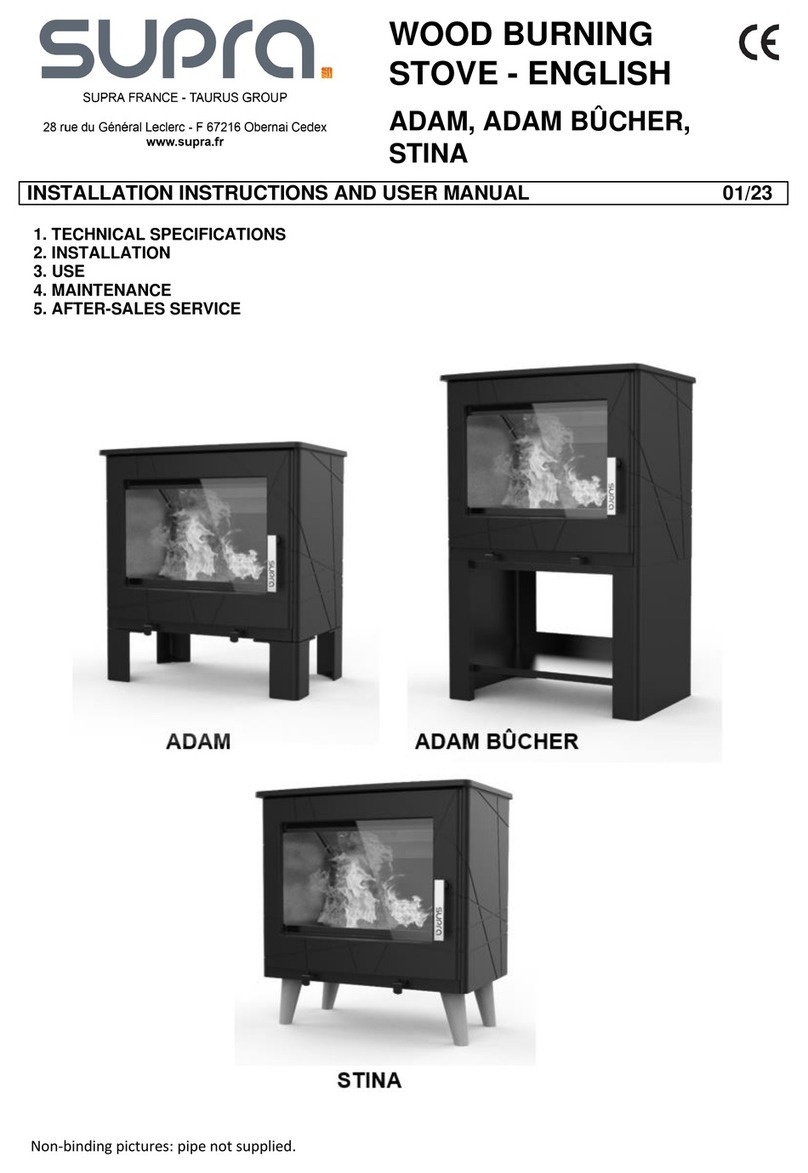

(MODEL LC300, LC500 & LC2500)

xi

TABLE OF CONTENTS

SECTION I: General Information

1-1 Specifications............................................................1-2

1-2 Heater Component Parts Model LC300 .......................3

1-3 Heater Component Parts Model LC500 .......................4

1-4 Heater Component Parts Model LC2500 .....................5

SECTION II: Installation of Heater

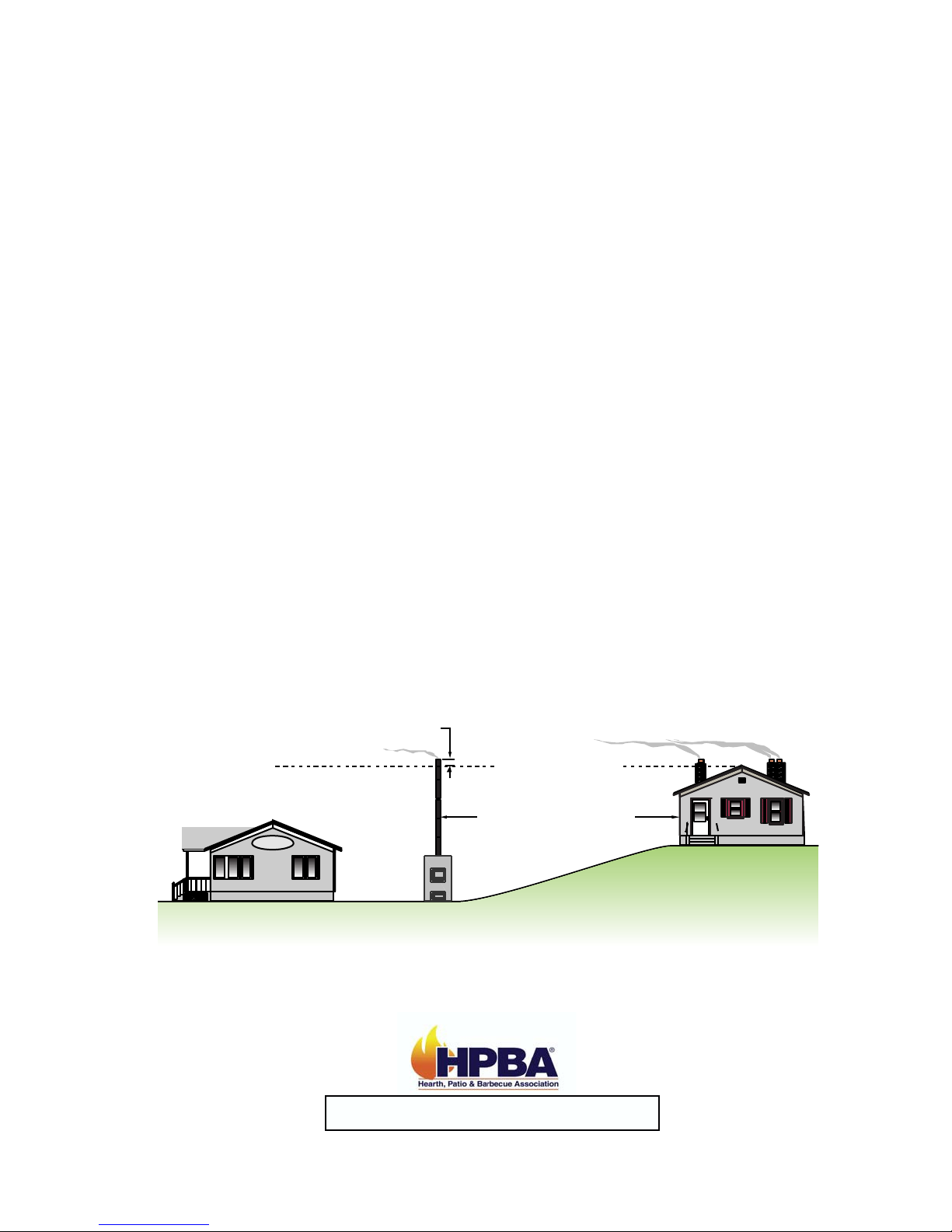

2-1 Location of Heater.....................................................6-7

2-2 Chimney Connection....................................................7

2-3 Hull Removal................................................................8

2-4 Set-Up of Grates .....................................................9-10

2-5 Location of Plumbing & Electrical Lines .....................11

2-6 Connection of Power to Heater ..................................12

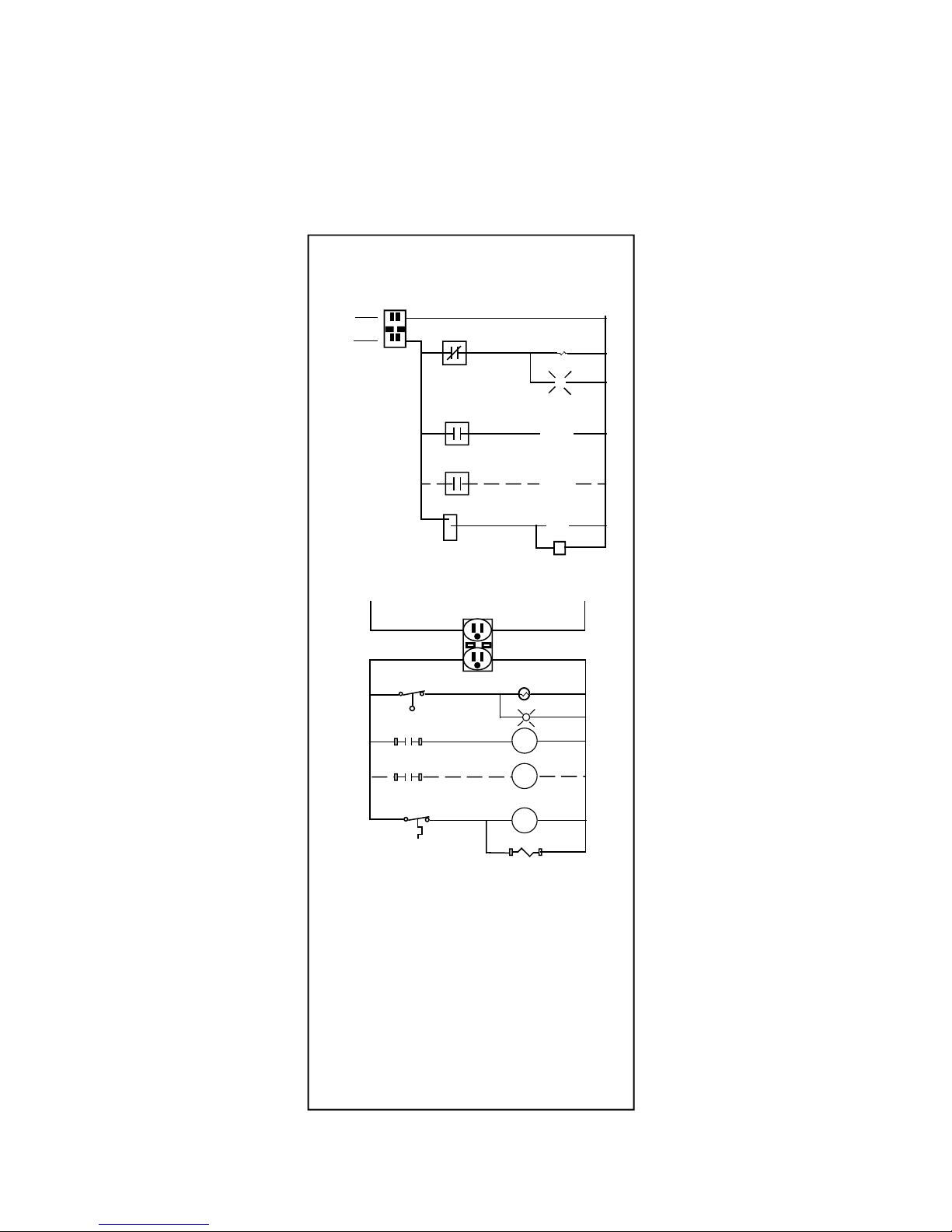

2-7 Wiring Diagram .....................................................13-14

SECTION III: Plumbing Instructions

3-1 Instructions for forced air systems .............................15

3-2 Location of heating coil.........................................16-17

3-3 Instructions for Hydronic systems.........................18-19

3-4 Instructions for Water Heater Hookups LC300 , LC500,

& LC2500 ..................................................................20

3-5 Replacing Hull ...........................................................21

3-6 Filling the Heater with water ......................................22

SECTION IV: Connection to Central Heating/AC System

4-1 Connection to Central Unit

with Existing Blower Relay ...................................23-24

4-2 Connection to Central Unit

with Existing Blower Relay Diagram .........................25

SECTION V: Heater Operation

5-1 Firing the Heater ........................................................26

5-2 Water Temperature ...................................................26

5-3 Moisture in the Firebox ..............................................26

5-4 Wood Usage..............................................................27

5-5 Improper Burning.......................................................27

5-6 Ash Removal .............................................................27

5-7 Ash Disposal .............................................................27

5-8 Creosote Formation and Removal.............................28