Charles CFDP10-EL18 Series Operating and maintenance instructions

Equipment Issue 1

Third Printing, July 2007

Section CFDP-EL-X-801

−CFDPtEL SERIES BACKBOARD CABLING INSTALLATION GUIDE −

Copyright 2007 Charles Industries, Inc. All rights reserved. Printed in the United States of America. PEDLOCKand Charlesare registered trademarks of and CFDPis a trademark of Charles Industries, Ltd. Availability of features and technical specifications herein subject to change without notice. Page 1 of 2

0707I1P3

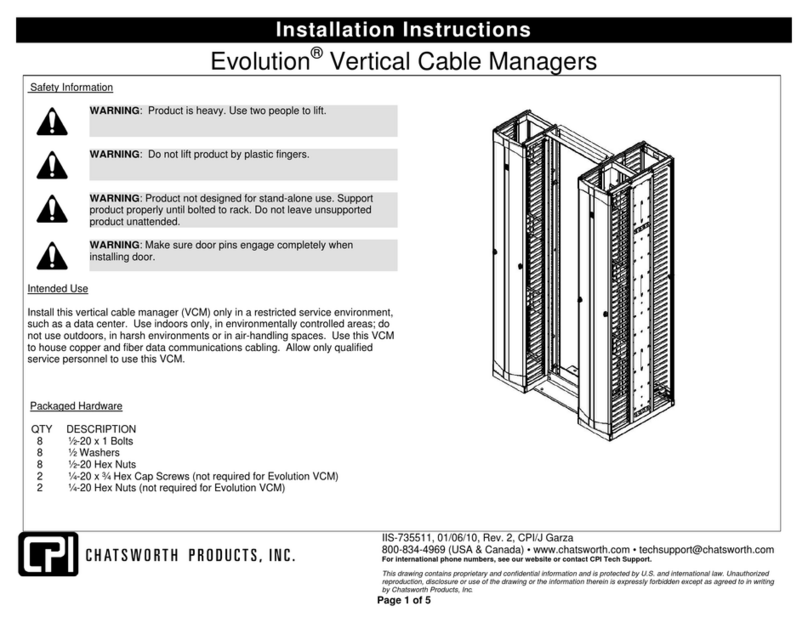

Closed pedestal,

dome on

Figure 1. Interior Views of the CFDP10-EL18

Base (the

bottom

section)

Customer or

Drop Side Feed or CO Side

Dome

(covers top

section)

CFDP12-EL24 supports 24 drops

Lockable

door

Bulkhead with

18 SC-type

adapters

Ground and

bonding areas

Back-

board

18 Strength

member clamps,

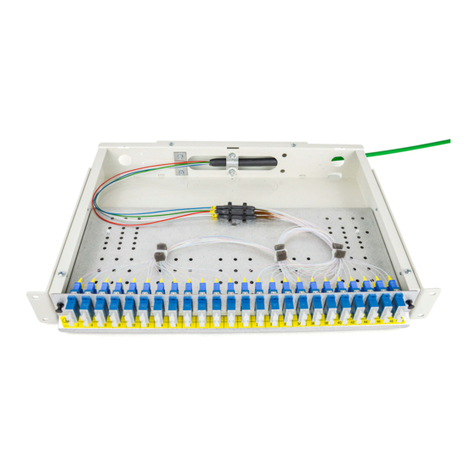

cable tie-downs,

and grommet ports

Pigtail cable

protection plate

(store pigtails behind

plate and splice tray)

Velco

(secures

splice tray)

Backboard

support leg

Fiber Cable Preparation, Termination and Splicing Instructions

for the

CFDP10-EL18 and CFDP12-EL24 Series of

CharlesrFiber CFDPtPedlockrOSP Pedestals

for

Fiber Interconnect Applications

1. GENERAL

1.1 Document Purpose. This document provides instructions for the fiber cable tech-

nician to properly perform fiber cable preparations, routings, splicing, terminations and

connections within the Charles Industries’ Fiber Distribution Point (CFDP) EL series

of Pedlockpedestals with 10” or 12” domes. (The CFDP EL series offers an interior

backboard designed for use in fiber applications where preconnectorized SC/APC or SC/

UPC connections are desired, such as at cell sites to service multiple wireless operators).

Figure 1 shows a dome-off interior-door-open view of a 10” dome CFDP10-EL18 mod-

el. The 12” models are identical except they support 24 drops. See Table 2 for

information on all models in this series, or call Charles Industries (see Part 3) to request

more information or literature.

- NOTE -

Hereafter all models in the series will be commonly referred to as the “CFDP” or “pedestal.”

Specific model numbers will be specified or referenced where important differences apply.

1.2 Document Status. Print 3 updates Table 2. Print 2 updated the document title,

Paragraphs 1.1 and 1.3, Steps 1, 5, 16 and 29 of Table 1, Table 2 (added models with SC/

APC adapters and separates and lists pigtails as kits), and added Paragraph 1.4.

1.3 Product Purpose and Description. The CFDP is an above-grade pedestal that of-

fers excellent OSP protection against floods, fire, dirt, weather, insects, and impact for

fiber-optic cable splices and customer service drops in FTTP deployments. This protec-

tion is achieved with a weather-resistant yet free-breathing interior enclosure that is

within the confines of a protective, exterior, buried-distribution-cable pedestal. The bot-

tom section of the pedestal is the base: a square-shaped, expanded-capacity, non-metallic,

locking, 2-piece, split base designed to open and easily install around conduit-fed cable

bundles or to accept less flexible cables. The top section of the pedestal contains a non-me-

tallic outer dome, which covers and protects an inner double-door enclosure, which in

turn protects the heart of the pedestal: the exclusive, versatile, and interchangeably-de-

signed, metallic, interior backboard. Two locking doors are provided on the CFDP EL

series, one on each side (CO-side vs. drop or customer side), to separate the drop connections

from the CO feed connections. On both sides of the backboard, quick and easy connections

are made with preconnectorized SC-type cables to SC-type adapters at the Interconnect bulk-

head at the top of the backboard. The other end of the SC-type cable (pigtail) should be spliced

to the feed cable within a provided splice tray. As an option, Charles provides three-meter-

long SC-type pigtails for feed cable connections (see Table 2 for details). The sturdy,

versatile, metallic backboard also enables technicians to route, bond, and attach various

cables, tubes, splice trays, splitters or other equipment. Grounding and bonding connec-

tions can be made either inside the locked interior compartment, or outside for easier line

maintenance and testing. Charles’ CFDP pedestals are designed to be installed in new

or replacement installations, to accommodate various soil and mounting applications as

well as various cable types and applications, to accommodate certain fiber slack situa-

tions, and to exceed Telcordia GR-771-CORE specifications.

1.4 Applications. The CFDP Interconnect Pedestal is ideal for multi-tenant cell site,

campus or strip mall environments where the customer requires high-capacity fiber

bandwidth for wireless backhaul, private networks or data and video broadband services.

With a built-in SC/APC or SC/UPC adapter bulkhead, Interconnect pedestals facilitate

fast and easy provisioning of fiber services to the end customer’s fiber multiplexing

equipment. Fiber drops can be turned up, moved or disconnected on an “as needed” basis,

giving telecom service providers added flexibility in their efforts to provide broadband

voice, data, and video services to customers whose bandwidth requirements may change

seasonally or due to major events.

1.5 Product Mounting. The CFDP pedestal base is typically installed at the cell site

or FTTP distribution point in a trench or hole in the ground up to the ground line indicator

on the base. The pedestal backboard, where all cable preparations are performed, mounts

to the base. Once all cable connections are complete, the inner doors are secured to pro-

tect all cabling and connections, then the outer dome is placed over and attached to the

base for further protection. The base contains holes or knockouts at the rear and both

sides that accept an optional, metallic, mounting stake or a pole-mount stake.

- CAUTION -

Perform all bonding and grounding prior to making any electrical and

communications connections.

2. CABLE INSTALLATION AND SPLICING

Table 1 helps the cable technician to perform all fiber feed and drop cable preparations,

routings, attachments, splicing, and connections, and presumes the following conditions:

Site Cable Configuration or Deployment - The fiber cable deployment is a CO or

feed cable in a stub-end configuration (though not described in these instruc-

tions, these pedestals support loop-through applications, as well).

Equipment Installation - A CFDPbase has been properly installed at the de-

sired field site (for base installation information, see the pedestal base installation

document factory-attached to the base).

Trench Setup - The trench is either dug and open, or backfilled with the feed cable

already placed and brought into the base bottom.

Feed Cable Type or Design - The CO or feed cable is a loose-buffer-tube type with

single fibers.

Drop Cable Type - Drop cables are SC/UPC or SC/APC-type preconnectorized

cables.

Transportation Tubing - Protective, flexible, transportation tubing is provided

for the feed cable pigtails (two 3-feet long pieces).

For information regarding other pedestal installation types or applications, or cable deploy-

ment types, contact Charles Industries at the phone number provided in Part 3.

3. CUSTOMER TECHNICAL SERVICE

If technical assistance or customer service is required, contact Charles Industries by calling

or using one of the following options:

847-806-8500 (Tech. Service local) 847-806-6300 (Customer Service)

800-607-8500 (Tech. Service toll-free) 847-806-6653 (Customer Service FAX)

- EYE DAMAGE WARNING -

Risk of serious eye damage! Never look into the end of a fiber optic line nor use a

magnifier in the presence of laser light or radiation. Always exercise caution when

installing, testing, or performing maintenance on live circuits. If eye exposure to

laser light or radiation has occurred or is suspected, immediately seek medical

treatment by a professional eye care physician.

- FIBER OR CABLE DAMAGE CAUTION-

Buffer tubes and fibers are sensitive to bending, pulling, and crushing forces.

Avoid buffer tube kinking and fiber damage: use care when working with fiber and

do not violate fiber, buffer tube, and cable minimum bend-radius requirements.

In cold environments, some loose tube cable designs may exhibit low temperature

induced signal attenuation when long lengths of buffer tubes have been exposed

and then stored. Contact the cable manufacturer concerning recommended

exposed buffer tube lengths in your installation area.

- WARNING -

Cable and fiber cleaning solvents may contain hazardous materials or harmful

ingredients. Always read and follow the manufacturer’s precautions, warnings,

and instructions when working with cleaning solvents or products.

Shards and cleaved glass fibers are very sharp and can easily pierce the skin. Use

tweezers to pick up cut glass fibers and place them on a loop of tape or in a

container specifically meant for this purpose. Good housekeeping is important.

Corrugated metal or armor that may be present in feed cables is very sharp when

cut or exposed. Exercise extreme caution to prevent personal injury. Use

protective work gloves when handling armored cable.

Table 1 −Branch or Stub-End Configuration Installation

Step # Instruction

1. Obtain tools, materials and equipment. Assemble the following tools and equip-

ment to perform fiber feed/drop cable connections in the installed CFDP pedestal.

216 tool/can wrench Properly installed base of CFDP10/12 model

Tape measure Dome & backboard with double doors (provided)

Cable marking tool Bag of parts (provided with the pedestal)

Labels for cables (optional) Assorted cable ties (12 provided)

Hose clamps (2 provided) Splice tray and labels for splice tray (2 provided)

Cable bond clamps (optional) Knife, snips, or puncture tool (to cut grommets)

Proper length drop cables Cable-entry tool or utility knife with hook blade

Drop trenching equipment Buffer tube stripper tool (to score/cut buffer tubes)

Wrenches or socket set Fiber optic stripper tool (for 900 micron pigtails)

Slotted screwdriver Fiber splicing tools and equipment

Gel removal compound Tweezers & tape (for cleaved glass fibers/shards)

(to clean stripped cables) Safety glasses & work gloves (optional)

Isopropyl alcohol & clean Shovel (to access drop cable hole)

wipes (to clean fibers) Grounding equipment & tools

Site clean-up tools

Preparing and Opening the Pre-Installed CFDP Pedestal

2. Verify pedestal is installed and inspect. Find the CFDP pedestal installation site,

inspect it, and verify the pedestal is properly installed in the ground. New pedestals

should be inspected thoroughly upon delivery. If the equipment was damaged in

transit, immediately report the damage to the transportation company.

3. Remove outer dome from base. If not

already off, remove the outer dome with a

216 tool or can wrench. Turn the snap

lock’s hex nut 1/4-turn counterclockwise,

hold it in that position, then lift up on the

dome. Set the dome aside until needed.

Hex nut in

snap lock on

dome

216 tool

4. Open inside doors. Open the

internal doors of the CFDP

using a 216 tool or can wrench

on the cup-washer screws.

Each door contains two

cup-washer screws.

Doors

closed Doors opened

5. Remove plastic bag and verify contents. Locate

the clear, plastic bag that is typically attached

to the pedestal’s interior backboard and

verify the following contents:

6 cable ties 2 bond straps

2 hose clamps document

1 FOSC B splice tray and tray label

6.

Backboard

support

leg

First press

the push tabs

Remove backboard (optional, to facilitate earth

ground installation). Remove the backboard, if

needed or desired, to facilitate the earth ground

installation, per local company practice. Remove

the backboard by first pressing one finger push tab

(located inside the base collar at the support

leg), pulling up on the support leg, and then

secondly, pressing the other leg’s push tab

and pulling up on the other support leg. When

the tabs are disengaged or released, pull the

backboard out of the base and temporarily

set it aside.

Then pull up

on legs or

backboard

This view

removes the base front, for

visual clarity of leg guide

Base

collar

7. Verify/prepare earth ground. Always follow local codes and company practice

when grounding cables/equipment. If an earth ground is not present at the pedestal

site and local practice requires an earth ground, prepare one at this time. Do not

connect earth ground until the backboard is re-attached to the base.

Preparing the Feed or Branch Stub Cable

8. Verify sufficient feed cable length. Verify 9 feet (approx.) of cable,

from the ground line to the cable’s stub-end, extends up through

the pedestal base, and lift it up. Press the cable toward the rear

of the base so it will be at the CO or feed side of the backboard

(the side with fewer but larger rubber grommet ports), when it is

installed. See the base installation document for instructions on

installing the base and routing cables into the base.

Approx. 9’

stub end to

ground line

9. Attach backboard. (Skip this step if the

backboard is already installed.) First, pos-

ition the feed cable so it will be at the CO or

distribution side of the backboard (see

Figure 1). Then install the backboard to

facilitate marking the cable for the proper

cable sheath removal length. Align the

backboard’s support legs with the leg guides

in the base collar. Once the leg guides are

lined up, press down on the backboard until it

stops and the tab locks are engaged (audible

clicks indicate proper leg insertion).

Once aligned,

press down

on each leg

until it clicks"

into place.

Align support

legs with leg

guides on

base collar.

Leg

guide Leg

Base collar

10. Backboard

bottom

grommet plate

Locate and remove single-port feed grommet.

Grommets on the CO or feed cable side of the

backboard accept one feed cable each (as

opposed to the drop cable grommets which accept

two smaller cables). Pull or slide out one of the

single-port feed-side grommets from the bottom

grommet plate. With a sharp or pointed tool, poke

a small hole in the center of the grommet.

Feed side,

1-port

grommet

Pull out grommet.

11. Push cable through grommet and re-install grommet. Place

the bottom center of the poked grommet at the stub end of the

cable and push the grommet down over the cable end. Slide the

grommet down the cable, stopping about 5" above the base.

Rotate the grommet, slide it up or down as necessary to get the

proper vertical alignment, align it with its slot on the grommet

plate, then re-insert the grommet in the plate. Feed cable

12. Mark cable for sheathing

removal. The cable sheathing

must be removed from the cable

stub to expose the fiber to be

spliced, but enough cable length

with sheathing must remain to hold

it in place against the backboard.

On the feed side of the backboard,

locate the T" cable tie-down

located directly above the chosen

grommet, pull the cable up until it is

almost taut, hold the cable against

the T, and mark a cut-line on the

cable midway between the T and

cable strength member clamp

above it (approximately 7 inches

above the top ot the base collar).

7"

9’ length of feed

cable stub

Make

mark

here

T" tie-

downs

CO/Feed side

of Backboard

Strength

member

clamp

Top o f co ll ar

Cut line

1.5"

T-

Bottom

CFDP10-EL18 shown

13. Remove backboard and/or grommet, for sheathing removal (optional). If

desired, remove the grommet or backboard (or both) to facilitate the sheathing

removal and bond clamp installation procedures. See Step 6 to remove backboard.

14. Remove cable sheathing and cut strength

members.Use the tool and method of choice to

remove the outer cable sheath from the mark to the

cable end (approx. 7.5 feet) to expose the buffer tube

and strength members. Discard the removed sheathing.

Per company practice, trim the cable strength

member(s) approximately 4" longer than the cable

sheath cut (so 4" remains). Do not cut the buffer tube.

Sheath cut

on cable

Strength

members

Buffer tube

(approx. 7.5 feet long)

Cable

4"

15. Clean buffer tube. Per company practice and cable type, find, unwrap, expose,

and clean the buffer tube, as needed.

030-300377 Rev. A Section CFDP-EL-X-801

−CFDPtEL BACKBOARD CABLING INSTALLATION GUIDE −

2

0707I1P3 VELCROis a registered trademark of Velcro Industries B.V.

16. Attach bond clamp to cable. To prepare the cable for bonding to the

pedestal bonding plate, attach a company-approved cable bond

clamp to the cable/shield at the sheath cut. Always follow clamp

manufacturer instructions or company practice to attach cable

bond clamps, as procedures and clamps used to bond cables

may vary per location, application, and cable type and size.

Sample

cable bond

clamps

17. Cut to length then remove buffer tube. Measure then make a mark on the buffer

tube approximately 32" from the cut end. Using local company procedures and

tools, and being careful to avoid the fiber inside the tube, score the tube at the mark

and remove the 32" length of surplus tube and discard it.

18. Clean fibers. Per company practice, clean the fibers.

19. Attach backboard. If still removed, re-attach the backboard (see Step 9).

20. Connect earth ground to

ground lug. Per local codes

and/or company practice, install

an earth ground wire of proper

gauge from the earth ground to

the pedestal at the ground

plate’s ground lug. Always

perform grounding prior to cable

attachment. Attach earth

ground to lug

Attach bond

straps to posts

Ground plate

Alternate bonding area

21. Bond cable to ground plate. Attach a bond strap (provided)

from the cable bond clamp (shown in Step 16) to one of the

bond posts (see Step 20 for bond post locations). Bond strap

22.

Cable

bond clamp

(optional) not

shown in this view.

Secure cable to backboard’s T tie-down.

First, if the cable has strength members

(and they were not termininated in an

optional cable bond clamp), loosen the

strength member clamp located above the

chosen grommet, and slide the strength

members under it. Next, place the cable

against the cable mounting plate at the T

tie-down, and vertically align the cable so

the sheath cut is midway between the T

and strength member clamp above it

(about 1.5" above the bottom of the T).

Hold the cable in this position and secure

it to the T by opening and firmly affixing

a hose clamp around both the cable

and T tie-down.

Strength member

(under clamp)

Hose clamp

(open and install around

cable and T)

Buffer tube

(not under clamp)

Cable

sheath

cut line

T

tie-down

1.5"

Strength member

clamp on cable

mounting plate

Grommet

Mounting

plate

Bottom

of T

23. Tighten strength member clamp (optional). If the strength members were placed

under the strength member clamp in Step 22, secure them by tightening the hex nut

of the strength member clamp. Trim the strength members per company practice.

24. Route the tube/fiber into fiber basket.

Route the buffer tube up through the

bottom opening of the fiber basket, and

wrap the length of tube inside the basket

(about 2 loops). Secure the tube to the

inside walls of the basket with cable ties,

especially where it first enters the

basket, but do not secure the last 3 feet

of tube. After the tube is attached to the

splice tray in Step 26, this 3’ length will

allow the technician sufficient tube slack

when the splice tray is accessed for fiber

splicing.

Fiber

basket

CO side of

backboard

Begin to route the

buffer tube up

through the bottom of

basket, attach it to

the basket’s inside

wall with a cable tie,

and loop it two times.

See steps 26 & 27 to

attach the tube end

to a splice tray and

wrap fiber in the

splice tray.

Fiber

(approx. 32")

Cable

Buffer tube

(approx. 4.5

feet)

Attach buffer

tube to inside of

basket here

where it first

enters basket.

25. Prepare a splice tray for tube attachment. Prepare a splice tray (provided) by

removing the cover and starting

two cable ties at a top tray corner,

using the inner tie-down slots.

Two trays are advised if using

more than 12 pigtails. Cable ties

Outer cable

tie-down slots Choose a tray corner

Inner slots

26. Attach tube to tray. Overlap the buffer tube onto the tray corner about 1" (see Step

27), then secure the tube to the tray with the two positioned cable ties.

27. Store fibers in splice tray. Per

company practice, wrap and

store the fibers in the splice

tray for later slicing, then

attach the tray cover.

Use additional trays

as needed.

Tube,

with

fiber

inside

Secured

cable ties

Fiber

1"

If more than 12 pigtails will be

spliced, additional splice

tray(s) can be used. Always

follow company practice.

28. Label the tube. Label both tube ends, per company practice.

29. Locate or obtain SC-type pigtails. Separately-ordered SC/APC- and

SC/UPC-type pigtail kits are available from Charles (see

Table 2). Obtain the correct type of pigtails for the

Interconnect pedestal used in this installation.

30. Attach SC-type connector end of pigtails. Attach

the connector end of the SC-type pigtails to the

SC-type bulkhead adapters at the top of the

backboard. Remove the caps from the

adapters prior to inserting the connect-

ors. Follow company practice for correct

cable color-coding, and consult the

label on the front side of the bulkhead

to locate the proper line numbers.

(Adapters not removable.

Adapter #1 is inner and

top-most one.)

Preconnectorized bulkhead

at top of backboard

Plug connector into adapter.

Sample of a

bulkhead adapter

900-micron SC-type

connector pigtail

31.

Route pigtail

fibers behind

pigtail

protection

plate.

Route pigtails behind

protection plate. Once all pigtail

connectors are attached to the

bulkhead, route their free ends

(either singly or collectively)

behind the pigtail protection plate,

starting at the left side of the plate,

then guide them down into the

fiber basket area.

Pigtail

protection

plate

Adapter

bulkhead

Fiber

basket

Free ends of

pigtails

32.

Group

ends of

pigtails

and insert

into tube

Route free ends of pigtails through transportation

tube. Provided are two 3-foot lengths of plastic 1/4"

tubing to protect the 900-micron pigtail cables. Gather

the free ends of the connected pigtails (12 pigtails per tray

and tube),align their ends as a group, and collectively

guide them into a transportation tube. Grouping the

fibers provides greater rigidity. Slide the fibers through

the tube until the free ends exit the opposite tube end.

Transportation

tube

Pigtail

ends

33.

Secure

transportation tube

to basket here (top

inside wall) with

cable tie

Attach one end of transportation

tube to the basket. With a cable

tie, doubled over, attach one end of

the transportation tube to the top,

left, inside wall of the fiber basket. Fiber basket

Transportation

tube

Bend-radius

control

Bottom splice tray tab

Pigtails and feed tube not

shown, for visual clarity

Velcro strap

34. (Optional − trim transportation tube to proper

length.) Before attaching the tube to the splice

tray, verify the tube length allows the splice tray

(which is attached to the tube in the next step)

to be easily positioned at the front of the fiber basket

after the tube is positioned in the basket. If needed, the

tranportation tube can be cut to length, or trimmed

approximately 4", if company practice is to wrap or

loop it just one time down into the fiber basket and then

up and over the bend-radius control. Alternately, the

uncut tube can be looped twice within the fiber basket,

then routed up and over the bend-radius control.

Trim

tube, if

needed

Feed tube

Transportation

tube

35. Prepare splice tray, attach other end of transportation

tube. Again prepare the splice tray for tube attachment,

starting two new cable ties at the same tray corner as

before, using the outer tie-down slots. Overlap the

transportation tube onto the tray corner about 1"

(alongside the feed tube), then secure the tube to the

tray with the two, new, positioned cable ties.

If splicing is not performed at this time, wrap

the pigtails in the tray per company and tray

manufacturer instructions, and continue with

Step 36. If splicing is to be performed at this

time, proceed to Step 38.

Cable

ties

Use same tray

corner and two

NEW ties.

Transportation

tube for pigtails

(12 pigtails per tube

recommended)

Feed buffer tube

Splice tray

36. Perform tube management. Always keep tubing neat and free of kinks. To man-

age the tube slack, loop and store the tubes inside the fiber basket, and hang the

tube-end with the attached splice tray up over the bend-radius control near the top

of the backboard. If desired, starting at the splice tray, attach the length of trans-

portation tube to the feed tube with cable ties at short intervals, for easy joint tube

management. Allow the splice tray to rotate freely when looping the tubes for

storage, to avoid stressing and kinking the tubes, which could cause fiber damage.

37. Close the pedestal (optional). If splicing or drop cable installation will be perform-

ed at a later time, do Steps 44-45 now to secure the splice tray(s) and to close the

pedestal. Go to Step 38 to perform splicing. Go to Step 46 to install drop cables.

Splicing Fibers at the CFDP Pedestal

38. Obtain tools. Prepare the area for splicing, and assemble and prepare any equip-

ment and tools needed to splice fibers. Review all the cautions and warnings herein.

39. Open pedestal. Remove the dome and open the CO side door, per Steps 3 and 4.

40. Remove the splice tray(s) from the backboard. Loosen the VELCROstraps that

secure the splice tray(s) and pull out the tray(s), unwinding/rotating it and the tubes

attached to it. Detach the clear plastic cover from the splice tray(s).

41. Perform splicing. Unwrap the working fibers to be spliced, perform all fiber splicing

at this time, and when complete, route/place the spliced fibers back into the splice

tray(s), all per local/company practice and product manufacturer’s instructions.

42. Label and identify splices/tray. Per company practice, label/identify the splices.

43. Cover splice tray(s). Re-attach the cover(s) to the splice tray(s).

44. Secure tray. Secure the splice tray(s) to the backboard. To do this, wind or rotate the

tubes and the tray(s) as needed to loop and store the tubing in the fiber basket, then

hang the splice tray(s) from the bend-radius control by routing the last foot of tubing

over the bend-radius control. Secure the tray(s) to the tabs at the front of the fiber

basket with the provided VELCROstraps. See Step 34 for alternate tube routing.

45. Re-check foam plug placement and cable management, and close the pedestal.

Perform Steps 54 through 56 to carefully close up the pedestal.

Installing Fiber Drop Cables

46. Dig trench from premises to pedestal. Per company practice, prepare a trench to

run the drop cable to the pedestal. Clear the soil from the bottom front of the base,

where the cable enters at the drop cable access hole.

47. Run the drop cable. Route the preconnectorized drop cable through the trench to

the pedestal base. Verify 9 feet of cable will be available above the ground line.

48.

cables are routed through the base to their final

length), re-install the plug by placing it in front of the

cables (cables at the back of the channel), angling the plug’s front edge down and

forward toward the first rib of the base front, and sliding it down and forward until it

rests on top of the base’s first rib. Press down on the plug’s back edge until it rests

on the bent flange at the rear of the channel.

Bring cable into base through drop cable

channel or conduit. Per company practice, route

the drop cable through the drop cable access

hole at the bottom front of the base and push it up

through the channel (or conduit) provided for the

drop cables. At the top of the channel, guide the

cable between the foam plug (installed at the top

of the channel) and the back wall of the channel.

If the plug dislodges during cable routing (after all

(Slide plug into

channel, set on

bent flange &

first rib of base)

Base Interior View,

Front Half Foam

plug

Channel, installed

Bent

flange

Drop cable

Drop cable hole

49. Route cable through grommet. At the drop cable side

of the backboard, at the bottom grommet plate, pull or

slide out one of the double-port grommets. Feed the

preconnectorized cable through the grommet port by

slicing into the grommet port at the notch provided in it,

then pressing or sliding the drop cable into the grommet

port at the sliced notch. Slide the grommet down the

cable until it is at the level of the grommet plate. Rotate

and align the grommet with its

slot, and re-insert the

grommet into the grommet

plate. Always populate or

use the rear-most ports

first, for best hand and

tool access and mobility.

Tie-down slot on bracket

(use with front grommet

port to the right)

Rear

grommet

port

Front

grommet

port

Notch

Notch

Cable

mounting

bracket

Tie-down T on bracket

(use with front grommet

port to the left)

Tie-down T

on rear wall

(use with rear

grommet ports)

50. Secure cable to backboard. Secure the cable to its appropriate tie-down T or

tie-down slot (see the drawing in Step 49) with a hose clamp. If cable ties are used,

per company practice, double the tie over the cable and T or slot, crisscross it, and

tighten the tie. Cables that are routed through rear grommet ports should use the

T’s on the backboard rear wall. T’s (and slots) are also provided on the cable

mounting brackets which are perpendicular to the back wall. Use the bracket T’s

and slots with the front grommet ports (the bracket T is used with the front port of

the grommet to the left of the bracket, and the bracket slot is used with the front

port of the grommet to the right of the bracket).

51. Label drop cable. Label the/all drop cable(s) with a cable marker or label. This

facilitates later cable identification for future troubleshooting, splicing, or rework.

52. Route, secure, and connect drop pigtail. Route and loop the drop cable pigtail

around the inside perimeter of the drop side backboard and hang the last slack loop

from the bend-radius control. Size the loops so that the connector will easily (with-

out tension) reach the appropriate bulkhead adapter. Secure the cable to the back-

board tie-down slots with cable ties at regular intervals. Plug the first connector into

adapter 1 at the top front corner. Adapter 2 is directly below it in the same column.

53. Prepare all drops. Repeat Steps 46-52 for all customer drop cables ready for

installation and connection at this time. If splicing is to be performed, go to Step 38.

54. (Re)Place foam plug. Verify the foam plug is properly installed in the drop channel

(see Step 48). If it was removed or dislodged, re-install it at this time.

55. Re-check cable management & lock inner door(s). Verify all tubing is neat and not

kinked, and that no cables, ties, wires or tubes protrude beyond the backboard walls.

Close and lock the inner doors by turning all cup-washer screws clockwise until tight.

56. Close the pedestal. Locate the outer dome and orient it so the snap lock faces the

front (the Charles logo is on the base front). Slide the dome down over the back-

board, align the dome’s snap lock with the base’s latch catch, and allow the self-

locking dome to drop down in place. An audible click" indicates the dome is locked.

Table 1. Branch or Stub-End Configuration Installation

Table 2. Model Numbers and Ordering Information

Model # CFDPtDescription

CFDP10-EL18 CFDPInterconnect PedlockOSP Pedestal, with a 10" diameter, locking, exterior

dome, a square, 2-piece, expanded-capacity, split base, a weather-tight interior

enclosure with two locking doors, a removable backboard for fiber cable routing,

attachment, storage, and splicing (tray capacity = 5 trays/120 splices at 24 fibers per

tray), a pre-connectorized bulkhead with 18 SC/APC adapters, 4 single-port 1"

diameter feed grommets and 9 double-port 0.625" diameter drop grommets for 18

drops, one FOSC B splice tray, a ground/bond plate and two 3’ lengths of

transportation tubing. Includes all equipment shown herein.

CFDP10-EL18C Same as above but with SC/UPC-type adapters in the interconnect bulkhead.

CFDP12-EL24 Same as CFDP10-EL18 but with 24 SC/APC adapters in the pre-connectorized

bulkhead, a 12" dome, 6 single-port 1" dia. feed grommets, 12 two-port 0.625"

diameter drop grommets for 24 drops, and an 8 tray capacity.

CFDP12-EL24C Same as CFDP12-EL24 but with SC/UPC-type adapters in the bulkhead.

Optional Equipment for Use with CFDPs

97-SCAPC18PT

97-SCUPC18PT

97-SCAPC24PT

97-SCUPC24PT

Kit of 18 fiber pigtails: SC/APC-type connector, color-coded, 900 micron, 3 meters

Kit of 18 fiber pigtails: SC/UPC-type connector, color-coded, 900 micron, 3 meters

Kit of 24 fiber pigtails: SC/APC-type connector, color-coded, 900 micron, 3 meters

Kit of 24 fiber pigtails: SC/UPC-type connector, color-coded, 900 micron, 3 meters

97-001911-A

97-001753-A

97-PKOR010A

Grommets, feed-side type, one 1" port per grommet, 50-piece kit.

Grommets, drop side, middle type,

two 0.625" ports per grommet, 50-piece kit

Dome cap, high visibility, orange, 10"

Strong durable solution for protecting wires

that are mounted to buildings and utility poles

PVC construction: lightweight and easy to cut

Various bends, lengths, offsets, and notches

Available in 7/8" and 1.25" diameters

Riser Pipes & U-Guards

119 series (7/8" risers)

122 series (7/8" U-guards)

219 series (1.25" risers)

222 series (1.25" U-guards)

Various replacement parts are available. Contact Charles Industries for more information.

Table 3. Physical Specifications

Feature 10" dome models 12" dome models

Height, overall 50.5 in. 128.3 cm 50.5 in. 128.3 cm

Height, base only, incl. collar (stake only for IPS) 18.5 in. 47 cm 18.5 in. 47 cm

Height, dome only 35.5 in. 90.2 cm 35.5 in. 90.2 cm

Height, base bottom to ground line 8.5 in. 21.6 cm 8.5 in. 21.6 cm

Height, dome top to ground line 42 in. 107 cm 42 in. 107 cm

Depth, base (front to back) 12.8 in. 32.5 cm 15.1 in. 38.4 cm

Width, base (side to side) 13.9 in. 35.3 cm 16.1 in. 41 cm

Diameter, base collar, O.D. 10.75 in. 27.3 cm 12.75 in. 32.4 cm

Diameter, base collar, I.D. 10.3 in. 26.2 cm 12.3 in. 31.2 cm

Diameter, dome, O.D. (not the cap) 11.25 in. 28.6 cm 13.25 in. 33.6 cm

Diameter, dome, I.D. 10.85 in. 27.6 cm 12.85 in 32.6 cm

Weight 36 lbs. 16.4 Kg 44 lbs. 20 Kg

NOTE: All dimensions and weights are approximate.

This manual suits for next models

1

Popular Cable Box manuals by other brands

Bebob

Bebob COCO-FX9-AMICRO user manual

Palmer

Palmer BALUN manual

HUBER+SUHNER

HUBER+SUHNER MASTERLINE Flex Box installation manual

Herman Miller

Herman Miller Canvas Vista Cable Management Installation and Disassembly

Seaside

Seaside DCT 2500 user manual

Minebea Intec

Minebea Intec PR 6130/64Sa installation manual