Heath Company Heathkit SB-220 User manual

LINEAR AMPLIFIER

MODEL

SB-220

Assembly

and

Operation

of

the

LINEAR AMPLIFIER

MODEL

SB-220

HEATH

COMPANY

BENTON

HARBOR, MICHIGAN

49022

Page

2

~~~-=m~

TABLE OF CONTENTS

INTRODUCTION

.............................

3

PARTS LIST

...............................

5

STEP-BY-STEPASSEMBLY

...........................

9

Circuit Board

.................................

10

Circuit Board Prewiring

..........................

11

InputCoil Assembly

...........................

12

Front Panel

...............................

20

Chassis

....................................

24

Chassis Parts Mounting

..........................

24

ALCWiring

...............................

27

Top-ChassisAssembly

..........................

28

Under-ChassisWiring

........................

46

........................

120-240

Volt Wiring

55

FinalTop-ChassisWiring

.......................

56

Cable Preparation

..........................

58

Knob Installation

..........................

59

TEST AND FINALASSEMBLY

......................

61

INSTALLATION

............................

65

OPERATION

Controls. Connectors. And Meters

.....................

69

General

................................

70

Tune-up

................................

71

...........................

Periodic Maintenance

74

INCASE OF DIFFICULTY

........................

75

TroubleshootingChart

..........................

76

Factory Repair Service

..........................

77

...............

Special Shipping Instructionsfor U.S. and Canada

78

............................

SPECIFICATIONS

79

CIRCUIT DESCRIPTION

PowerSupply

..............................

81

Relay

.................................

82

RF Circuits

...............................

83

ALC Circuit

...............................

83

MeteringCircuits

............................

84

CIRCUIT BOARD X-RAY VIEW

......................

85

CHASSIS PHOTOGRAPHS

........................

86

SCHEMATIC

..

.(fold.out from page)

....................

87

REPLACEMENTPARTSPRICE LIST

...................

90

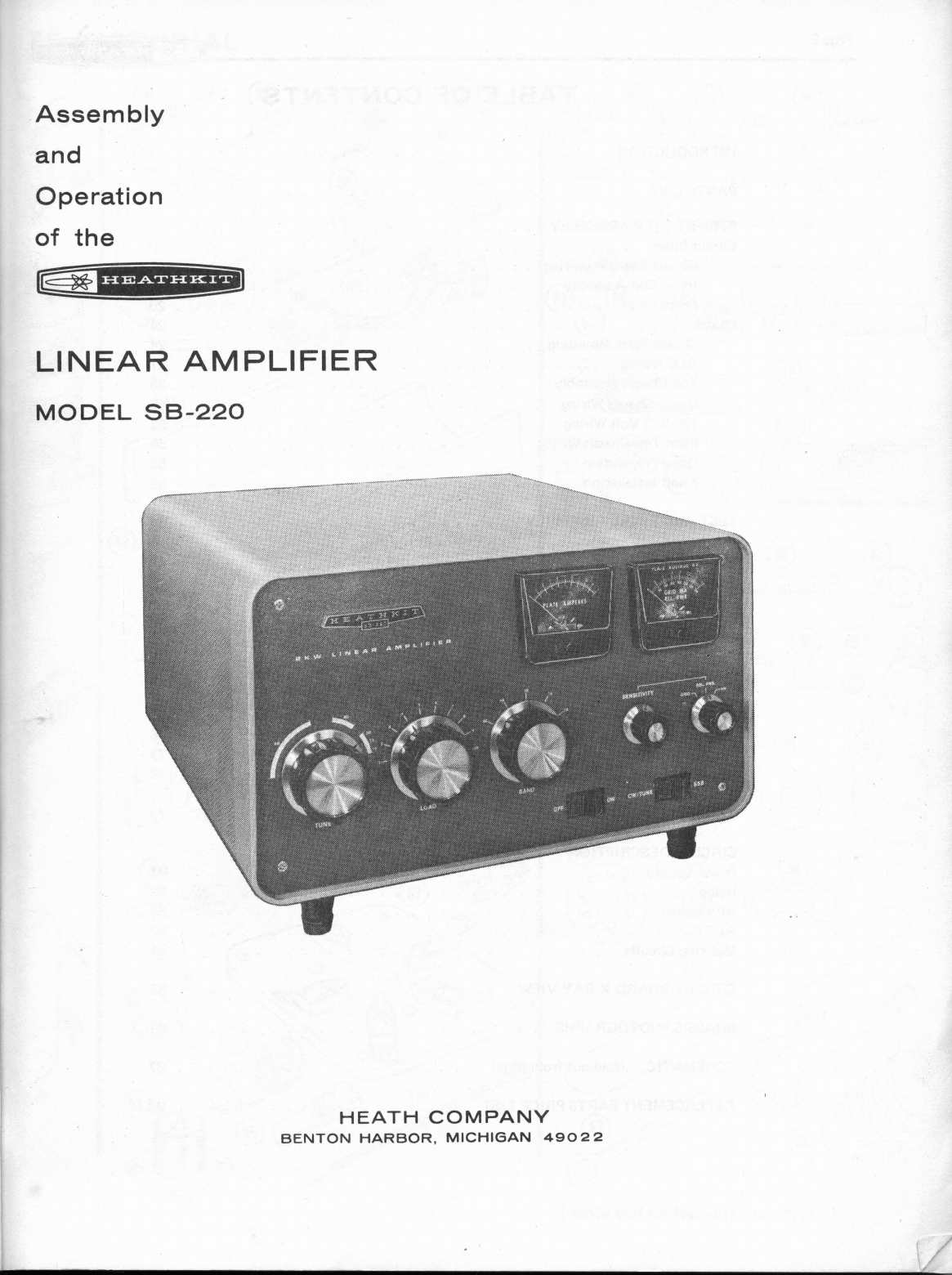

INTRODUCTION

The Heathkit Model

SP-220

Linear Amplifier

is

e

completely self-contained, table top, grounded grid, linear

amplifier.

It

is

designed tooperate at the maximumamateur

power limit on

SSB,

CW, and RTTY.

Its

stylingmatchesthe

Heath

SB

series of amateur equipment.

The Amplifier

is

designed to

be

used with exciters which

deliver

100

watts

or

more output.

It

can

be

used with less

drivingpower, butwill givealower output.

A

broad-band, tuned input circuit for each band feeds the

two Eimac

3-5002

triode tubes connected in grounded grid

configuration. The tubes are biased beyond cut-off in the

receive1 mode, and zener-regulated bias controlsthe idling

current in thetransmitmode. The tubes arecooled by afan.

An ALC circuit develops negative voltage to be fed back to

the exciter to reduce

its

gain when the Amplifier

is

overdriven.

The antenna change-over relay

is

normally actuated by

exciter relay contacts to place the Amplifier inthe transmit

mode.

The Amplifier can be operatedfrom either

120

VACor

240

VAC

50/60

Hz lines and can be easily changed from one to

the other. Operation from a

240

volt line is recommended.

Each side of the line cord

is

equipped withacircuit breaker

to protectagainstoverloads.

An important feature of this Amplifier is that

it

can be

tuned up at the one kilowatt limitand can then

be

switched

to operate on

SSB

at

two kilowatts

P.E.P.

input. As the

switching changes both the voltage and current tothe final

tubes, the impedance remains the same and no additional

adjustmentof tuned circuits

is

required.

The tubes are "instant heating" types, and transmission may

be

started as soon as the Amplifier

is

switched on (after

Here is

a

full legal-limitAmplifier that can take

its

placeon

your operating table and give you years of troublefree

pleasure. ThisAmplifier hasacommandingvoice.

Read the "Kit BuildersGuide" for complete informationon

unpacking, parts identification, tools, wiring, soldering, and

step-by-stepassernbly procedures.

v

PARTS PICTORIAL

BROWN

u

(continued on fold-outfrom

Page

7)

PARTS

LIST

This Parts List contains all of the partsused intheassembly To order replacement parts, refer to the "Replacement

of the kit. Some parts are packaged in envelopes with the PartsPrice List" and use the Parts Order Formfurnished.

part number of the contents printed onthe outside. Except

for

the

initial

parts

check,

retain

these

parts

in

their

Check each

part

against the following Parts List. The key

envelopesuntilthey are calledfor intheassembly steps. numbers correspond to the numbers on the Parts Pictorial

(fold-out from Pages

4

and

7).

KEY PART PARTS DESCRIPTION

No. No.

--

Per Kit KEY PART PARTS DESCRIPTION

No. No.

--

Per Kit

RESISTORS CAPACITORS

112

Watt

1 1-9

1-44

1-18

1-22

1-23

1-24

1-25

1-26

Other Resistors

2 1-8-1

1-38-1

1000

S2 (brown-black-red)

2200

S2.

(red-red-red)

5600

S2

(green-blue-red)

22

kS2 (red-red-orange)

27

kS2 (red-violet-orange)

33

kS2 (orange-orange-orange)

47

kS2 (yellow-violet-orange)

100

kS2 (brown-black-yellow)

68

kS2

1

watt (biuegray-orange)

4.7

MS2

1

watt (yellow-violet-

green)

.82

S2

wire-wound

2

watt (gray-

red-silver)(same sizeas

1

watt),

5%

1

S2 wire-wound,

5

watt,

1%

3600

$2 wire-wound,

5

watt,

1

%

30

kS2 film,

7

watt

Molded

Mica

5 20-3

6 20-123

Mica

7 20-99

20-124

20-103

20-105

20-120

20-116

20-113

20-107

Disc

8 21-79

9 21-14

21-70

21-31

200

pF (red-black-brown)

500

pF

(.0005

pF)

.001

pF

6

kV

.001

pF

500

volt

.O1

pF

1.4

kV

.02

pF

500

volt

Page 6

KEY PART PARTS

No. No.

--

Per Kit

Other Capacitors

10 2i-28

I

CONTROLS-SWITCHES

DESCRIPTION

10 pF (10MMF or 10pyF)

tubular ceramic

,001 pF (1000MMFD)

6 kV, ceramic

20 yF (MFD)electrolytic

200 yF (MFD) electrolytic

437-437 pF ganged

variable, 2-section

250 pF variable

100kS2 control

DPST rocker switch

DPDT rocker switch

3-positionrotary switch

5-positionrotary switch

Rotary switch wafer

Circuit breaker

TPDT 110VDC relay

COILS-CHOKES-TRANSFORMERS

80120 plate coil

10115-meterinput coil

20-meter input coil

40-meter input coil

80-meter input coil

15/10 plate coil

Parasitic choke

1 mH RF choke

8.5 pH RF choke

9 pH RF choke

50 uH RF choke

Highvoltage transformer

Filament and bias transformer

DIODES-TUBES

33 56-24 1 1N458 silicon diode (yellow-

green-gray

)

34 56-26 1 1N191 germanium diode

(brown-white-brown)

35 56-82

1

1N3996A zener diode, 5.1V,

10watt, wlmounting hardware

36 57-27 15 Silicon diode

37 411-245 2 3-5002tube

KEY PART PARTS DESCRIPTION

No. No.

--

Per Kit

INSULATORS-GROMMETS-TERMINAL STRIPS-

CONNECTORS

38 71-2 1 Ceramic feedthrough insulator

(disassembled inbag)

39 73-4 1 5116" grommet

73-3 4 112" grommet

73-2 1 314" grommet

40 75-123

1

Linecord strain relief

75-124 1 6" x 4-112" fish paper

insulator

41 75-125 8 Capacitor mounting insulator

42 255-39 1 6-32x 1-114" tapped

phenolic spacer

43 255-42 3 6-32x 314" tapped phenolic

spacer

44 431-14

1

2-lugterminal strip

45 431-10 3 3-lugterminal strip

46 43142

1

5-lugterminal strip

47 431-20 1 6-lug terminal strip

48 431-13 1 4-screwterminal strip

49 432-137 6 Connector tab (large)

kXA3S66

L/'c-51-^-42memW

@mat

I)

'-.

51 43442 2 Phonosocket

52 434-93 2 5-lugceramic tube socket

53 436-5 2 Coaxial jack

54 438-9 1 Coaxial plug

55 438-12 1 Coaxial plug insert

WIRE-CABLE-SLEEVING

89-40 1 Line cord

134-36 2 Phonocable assembly

340-1 1 Barewire

343-2 1 Coaxial cable, RG-58AlU

343-8 1 Coaxial cable, RG-8lU

344-2 1 Small black strandedwire

344-7 1 Large black strandedwire

344-13 1 Blue hookupwire

344-50 1 Black hookupwire

344-51 1 Brown hookup wire

344-52 1 Red hookup wire

344-53 1 Orange hookup wire

344-54 1 Yellow hookupwire

344-55 1 Green hookup wire

,

344-56 1 Blue hookupwire (thick

insulation)

345-1 1 Large metal braid

345-2 1 Small metal braid

346-4 1 Black sleeving

346-7 2 Clear sleeving (large)

346-29

1

Clear sleeving (small)

56 354-5 6 Cable tie

Page

7

KEY PART

No. No.

--

HARDWARE

#6

Hardware

57 250-138

58 250-56

59 250-416

60 250-8

61 250-32

62 250-89

63 250-218

64 250-206

65 250-40

66 250-47

67 252-3

68 253-1

69 253-2

70 254-1'

71 255-71

PARTS

Per Kit

#8

Hardware

74 250-43

75 250-137

76 2524

77 254-2

78 25566

79 259-2

#10

Hardware

80 250-188

81 252-30

82 252-31

83 254-3

Other

Hardware

84 207-8

85 250-213

86 252-15

87 252-7

88 252-10

89 253-10

90 253-42

91 253-19

92 254-4

93 254-9

94

259-25

DESCRIPTION

6-32x 3/16"

screw

6-32x 114"

binderheadscrew

6-32

x

114"

flat head screw

#6 x 318"

sheet metalscrew

6-32x 318"

flat head screw

6-32x 318"

binderhead screw

6-32x 318"

phillipshead screw

6-32x

1

1116"

screw

6-32x 1-112"

screw

6-32x 2"

screw

6-32

nut

#6

fiber flatwasher

#6

fiber shoulder washer

#6

lockwasher

6-32x 3/4"

tapped :metal

spacer

6-32x 1-118"

tappedspacer

#6

solder lug

8-32x 114"

setscrew

8-32x 318"

screw

832

nut

#8

lockwasher

8-32.x1-318"

spacer

#8

solder lug

10-24

x

1

"

round head screw

10-24

riut

10-24

wing nut

#10

lockwasher

Cable damp

440x 5/16"

screw

440

nut

Control nut

Speednut

Control flatwasher

112"

flatwasher

314"

flatwasher

Control lockwasher

#5

lockwasher

#10

double lug

KEY PART PARTS DESCRIPTION

No. No.

--

Per Kit

Other Hardware(cont'd.)

95 258-115

1

Brass spring

518" x 5112"

96

25410 1

Control solder lug

97 25424 1

Longsolder lug

98 260-12 2

Plateconnector

99 456-16 1

Shaftcoupler

METAL PARTS

MISCELLANEOUS

Cabinet

Chassis.

.

Capacitorbank bracket

Front panel

Rear panel

Leftside panel

Right side panel

Angle bracket

Platecoil bracket

Top rear platecover

Perforatedtopcover

Perforatedfancover

RF shield

Coil mountingshield

Silver platedstrip

Printedcircuit board

Black tapered spacer

Rubberfoot

Fan blade

Siliconegrease

Plateamperes meter

Multi-meter

Fan motor

Phenolicshaft

Small knob

Largeknob'

Danger highvoltagelabel

Nameplate

Blueand white label

Nutstarter

PartsOrder Form

KitBuildersGuide

Manual

(See

front cover

for

partnumber.)

,

Solder

PARTS PICTORIAL

(cont'd.)

Page

8

pre

b=~----=*-l&g

STEP-BY-STEP ASSEMBLY

Before starting to assemble this kit, read the "Kit Builders

Guide" for complete information on wiring, soldering, and

step-by-stepassembly procedures.

The illustrations in this section of the Manual are called

Pictorials and Details. Pictorialsshow the overall operation

for

a

group of assembly steps; Detailsare used inadditionto

the Pictorials to illustrate

a

single step. When you are

directed to refer to a certain Pictorial "for the following

steps," continueusingthat Pictorial untilyou are referred to

another Pictorialfor another group of steps.

86 through 89) from time totime to setheactual positions

of wires and components.

Lockwashers and nuts will be used with most screws when

mounting parts, unless the assembly steps state otherwise.

Consequently, the applicable stepswillcall out only the size

and type of hardware used. For example, the phrase "Use

6-32

x

114"

hardware" means to use

6-32

x

114"

screws, one

or more #6 lockwashers, and 6-32nuts. Refertothe Details

for the proper installationof hardware. Be sure to position

each part as shown in the Pictorials. Follow the instructions

carefully, and read the entire step before performing the

operation.

As

,the drawings in the Manual may be slightly distorted to When

a

step directsyou to "connect" an insulatedwire, first

show all the parts clearly, look at the Chassis Photos (Pages prepare

its

ends by removing

114"

of insulation.

Page

10

-k-J

CIRCUIT BOARD

Solder a part or group of parts only when directed. Use

112

On the circuit board, be especially careful not to cover

watt resistoks unless directed otherwise in a step. Each unused holes with solder or bridge solder acrossfoilsduring

resistor will be called out by the resistance value (in

a,

kQ,

assembly. Perform thesteps inPictorial

1-1.

or

MQ)

and color code. Capacitors will becalled out bythe

capacitance value and type.

START

FOR GOOD SOLDERED

CONNECTIONS. YOU MUST

KEEP THE SOLDERING

IRON TIP CLEAN..

WIPE IT OFTEN WlTH

A

DAMP SPONGE OR CLOTH.

NOTE: DIODES MAY BE SUPPLIED

I

N ANYOF THE FOLLOWING SHAPES.

THE

CATHODE

END

OF THE DIODE

IS MARKED WlTH A BAND OR

2ANDS. ALWAYS POSITION THIS

END AS SHOWN INTHE PICTORIAL.

(y/~ositionthe circuit board as

shown andinstalldiodes(#57-27)

at D7, D5, D3, Dl, D9, D11, and

D13. Make sure all seven cath-

ode banded ends are to the

({)

Solder.all leads to the foil and

cut off the excess lead lengths.

(dInstall diodes (#57-27) at D6,

D4, D2, D8, D10, D12, and Dl4

with their cathode ends to the

(

\/)

Solder all leads to the foil and

cut off the excess lead lengths.

(4

CAREFULLY INSPECT ALL

DIODES IN THE PRECEDING

STEPS TO BE SURE THEYARE

POSITIONED

AS

SHOWN IN

THE PICTORIAL AND ON THE

1

CIRCUIT BOARD.

CONTINUE

PICTORIAL

1-1

Page 11

~~=*~--*=*=~J

CIRCUIT BOARD PREWlRlNG

Refer to Pictorial 1-2for the following steps.

From the component side of the circuit board, insert one

NOTE:

To prepare lengths of hookup wire, as in the end of each of the following wires intothe designated hole.

following step, cut the wire to the indicated length and Solder each wire onthefoil side.

remove 114" of insulation from each end. If the wire is

solder to hold the strands together. Unlessotherwise stated,

V/

sranded, twist the ends tightly and apply amamountof

(

Connect a 5-114" length of red hookupwire to hole

A

inthe circuit board (S-1

).

"hookup wire" will mean the small solid-conductor wire

supplied invariouscolors.

(

d"

Connect a 3-314" length of black hookupwiretohole

B

onthe circuit board 6-1).

(

/

)

Preparethefollowing lengthsof hookupwire:

L.--

-

5-1

14"

red

3-314" black

6-112" black

17-112" small black strandedwire

7-112" orange

6-112" yellow

9-112" heavy blue (thick insulation)

I

2-314"'heavy blue (thick insulation)

(,/Connect a 6-112" length of black hookupwireto hole

Con the circuit board (S-1

1.

(

f

1

Connect a 17-112" length of black stranded wire to

hole

E

onthe circuit board 6-1).

Connect a 7-112" length of orange hookup wire to

hole

G

onthe circuit board 6-1).

(d

Connect

a

6-112'' length of yellow hookup wire to

hole

F

onthe circuit board (S-1).

(

J)

Connect a 9-112" lengthof heavy blue hookupwireto

hole

H

onthecircuit board 6-1).

(/Connect a 2-314" lengthof heavy blue hookupwireto

hole

J

onthe circuit board 6-1).

(./fTrim all excess lead lengths from the foil side of the

circuit board.

-2-314"

HEAVY

BLU

BLU

17-112" BLK--

STRANDED

PICTORIAL

1-2

RED-

BLK-

BLK-

Page

12

-*;--).-3

(

)

Carefully inspect the foil side of the circuit board;

all

lettered holes except

D

and

K

should be soldered.

Make sure there are no solder bridges between foils.

Also notethat one diode

is

not installed.

This completes the prewiring of the circuit board. Set

it

aside until called for later. Proceed with the "Input Coil

Assembly" section.

INPUT COIL ASSEMBLY

Refer to Pictorial

2-1

for thefollowingsteps.

Refer to Detail 2-1Afor the next two steps.

NOTE: A

plastic nut starter has been providedwiththis kit.

Use

it

to hold and start nuts on screws. See Page

3

of the

"Kit BuildersGuide" for more information.

PICTORIAL

2-1

Detail

2-1A

Page 13

INSIDE OF

COIL MOUNTING

n

SHIELD

LUG

1

LOCATING

LUG

LOCATING

SLOT

ING

IS

Detail

2-1C

Detail 2-18 shows the coil mounting locations for the

following steps. Notethat the locatinglugofeach

mil

must

be

positioned inthe locatingslot, and that each mil.must be

pushed into

its

mounting hole until the mountingears snap

outto holdthecoil inplaceas shown inDetail2-1C.

Detail

2-1B

(d

lnstall the 2ameter

mil

(#40965) at CV.

See

Detail

2-1C.

/

( )

Installthree #6 solder lugsonthe coil mountingshield

(4

Install

a

10115-metercoil

(#40-964)

at CX.

(#206-457)

at

CLwith 6-32x 318" hardware. Position

the lugsas shown inDetail2-1

0.

(4

Installa 10115-meter

mil

(#40-964)

at CY.

(d

Installthe 8hetercoil (#40-1012) at

CS.

;

(d

Installa

#6

solder lug at DFwitha6-32

x

1/4"&rew

and a6-32nut. Formthe solder lugas shown.

(d

Installthe40meter

mil

(#40-966) at CT.

(4

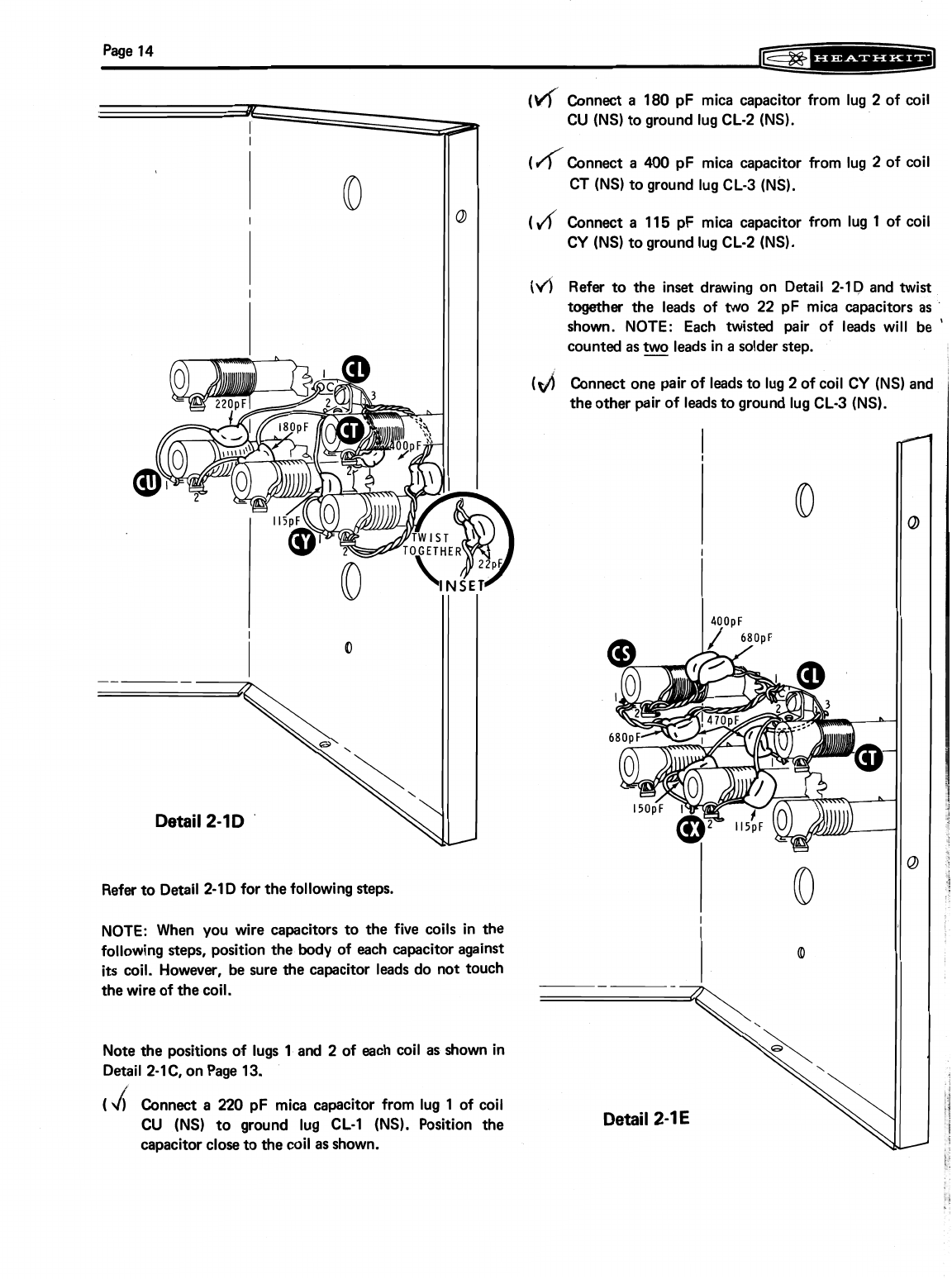

Connect a

180

pF mica capacitor from lug

2

of coil

CU

(NS)toground lug

CL-2

(NS).

Detail

2-1D

'

Refer toDetail

2-1

Dfor thefollowingsteps.

NOTE: When you wire capacitors to the five coils in the

following steps, position the body of each capacitor against

its

coil. However, be sure the capacitor leads do not touch

thewireof the coil.

(/(Connect a

400

pF mica capacitor from lug

2

of coil

CT

(NS) toground lug

CL-3

(NS).

(

d

Connect a

115

pF mica capacitor from lug

1

of coil

CY

(NS)toground lug

CL-2

(NS).

(4

Refer to the inset drawing on Detail

2-ID

and twist

together the leads of

two

22

pF mica capacitors as

shown. NOTE: Each twisted pair of leads will be

'

countedas leads inasolder step.

I

('t/j

Connect one pair of leads to lug

2

of coil

CY

(NS) and

theother pairof leadstoground lug

CL-3

(NS).

Notethe positionsof lugs

1

and

2

of each coil as shown in

Detail

2-1C,

on Page

13.

(

d

Connect a

220

pF mica capacitor from lug

1

of coil

CU

(NS) to ground lug

CL-1

(NS). Position the

capacitor closetothe coil as shown.

Page

15

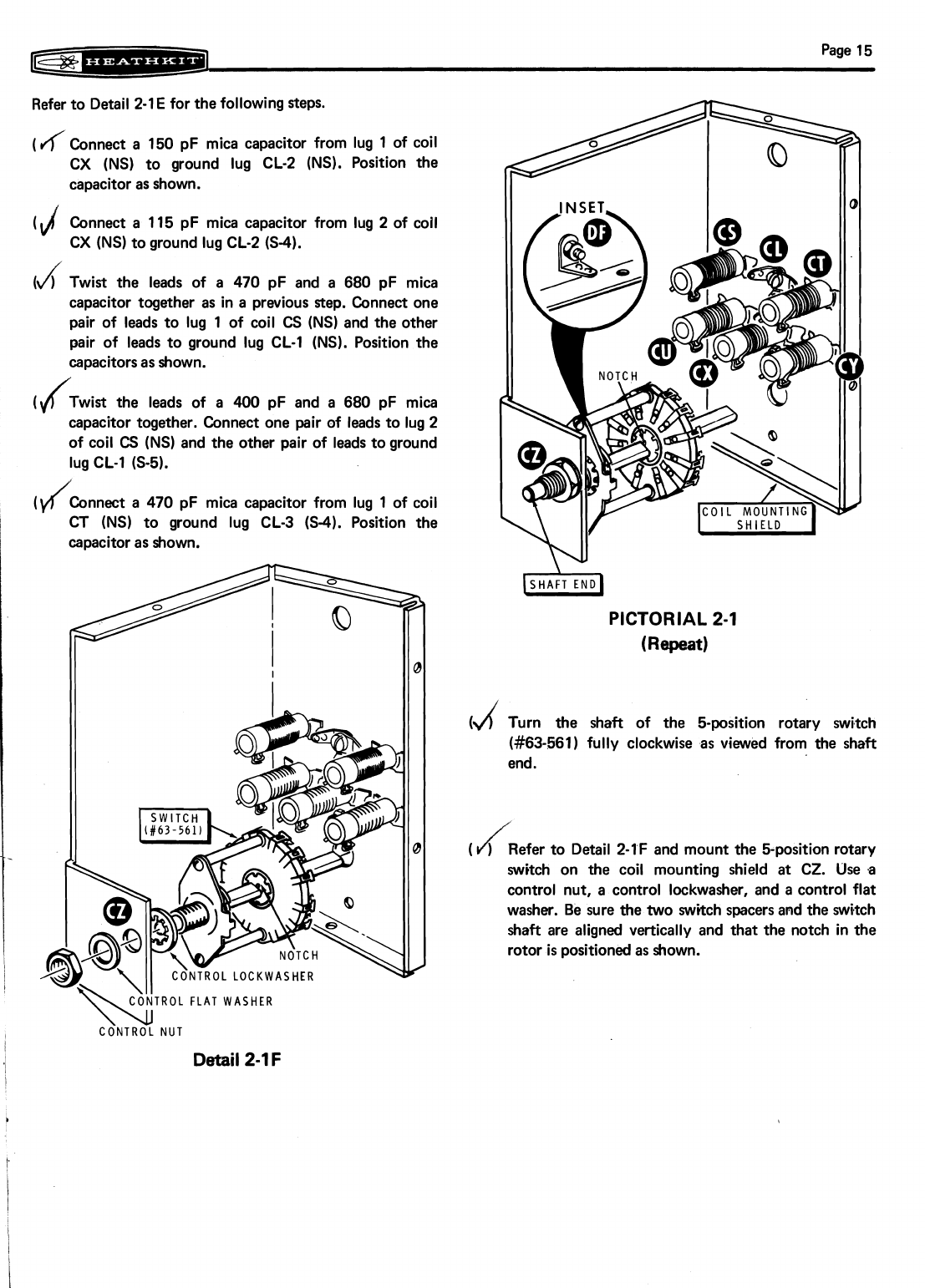

Refer to Detail 2-1

E

for thefollowing steps.

(

Jf

Connect a

150

pF mica capacitor from lug

1

of coil

CX

(NS)

to ground lug CL-2

(NS).

Position the

capacitor as shown.

(4

Connect a 115 pF mica capacitor from lug

2

of coil

CX

(NS)

toground lug CL-2

(S-4).

Id

Twist the leads of a

470

pF and a

680

pF mica

capacitor together as in a previous Rep. Connect one

pair of leads to lug

1

of coil

CS

(NS)

and the other

pair of leads to ground lug CL-1

(NS).

Position the

capacitorsas shown.

(4Twist the leads of a

400

pF and a

680

pF mica

capacitor together. Connect one pair of leads to lug

2

of coil

CS

(NS)

and the other pair of leads toground

lug CL-1

6-5).

(y/Connect

a

470

pF mica capacitor from lug

1

of coil

CT

(NS)

to ground lug CL-3

(S-4).

Position the

capacitoras shown.

PICTORIAL

2-1

(Repeat)

(d

Turn the shaft of the bposition rotary switch

(#63-561)

fully clockwise as viewed from the shaft

end.

J

(

)

Refer to Detail

2-IF

and mount the 5-position rotary

switch on the coil mounting shield at CZ. Use a

control nut, a control lockwasher, and acontrol flat

washer. Be sure the two switchspacers and the switch

shaft are aligned vertically and that the notch in the

rotor

is

positionedas shown.

CONTROL

FLAT

WASHER

\\

Detail

2-1

F

Page

16

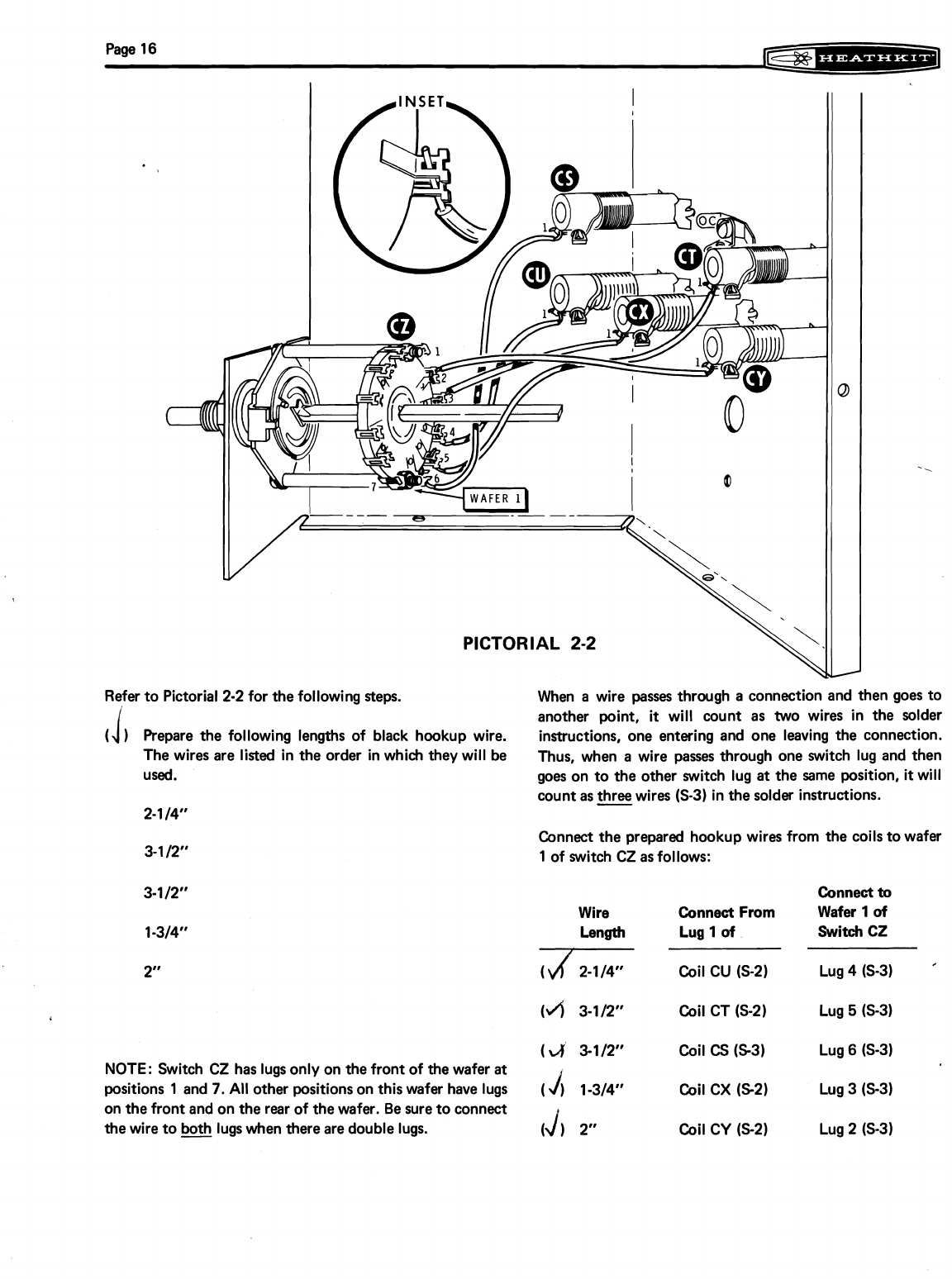

Refer to Pictorial

2-2

for thefollowing Reps. When a wire passes through a connection and then goes to

another point,

it

will count as two wires in the solder

1

Prepare the following lengths of black hookup wire. instructions, one entering and one leaving the connection.

The wires are listed in the order inwhich theywill be Thus, when a wire passes through one switch lug and then

used. goes on to the other switch lug at the same position,

it

will

countas

three

wires

6-3)

inthesolder instructions.

2-114"

Connect the prepared hookupwires from the coilstowafer

1

of switch CZ as follows:

Connect

to

Wire Connect

From

Wafer

1

of

Length Lug

1

of

Switch

CZ

IV/2-1/4"

Coil

cu

(s-2)

Lug

4 6-31

(4

3-112"

Coil CT

(S-2)

Lug

5

(S-31

(4

3-112"

Coil

CS

6-31

Lug

6

6-31

NOTE: Switch CZ has lugsonly on thefront of thewafer

at

positions

1

and

7.

All other positionson this wafer have lugs

(

j)

13/4"

Coil CX

(S21

Lug

3 631

on thefront and on the rear of thewafer. Be sure toconnect

thewire to

@

lugswhen thereare double lugs.

(1

2"

Coil CY

6-21

Lug

2 6-31

Table of contents