GREAT PLANES Extra-300 50 EP User manual

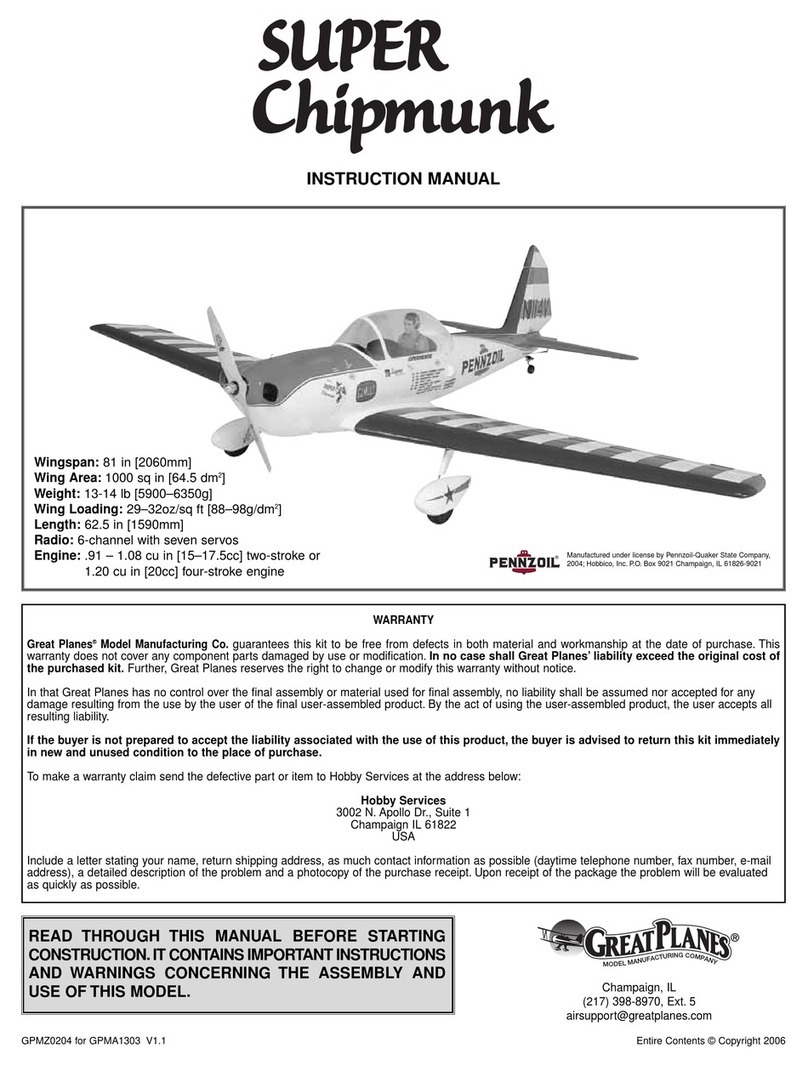

Other GREAT PLANES Toy manuals

GREAT PLANES

GREAT PLANES Yak-55M Performance Series User manual

GREAT PLANES

GREAT PLANES Giant Aeromaster ARF User manual

GREAT PLANES

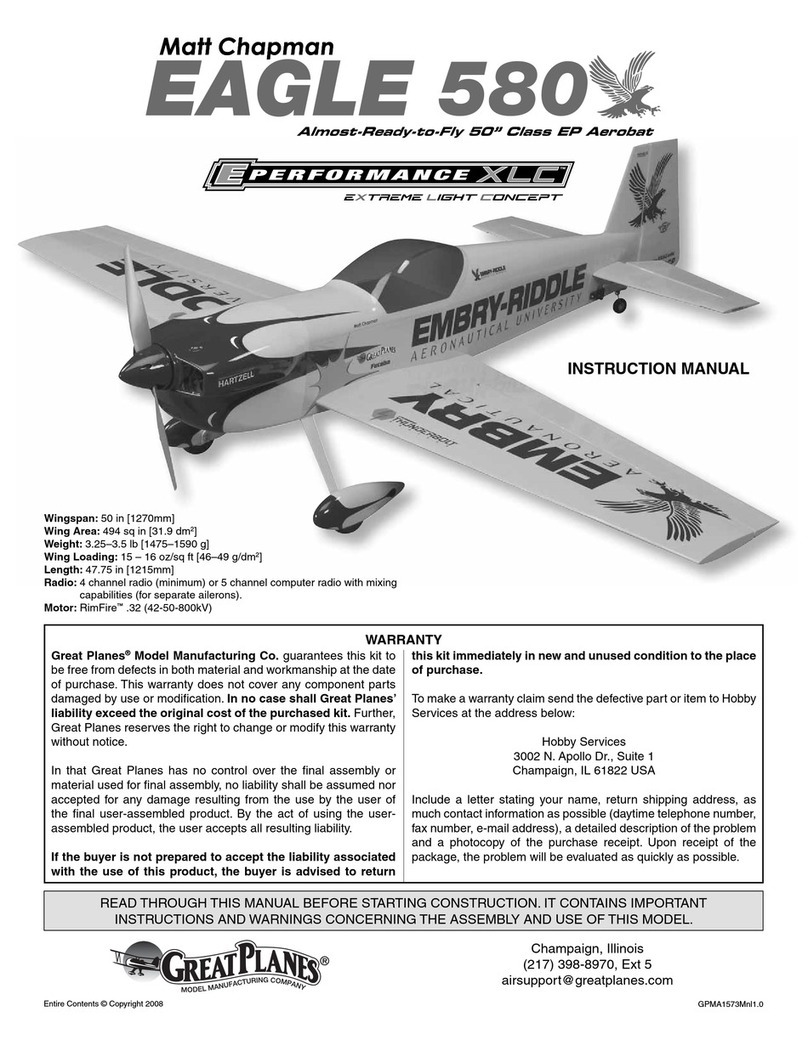

GREAT PLANES matt chapman eagle 580 User manual

GREAT PLANES

GREAT PLANES PT-40 User manual

GREAT PLANES

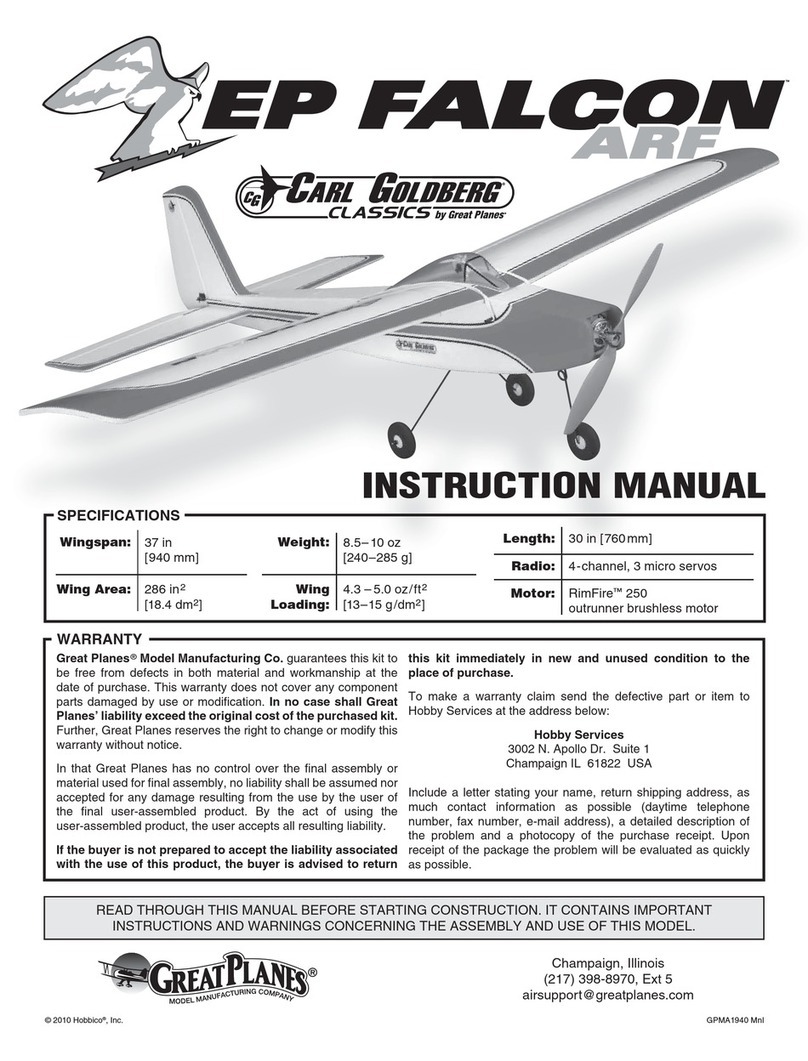

GREAT PLANES EP FALCON ARF User manual

GREAT PLANES

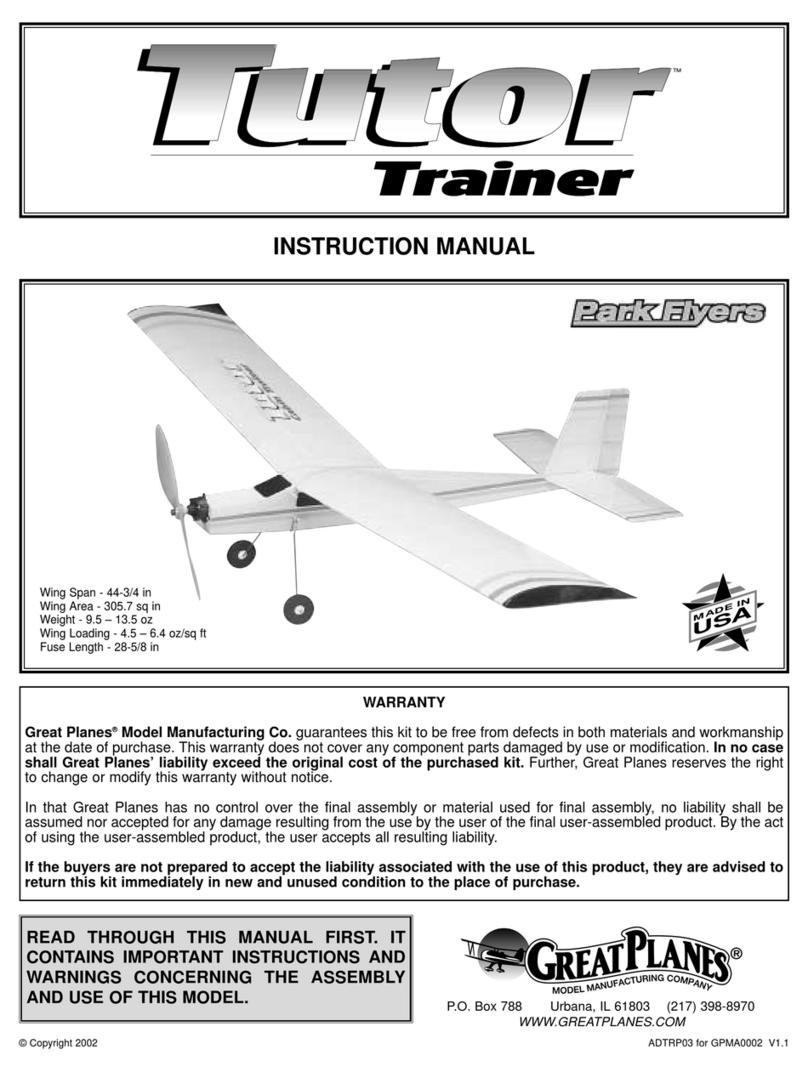

GREAT PLANES Tutor Trainer User manual

GREAT PLANES

GREAT PLANES Extra 300S ARF User manual

GREAT PLANES

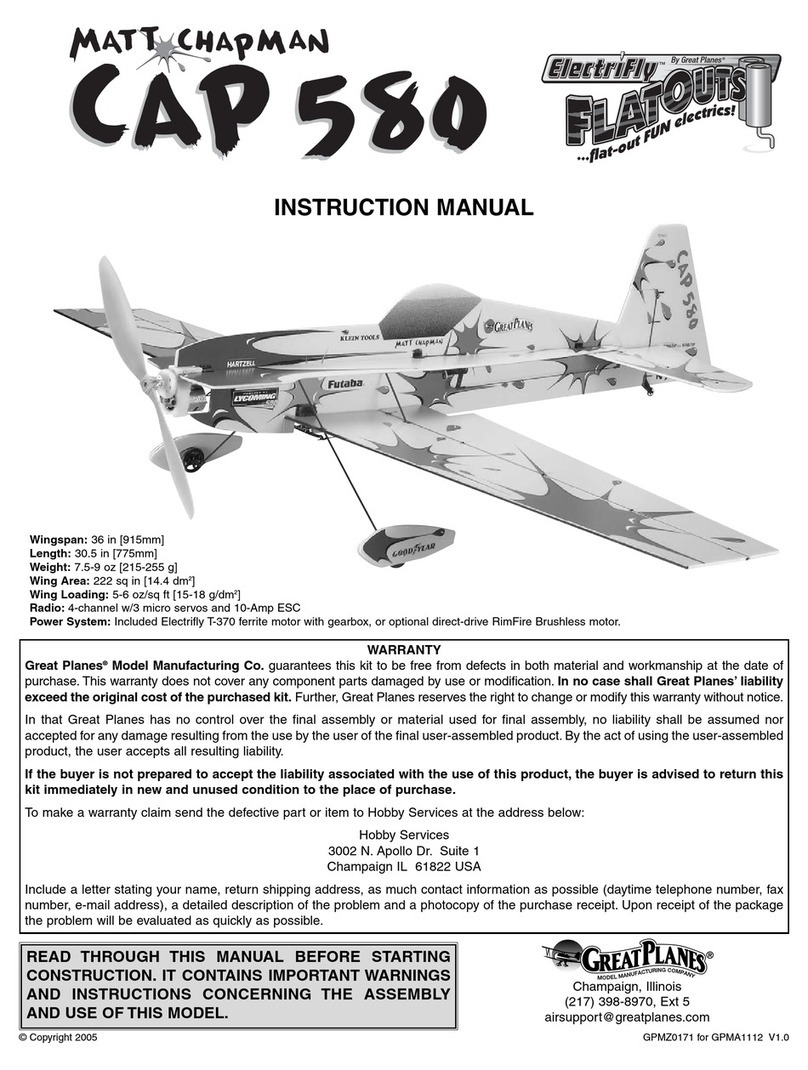

GREAT PLANES Matt Chapman Cap 580 User manual

GREAT PLANES

GREAT PLANES Jancair ES EP ARF User manual

GREAT PLANES

GREAT PLANES Spirit User manual

GREAT PLANES

GREAT PLANES Giles G-202 User manual

GREAT PLANES

GREAT PLANES F1 Rocket Evo User manual

GREAT PLANES

GREAT PLANES Siren ARF User manual

GREAT PLANES

GREAT PLANES Viper 500 RTC Configuration guide

GREAT PLANES

GREAT PLANES PT-17 Stearman User manual

GREAT PLANES

GREAT PLANES CAP 232 User manual

GREAT PLANES

GREAT PLANES Ryan STA EP User manual

GREAT PLANES

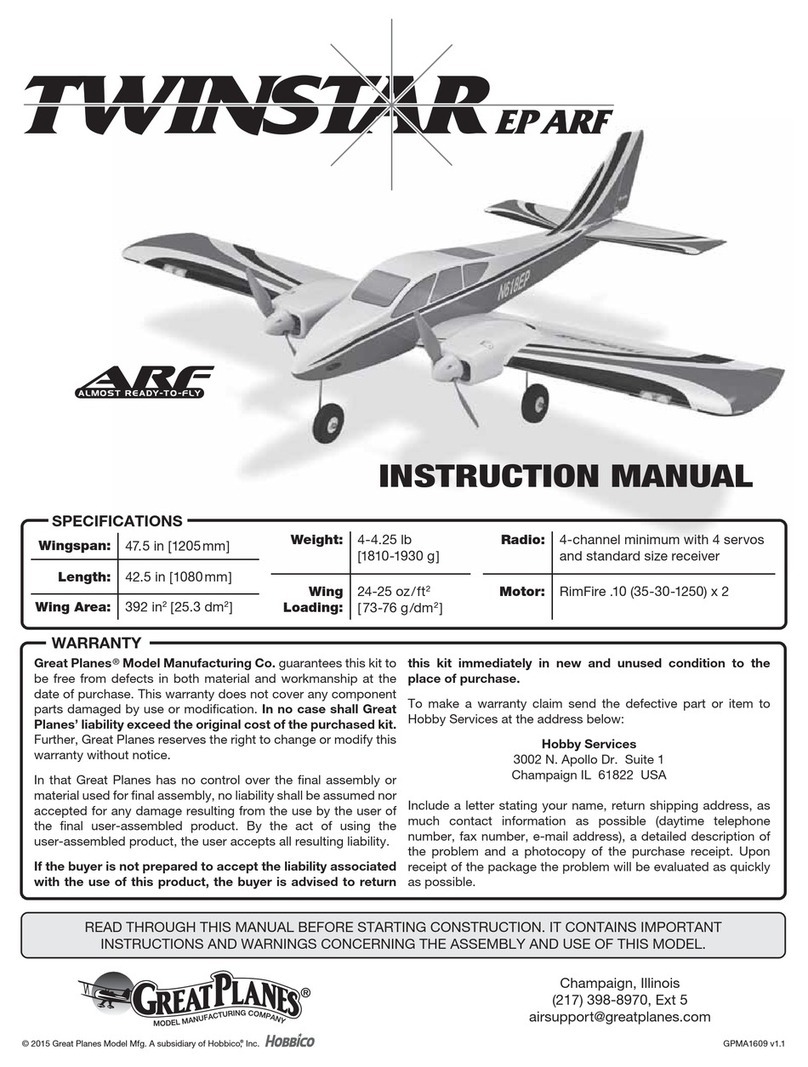

GREAT PLANES TWINSTAR EP User manual

GREAT PLANES

GREAT PLANES Venus II User manual

GREAT PLANES

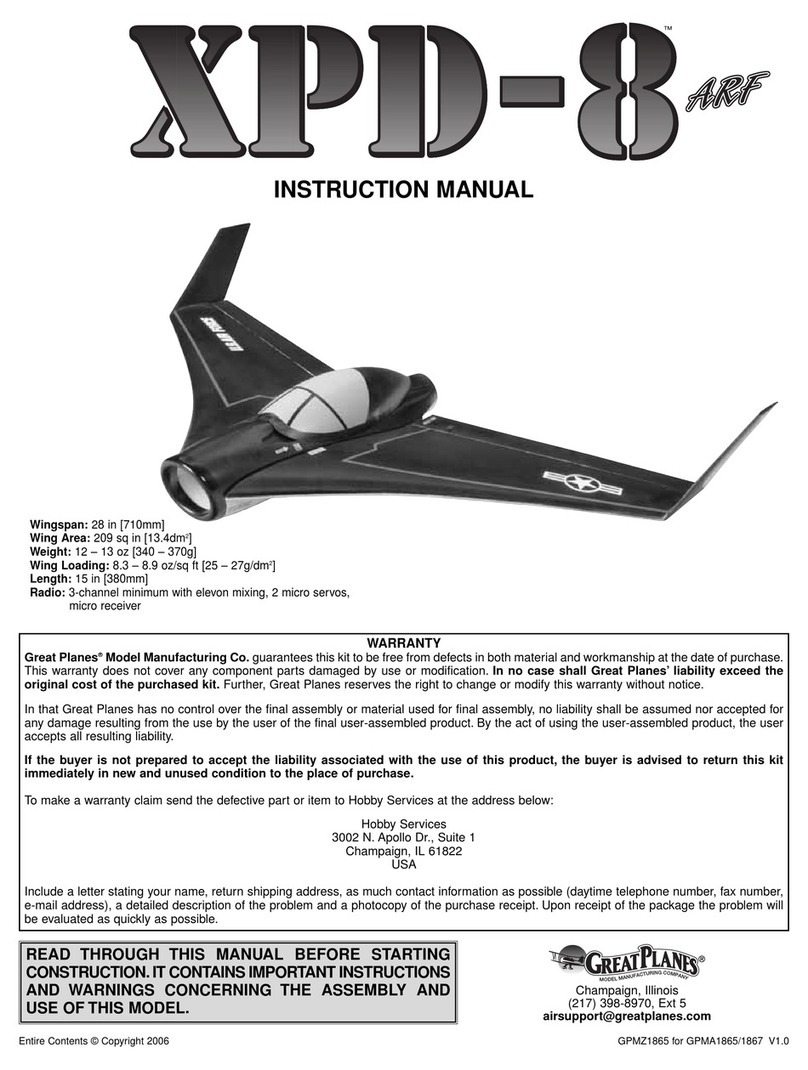

GREAT PLANES XPD-8 User manual