HBM VK20A User manual

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

VK20A

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbm.com

Mat.: 7-2001.2335

DVS: A2335-2.0 HBM: public

08.2017

EHottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos produits

que sous une forme générale. Elles n'impliquent aucune

garantie de qualité ou de durabilité.

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

VK20A

2A2335-2.0 HBM: public VK20A

English

1 Safety instructions 3........................................

2 Markings used 6............................................

2.1 The markings used in this document 6..........................

2.2 Symbols on the product 6.....................................

3 Application 8...............................................

4 Installation 9...............................................

4.1 Dimensions 9...............................................

4.2 Mechanical design 10.........................................

5 Electrical connection 11......................................

5.1 Connection cable for evaluation electronics 11....................

5.1.1 Mechanical connection of the connector cables 14................

5.1.2 Electrical connection of T20WN, T21WN (St1 and St2) 16..........

5.1.3 Electrical connection of T22 (St1 and St2) 17.....................

5.1.4 Electrical connection of the voltage supply (St7) 18................

5.1.5 Electrical connection of torque output Md [V] 19...................

5.1.6 Electrical connection of torque output Md [I] 19...................

5.1.7 Electrical connection of speed/angle of rotation output (n/) 20.......

5.1.8 Functional check 21...........................................

5.1.9 Control signal (T20WN, T21WN) 21.............................

6 Specifications 23............................................

7 Accessories 25..............................................

Safety instructions

VK20A A2335-2.0 HBM: public 3

1 Safety instructions

Appropriate use

To ensure safe operation, the junction box may only be

used as described in the mounting instructions. It is also

essential to follow the respective legal and safety regula

tions for the application concerned during use. The same

applies to the use of accessories.

The junction box is not a safety element in terms of

appropriate use. For correct and safe operation of this

junction box, it is essential to ensure appropriate trans

portation, storage, installation, and fitting and to operate

and maintain all equipment with care.

General dangers of failing to follow the safety

instructions

The junction box corresponds to the state of the art and

is safe to operate. If the junction box is used and oper

ated inappropriately by untrained personnel, residual

dangers may arise.

Everyone responsible for installing, starting up, maintain

ing or repairing the junction box needs to have read and

understood the operating manual and in particular the

safety instructions.

Residual dangers

The scope of performance and supply of the junction box

covers only part of the connection technique. In addition,

equipment planners, installers and operators should plan,

implement and respond to the safety engineering consid

erations of the connection technique in such a way as to

minimize residual dangers. Prevailing regulations must

be complied with at all times. Residual dangers con

Safety instructions

4A2335-2.0 HBM: public VK20A

nected with the connection technique need to be pointed

out.

Qualified personnel

The junction box may be used by qualified personnel

only, the specifications and the special safety require

ments and regulations need to be followed in all cases. It

is also essential to observe the appropriate legal and

safety regulations for the application concerned during

use. The same applies to the use of accessories.

Qualified personnel means. personnel familiar with the

installation, fitting, starting up, and operation of the prod

uct and trained according to their job.

Conditions on site

Protect the junction box from dirt and humidity.

Maintenance

The junction box provides IP65 protection (protection

against dust and water jets). Make regular checks to

ensure the tightness and efficiency of the rubber lid seal

and the screw fittings.

Prevention of accidents

The prevailing accident prevention regulations must be

observed.

Unauthorized conversions and modifications are

prohibited

HBM's express consent is required for modifications

affecting the equipment's design and safety. HBM does

not take responsibility for damage resulting from unau

thorized modifications.

Safety instructions

VK20A A2335-2.0 HBM: public 5

It is strictly forbidden to carry out any repairs and solder

ing work on the motherboards or to replace any compo

nents. Repairs may only be carried out by persons autho

rized by HBM.

SDuring installation and when connecting the cables,

take action to prevent electrostatic discharge as this

may damage the connected electronics.

SWhen connecting additional devices, comply with the

safety requirements for electrical measurement, con

trol, regulatory and laboratory equipment (EN 61010).

SAll the interconnecting cables must be shielded

cables. The shield must be connected extensively to

ground on both sides.

Markings used

6A2335-2.0 HBM: public VK20A

2 Markings used

2.1 The markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions in

order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Emphasis

See….

Italics are used to emphasize and highlight text and

references to other chapters and external documents.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the declaration of conformity is avail

able at http://www.hbm.com/HBMdoc).

Statutory marking requirements for waste disposal

National and local regulations regarding the protection of

the environment and recycling of raw materials require

old equipment to be separated from regular domestic

waste for disposal.

Markings used

VK20A A2335-2.0 HBM: public 7

For more detailed information on disposal, please contact

the local authorities or the dealer from whom you pur

chased the product.

Application

8A2335-2.0 HBM: public VK20A

3 Application

The VK20A junction box enables T20WN, T21WN and

T22 torque transducers to be connected to HBM mea

surement electronics. If the measurement electronics do

not feed supply voltage, the junction box needs to be

powered by a 24 V power source (14 V...30 V) to St7.

Installation

VK20A A2335-2.0 HBM: public 9

4 Installation

4.1 Dimensions

138

150

approx. 25

23.5

53

6

Ø 4.4

40

18.25

A

23.5

View A

65

18.25

53.5

approx. 25

Dimensions (in mm;

1 mm = 0.03937 inches)

Fig. 4.1 Dimensions

Installation

10 A2335-2.0 HBM: public VK20A

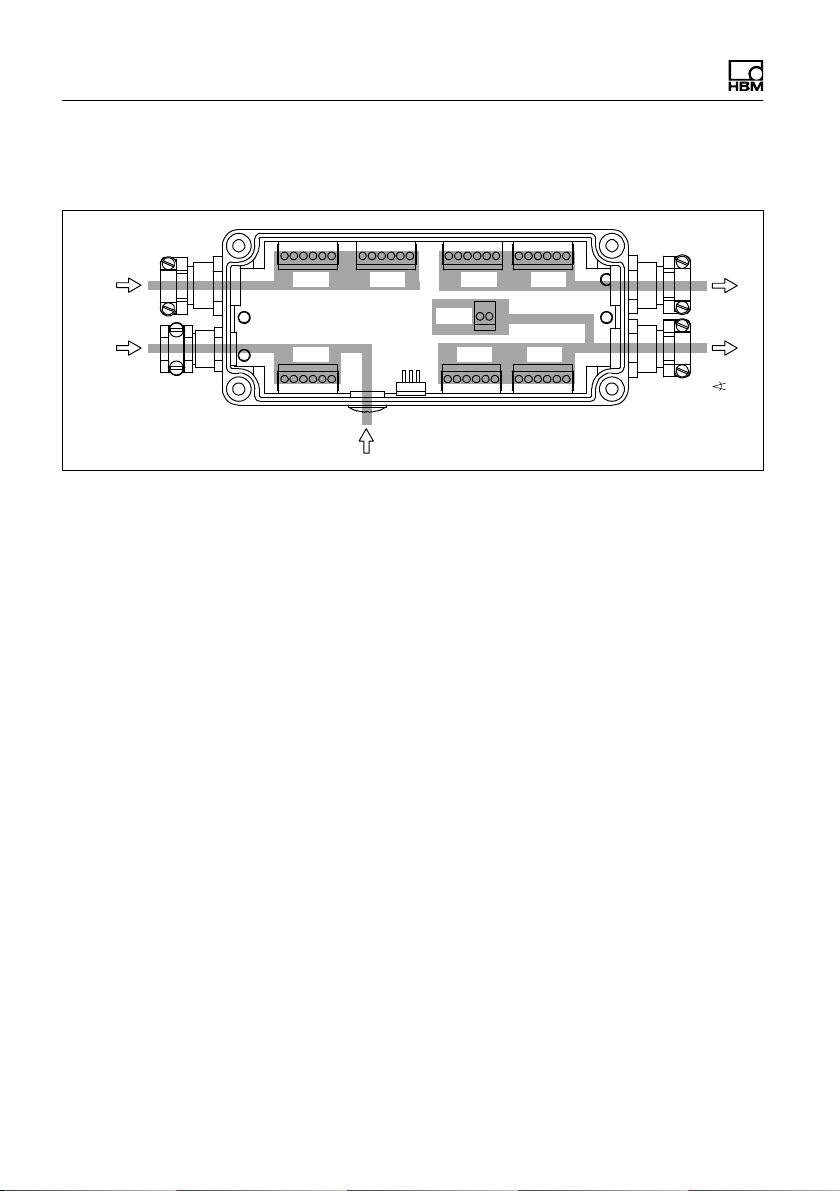

4.2 Mechanical design

St1 St2 St3 St4

St7 St6 St5

16161616

616161

Md [V]

n

External control signal

T20WN

T21WN

T22

Supply

voltage

St8 Md [I])

Fig. 4.2 Connection clamps in the opened VK20A junction

box

Electrical connection

VK20A A2335-2.0 HBM: public 11

5 Electrical connection

5.1 Connection cable for evaluation

electronics

HBM provides the following connector cables for con

necting the T20WN, T21WN and T22 through the VK20

junction box to the evaluation electronics:

S1-Kab 151-1.5 (15‐pin D‐sub connector (male) - free

ends)

S1-Kab 152-1.5 (SUBCON5 - free ends)

YE/RD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

YE

BK

BU

BN/BU

WH

PK

GY/PK

GY

GN

BN

RD

1-Kab151-1.5 1-Kab152-1.5

1

2

3

4

5

bared

BK

BU

WH

RD

GN

Shield

Fig. 5.1 Cable for connecting to the evaluation electronics

Electrical connection

12 A2335-2.0 HBM: public VK20A

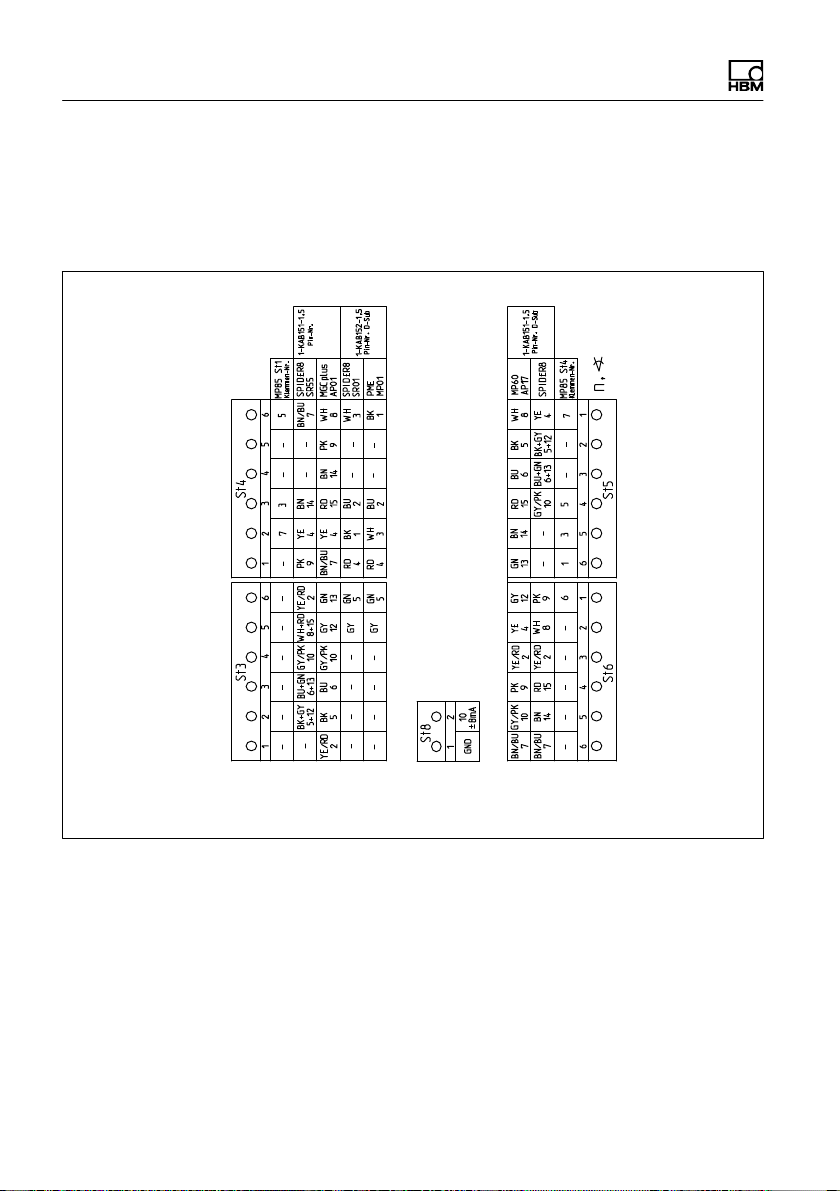

The cable configuration is adjusted to the system device

to be connected. In the junction box housing, there is an

instruction leaflet with the connection diagram for the var

ious HBM system devices (see both parts of Fig. 5.2).

Md [V]

Md [I]

Continuationof the figure on next page

Electrical connection

VK20A A2335-2.0 HBM: public 13

T20WN

T21WN

T22

Fig. 5.2 Connection diagram for the various HBM system

devices

Electrical connection

14 A2335-2.0 HBM: public VK20A

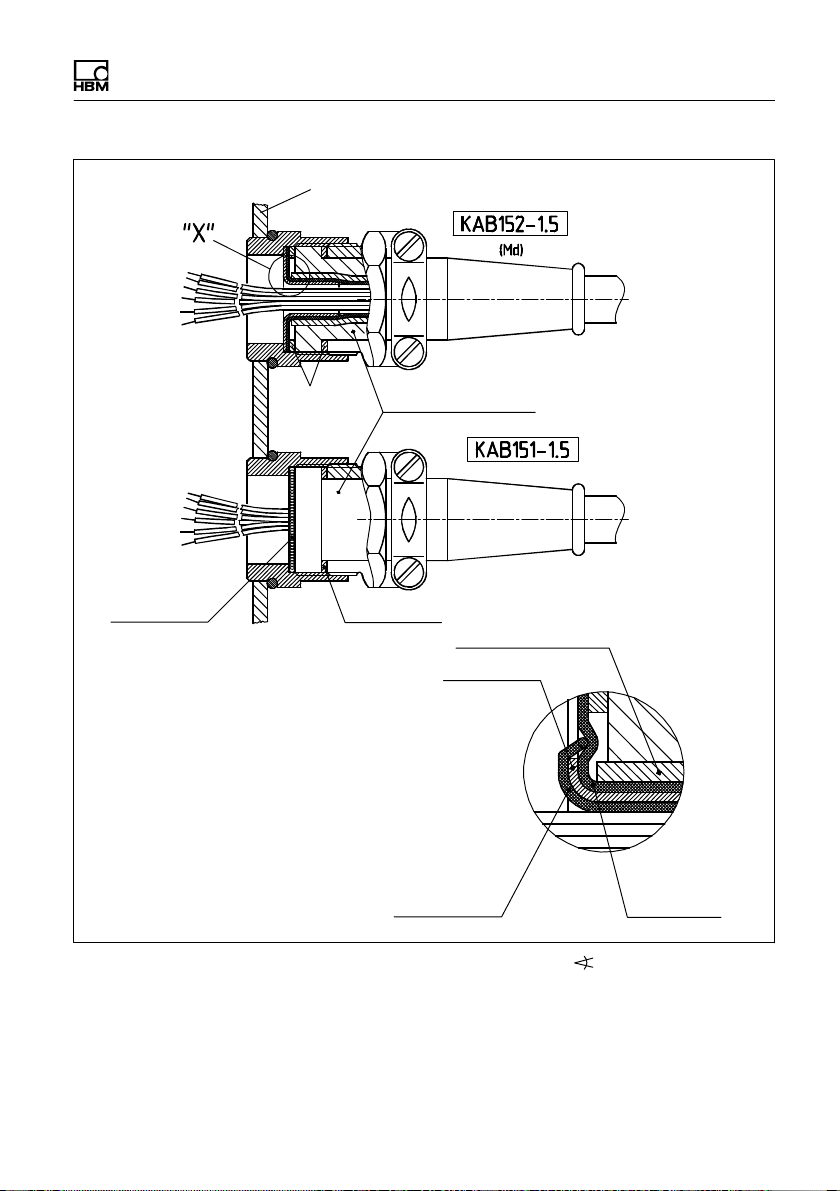

5.1.1 Mechanical connection of the connector

cables

The junction box includes a set of cable sleeves,

intended for bushing the transducer connection cable, the

voltage supply and the Md/n outputs. The side hole for

the external control signal is closed with a screw for

delivery. If need be, use a suitable PG7 screwed joint

with an anti‐buckling socket.

Anti‐buckling socket,

internal Ø 7 mm

Clamping ring

T20WN, T21WN, T22

Power

Cable shield

looped round

clamping ring

Anti‐buckling

socket, internal

Ø 5 mm

Cable sleeve

Rubber seal Wall of the housing

Fig. 5.3 Cable bushing ”T20WN, T21WN, T22” and

”POWER” at the junction box

Electrical connection

VK20A A2335-2.0 HBM: public 15

Wall of the housing

Clamping ring Anti‐buckling socket,

internal Ø 8.5 mm

Cable shield

looped round

clamping ring Clamping ring

Outer sheath of cable

Earth sleeve

Stranded filler wire

of the internal

cable shields Cable shield

Detail X

Fig. 5.4 Cable bushing ”Md” and ”n/ ” at the junction box

Electrical connection

16 A2335-2.0 HBM: public VK20A

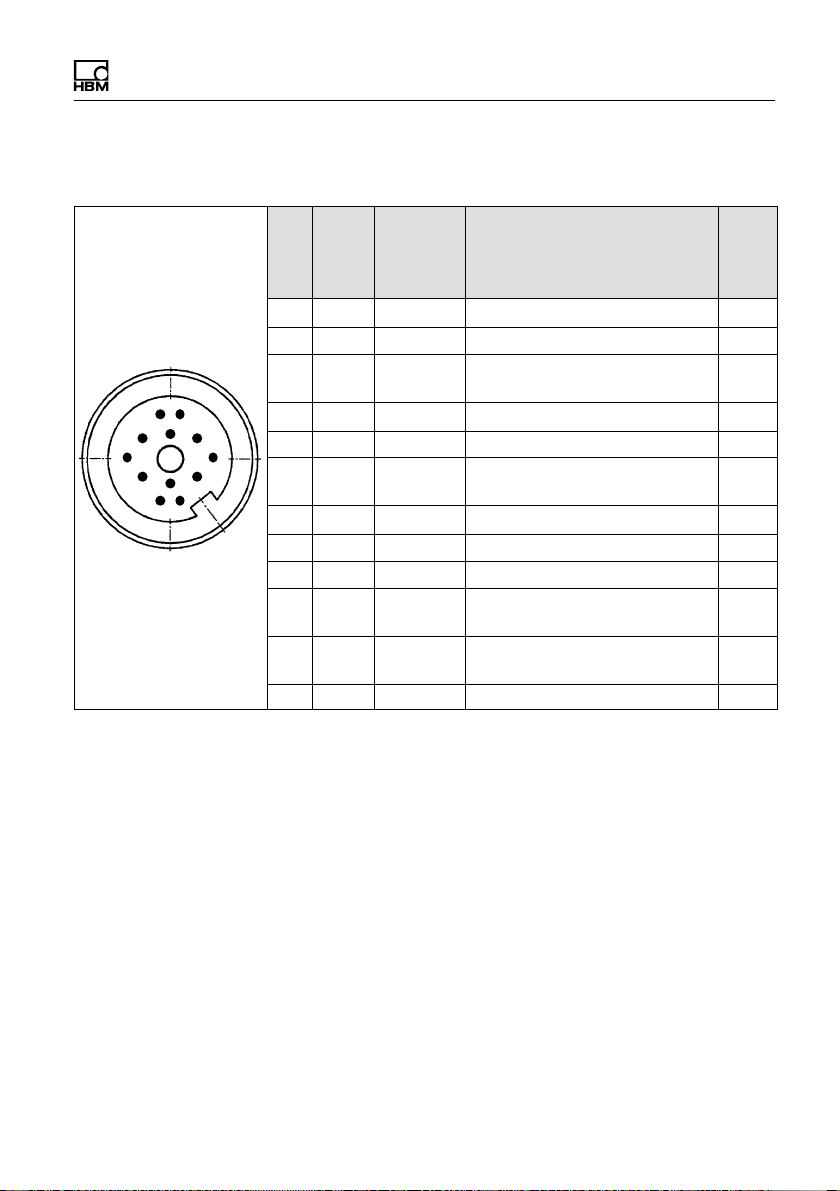

5.1.2 Electrical connection of T20WN, T21WN (St1

and St2)

A

B

C

D

E

F

G

J

H

L

M

K

Pin Wire

color

Strip

terminal/

terminal

VK20A

Function I/O1)

A BK St1/1 None -

B RD St2/1 Measurement signal: speed/

angle of rotation

I

C BN St1/3 Measurement signal: torque

±10 V

I

D WH St1/4 0 V; I

E YE St1/5 Supply voltage 0 V O

F VT St1/6 Supply voltage 12 V O

G GN St1/2 Measurement signal: speed/

angle of rotation (90°phase

shifted)

I

H PK St2/2 None -

J GY St2/3 None -

K GY/

PK

St2/4 Trigger control signal O

L BU/

RD

St2/5 None -

M BU St2/6 Cable shielding -

Tab. 5.1 Transducer connection T20WN, T21WN

1) O=Output; I=Input

Electrical connection

VK20A A2335-2.0 HBM: public 17

5.1.3 Electrical connection of T22 (St1 and St2)

A

B

C

D

E

F

G

J

H

L

M

K

Pin Wire

color

Strip

terminal/

terminal

VK20A

Function I/O1)

A BK St1/1 None -

B RD St2/1 None -

C BN St1/3 Measurement signal:

torque"5V

I

D WH St1/4 Ground (torque) I

E YE St1/5 Ground (supply) O

F VT St1/6 Supply voltage

+11.5 V … 30 V

O

G GN St1/2 None -

H PK St2/2 None -

J GY St2/3 None -

K GY/

PK

St2/4 None -

L BU/

RD

St2/5 Measurement signal: torque

10"8 mA I

M BU St2/6 Cable shielding -

Tab. 5.2 Connection T22

1) O=Output; I=Input

Electrical connection

18 A2335-2.0 HBM: public VK20A

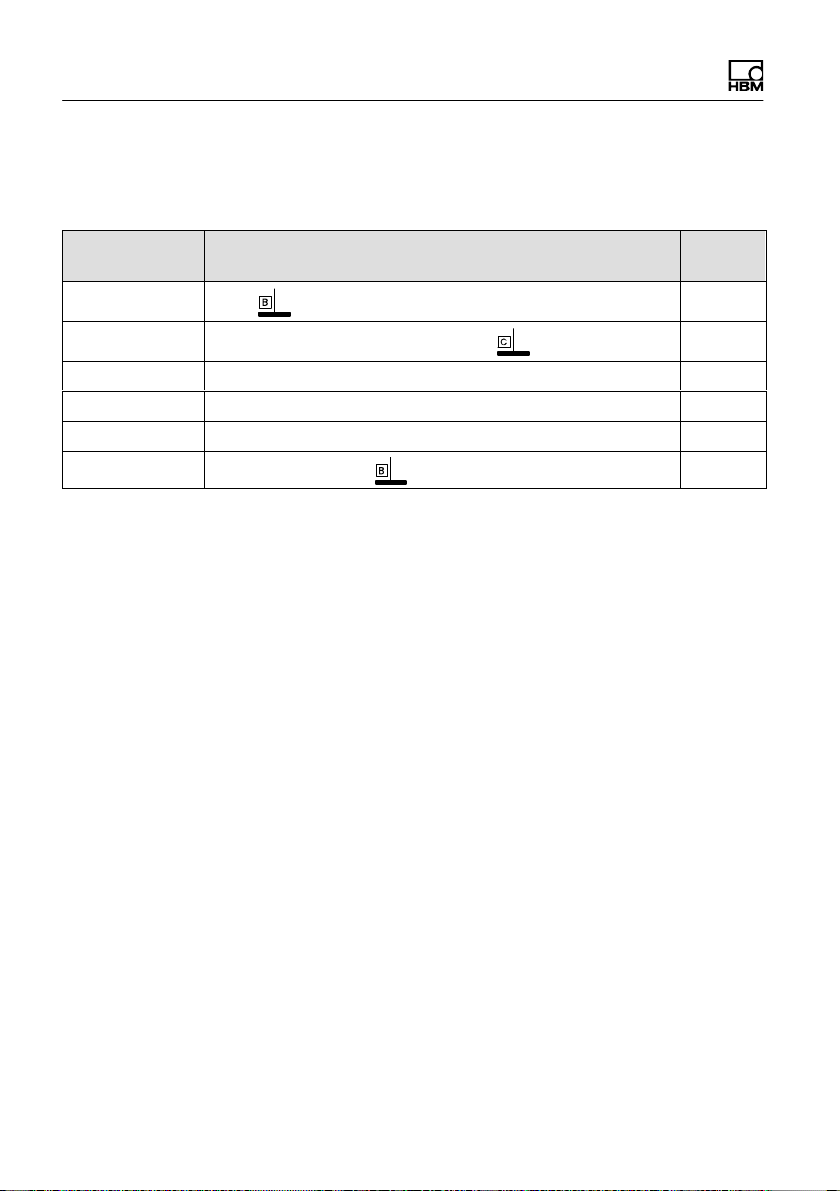

5.1.4 Electrical connection of the voltage supply

(St7)

Strip terminal/

terminal

Function I/O1)

St7 /1 0 V; 2) O

/2 control signal (external trigger 0 V; ) I

/3 control signal (external trigger 5 V … 30 V) I

/4 24 V3) O

/5 Supply voltage VK20 24 V (14 … 30 V)4) I

/6 Supply voltage 0 V; I

Tab. 5.3 Connector pin assignment St7

1) O=Output; I=Input

2) Linked internally with St7/Pin6. Can be bridged with St7/Pin2 if necessary.

3) Linked internally with St7/Pin5. Can be used for triggering the control signal if necessary.

4) In conjunction with MGCplus through St3/1.

Other manuals for VK20A

1

Table of contents

Languages: