P/N G610B

April, 2016 (Rev 0)

Page 2

INTRODUCTION

There exist a variety of causes for cooking fires, but

most causes involve unattended cooking. Here are

some tips to help prevent a cooking fire in your

kitchen.

FIRE PREVENTION TIPS:

•Never leave the kitchen when cooking food.

•Use fresh cooking oil whenever possible. The

ignition temperature of used cooking oil can be

lower than normal and it may contain left-over

solids which can ignite.

•Smoke generated from cooking oil is an indication

that the temperature of the oil has exceeded the

desired cooking temperature of 350-375 F. As the

oil temperature increases, the smoke produced

will increase significantly. If this occurs, simply

turn the burner down or turn it off to prevent the oil

from reaching its ignition temperature.

•Be sure to keep the cooking surface and

surrounding counter areas clean and clear of

combustible materials which could ignite.

•If you must leave the kitchen when frying food,

turn the burner off or remove the pan from the

burner until you return.

IN CASE OF A FIRE:

NEVER attempt to move a burning cooking vessel

after it has ignited. Any movement could splash

burning grease and spread the fire or cause severe

injury. NEVER TRY TO EXTINGUISH A GREASE

FIRE USING WATER. Evacuate the kitchen and call

the Fire Department immediately, then alert others

and evacuate the building. Let your Guardian G600-B

extinguish any range top fire. Because of the heat and

smoke associated with a cooking fire, it is

recommended that you wait at least 30 minutes after

the fire has been extinguished before re-entering the

building and approaching your kitchen range.

OPERATION:

The Guardian G600-B system is an automatic fire

suppression system designed to detect and extinguish

cooking fires on residential type range tops. In the

event of a stovetop fire, the sensors will activate at a

pre-set temperature and signal the main CPU board.

The main CPU automatically sends a signal to release

the extinguisher valve assembly, releasing the

extinguishing agent and simultaneously activates the

CPU-mounted alarm, and the fuel shutoff which

disconnects the gas and/or electricity to the range.

APPLICATION AND LIMITATION

•The Guardian G600-B is designed and Listed for the

protection of 30 in. wide, gas or electric residential

range tops when installed in conjunction with a 30 inch

wide exhaust hood or microwave/exhaust hood

combination with a flat ferromagnetic underside. The

extinguishing system is intended for installation within a

kitchen cabinet having an internal height of 12" or taller

and located either directly above, or adjacent to the

range top and exhaust hood.

•Guardian G600-B System is acceptable for use with

either a ductless or ducted exhaust hood.

•The extinguisher enclosure assembly is intended for

installation within a protected space, such as a kitchen

cabinet as outlined in this manual.

•Only components identified by part numbers in this

manual are authorized for use with the Guardian G600-

B system unless expressly stated in this manual.

•All electrical wiring and alarm connections are to be in

compliance with the National Electrical Code (NFPA

70), National Fire Alarm Code (NFPA 72) and any

applicable state or local municipal codes.

RESIDENTIAL RANGE-TOP USE ONLY

•The Guardian G600-B extinguishing system is designed

and thoroughly tested in accordance with UL Subject

300A for normal residential type cooking applications

which originate from residential range top cooking

appliances when used in conjunction with a flat faced

(bottom) exhaust hood or microwave hood only.

•The Guardian G600-B extinguishing system is not

intended for the protection of commercial "restaurant-

style" cooking equipment.

•The maximum range top cooking surface protected by

the Guardian G600-B System is 720 square inches

measuring 30" wide and 24" deep.

•The Guardian G600-B is not designed or intended for

the protection of areas adjacent to, or within the

residential range top, such as nearby counter tops or

within the range oven.

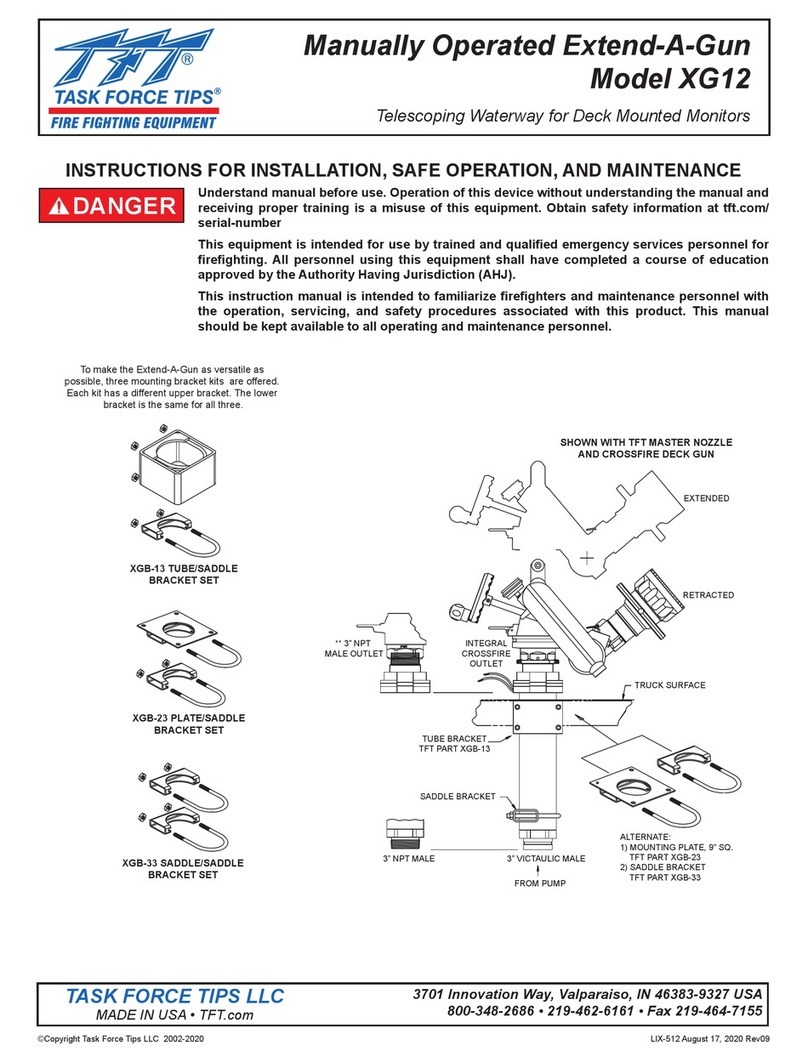

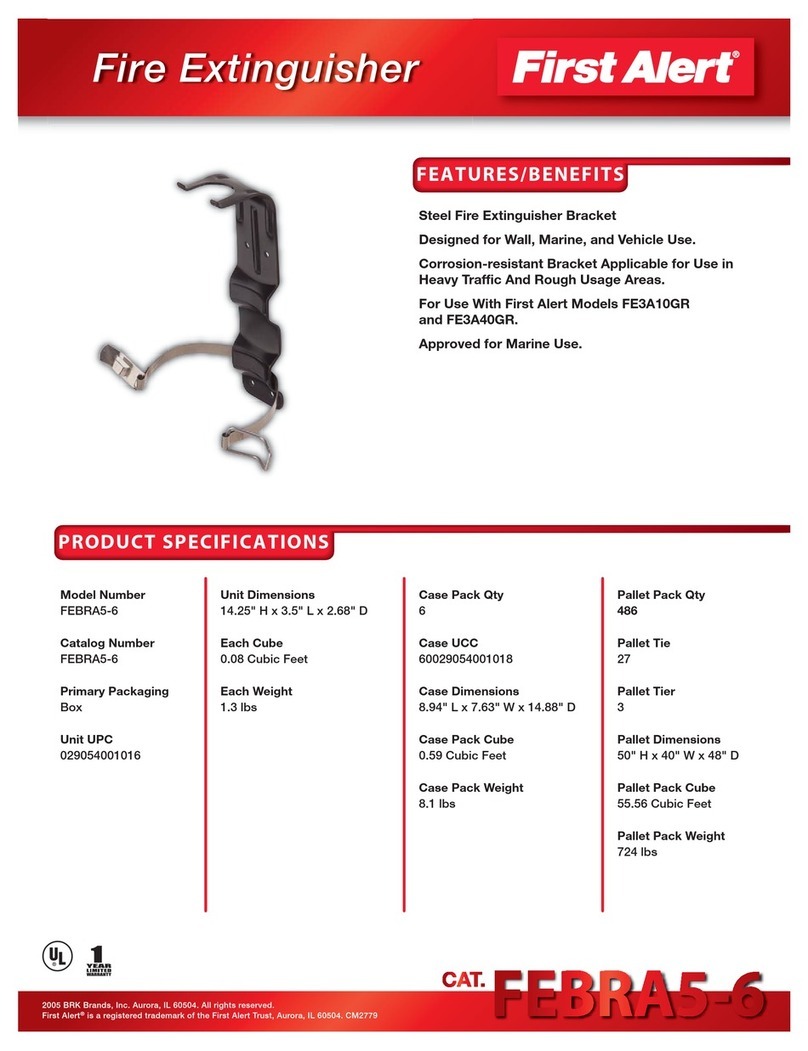

PACKING LIST

Check contents for missing or damaged parts (see

FIGURES 1, 2, 3 & 4). Check fire extinguisher for proper

operating pressure. Needle should point in the operable

(green) zone. Report any damage or missing parts to the

manufacturer before starting installation.

CAUTION:

DO NOT REMOVE SAFETY PIN FROM FIRE

EXTINGUISHER AT THIS TIME!!!

NOTE:

Additional equipment or components necessary to install the system in accordance with the instructions and limitations listed

are to be provided by the authorized installer if not purchased with the basic system (i.e., electrical Wire, wire mold, shut-off

components, etc.). Additional equipment and components may be obtained from a Guardian Safety Solutions International

distributor or the manufacturer.