Heatmor 200 SSP User manual

Outdoor Furnaces

TM

SAVE THESE INSTRUCTIONS

ii

When these safety symbols appear on the following pages, they will

alert you to the possibility of serious injury if you do not comply with the

corresponding instructions. The hazard may originate from something

mechanical or electrical shock. Please read the instructions carefully.

When you see this safety symbol on the following pages, it will alert you

to the possibility of damage to your HEATMORTM Stainless Steel Outdoor

Furnace if you do not comply with the corresponding instructions. Please

read the instructions carefully.

The HEATMORTM Stainless Steel Outdoor Furnace is certied to offer safe

service provided it is installed, operated and maintained in accordance with

the instructions contained in this manual.

Proper personal protective equipment, (PPE), MUST BE WORN AT ALL

TIMES when servicing and maintaining any of the HEATMORTM Stainless

Steel Outdoor Furnace product line.

iii

TABLE OF CONTENTS Page #

DEAR HEATMOR™ OWNER 1

NOTICE TO THE READER 2

3

4

1 FURNACE PHOTO 5

RESIDENTIAL FURNACE SPECIFICATIONS 6

2 FRONT CUT AWAY VIEW OF MODEL 200 SSP7

FURNACE PARTS LIST 8

3 REAR CUT AWAY VIEW OF MODEL 200 SSP 9

FURNACE PARTS LIST 10

4 MINIMUM CLEARANCE SEPARATION SPECIFICATIONS 11

5 WARNINGS AND PRECAUTIONS 12

A Installation 12

B Electrical 13

C Other 13

6 CONCRETE PAD SPECIFICATIONS 14

A Model 200 SSP Pad Specifications 14

7 INSTALLATION OF THE HEATMOR™ FURNACE 15

A Equipment Required 15

B Placing the HEATMOR™ on the Concrete Pad 15

C CaulkingAround the Outside Perimeter of HEATMOR™ 15

D Filling the HEATMOR™ Outdoor Furnace Initially with Water 16

E Maintaining Water in the Bladder and in the HEATMOR™ 17

F Heatmor Recommended Installation Instructions 18-20

8 SAFE OPERATING GUIDELINES 21

A Operation 21

B Lighting Your HEATMOR™ for the First Time 23

C Dew Point 24

D Loading Wood Pellets into the HEATMOR™ 24

E What can I burn? 25

i. Wood Pellets 25

F How does a fire burn out? 25

G Stages of Combustion 25

H Efficiency Measurements and Types of Fires 26

I Handling and Storage of Wood Pellets 26

9 WATER 28

A Qualities of Water to Use 28

B Water Level Maintenance 28

C Removal of water and replacement of water 28

D Water Additives 29

E Water Treatment Additives and Safety Specifications 30

iv

F Adding Freeze Protection Products 31

10 BLADDER ASSEMBLY 32

A Bladder 32

B Bladder Gate Valve and Bladder Hose 33

11 WATER JACKET 34

A Water Jacket 34

B Supply Line and Return Line Connectors 34

C Relief Vent Pipe and Weighted Pop off Ball 34

12 FIREBOX AND OTHER COMPONENTS 35

A Firebox 35

B Firebox Door 36

C Firebox Door Handle 37

D Firebox Door Hinge 37

E Firebox Door Gasket 37

F Firebox Door Frame 38

13 AIR SUPPLY 39

A Combustion Air Blower and Flipper Assembly 39

i. Operation of the CombustionAir Blower and FlipperAssembly 39

ii. Steps to Maintain your Blower / FlipperAssembly 39

B Air Box(s) 40

14 CHIMNEY AND FLUE 41

A Chimney 41

B Chimney Extension(s) 41

C Flue 42

D Flue Covers 42

E Flue Scraper 42

15 ASHES 43

A Ash Management and Ash Removal 43

B Ash Pan 43

C Ash Pan Cover Plate 44

16 ELECTRICAL 45

A Electrical Supply 45

B Electrical Supply Junction Box 45

C Double Electrical Outlets at rear 46

D Electronic Controller 46

E Electronic Controller Temperature Probe 46

F Watlow Flame Sensor Control 47

G Watlow Flame Sensor Control Temperature Probe 48

H DaytonAuger Speed Control 48

I High Water Temperature Safety Shutoff Control 49

J Front Light and Fan Power Switch 50

K Iginition Switch 51

L In The Event of a Power Failure 51

v

17 PELLET SUPPLY 52

A Internal Hopper of the HEATMOR™ 52

B Auger and Auger Motor 52

18 EXTERIOR CLADDING AND INSULATION 53

A Outer Front and Side Doors of the HEATMOR™ 53

B Roof of the HEATMOR™ 53

C Sides of the HEATMOR™ 54

D Insulation 54

19 AIR LEAKS 55

A Checking For Air Leaks 55

20 WATER LEAKS 56

21 SEASON START UP & SHUT DOWN CHECKLISTS 57-58

22 FREQUENTLY ASKED QUESTIONS 59-60

23 TROUBLESHOOTING AND SOLUTIONS 61-71

HEATMOR™ STAINLESS STEEL LIMITED WARRANTY 73-74

HEATMOR™ FOR LIFE 75

NEW FURNACE DELIVERY CHECK SHEET 76

WIRING DIAGRAMS 77

1

Dear HEATMOR™Owner,

On behalf of myself and the employees of HEATMOR™, I would like to take this opportunity to personally

thank you for the purchase of our HEATMOR™ Stainless Steel Outdoor Furnace. You can be assured that

your HEATMOR™ was constructed with great emphasis on quality and workmanship. It is our commitment to

provide you with the finest outdoor furnace in the industry. We wish you many years of trouble-free use and we

sincerely hope you enjoy the comforts of burning wood pellets.

This manual contains the manufacturer’s recommendations for operation and maintenance of the HEATMOR™

Stainless Steel Outdoor Furnace. Also included are some regular maintenance tips and FAQ’s (frequently

asked questions). Please observe and follow all safety instructions as directed in this manual. SAVE THESE

INSTRUCTIONS FOR FUTURE REFERENCE.

Finally, please fill out your registration and warranty forms, if you haven’t done so already. If you have any

further questions on the operation or maintenance of your HEATMOR™ Outdoor Furnace, please contact your

local dealer.

Sincerely,

Gerry Reed,

President

2

NOTICE TO THE READER

HEATMOR™ Inc. warrants and guarantees ALL HEATMOR™ Stainless Steel Outdoor Furnace Models.

HEATMOR™ Inc. does not warrant or guarantee any of the supporting products described within this

Operations and Maintenance Manual.

The contents, descriptions, directions, diagrams, and recommendations within this material are for the sole

purpose of suggested operation and maintenance methods.

Furthermore, HEATMOR™ Inc. shall not be liable for any special, consequential, or exemplary damages,

resulting, in whole or part, from the readers’ neglectful use, based upon the material within this Operations and

Maintenance Manual. Adhere to and follow all maintenance procedures set forth in this manual.

Person(s) operating an OWHH is/are responsible for operation in a manner that does not create a public or

private nuisance condition. Meeting the distance and stack height recommendations from the manufacturer

and requirements in applicable state and local regulations may not always be adequate to prevent nuisance

conditions in some areas due to terrain or other factors.

The methods of operation described within this Operations and Maintenance Manual have proven to be

effective for HEATMOR™ Inc. for the sole purpose of the operation of a HEATMOR™ Stainless Steel Outdoor

Furnace.

All formulas and gures listed within this Operations and Maintenance Manual are approximated and should be

read as such.

For additional copies or information, contact

HEATMOR™ Inc.

105 Industrial Park Court NE,

P.O. Box 787,

Warroad, MN 56763 USA

Phone: (218) 386-2769

Fax: (218) 386-2947

Website: www.heatmor.com

E-mail: woodheat@heatmor.com

Copyright © 2011 - HEATMOR™ INC.

All rights reserved. No part of this Operations and Maintenance Manual may be reproduced or used in any

form or by any means - graphic, electronic or mechanical, including photocopying, recording, taping, or

information storage and retrieval systems - without the written permission of HEATMOR™ Inc.

MODEL 200 SSP

Printed - 2011

3

EPA PHASE 2 HANGTAG MODEL 200 SSP

4

5

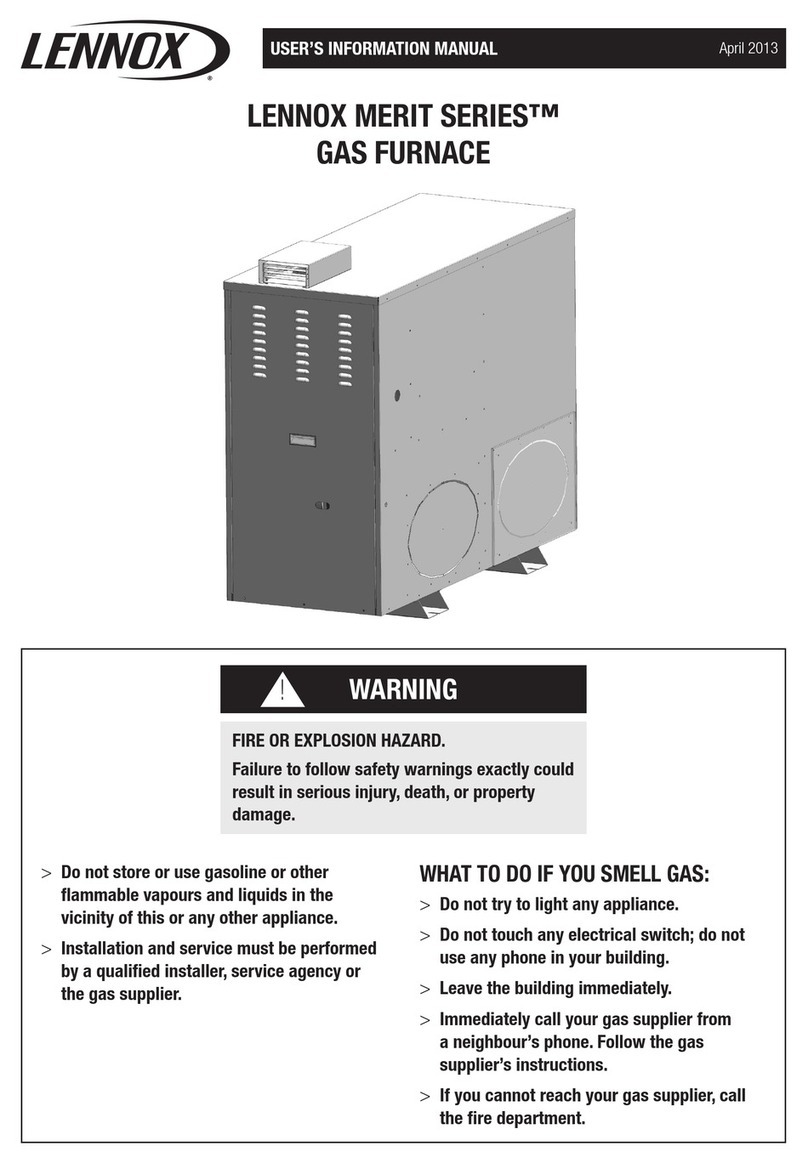

HEATMOR™ STAINLESS STEEL PELLET

BURNER OUTDOOR FURNACE MODEL

CHAPTER 1

Model 200 SSP

6

RESIDENTIAL FURNACE SPECIFICATIONS

Specications Model 200 SSP

Overall Width (Inches)

Base Width (Inches) (Footprint) 38

34.5

Overall Length (Inches)

Base Length (Inches) (Footprint) 77

65.5

Total Weight (lbs., without water) 1196

Water Capacity (U.S. gallons) 110

Forced Draft (C.F.M.) 75

Chimney Size (Inches) 8

Internal Hopper Holds 4 bags (40lbs per bag)

Insulated Heating Area (Sq. Ft.)*

1 Loading/day

2 Loading/day 2500

5000

Firebox Width (Inches) 20

Firebox Length (Inches) 20

Firebox Height (Inches) 20

Volume of Firebox (Cu. Ft.) 4.6

Firebox Door Size (Diameter) 13.5

Flue Transfer Area (Sq. Ft.) 97

BTU’s (maximum)** 200,000

Water Jacket Steel

Gauge 409 Stainless

10

Firebox Steel

Gauge 409 Stainless

14

Flue Steel

Gauge 409 Stainless

14

Base of Unit to

Internal Hopper Opening (Inches) 43

Warranty - Workmanship Limited Lifetime

Warranty - Corrosion Limited Lifetime

Hook-ups Back

Total Heat Extraction Area (Sq. Ft.) 108

Type of Fuel Wood Pellets Only

Electrical Supply (14-3 wire) 115 V, 60HZ, 1

Phase

* This is an estimate only.Actual loadings per day may vary depending on structures heated and type of wood pellets used.

** This value should only be used as an indication of the furnace’s heat recovery ability. Sustained outputs at this rate will increase the

pellets used per day. Some types of pellets may prevent the furnace from reaching this maximum output.

7

CHAPTER 2

FRONT CUT-AWAY VIEW OF HEATMOR™ 200 SSP OUTDOOR FURNACE

(For parts not shown on the cut-away view, please refer to the appropriate chapter for further details.)

8

FURNACE PARTS LIST

Firebox

1) Firebox

2) Firebox door

3) Firebox door handle

4) Firebox door hinge

5) Firebox door latch

6) Firebox door gasket

7) Firebox door frame

8) Firetube

9) Firetube holders (not shown)

10) Firepot (not shown)

Water jacket

11) Water jacket (surrounds rebox)

12) Supply line threaded connector

13) Return line threaded connector

14) Drain line threaded connector

15) Relief vent pipe

16) Weighted pop off valve

Air supply

17) Combustion air blower

18) Flipper assembly (not shown)

19) Air box

20) Airbox Cleanout Cover

Chimney and top flue

21) Chimney

22) Chimney extension(s) (not shown)

23) Tubed ue (not shown)

24) Flue cover plate A

25) Flue scraper (not shown)

26) Flue cover plate B

27) Flue Cover plate C

Lift hook

28) Lift ring

Ashes

29) Ash pan cover

30) Ash pan (not shown)

Bladder assembly

31) Bladder

32) Bladder gate valve and hose

Electrical

33) Dwyer Water Temp Display

34) Electrical supply junction box (not shown)

35) Electrical plug outlets (not shown)

36) Water temperature high-limit

controller (aquastat)

37) Front light and combustion air

blower control switch(not shown)

38) Ignitor switch (not shown)

39) Watlow Flame Sensor Control

40) Dayton Auger Speed Control

41) Temperature Probe for Dwyer

42) Temperature Probe for Watlow Flame

Sensor

Pellet Feed

43) Internal Hopper

44) Auger Motor

45) Auger

46) External Hopper Hook up

47) Internal Hopper Fill Door

Housing - (not shown)

48) Large Outer door

49) Small Outer door

50) Roof

51) Side Panels

52) Corners

53) Insulation

- FRONT CUT-AWAY OF 200 SSP

9

SIDE CUT-AWAY VIEW OF HEATMOR™ 200 SSP OUTDOOR FURNACE

(For parts not shown on the cut-away view, please refer to the appropriate chapter for further details.)

CHAPTER 3

10

FURNACE PARTS LIST

Firebox

1) Firebox

2) Firebox door

3) Firebox door handle

4) Firebox door hinge

5) Firebox door latch

6) Firebox door gasket

7) Firebox door frame

8) Firetube

9) Firetube holders (not shown)

10) Firepot (not shown)

Water jacket

11) Water jacket (surrounds rebox)

12) Supply line threaded connector

13) Return line threaded connector

14) Drain line threaded connector

15) Relief vent pipe

16) Weighted pop off valve

Air supply

17) Combustion air blower

18) Flipper assembly (not shown)

19) Air box

20) Airbox Cleanout Cover

Chimney and top flue

21) Chimney

22) Chimney extension(s) (not shown)

23) Tubed ue (not shown)

24) Flue cover plate A

25) Flue scraper (not shown)

26) Flue cover plate B

27) Flue Cover plate C

Lift hook

28) Lift ring

Ashes

29) Ash pan cover

30) Ash pan (not shown)

Bladder assembly

31) Bladder

32) Bladder gate valve and hose

Electrical

33) Dwyer Water Temp Display

34) Electrical supply junction box (not shown)

35) Electrical plug outlets (not shown)

36) Water temperature high-limit

controller (aquastat)

37) Front light and combustion air

blower control switch(not shown)

38) Ignitor switch (not shown)

39) Watlow Flame Sensor Control

40) Dayton Auger Speed Control

41) Temperature Probe for Dwyer

42) Temperature Probe for Watlow Flame

Sensor

Pellet Feed

43) Internal Hopper

44) Auger Motor

45) Auger

46) External Hopper Hook up

47) Internal Hopper Fill Door

Housing - (not shown)

48) Large Outer door

49) Small Outer door

50) Roof

51) Side Panels

52) Corners

53) Insulation

- SIDE CUT-AWAY OF 200 SSP

11

MINIMUM CLEARANCE SEPARATION SPECIFICATIONS

The HEATMOR™ furnace, is certied to be installed outside, away from other buildings. Please observe the

following “Clearance to Combustibles” guidelines. If you have any further questions, which are not addressed

in this Operators Manual, please contact your local dealer for further information.

♦To HEATMOR™ Stainless Steel Outdoor Furnace Back. 96 Inches

♦To HEATMOR™ Stainless Steel Outdoor Furnace Top. 18 Inches

♦To HEATMOR™ Stainless Steel Outdoor Furnace Front. 48 Inches

♦To HEATMOR™ Stainless Steel Outdoor Furnace Chimney. 18 Inches

♦To HEATMOR™ Stainless Steel Outdoor Furnace Sides. 6 Inches

♦Do not store combustible liquids or materials near the furnace.

♦It is not recommended to install the furnace in any form of building.

Before installing your HEATMOR™ Stainless Steel Outdoor Furnace, if in the United States, always check

any and all applicable state and local regulations and inform your insurance agent.

Before installing your HEATMOR™ Stainless Steel Outdoor Furnace, if in Canada, always check any and all

applicable Provincial and Municipal regulations and inform your insurance agent.

HEATMOR™ Inc. strongly recommends not installing a HEATMOR™ Stainless Steel Outdoor Furnace within

50 feet of any ammable structure.

A HEATMOR™ Stainless Steel Outdoor Furnace should be located with consideration to your neighbor’s

property and in accordance with local ordinances. Refer to the “Best Burn Practices” for further operating

considerations.

HEATMOR™ Outdoor Furnace, is not designed or certied to be located in densely populated areas.

CHAPTER 4

12

WARNINGS AND PRECAUTIONS

Please read the following list of cautions, warnings and dangers before installing and operating

your HEATMOR™ STAINLESS STEEL OUTDOOR FURNACE. If you have any questions or concerns

regarding any of the following cautions, warnings, dangers or instructions in this Operations and

Maintenance manual, please contact your local dealer.

Familiarize yourself with the “Best Burn Practices” located on the inside front cover.

Installation

If you are installing parts of this heating system on a “do-it-yourself” basis, it is highly recommended

that you purchase a total system installation manual recommended by your dealer.

1) The HEATMOR™ furnace is designed for outside installations, away from other buildings.

2) Please observe the following “ Clearance to Combustibles “ guidelines.

To unit back = 96 inches To unit sides = 6 inches

To unit front = 48 inches To chimney = 18 inches

To unit top = 18 inches

3) Before installing the furnace, always check any and all applicable state, provincial, and local

regulations.

4) HEATMOR™ Inc. strongly recommends not installing a HEATMOR™ Stainless Steel Outdoor

Furnace within 50 feet of any ammable structure.

5) A HEATMOR™ Stainless Steel Outdoor Furnace should be located with consideration

to your neighbor’s property and in accordance with local ordinances. The HEATMOR™ Outdoor

Furnace is not designed to be located in densely populated areas.

6) HEATMOR™ suggests the use of brass ttings when installing the unit.

7) Before installing the HEATMOR™ furnace, contact and inform your insurance agent.

8) The HEATMOR™ Outdoor Furnace is to be installed on a concrete base only.Any attempt to place

the furnace on any other surface may void the warranty.

9) Do not connect the HEATMOR™ furnace to the chimney of any existing heating system.

10) This unit was not designed, nor is it recommended, for use as a stand-alone heating system.A back

up source of heat must be in place to prevent the outdoor furnace from freezing and to provide

supplementary heat for the heated buildings.

11) Do not pressurize the HEATMOR™ Outdoor Furnace. This unit is designed to operate under

atmospheric pressure only.

12) Place the in-line ll/drain assembly in a location where the drained contents of the HEATMOR™ will

not cause damage to the surrounding areas or it’s contents.

CHAPTER 5

13

Electrical

1) Do not connect the electrical components of the HEATMOR™ Outdoor Furnace to any other

electrical appliance.

2) This HEATMOR™ Outdoor Furnace operates on 115-volt power only. Do not connect the furnace to a 220-

volt electrical supply. Use 14-3 wire.

3) HEATMOR™ INC. recommends a licensed professional electrician make all the necessary

electrical connections involved with the installation of the furnace.

4) Always disconnect the HEATMOR™ Outdoor Furnace from the main electrical supply before

servicing any of the electrical components of the HEATMOR™ Outdoor Furnace.

5) Always disconnect any existing electrical connections to any in-house heating system, before

installing the outdoor furnace to any existing indoor heating system or appliances.

6) The red wire from the high-limit aquastat on the back of the HEATMOR™ should be wired to the

indoor temperature control to override the thermostat. This will dissipate excess heat in the event of a

possible malfunction with the HEATMOR™. (The red wire is capped off in the electrical junction

box when the HEATMOR™ is new.)

Other

1) The unit may be connected to an existing indoor boiler system by installing a water-to-water heat

exchanger.

1) HEATMOR™ INC. recommends that you contact a licensed professional plumber to make

all necessary plumbing installations between the HEATMOR™ furnace and the existing heating

system of your building(s).

2) Do not operate the HEATMOR™ furnace until all electrical and water line connections have

been properly installed and tested.

3) Do not allow any re in the rebox until the HEATMOR™ has the correct amount of water

installed.

14

CHAPTER 6

7”

BASE: OUTDOOR FURNACE SITS ON THIS PAD

Hole for Plumbing

67.5”

18”

9”

12”

OUTDOOR FURNACE SITS HERE GROUND

LEVEL

UNDERGROUND LINES

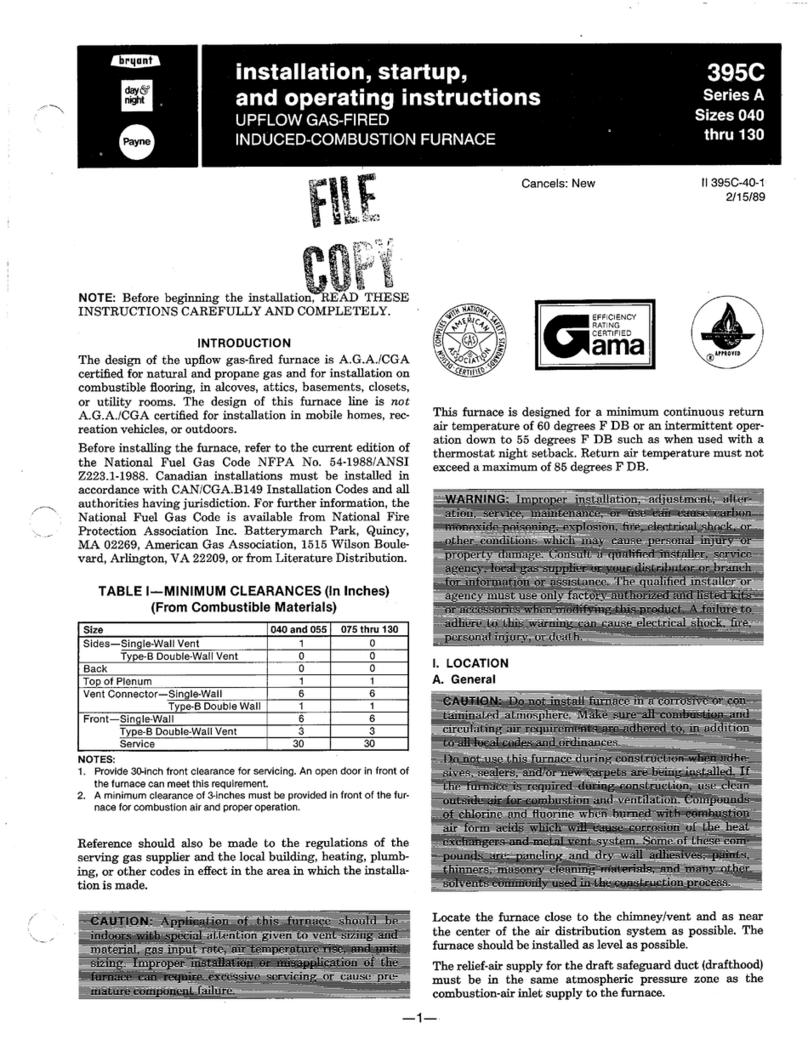

200 SSP PAD SPECIFICATIONS

The actual pad size is 36” x 67.5”. This gives

approximately 1” extra on all sides of furnace.

CAUTION: Do not exceed this length measurement.

Width can be wider if desired.

The internal hopper opening is 43” above ground or

base of furnace.

If patio stones or a separate cement pad are put

around the cement pad for the HeatmorTM, they

should NOT be attached to main base pad of

furnace.

It is recommended to make the pad 4” thick and use

steel mesh or R-bar in pad for strength.

INTERNAL

HOPPER

DOOR

36”

SIDE VIEW

OUTDOOR FURNACE SITS HERE

FOUR INCH GRAVEL BASE

CEMENT BASE

15

INSTALLATION OF THE HEATMOR™ FURNACE

Principles

1) Need to have an airtight seal the perimeter of the entire HEATMOR™ so rodents are not able to nd

a home inside the HEATMOR™.

2) Need to lift the HEATMOR™ without damaging it.

Equipment Required

1) It is not possible to lift a HEATMOR™ with the forks of a forklift under the

HEATMOR™. It must be lifted from the top, by the lift hook. Acrane or heavy

backhoe works best, although a heavy duty farm tractor is acceptable.

a) With a farm tractor, extreme care must be taken to prevent the

HEATMOR™ from swinging and causing damage to the HEATMOR™.

Placing the HEATMOR™ on the Concrete Base

2) Before setting the HEATMOR™ onto the concrete base, it is a

good idea to place a solid sheet of the proper “reective air foil” (also called

bubble foil) between the concrete and the HEATMOR™. This will absorb

ridges in the concrete and make it easier to apply caulking. This reective

foil will also reect escaping heat up into the unit and help prevent air leaks into

the rebox if cement cracks.

3) Make sure the total area of the HEATMOR™ is on solid concrete. Do not let

the HEATMOR™ extend past the hole in the concrete where the lines come in.

4) After the HEATMOR™ is in place perform the following;

Caulking around the Outside Perimeter of HEATMOR™

a) With a sharp knife, trim any excess bubble foil

that extends past the housing of the HEATMOR™.

b) Apply a bead of caulking around the entire outside

perimeter of the HEATMOR™ to seal out rodents.

CHAPTER 7

Lift Hook

Table of contents

Other Heatmor Furnace manuals

Popular Furnace manuals by other brands

Amana

Amana EGHW Installation & operation instructions

Airxcel

Airxcel Suburban SF-20F installation instructions

Bryant

Bryant 395C Series Installation, start-up, and operating instructions

American Standard

American Standard UHMB060ACV3VB Series Service facts

FURNACE & ASSAY

FURNACE & ASSAY 168 Operation & maintenance manual

Bryant

Bryant 4-WAY MULTIPOISE TWO-STAGE CONDENSING GAS FURNACE... Product data

Dettson

Dettson C45-1-D Installation instructions and homeowner's manual

Bryant

Bryant 925SA Series Product data

MrCool

MrCool Signature Series Owners & installation manual

Carrier

Carrier ENH4X Series installation instructions

UPG

UPG 1HA0409 installation instructions

Goodman

Goodman GKS9 installation instructions