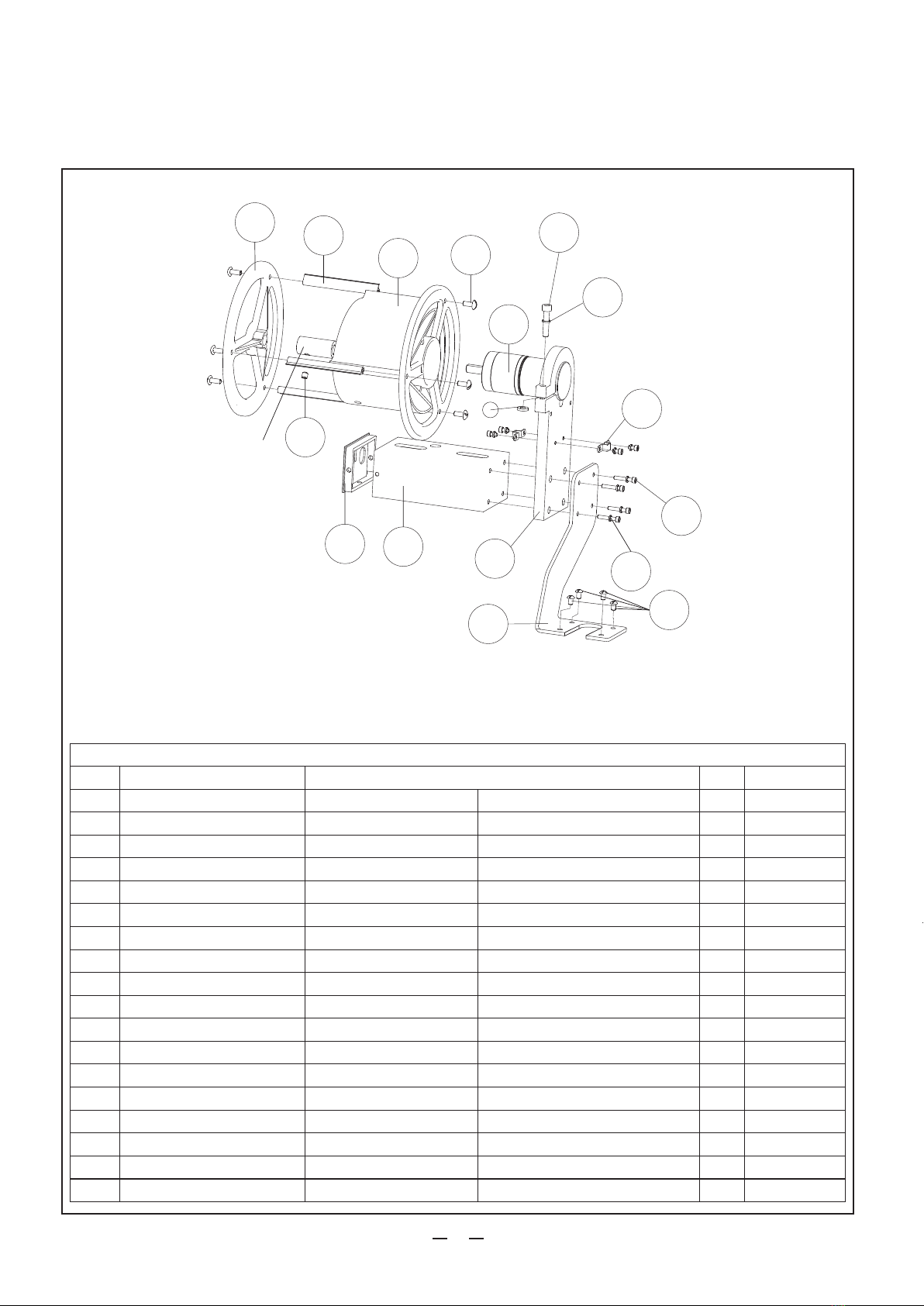

“ ”范围: ,出厂值90,值越大,灵敏度越高;若段拉力设定在990-999之间,请在

95-99间选择;990以下时请对应95及以下;全部要求以有回带动作及带不抖动为最佳(从高

值到低值每次减少2-3个数字,试机找到最佳点)。

01~09

2 SENSI/灵敏度设定(Sensitivity setting):

1 FREE/回带拉力设定(Tension setting):

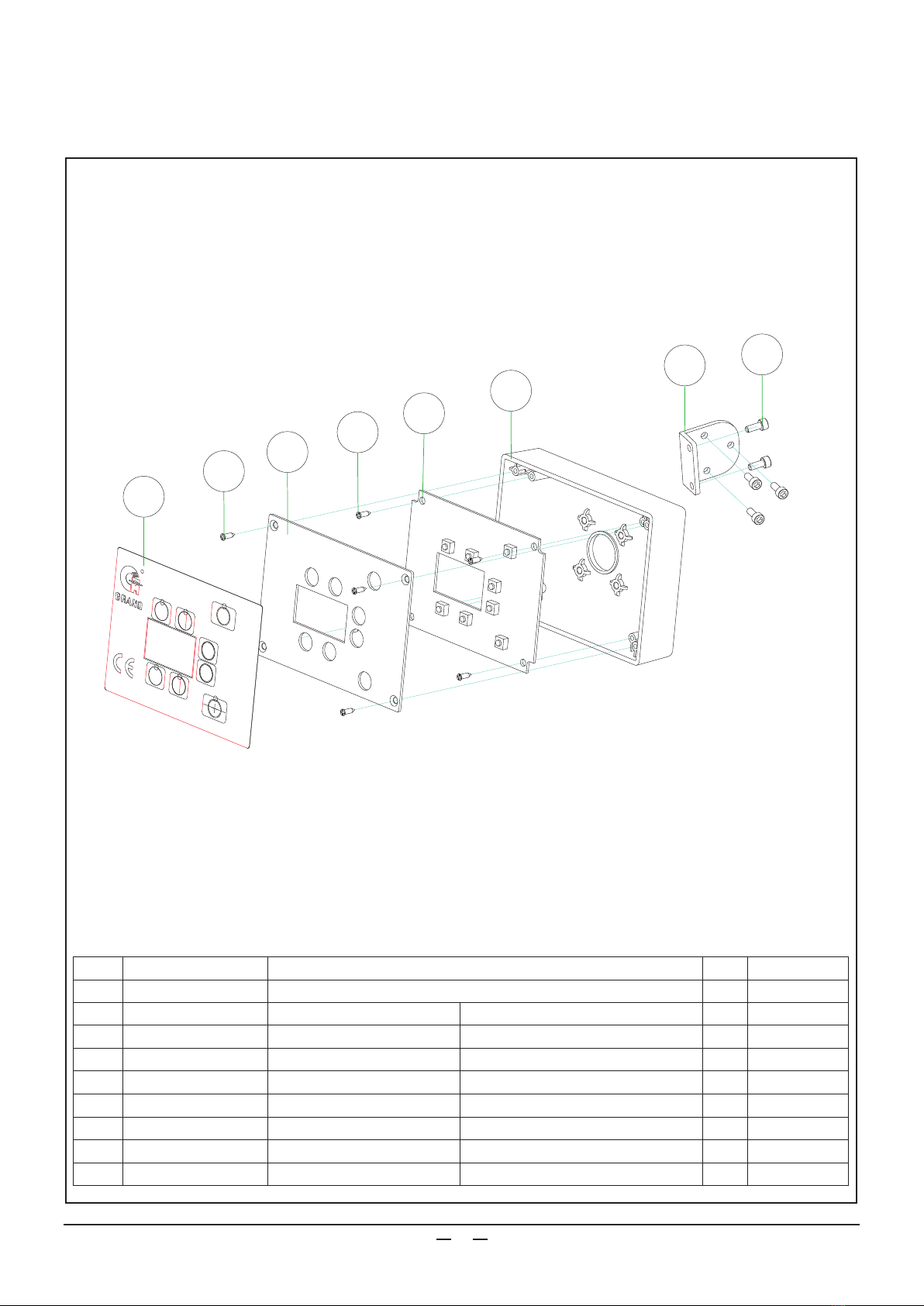

Sent with the tension and sensitivity settings:

(Press "FUNCTION", into the interface:)

In this interface, press " 1 ", press " + "" - " set to send with a delay time.

2 ) 松带松紧度和灵敏度设定:

1. 按“功能”,进入界面:

2. 在此界面时,按“ 2 ”后,再按“ + ”“ - ”设置松带松紧度。

When there is need to condition, need to insert between the two pieces of inching function, adjust

to increase the tension setting value, more than 999 will display a MAC and into inching function,

at this time only tension control, pull the belt will send one to send forward..

3 ) Fre/ 寸动功 能设定(Inching function set):

当有工 况需要, 需要在两段之间插入寸动功能,调整增加此 段拉力值 设定,超 过999将显 示

Fre并进入寸动功能,此时只受拉力控制,拉一拉带就向前送一送带。

3. 按“ 4 ”后,再按“ + ”“ - ”,可设置灵敏度。

Press " 4 ", press " + "" - ", can set the sensitivity.

2

4. 再按“功能”,进入版本查询界面,第1列显示显示器软件版本,第2列显示控制盒主板软件版本。

Then press the "function", enter version query interface, column 1 display monitor software version, the

second column display control box of the mainboard software version.

“ ”范围 01~09,出厂值02,值越小,回带拉力的松紧度越低。在缝制过程中需要过厚时,当

压脚抬起时回带拉力的松紧度(为防拉针而设计),此功能需配合使用松带开关之动作(需要将

此开关安装在压脚功能杆上),一般调到有回带动作时最佳。

:

“ ”Scope of 01~09, factory value , the smaller the value, the lower back to the looseness of belt tension.

In the process of sewing process need too thick,When the presser foot lift back to the looseness of belt tension

(designed for defense needle), this function should be used loosely with switch action (needs to install this

switch on the function of presser foot pole), generally to have to drive for the best.

02

“ ”Scope: 01-99, the factory value of 90, the larger the value, the higher the sensitivity; If the tension is

set in 990-990, please adjust to95-99; 990 the following please corresponding to 95 and the following;

All request to have to drive and take not jitter is the best (from on high Value to the minimum time to reduce

two or three Numbers, commissioning to find the best point).