Esta TK-4 User manual

The World of Extraction

OPERATING INSTRUCTIONS

OM/TK/OMF

Mini Dust Collector

C

E

R

T

I

F

I

E

D

I

S

O

9

0

0

0

:

2

0

0

8

QUALITY

Your purchase of an ESTA machine has

been a good decision. The design of

our quality products complies with the

latest state of the art. ESTA products

have been devised to provide for clean

air at the workplaces at which they are

applied. This results in an even more

enhanced level of quality and longer

machine times and, particularly, healthier

working conditions. Should you have

any questions pertaining to suction tech-

nology issues, please feel free to contact

us at any time. Our experts will be gladly

at your disposal.

Your ESTA Absaugtechnik Team

The World of Extraction

www.esta.com

Welcome to the sphere of suction

technology

Installation instructions

TK / OM / OMF

Item No. 31.041 (TK-4)

Item No. 31.061 (TK-6)

Item No. 41.032 (TK-H)

Item No. 41.033 (TK-2.2)

Item No. 21.081 (OM-8)

Item No. 21.101 (OM-10)

Item No. 21.122 (OM-12)

Item No. 21.127 (OM-12 S)

Item No. 21.308 (OMF-8)

Item No. 21.310 (OMF-10)

Item No. 21.312 (OMF-12)

Do not use this device unless you have

read theiInstallation instruction and understand it.

Translation of the original installation instructions

31061-08-05

2

TK/OM/OMF

31061-52-05

Edition notice

Original installation instructions

Document No.: 31061-08-05

Publishing date: 26.04.2017

Type of device: TK // OM // OMF stationary extractor

Item No.: 31.041 // 31.061 // 41.032 // 41.033 // 21.081 // 21.101 // 21.122 // 21.127 //

21.308 // 21.310 //21.312 and variations

Publisher

ESTA Apparatebau GmbH & Co. KG Tel.: +49 (0) 73 07 80 4 -0

Gotenstraße 2-6 Fax: +49 (0) 73 07 80 4 -500

Germany www.esta.com

Copyright notice (per DIN ISO 16016:2007-12)

Transfer or reproduction of this document, or the use or communication of its content, is

forbidden without explicit consent. Violators will be liable for damages. All rights to patent, utility

or design registration are reserved.

Warnings and safety instructions

Electrical current hazard

Note

Reference to ESTA customer service

Reference to legal regulations

31061-52-05

TK/OM/OMF

3

Contents

Contents .....................................................................................................................................3

1. General safety notes ...........................................................................................................4

2. Preventing mechanical hazards.........................................................................................6

3. Preventing electrical hazards.............................................................................................6

4. Preventing dust hazards.....................................................................................................6

5. Intended use ........................................................................................................................7

6. Technical data and description..........................................................................................8

6.1 Small dust extractor models ...............................................................................................8

6.1.1 TK....................................................................................................................................8

6.1.2 OM...................................................................................................................................8

6.1.3 OMF ................................................................................................................................9

6.2 Functional description.........................................................................................................9

7. Delivery, installation and start-up....................................................................................10

7.1 Delivery and transport ......................................................................................................10

7.2 Installation........................................................................................................................10

7.3 Start-up.............................................................................................................................11

8. Maintenance & troubleshooting.......................................................................................12

8.1 Maintenance instructions..................................................................................................12

8.2 Inspection and maintenance intervals .............................................................................13

8.3 Troubleshooting................................................................................................................14

9. Monitoring the minimum airflow volume.........................................................................15

10. Cleaning .............................................................................................................................15

10.1 Cleaning the filter manually............................................................................................15

10.2 Filter replacement...........................................................................................................16

11. Disposal..............................................................................................................................17

11.1 Disposing of collected dust materials .............................................................................17

11.2 Disposing of the device ..................................................................................................18

12. Optional equipment...........................................................................................................18

12.1 Water pre-separator for reducing fire hazards................................................................18

12.2 Muffler ............................................................................................................................18

12.3 Movable stand................................................................................................................18

13. Device diagram..................................................................................................................19

14. Declaration of incorporation.............................................................................................20

Notes.........................................................................................................................................22

Notes.........................................................................................................................................23

4

TK/OM/OMF

31061-52-05

1. General safety notes

Before operation, all persons who are to use the device or perform maintenance

on it must be provided with information, instructions and training in using the

device and on the substances for which it is to be used, including the procedure

for safe disposal of the collected material. Responsibilities must be clearly

established for the following:

Installation

Start-up

Operation

Maintenance and repair

The device must be used only by persons who have been instructed in its

handling and are explicitly authorized to use it.

Always keep the operating manual at the place where the dust extractor is being

used, so that it can be seen by personnel at all times.

The dust extractor is intended only for dry cleaning and must not be used or

stored outdoors or under wet conditions.

No liquids, aggressive gases, easily flammable materials or glowing particles

(such as hot embers) may be aspirated. For example, it is prohibited to use the

dust extractor in painting operations. It is forbidden to exhaust processing

machines with active ignition sparks or hot embers (such as multi-blade saws).

Installation and operation in dust-explosive or gas-explosive areas is forbidden.

Only original ESTA replacement parts must be used; use of other products will

void the warranty.

During exhaust, the volume flow returned from the dust extractor into the room

must be no more than 50% of incoming air. With free room ventilation, the

incoming airflow must equal the room volume every hour. This means that the rate

of air replacement must be once per hour.

Incoming airflow [m³/h] = room volume [m³] air replacement rate [1/h]

Example:

When the ESTA dust extractor is operating at the nominal airflow volume of 1200

m³/h the same volume of fresh air must therefore be fed in. This occurs with

natural ventilation if the volume of the work room is 1200 m³ (e.g., 400 m² surface

with a 3 m ceiling height).

31061-52-05

TK/OM/OMF

5

The devices are delivered without a switching device. The operator of the device

must properly determine that the device can be safely connected to the electrical

source and operated. The motor must be electrically secured against overload.

Operating the device without such protection voids the motor warranty. It is

recommended that a motor safety switch be used, with which the device can be

turned on or off immediately.

The power cable must be connected or replaced only by an electrical

specialist or by a person trained for the purpose.

Only plugs and connectors complying with EN 61241-14 must be used for

connecting electrically driven industrial vacuums and dust extractors. Coupling

plugs and connectors or adapters are not permitted.

Make sure that the power cable does not become damaged by being run over,

compressed, pulled, etc.

The power cable must be examined regularly for signs of damage or ageing.

The device must not be used if damage to the power cable is determined.

Only original ESTA conductive accessories may be used for operating the

dust extractor.

From its first use, the dust extractor contains toxic dust. Emptying and

maintenance processes, including removal of the dust collection container,

must be performed by expert personnel who are wearing appropriate

protective gear. The dust extractor must not be operated without the

complete filtration system!

According to directive 2009/104/EG and TRGS 560, safety devices for

prevention or removal of hazards must be regularly maintained and

regularly inspected by an expert for safe, flawless operation.

In all emergencies, the device must be disconnected from the power supply

immediately. If there is a fire, the fire department is to be alerted

immediately, and the fire must be contained by appropriate means.

6

TK/OM/OMF

31061-52-05

2. Preventing mechanical hazards

All movable machine parts driven by electric motors must be covered by fixed,

securely fastened protective covers that can be removed only with tools.

Residual risk:

If a covering that can only be unfastened with a tool is removed, there is risk

of injury if the machine is running.

3. Preventing electrical hazards

All electrical parts must be covered by fixed, securely fastened protective covers

that can be removed only with tools. The device complies with Protection Class I

according to EN 60 335.

Residual risk:

If a covering that can only be unfastened with a tool is removed, a hazard is

posed by electric current.

4. Preventing dust hazards

When removing the dust collection container, it is possible to inhale dust.

Following the instructions in the section “Disposing of collected materials” will

minimize this hazard. When transporting the device, close the exhaust openings to

prevent dust from escaping.

31061-52-05

TK/OM/OMF

7

5. Intended use

ESTA dust extractors have been manufactured according to the state of the art

and in compliance with safety regulations.

When used as intended, the devices are suitable for removing dry, non-

flammable, non-explosive, nontoxic dusts.

The dust extractor must not be used outdoors or under wet conditions.

The devices are suitable for commercial use, such as in industrial enterprises and

workshops.

Other applications are considered unintended use. ESTA is not liable for damages

due to unintended use!

ESTA sets up the dust extractor according to the operator’s information.

When connecting the suction hose, make sure to use only electrically conductive

hoses and that the electrical connection between the hose and the port is perfect.

If a so-called “spiral hose” is used, the metal spirals must be stripped and pressed

to the bare wall of the exhaust port with a pipe clamp after the hose is attached.

Only plugs and connectors complying with EN 61241-14 must be used for

connecting electrically driven industrial vacuums and dust extractors.

Extension cords, coupling plugs and connectors or adapters are not

permitted.

8

TK/OM/OMF

31061-52-04

6. Technical data and description

6.1 Small dust extractor models

6.1.1 TK

Model:

(see model plate)

TK-4

TK-6

TK-H

TK-2.2

Max. air volume

[m³/h]

300

450

300

300

Max. vacuum

[Pa]

1.100

1.400

24.000

21.000

Connection voltage

[V]

400/230*

400

Nominal frequency

[Hz]

50

Drive output

[kW]

0,55

2,2

RPM

[1/min]

2.800

Filter area

[m²]

1

Connection

diameter

[mm]

60

80

50

Dimensions

(L/W/H)

[mm]

400x400x590

400x630x

590

930x460x

655

Total depth

[mm]

600

-

900

Weight

[kg]

40

60

105

Environmental

conditions

[°C]

540

Max. air humidity

[%]

approx. 60

Production year

See model plate

*Custom design for AC current

6.1.2 OM

Model:

(see model plate)

OM-8

OM-10

OM-12

OM-12S*

Max. air volume

[m³/h]

500

600

800

Max. vacuum

[Pa]

1.600

1.500

1.800

Connection voltage

[V]

400

Nominal frequency

[Hz]

50

Drive output

[kW]

0,55

1,1

RPM

[1/min]

2.800

Filter area

[m²]

2,4

Connection diameter

[mm]

80

100

150

Dimensions (L/W/H)

[mm]

720x630x

1.120

740x610x

1.080

740x610x

1.150

720x600x

1.420

Total depth

[mm]

670

Weight

[kg]

60

65

70

Environmental

conditions

[°C]

540

Max. air humidity

[%]

approx. 60

Production year

See model plate

*Larger dust collection drawer

31061-52-05

TK/OM/OMF

9

6.1.3 OMF

Model:

(see model plate)

OMF-8

OMF-10

OMF-12

Max. air volume

[m³/h]

500

600

800

Max. vacuum

[Pa]

1.600

1.500

1.800

Connection voltage

[V]

400

Nominal frequency

[Hz]

50

Drive output

[kW]

0,55

1,1

RPM

[1/min]

2.800

Filter area

[m²]

2,4

Connection diameter

[mm]

80

100

150

Dimensions (L/W/H)

[mm]

600x670x1.130

Total depth

[mm]

670

Weight

[kg]

65

85

Environmental

conditions

[°C]

540

Max. air humidity

[%]

approx. 60

Production year

See model plate

Technical changes reserved

6.2 Functional description

Depending on the model, the small dust extractor is equipped with a three-phase

fan (custom equipment with AC current), with a suction turbine (TK-H) or with a

side channel compressor (TK-2.2).

Through the intake port, the exhausted air enters a pre-separator area, which on

the OMF models is additionally equipped with a spark separator. On the OMF

variants, heavy dusts and any sparks fall directly into the dust collection drawer.

The rest of the dust is separated into the connected bag filter, which, depending

on the application, can be provided in various separation classes and materials.

The clean air then enters the suction unit and is led back into the work area

through an exhaust port with a muffler. Filter cleaning can be done manually

during downtime using the installed tapping device. This knocks the adhered dust

into the dust collection drawer.

10

TK/OM/OMF

31061-52-04

7. Delivery, installation and start-up

7.1 Delivery and transport

The devices are delivered mounted to a Europallet or a one-way pallet. The

devices are wound in stretch wrap to prevent scratches and transport damage.

Please dispose of the packing material according to local regulations.

Upon delivery, please inspect the device for transportation damage.

Detected damage must be documented and reported immediately.

ESTA customer service: +49 (0) 7307 804 - 0

When setting up the device, make sure the ground can support it.

7.2 Installation

The devices are delivered without a switching device. The operator of the device

must properly determine that the device can be safely connected to the electrical

source and operated. The motor must be electrically secured against overload.

Operating the device without such protection voids the motor warranty. It is

recommended that a motor safety switch be used, with which the device can be

turned on or off immediately.

Installation work must be performed only by an electrical specialist or by a

person trained for the purpose!

Before setting up the cable connection between the device and the power

grid, check to make sure the operating voltage shown on the model plate is

the same as that of the grid.

Plugs and connectors complying with EN 61241-14 must be used for

connecting electrically driven industrial exhausts and dust extractors.

Coupling plugs and connectors or adapters are not permitted.

The device must be set up so that the dust collection drawer and tapping device

are accessible. When connecting a suction hose, make sure to use only

electrically conductive hoses and that the electrical connection between the hose

and the port is perfect. If a so-called “spiral hose” is used, the metal spirals must

be stripped and pressed to the bare wall of the exhaust port with a pipe clamp

after the hose is attached.

31061-52-05

TK/OM/OMF

11

7.3 Start-up

Only persons authorized in the section “General safety instructions” must

commission the device.

Before the device is first used, its operation must be tested; such testing is

required monthly.

Pay attention to the direction of rotation!

Before the device is commissioned, check whether the direction of rotation of the

impeller wheel (OM, OMF, TK-4/6), the suction turbine (TK/H) or the side channel

compressor (TK-2.2) is correct. To do this, observe a brief start-up of OM, OMF,

and TK4/6 model devices in the direction of the arrow shown on the motor. The

motor’s fan wheel must turn in the direction of the arrow. For TK/H and TK-2.2

internal suction units, the suction performance must be checked.

When the direction of rotation is wrong, the device gets impermissibly hot,

the airflow volume gets weaker, or reverses on the TK-2.2, and the device’s

performance suffers. This can also damage the device.

12

TK/OM/OMF

31061-52-05

8. Maintenance & troubleshooting

8.1 Maintenance instructions

For maintenance by qualified personnel, the device must be opened, cleaned and

inspected at the given locations, as well as possible, without any hazard being

posed to maintenance personnel or other persons. Proper precautions must be

taken before cleaning and removal of wearing parts. This includes locally filtered

forced-air ventilation in the area in which the device is being maintained, and

proper personal protective gear.

During maintenance or repair work, all soiled objects that can no longer be

adequately cleaned must be disposed of. Such objects must be discarded in an

impermeable bag in compliance with applicable regulations for disposal of such

refuse.

If necessary, the device can be cleaned with a damp cloth.

It must never be cleaned with flowing water.

The operator is obligated to have maintenance performed once per year.

During maintenance, the entire system is to be tested by a trained expert for

correct operation. A log is to be kept of the main annual inspection in the

included maintenance book. It must document the date of inspection,

deficiencies determined and the name of the inspector. The date of the next

inspection can be read from the test plate installed on the device.

31061-52-05

TK/OM/OMF

13

8.2 Inspection and maintenance intervals

Regular maintenance consists of 3 intervals:

1. Daily inspection includes:

By the dust extractor’s user

Visual inspection

for damage to the device or its parts,

for mechanical damage to the power cable,

Cleaning the filter

for a full dust collection container (regulations require that the container be

emptied if it is more than 2/3 full)

2. Monthly inspection includes:

By expert maintenance personnel

Visual and functional inspection,

for filter leaks (dust trails or deposits on the air outlets)

to assure suction performance. During the inspection, the strength of the air

flow at the exhaust opening must be checked. If the performance is too

weak, the filter must be cleaned also.

3. The main annual inspection includes:

The last test by ESTA is documented on the device!

In collaboration with the ESTA maintenance service

Flow volume measurement

Vacuum measurement

Current consumption measurement

Visual check of filters

Seal inspection

After maintenance, the device receives a new test plate to document that

maintenance has been performed.

This inspection must be done once per year!

The maintenance work must be recorded in writing in the maintenance book

provided. This must make clear the equipment inspected and, if necessary,

the deficiencies found, along with the name of the inspector and the date of

the inspection.

If there is a malfunction, the dust extractor must be switched off

immediately and the responsible maintenance service notified.

Maintenance must be performed according to accident prevention

regulations. The device must be disconnected from the power supply.

14

TK/OM/OMF

31061-52-05

According to work equipment user directives 2009/104/EG and TRGS 560,

safety devices for prevention or removal of hazards must be regularly

maintained and regularly inspected by an expert for safe, flawless operation.

Get the most from ESTA’s maintenance service!

A maintenance contract ensures a long life and top-notch operation for your

dust extractor.

We’ll make you a great offer — just call us up:

ESTA maintenance service: +49 (0) 7307 804 - 0

ESTA replacement part service: +49 (0) 7307 804 - 0

8.3 Troubleshooting

Always use the following checklists if a malfunction is evident. Call ESTA

maintenance service immediately if there is a malfunction that is not discussed in

this list. Do not perform any repairs on the device yourself if they are not explicitly

specified.

Problem

Possible cause

Possible solution

Device shuts off

The motor protection

relay has been tripped

due to low voltage or

overload

Voltage too low

Clean filter

Allow to cool for 30 min.

The housing is too hot

Suction unit is rotating in

the wrong direction

Exhaust paths clogged

Change the connection

polarity

Clean filter

Clean the exhaust hose in

an environmentally sound

manner

Suction too weak

Main filter dirty

Suction hose clogged

Clean filter

Clean the exhaust hose in

an environmentally sound

manner

Suction too weak, even

after filter cleaning

Clogged filter pores

Replace filter

If dust escapes or clouds up from the air outlets, if smoke develops or the

suction assembly runs loud, the device must be switched off immediately!

31061-52-05

TK/OM/OMF

15

9. Monitoring the minimum airflow volume

For safe dust exhaust at the work area, the minimum airflow volume must be

checked before every use. If suction is too weak, turn off the device and clean the

filter and the connected suction equipment.

10. Cleaning

The people assigned to disposal work must be instructed on the aspirated

toxic materials and wear a breathing protection mask with a class P3

particle filter, as well as protective clothing. All distractions by uninvolved

persons must be prevented.

During cleaning work, all soiled objects that can no longer be adequately

cleaned must be disposed of. Such objects must be disposed of in an

impermeable bag in compliance with applicable regulations for disposal of

such refuse.

10.1 Cleaning the filter manually

Before each start-up and when suction decreases, turn the crank

clockwise 3 to 5 times when the motor is still. After the filter has

been cleaned, the dust collection container must be emptied (see

the “Disposal” section).

Additionally, on OMF devices with a spark separator, before activating the hand

crank, remove the spark separator drawer that is integrated into the device. For

this, loosen the screws that lock the drawer. Then the hand crank can be turned

for cleaning. To allow the dust to settle in the device, wait about 1-2 minutes. Then

the spark separator drawer can be installed back into the device.

If fine dust is being exhausted, the filter needs to be cleaned more often.

16

TK/OM/OMF

31061-52-05

10.2 Filter replacement

Filter replacement must be performed in a well-ventilated room or outdoors.

The people assigned to this work must be instructed on the aspirated toxic

materials and wear a breathing protection mask with a class P3 particle

filter, as well as protective gloves. All distractions by uninvolved persons

must be prevented.

After an extended operation period, the filter pores can be clogged by extremely

fine dust. Even the cleaning equipment cannot remove this dust. The filter must be

replaced with a new one.

If possible, filter replacement must be done when there is no work going on. Used

filters must be discarded in compliance with local regulations.

Before the filter is replaced, it must first be cleared of loose dust using the

available cleaning system, and the power must be cut off.

If the bag filter needs replacement, proceed as follows:

10.2.1on TK model devices

1. Remove the housing cover by loosening the screws.

2. Loosen the 6 nuts on the filter fittings.

3. Remove the tapping device by loosening the three screws (bearing plate).

4. Loosen the 10 nuts on the filter frame and remove the filter.

5. Remove the filter fitting by loosening the screws.

To reinstall the filter, follow the same procedure in reverse.

31061-52-05

TK/OM/OMF

17

10.2.2 OM / OMF model devices

1. Remove the fan housing, including the motor and fan

2. Undo the four latches and remove the two screws on the blower box.

3. Loosen the 8 nuts on the filter fittings.

4. Remove the tapping device by loosening the four screws (front side of the

machine).

5. Loosen the 12 nuts on the filter frame and remove the filter.

6. Remove the filter fitting by loosening the screws.

To reinstall the filter, follow the same procedure in reverse.

11. Disposal

The people assigned to disposal work must be instructed on the aspirated

toxic materials and wear a breathing protection mask with a class P3

particle filter, as well as protective gloves. All distractions by uninvolved

persons must be prevented.

11.1 Disposing of collected dust materials

11.1.2 TK model devices

To dispose of the collected material, remove the dust collection drawer from the

device by removing both knurled nuts. Now the dust collection drawer can be

pulled out.

Dispose of the dust contained in the drawer in keeping with local regulations.

Reinsert the emptied container and tighten the knurled nuts again. The device is

now ready to operate again.

11.1.3 OM / OMF model devices

For removing the collected material, the dust collection container’s two latches (on

the underside of the device) must be undone. Now the container can be pulled

out. The collected material must be discarded in compliance with local regulations.

Reinsert the emptied container and lock the latches again. The device is now

ready to operate again.

18

TK/OM/OMF

31061-52-05

11.2 Disposing of the device

Before disposing of the device, empty the dust collection drawer, remove the bag

filter, and dispose of both of them in compliance with local regulations.

Pack the device in a suitable manner and also dispose of it in compliance with

local regulations.

Due to contamination of the device with toxic dust, ESTA cannot take the device

back.

12. Optional equipment

12.1 Water pre-separator for reducing fire hazards

Devices in the OM-8, OM-10, OM-12 and OM-12S line can be optionally equipped

with a water pre-separator, if suction of glowing sparks cannot be ruled out.

The lower port is connected to the suction device and the

upper one to the exhaust equipment.

The housing is filled with water up to the lower edge of the

inspection glass.

Check the water level daily, and change the water every

two weeks.

12.2 Muffler

All devices in the TK, OM and OMF lines can be equipped with a muffler.

12.3 Movable stand

All devices in the TK, OM and OMF lines and the water pre-separator can be

equipped with a movable stand.

This manual suits for next models

21

Table of contents

Popular Dust Collector manuals by other brands

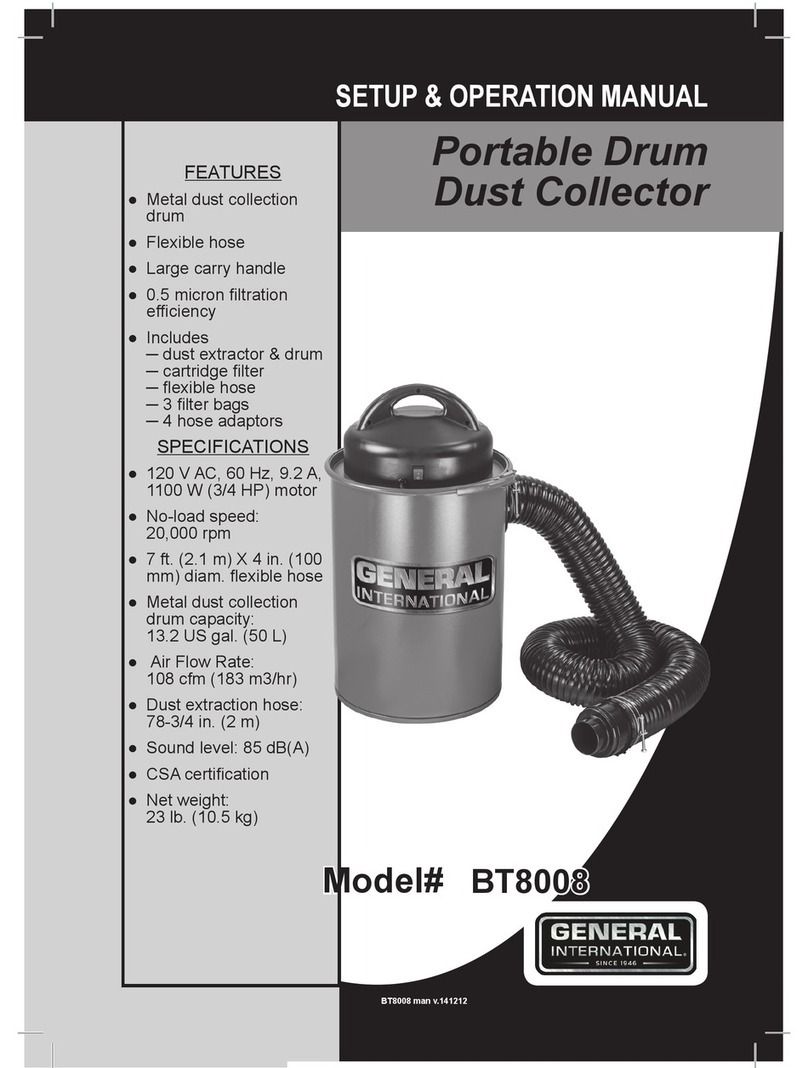

General International

General International BT8008 Setup and operation manual

Jet

Jet DC-1900A operating instructions

AAF

AAF RotoClone W Installation, operation and maintenance manual

Central Machinery

Central Machinery 61808 Owner's manual & safety instructions

Draper

Draper DE1030H instructions

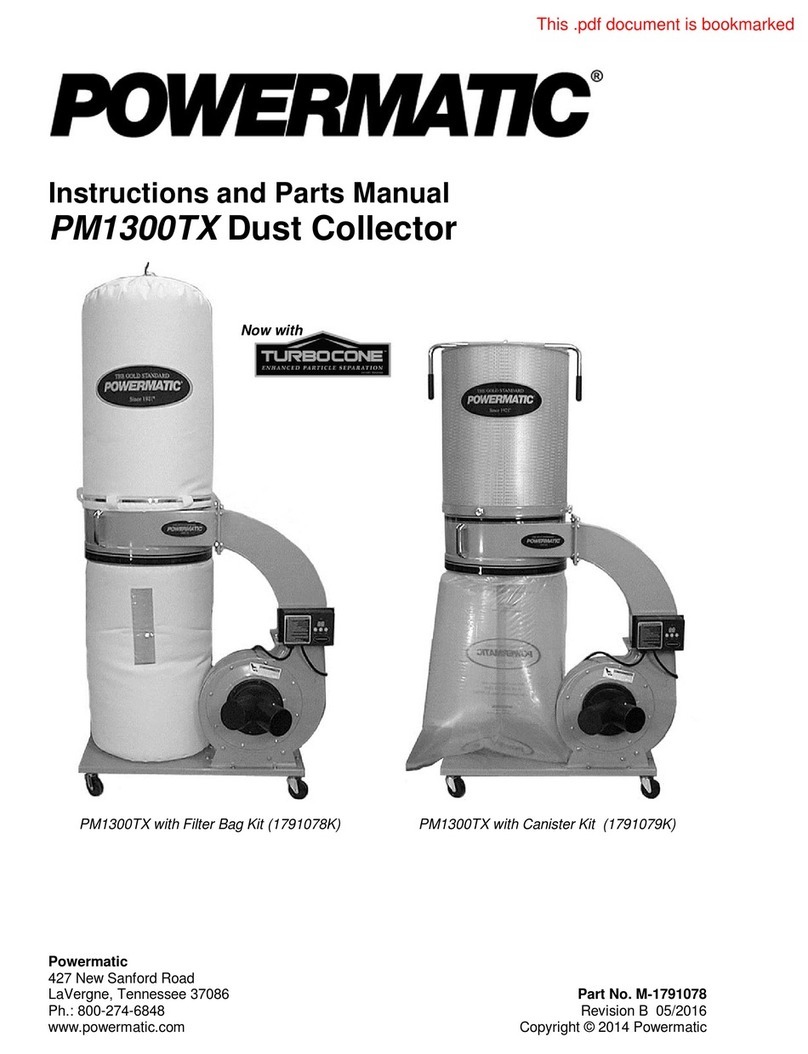

Powermatic

Powermatic PM1300TX-BK Instructions and parts manual