S5000 User Guide

2

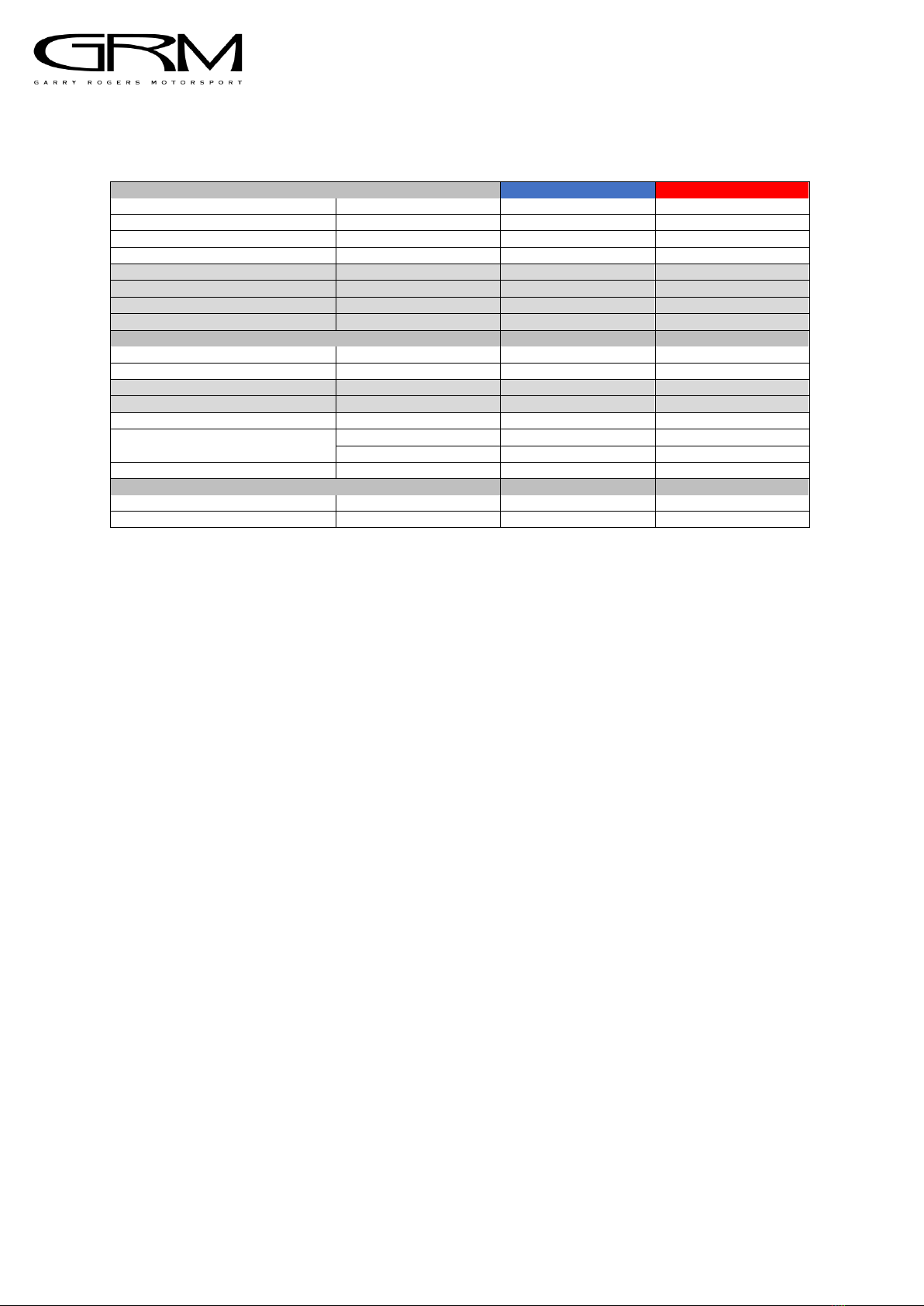

TABLE OF CONTENTS

1 CUSTOMER SERVICE CONTACT...........................................................4

1.1 Technical Support ......................................................................... 4

1.2 GRM Workshop ............................................................................. 4

2 OVERVIEW.........................................................................................5

2.1 General Dimensions ...................................................................... 5

2.2 Baseline Set-Up ............................................................................ 6

2.3 Chassis Identification .................................................................... 7

3 CAR CHARACTERISTICS.....................................................................8

3.1 A - ENGINE .................................................................................. 8

3.1.1 General Information................................................................. 8

3.1.2 Engine Power Curve ................................................................. 8

3.1.3 Engine Identification ................................................................ 9

3.2 B - ENGINE SYSTEMS .................................................................. 10

3.2.1 Cooling System ..................................................................... 10

3.2.2 Oil System ........................................................................... 10

3.2.3 Intake System ...................................................................... 11

3.2.4 Exhaust System .................................................................... 11

3.2.5 Fuel System ......................................................................... 11

3.3 C - TRANSMISSION ..................................................................... 12

3.3.1 Clutch ................................................................................. 12

3.3.2 Transmission ........................................................................ 12

3.3.3 Lubrication ........................................................................... 13

3.3.4 Pneumatic Gear selection system ............................................. 14

3.3.5 Differential ........................................................................... 14

3.3.6 Driveshaft ............................................................................ 14

3.4 D - WARM UP PROCEDURE ........................................................... 15

3.5 F - FRONT AND REAR SUSPENSION ............................................... 16

3.5.1 Overview ............................................................................. 16

3.5.2 Set-Up Adjustments ............................................................... 17

3.5.3 Front Suspension Geometry adjustment .................................... 17

3.5.4 Front Anti-Roll bar ................................................................. 18

3.5.5 Front Spring ......................................................................... 19

3.5.6 Rear Suspension Geometry adjustment ..................................... 20

3.5.7 Rear Anti-Roll bar .................................................................. 20

3.5.8 Rear Spring .......................................................................... 22