1.2 OPERATING CONDITIONS

The hydraulic amphibious excavator AT300-V2/AT300PS-V2 is strongly recommended for

working on wet ground, marshland, and shallow water. To avoid overturning and damage, the

amphibious excavator must be operated strictly in accordance with the following allowable

conditions:

1.2.1 ALLOWABLE CONDITIONS

1. Work on wet ground, marshland, and shallow water.

2. The machine can travel and work in water not deeper than 2 meters, and work normally

under the following conditions:

a) The water flow speed: is 24 m/min (1.31 feet/second) or less.

b) The wave height: is 0.1m (3.93 in) or less.

c) The wind speed: is 240 m/min (8.94 mph) or less.

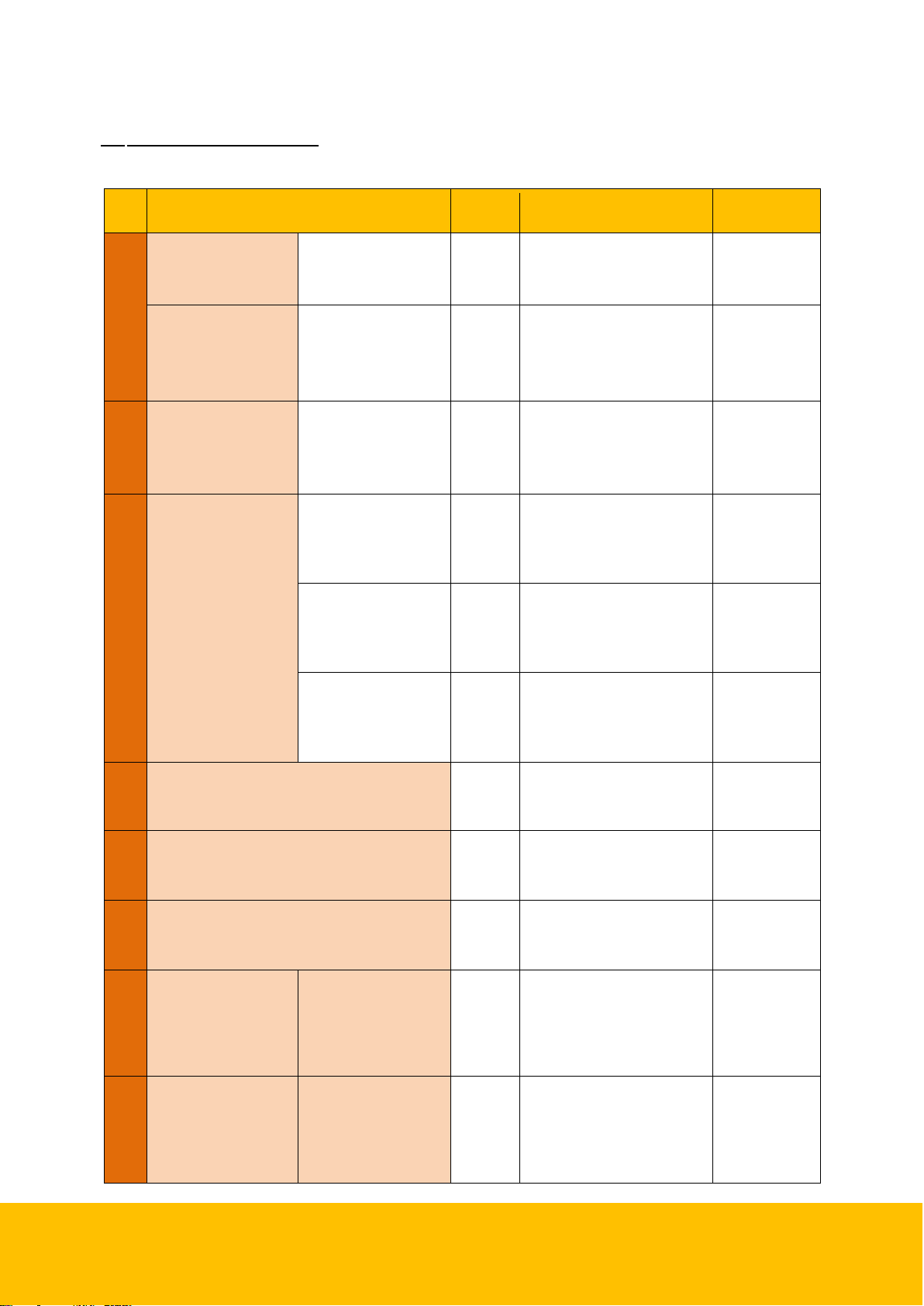

1.2.2 NON-ALLOWED CONDITIONS

1. Do not operate the machine on stumps, hard stones, or uneven ground that is frozen

and solid, when mounted with additional pontoons.

2. Do not attempt to operate the excavator when completely floating in water.

3. Do not travel over water of an unknown depth.

4. Do not use a bucket larger than the designated one. Otherwise, it will affect the stability

of the machine. The machine is only used for light loads and shouldn't be used for heavy

loads.

2.0 STRUCTURE

The AT300-V2/AT300PS-V2 hydraulic amphibious excavator has four traveling devices (two

traveling motors per amphibious undercarriage). Figure 2.0 shows a simple drawing of the

structure of the machine.