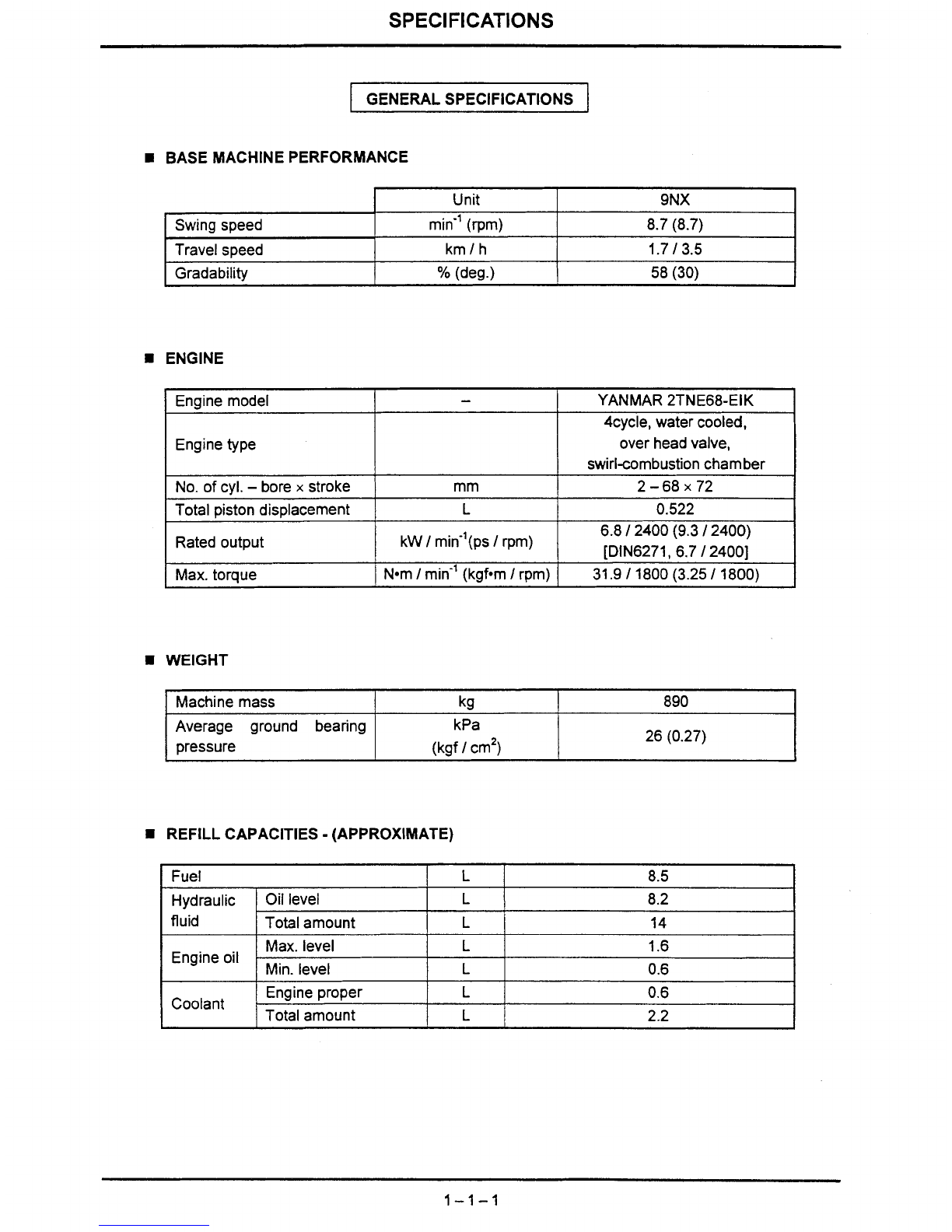

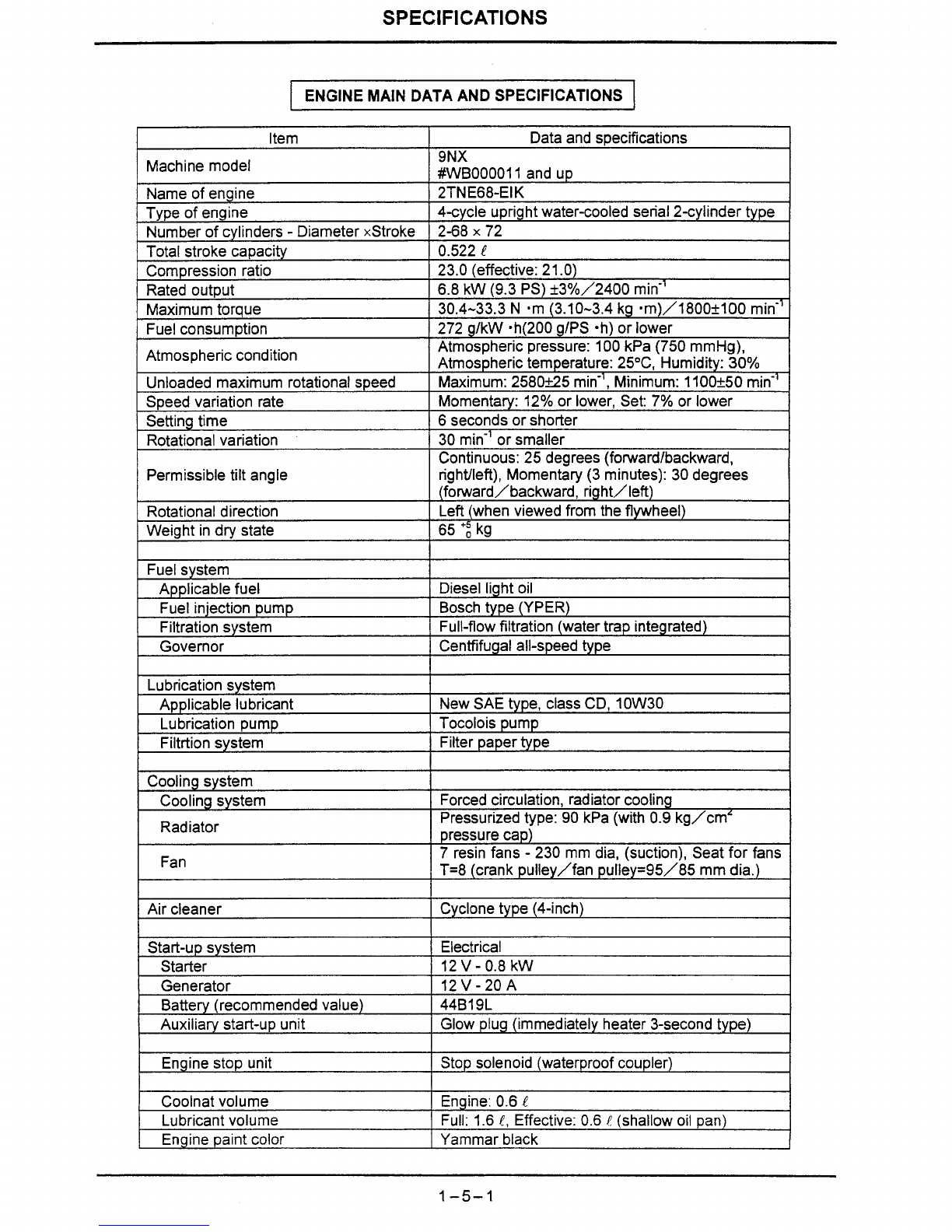

SPECIFICATIONS

ENGINE MAIN DATA AND SPECIFICATIONS

ltem

Machine model

Name of engine

Type of engine

Number of cylinders

-

Diameter xStroke

Total stroke capacity

Compression ratio

Ratedoutput

Maximumtorque

Fuelconsumption

Atmospheric condition

Unloadedmaximum rotationalspeed

Speed variation rate

Settingtime

Rotationalvariation

Permissibletilt angle

Rotationaldirection

Weight in

dry

state

Fuelsystem

Applicable fuel

Fuel injection pump

Filtrationsystem

Governor

Lubricationsystem

Applicable lubricant

Lubrication pump

Filtrtionsystem

Coolingsy&m

Cooling system

Radiator

Fan

Air cleaner

Start-up system

Starter

Generator

Battery (recommended value)

Auxiliary start-up unit

Enginestop unit

Coolnat volume

Lubricantvolume

Enginepaint color

Dataand specifications

9NX

#WB000011and up

2TNE68-EIK

4-cycle uprightwater-cooledserial 2-cylinder type

2-68

x

72

0.522

!

23.0 (effective:21.O)

6.8 kW (9.3 PS) st3%/2400 min-'

30.4-33.3 N .m (3.10-3.4 kg .m)/1800+100 min-'

272 g/kW ~h(200g1PS ah) or lower

Atmospheric pressure: 100kPa (750 mmHg),

Atmospherictemperature: 25"C, Humidity: 30%

Maximum: 2580k25min", Minimum: 1100+50 min-'

Momentary: 12%or lower, Set: 7% or lower

6 seconds or shorter

30 min-' or smaller

Continuous:25 degrees (forwardlbackward,

rightlleft), Momentary(3 minutes): 30 degrees

(forward/backward, right/left)

Left(when viewed from the flywheel)

65

':

kg

Diesellight oil

Boschtype (YPER)

Full-flow filtration (watertrap integrated)

Centfifugalall-speedtype

New SAEtype, class

CD,

10W30

Tocolois pump

Filterpapertype

Forcedcirculation, radiatorcooling

Pressurizedtype: 90 kPa (with 0.9 kg/cmL

pressurecap)

7 resin fans

-

230 mm dia, (suction), Seat for fans

T=8 (crank pulley/fan pulley=95/85 mmdia.)

Cyclonetype (4-inch)

Electrical

12V-0.8 kW

12V-20A

44B19L

Glow plug (immediately heater 3-second type)

Stop solenoid (waterproof coupler)

Engine: 0.6

E

Full: 1.6

E,

Effective: 0.6

!

(shallowoil pan)

~

~-

Yammar black