Operation Manual Total 26

page 3

1.10 Superior quality material with special treatment for the wear-resisting purpose has been

used for transmission parts such as gears, worm and worm shaft, rack, lead screw etc as

well as for some key parts like spindle and spindle quill.

1.11 An adjustable safety protection clutch in the spindle feed device is available in order to

prevent the machine and tools from damage when overloaded.

1.12 A safety protection guard under the spindle box is

coolant splash while cutting but also could observe the machining status.

The guard is interlocked with the spindle, so when the guard is opened, the spindle

could not be running until the protection guard keeps his position.

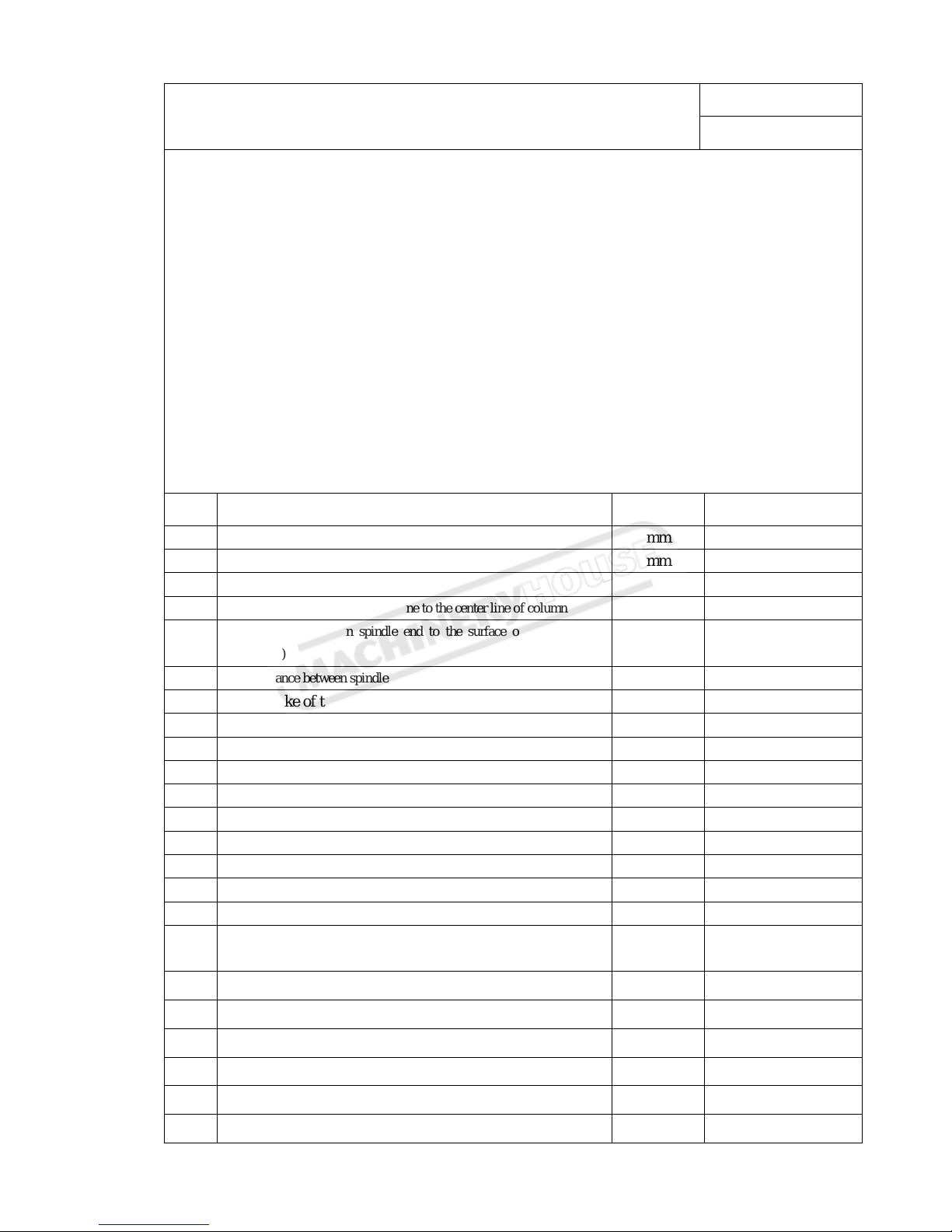

2. Main technical data:

2.1 Main technical data

No. Name of the items Unit Data

1 Max. drilling diameter (steel) mm 50

2 Max. tapping diameter (steel) mm M30

3 Max. milling cutter diameter mm 80

4 Distance between spindle center line to the center line of column mm 360

5 Max. distance between spindle end to the surface of the worktable

(automatic) mm 585(550)

6 Max. distance between spindle end to the worktable surface of the base mm 1170

7 Max. stroke of the spindle mm 240

8 Spindle taper Morse MT4

9 Number of speed steps of the spindle Step 12

10 Spindle speed range r/min 52~1400

11 Feed steps of the spindle Step 4

12 Feed range of the spindle mm/r 0.1-0.4

13 Max. stroke of worktable and its bracket Mm 530(410)

14 Rotation degree of worktable and its bracket in cross direction degree ±45°

15 Working area of the worktable (Lx W) mm 580×460

16 Working area of the worktable of the base (L x W) mm 445×435

17 Numbers and width of the T sl

worktable of base mm 3-T14, 2-T14

18 Diameter of column mm φ180

20 Power and speed of the main motor Kw, rpm 3/1440

21 Power and speed of the worktable up and down motor. Kw, rpm 0.25/1440

22 Power and flow rate of the coolant pump motor Kw, L/min 0.085/6

23 Machine dimension (L x W x H) mm 950×680×2405

24 Weight of the machine (Net weight/Gross weight) Kg 670/730