Page 5 98658C (Rev. B - 1/11)

HACFSCWSD*1D HAC8FSCWSBLQ*1D HACFSCDWSBL*1D HAC8FSCWSBLQ*1D HACFSCWSDBL*1D

CHANGING THE FILTER AND RESETTING THE VISUAL FILTER MONITOR

The electronic sensor includes LED filter status indicators that are factory preset to monitor filter life. The sensor monitors the “ON” time

of the water valve solenoid and keeps track of total time water is dispensed.

There are (3) LED’s that indicate the following:

Green: LED (Good) indicates that the filter is operating within 0% - 80% of its life.

Yellow: LED indicates that the filter is operating within 80% - 100% of its life.

Red: LED (Replace) indicates that the filter needs to be replaced since it has reached end of filter life.

TO CHANGE THE FILTER:

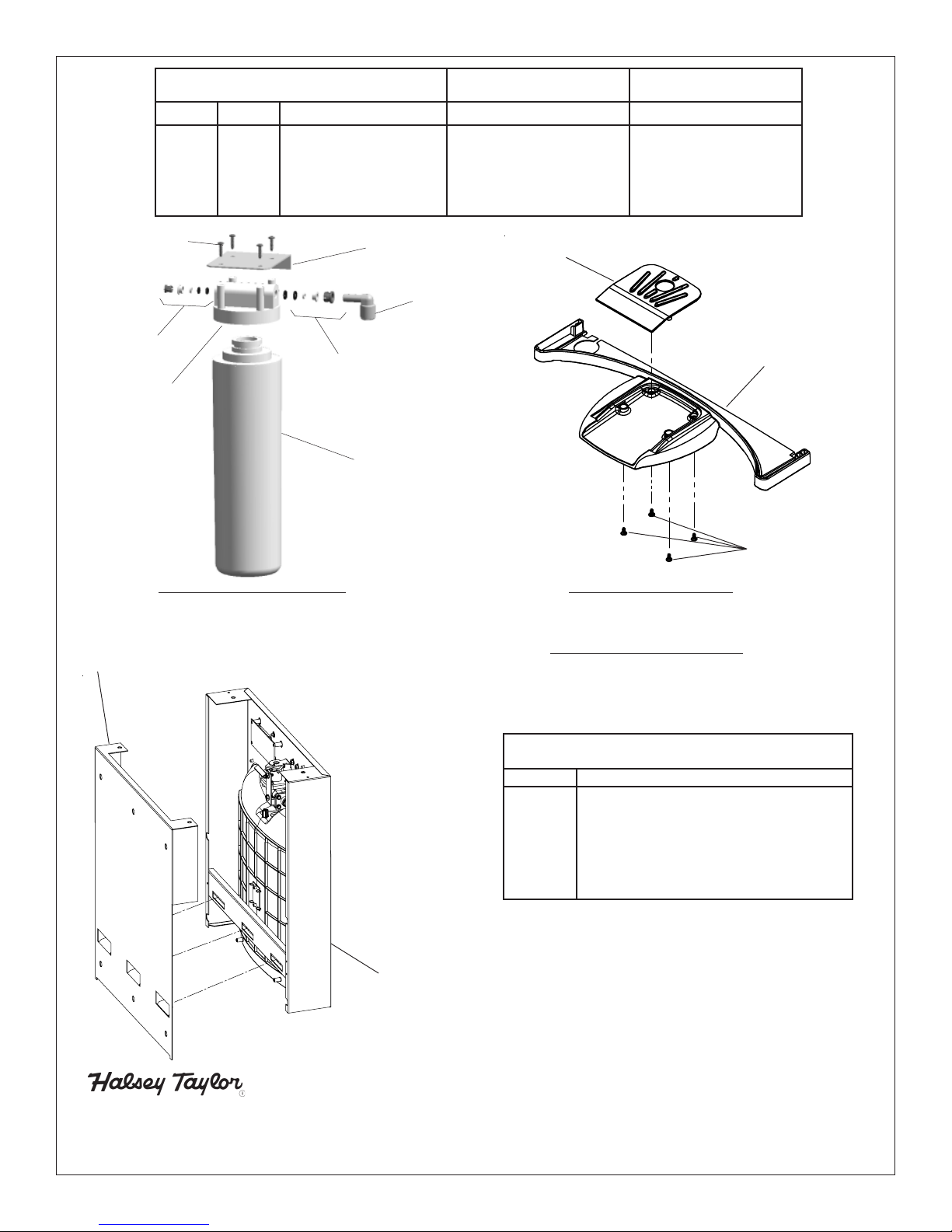

1) Remove the lower front panel of the watercooler by removing the four (4) screws

2) Turn inlet water valve off.

3) Open bubbler to relieve pressure build-up in the system.

4) Remove filter from head by rotating filter counterclockwise.

5) Remove new filter from carton, remove protective cap; cap may be placed on old filter to reduce the chance of water spilling from

filter housing.

6) Attach filter to filter head by firmly inserting into head and rotating filter clockwise.

7) Turn on water supply and hold open the bubbler on cooler until approximately 1 gallon of water is dispensed. This flushing

procedure purges air and fine carbon particles from the filter.

TO RESET THE FILTER MONITOR:

1) In order to reset the visual filter monitor status LED’s, you must remove the top cover of the bottle filler. Remove the two (2) screws

with a 5/32 allen wrench holding top cover to Bottle Filler. Remove top cover. Do not discard mounting screws, they will be needed

to reinstall the top cover

2) With your finger, reach inside the opening and depress the program button located behind the LCD display outside of the electron-

ics cover for approximately 2 seconds until the display changes then release. The display will change and scroll through three

messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

If the program button is not pushed again the display will scroll through the three messages above for three cycles and then default

back to bottle count and be back in run mode.

3) When the display changes to “RST FLTR”, depress the button again. The display will change to show “FLT =”. Depress the button

again and the display will show “FLTR =0”

4) The Green LED should be illuminated indicating that the visual filter monitor has been reset. Reinstall the top cover.

SETTING THE CONTROL BOARD – SETTING RANGE OF THE IR SENSOR

1) In order to access the programming button, you must remove the top cover of the bottle filler. Remove the two (2) screws with a

5/32” allen wrench holding top cover to Bottle Filler. Remove top cover. Do not discard mounting screws, they will be needed to

reinstall the top cover

2) With your finger, reach inside the opening and depress the program button located behind the LCD display outside of the

electronics cover for approximately 2 seconds until the display changes then release. The display will change and scroll through

three messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

If the program button is not pushed again the display will scroll through the three messages above for three cycles and then default

back to bottle count and be back in run mode.

1) To set the RANGE of IR Sensor: when display shows “RNG SET” push program button once the display will show current value (can

be 1 – 10) i.e. “RNG = 3”.

2) Once display shows current value push the program button to scroll through value of 1 – 10. Select the desired range setting.

3) Once range is selected allow approximately 4 seconds to pass and then the display will go back to bottle counter and be in run

mode.

4) Test bottle filler by placing bottle or hand in front of sensor to make sure water is dispensed.

SETTING THE CONTROL BOARD – RESETTING BOTTLE COUNT

1) In order to access the programming button, you must remove the top cover of the bottle filler. Remove the two (2) screws with a 5/

32 allen wrench holding top cover to Bottle Filler. Remove top cover. Do not discard mounting screws, they will be needed to

reinstall the top cover

2) With your finger, reach inside the opening and depress the program button located behind the LCD display outside of the electron-

ics cover for approximately 2 seconds until the display changes then release. The display will change and scroll through three

messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

If the program button is not pushed again the display will scroll through the three messages above for three cycles and then default

back run mode which display bottle count.

3) To reset the BOTTLE COUNTER: when display shows “RST BCNT” push program button once the display will show current value

i.e. “BC0033183”.

4) Once display shows current value push the program button once more to reset back to 0. The display will show BTLCT = 0 for

approximately 2 seconds and then return to run mode showing 00000000 bottles.

5) To test bottle counter, you can place bottle or hand in front of sensor for approx 5 seconds to see bottle counter count 00000001.

(This is based on filling a 16 oz bottle)