9

OPERATION MANUAL

Ensure that keys and adjusting wrenches have been removed from the machine before

turning on the power. Appropriate storage for tooling should be provided.

Ensure that all cutting tools and blades are clean and sharp. They should be able to cut freely

without being forced.

Stop the machine before measuring, cleaning or making any adjustments.

Wait until the machine has stopped running to clear cuttings with a vacuum, brush or rake.

Keep hands away from the cutting head and all moving parts.

Avoid awkward operations and hand positions. A sudden slip could cause the hand to move

into the cutting tool or blade.

Return all portable tooling to their proper storage place after use.

Clean all tools after use.

Keep work area clean. Floors should be level and have a non-slip surface.

Use good lighting so that the work piece, cutting blades, and machine controls can be seen

clearly. Position any shade lighting sources so that they do not cause any glare or reections.

Ensure there is enough room around the machine to do the job safely.

Obtain rst aid immediately for all injuries.

Understand that the health and re hazards can vary from material to material. Make sure all

appropriate precautions are taken.

Clean machines and the surrounding area when the operation is nished.

Use proper lock out procedures when servicing or cleaning the machines or power tools.

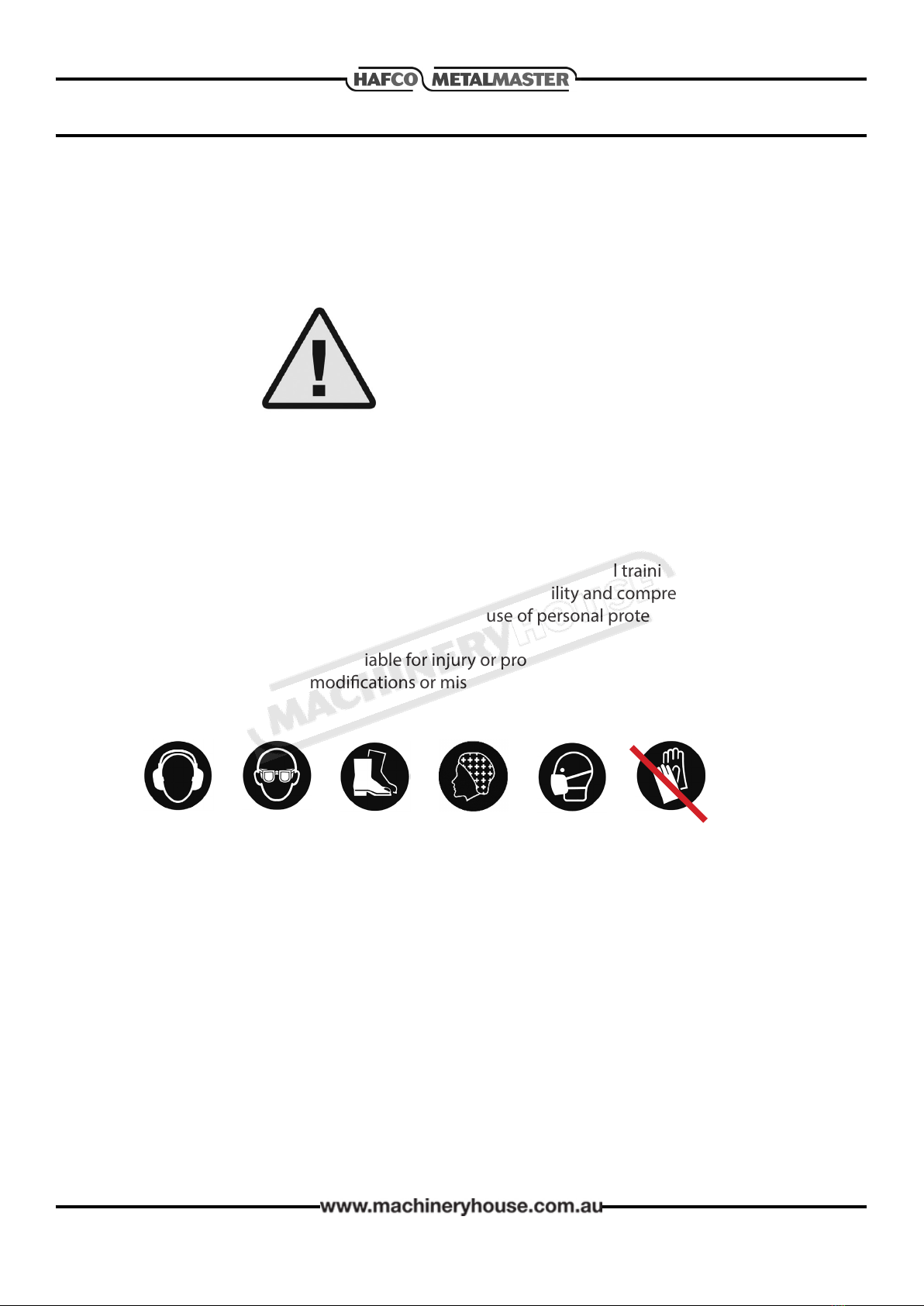

DO NOT

×Do not distract an operator. Horseplay can lead to injuries and should be strictly prohibited.

×Do not wear loose clothing, gloves, necktie’s, rings, bracelets or other jewellery that can be

come entangled in moving parts. Conne long hair.

×Do not handle cuttings by hand because they are very sharp. Do not free a stalled cutter

without turning the power o rst. Do not clean hands with cutting uids.

×Do not use rags or wear gloves near moving parts of machines.

×Do not use compressed air to blow debris from machines or to clean dirt from clothes.

×Do not force the machine. It will do the job safer and better at the rate for which it was

designed.

2.1 GENERAL METALWORKING MACHINE SAFETY Cont.

BEFORE OPERATING ANY MACHINE, TAKE TIME TO READ

AND UNDERSTAND ALL SAFETY SIGNS AND SYMBOLS.

IF NOT UNDERSTOOD SEEK EXPLANATION FROM YOUR

SUPERVISOR.