9

OPERATION MANUAL

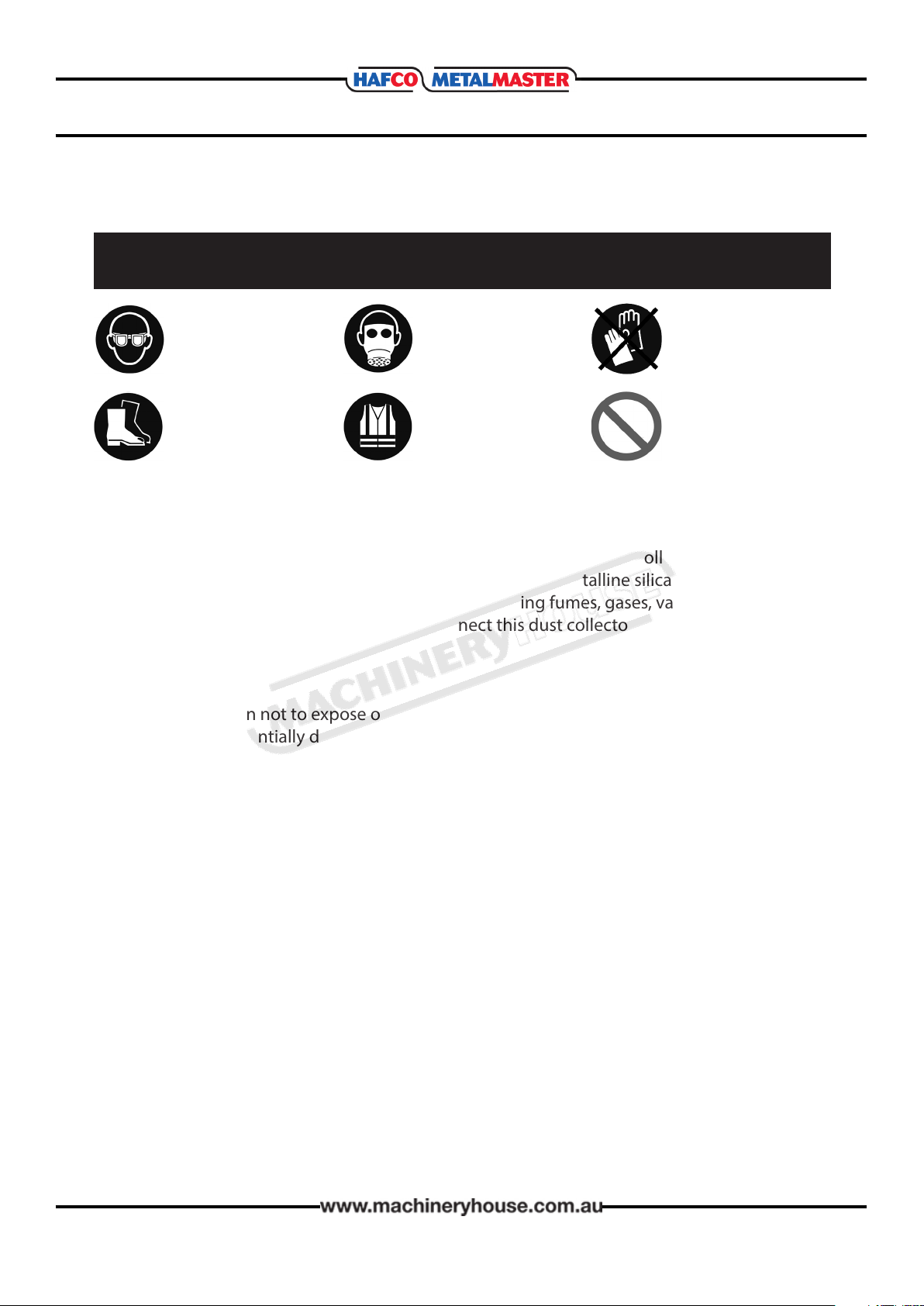

2.2 SPECIFIC SAFETY FOR DUST COLLECTORS

DO NOT use this machine unless you have been instructed in its safe use and

operation and have read and understood this manual

Safety glasses must be

worn at all times in work

areas

Approved respirator

should be worn.

Gloves must not be

worn when using this

machine.

Sturdy footwear must be

worn at all times in work

areas

Close tting/protective

clothing must be worn

Rings and jewelery must

not be worn.

USE FOR INTENDED PURPOSE.

This is a metal dust collector and is only designed to capture noncombustible or non-explosive

metal particles. When using the dust collector only collect one type of metal/material at one

time. DO NOT use to collect wood or wood products. DO NOT use it to collect lead, magnesium,

niobium, tantalum, titanium, zirconium, hafnium, asbestos, crystalline silica, gypsum, or any

other non-metal products. DO NOT use to capture welding fumes, gases, vapors, liquids, smoke,

or ordinary combustible materials. DO NOT connect this dust collector to any machine using a

coolant system.

TOXIC MATERIALS.

Care should be taken not to expose operators to certain types of metal dusts or fumes that can

result in serious, potentially deadly health eects. To reduce this risk, investigate the toxicity of

metal types you work with and always seek to minimize or eliminate exposure to the operator

and other bystanders.

KNOW WHEN TO CHANGE FILTERS

A simple but important safety requirement is to change lters when airow through the system

reaches a reduced pressure. Filter changing is also necessary when the pressure drop across

the collector is aecting the ability of the system to capture dust, allowing it to escape into the

atmosphere. Some cartridge lters can operate longer between changes. However, for heavy

dust-loading applications, lter replacement might be much more frequent.

RISK OF FIRE/EXPLOSIONS.

Only connect with smooth-walled, sheet-metal ducting, to minimize static electrical charge.

DO NOT use PVC pipe. If using ducting, the system must be sealed and grounded. Fine metal

dust particles can ignite, depending on material type and circumstances. Be educated and

prepared to ght a combustible metal re. Keep the dust collector away from pilot lights, open

ames, or other ignition sources.

NEVER use near chemical fumes or within an enclosed spray booth.