Hillphoenix Adaptapak ADP-M0048-L0000 Owner's manual

INSTALLATION AND OPERATION

Contents

Copyright© 2018 by Hillphoenix

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means—

electronic or mechanical, including photocopying or recording; or any other information storage and retrieval

system—without express written permission from Hillphoenix.

P096412C ∙ V2 10/31/2018

Due to our commitment to continuous improvement, all specifications shown in this manual are subject to change without notice.

Important Notices............................................... 2

General Information ............................................ 3

AdaptaPAK®Product Information.............................. 5

Two Fan AdaptaPAK®Unit................................... 4

Three Fan AdaptaPAK®Unit................................. 5

Two Fan AdaptaPAK®Unit....................................... 8

Three Fan AdaptaPAK®Unit................................... 10

Four Fan AdaptaPAK®Unit.................................... 12

AdaptaPAK®Models Overview................................ 14

Key to Codes in AdaptaPAK®Model Numbers................ 16

DX Refrigeration Systems..................................... 17

Refrigeration System Components ........................ 17

multiMAXTM Controller for AdaptaPAK® ...................... 21

multiMAXTM Controller I/O Connections..................... 23

AdaptaPAK®Installation ...................................... 29

Systems Start-Up Checklist................................. 43

AdaptaPAK®Maintenance and

Troubleshooting Procedures................................... 45

2AdaptaPAK® Parallel Refrigeration System

Thank You!

The Hillphoenix AdaptaPAK® refrigeration system provides customers with a compact refrigeration

package designed to remove heat from both medium- and low-temperature loads. Such a system,

as selected by the customer, is built to closely match the necessary heat removal capacity. It is a

DX system with a refrigerant charge matched to the needs of the facility where it is installed. Each

The fans and condensing units are sized to provide for sufficient heat rejection under the most

demanding ambient conditions.

Each Unit utilizes a comprehensive controls system which monitors the refrigeration system to

minimize energy and optimize performance.

The controls system allows field networking to the store’s Building Management System. In

addition, local networks may be installed to create coordinated case defrosts on a common

schedule, similar to traditional refrigeration circuits of traditional remote systems.

Important Notices

Hillphoenix designates important information in all Hillphoenix installation and operations

handbooks with alert symbols. These notices provide information about potential dangers to

personal health and safety – as well as case damage – if these instructions are not carefully

followed.

Service Notes

To ensure optimum unit performance, we strongly recommend that Hillphoenix refrigeration

units be installed and serviced by trained and qualified technicians who have experience working

with commercial refrigerated systems, piping, display cases and storage cabinets. For a list of

Hillphoenix-authorized installation and service contractors, visit hillphoenix.com/dealer-group.

ATTENTION!

Indicates important information that is

critical to proper system performance.

CAUTION!

Indicates the threat of potential injury if all

instructions are not followed carefully.

DANGER!

Indicates an immediate threat of serious injury

or death if all instructions are followed carefully.

3

AdaptaPAK® Parallel Refrigeration System

General Information

This manual covers general installation and operational information for the Hillphoenix AdaptaPAK® refrigeration

system. Hillphoenix recommends you retain a copy for future reference

Store Conditions

Hillphoenix refrigeration systems are designed to operate in ASHRAE conditions: a climate-controlled store that

maintains a 75 oF (24 oC) interior temperature and a maximum 55% relative humidity. System and display case

operation will be adversely affected by exposure to excessively high ambient temperatures and/or humidity.

Receiving Units

Inspect received units carefully. In the event of shipping damage and/or shortages, please contact the Hillphoenix

Service parts Department at 800-283-1109.

Unit Damage

Claims for damage must be: (1) noted on either the freight bill or the express reciept, and (2) signed by the carrier’s

agent. Otherwise, the carrier may refuse the claim. If damage becomes apparent after the cases are unpacked,

retain all packing materials and submit a written request (along with photos of the damage) to the carrier for

inspection within 14 days of receipt of the unit.

Missing Items

Hillphoenix refrigeration systems are inspected before shipping to ensure the highest level of quality. Any claim for

missing items must be made to Hillphoenix within 48 hours of receipt of cases.

Technical Support

For technical support issues regarding this unit, contact the Hillphoenix Systems Division Technical Support

at 1-800-518-6630.

Ordering Unit Parts

If you need to contact Hillphoenix regarding specic xtures or parts, call 800-283-1109 and ask for a Service Parts

If the part does not have a barcode afxed to it, provide the following information:

• Model number and serial number of the unit for which the part is intended. The serial number may be found

on the serial plate located on the unit.

• Length of the part, if applicable.

• Color of part (if painted) or color of polymer part.

• Whether the part is for a left-handed or a right -handed application.

• Quantity of parts

• Ship-to location.

If Hillphoenix Service Parts decides that a part must be returned instead of scrapped, you will be issured a Return

Material Authorization number.

Hillphoenix Part Barcode

Part Number located at bottom left.

4AdaptaPAK® Parallel Refrigeration System

5

AdaptaPAK® Parallel Refrigeration System

Section 1:

AdaptaPAK®Product Information

Hillphoenix offers the AdaptaPAK® range of parallel refrigeration systems to

provide customers with an effective alternative to centralized parallel systems.

The various versions of AdaptaPAK® are designed to meet a wide range of

requirements.

AdaptaPAK® Features and Benets

The Hillphoenix AdaptaPAK® parallel system works like any conventional DX refrigeration system, with the main

difference being that there may be one or more individual systems required to serve the full range of refrigeration

loads in a store. The arrangement is different than the installation of one, single, large centralized refrigeration

system, the multiple condensers are an integral part of the unit.

It is also designed specically to improve on the

performance of low and/or medium temperature

refrigeration installations in drug stores, convenience

stores, and other smaller-footprint retail establishments.

An AdaptaPAK® parallel system shares suction,

discharge, and an integrated condenser across several

compressors. As a result, compressor capacity may

be varied to match the required loads—a much more

efcient design.

Multiple, single units with compressors running

constantly at maximum output waste energy and reduce

component life. Parallel installations, on the other hand,

do just the opposite. Because compressor capacities are allowed to vary to match refrigeration loads, there is a

marked savings of energy utilized—20% or more compared to single compressor unit—as well as positive benets on

the live of all system components.

There is also a savings in initial capital outlay with a parallel system. Shared suction, discharge, and an integrated

condenser among compressors virtually guarantees cost savings versus the expense inherent in purchasing

several, self-contained single units. Plus, the single point electrical connection along with a single roof curb and roof

penetration add up to additional savings in installation costs.

Hillphoenix AdaptaPAK® parallel systems are available in a 2 fan unit, a 3 fan unit, and a 4 fan conguration. The

compressors would be arranged in up to two suction groups, with one loop per suction group.

6AdaptaPAK® Parallel Refrigeration System

Whether a 2 fan unit or a 3 fan unit, the AdaptaPAK® system will arrive fully designed for your load conguration,

and ready for placement at the site in your designated pad or roof location. Placement would most commonly be

performed with a cable/rope with proper rigging (refer to drawings for details).The remaining tasks would include

charging with refrigerant, making electrical connections, and completing the connection of the AdaptaPAK® unit up

to your refrigeration loads.

Dimensions of AdaptaPAK® Units

The 2 fan unit is 139 1/4 inches long by 50 1/2 inches wide by 51 1/4 inches high.

The 3 fan unit is 180 inches long by 50 1/2 inches wide by 51 1/4 inches high.

The 4 fan unit is 220 inches long by 50 1/2 inches wide by 51 1/4 inches high.

Clearances for AdaptaPAK® Units (2 fan and 3 fan)

Air Intake: 36 inches recommended

Air Exhaust: 36 inches recommended

Piping Clearance: 36 inches (minimum) recommended

Hinged Front Door: 36 inches (outward from door) by 50 inches (width)

NEC Electrical: 36 inches (outward from door) by 50 inches (width)

Weights of AdaptaPAK® Units (2 fan and 3 fan)

Fans Compressors Estimated Weight

2 4 3,000 lbs

3 6 3, 500 lbs

4 8 4,000 lbs

AdaptaPAK® Units’ Standard Features

The following features are provided as standard equipment on AdaptaPAK® units (2 fan, 3 fan, and 4 fan):

• Pre-painted, galvanized steel cabinet (pueblo tan).

• Refrigerants available are R-407A and R-448A/R-449A

• Uncoated copper tube/aluminum n condenser coil.

• Main power is 208V.

• Scroll compressors (only).

• Digital scroll compressor as the lead compressor per suction group

• Receiver includes analog liquid level indicator/alarm.

• Replaceable core lter/drier and sight glass.

• Oversized receiver.

• Fixed speed AC condenser fan motors.

7

AdaptaPAK® Parallel Refrigeration System

• One low pressure control per suction group.

• One high pressure control per compressor.

• OMB electronic oil oat per compressor.

• Discharge centrifugal oil separator with integral oil reservoir.

• Through-the-door power disconnect for serviceability.

• Phase loss monitor with brownout protection.

• IEC contactors for all compressors.

• Convenient service control switches for compressors.

• Off cycle and electric defrost are available.

• Remote defrost panel (when required) will be shipped loose for eld installation.

• Hillphoenix multiMAX™ control system installed in control panel.

Note that the AdaptaPAK® units are designed for outdoor placement, and thus are constructed with a painted

steel nish for durability. Each unit has its own designated lifting points to facilitate easy lifting and site placement.

Removable panels and hinged access doors provide for both equipment protection and serviceability.

In addition to the standard equipment detailed in the list above, customer-selectable options may have been include

on the unit being installed. Please check the customer order or the Hillphoenix acknowledgement to determine

which custom options have been provided for your specic unit. These options are detailed below.

Available AdaptaPAK® Unit Options

The following features are available as optional equipment on AdaptaPAK® units:

• Variable speed EC condenser fan motors.

• 460V main power.

• Electron coated condenser coil.

• Heat reclaim valve package (remote only).

• Cold Weather Package - split condenser and heated/insulated receiver

• Hail guard.

• Digital liquid level indicator/alarm.

• Low-pressure control per compressor.

8AdaptaPAK® Parallel Refrigeration System

Two Fan AdaptaPAK® Unit

As noted earlier, this unit has two condenser fans and up to two condensers sized appropriately for the design-

specied refrigeration heat removal loads.

The dimensions of the two fan unit, as well as the required clearances for operation and serviceability were provided

earlier in this section.

Of course, the design-specied refrigeration heat removal load would be the determining the number/capacity of the

compressors, the receiver size, and the details of the parallel system.

A rear, isometric view of the two fan AdaptaPAK® unit is shown below. Note that on this drawing the access panels

and doors have been removed.

Note that the condenser coil(s) are located at the rear of the unit. The two fans on the top of the unit would draw

ambient outdoor air in through the condenser coil(s) and exhaust that air through the fans on top. As noted

previously, sufcient clearances are required for proper unit operation.

Two Fan AdaptaPAK® Unit

Rear Isometric View

Access Panels Removed

For Clarity

9

AdaptaPAK® Parallel Refrigeration System

The layout drawing provided below shows the front view of the two fan unit, as well as the two end views.

Also, as previously noted. a drawing is supplied which depicts the lifting points on the two fan AdaptaPAK® unit, and

details an appropriate lifting jig and the necessary rigging for the cable/rope to perform a level lift and successful

placement of this unit.

Two Fan AdaptaPAK® Unit

LEFT END VIEW FRONT VIEW RIGHT END VIEW

Lifiting

Detail

Two Fan AdaptaPAK® Unit

10 AdaptaPAK® Parallel Refrigeration System

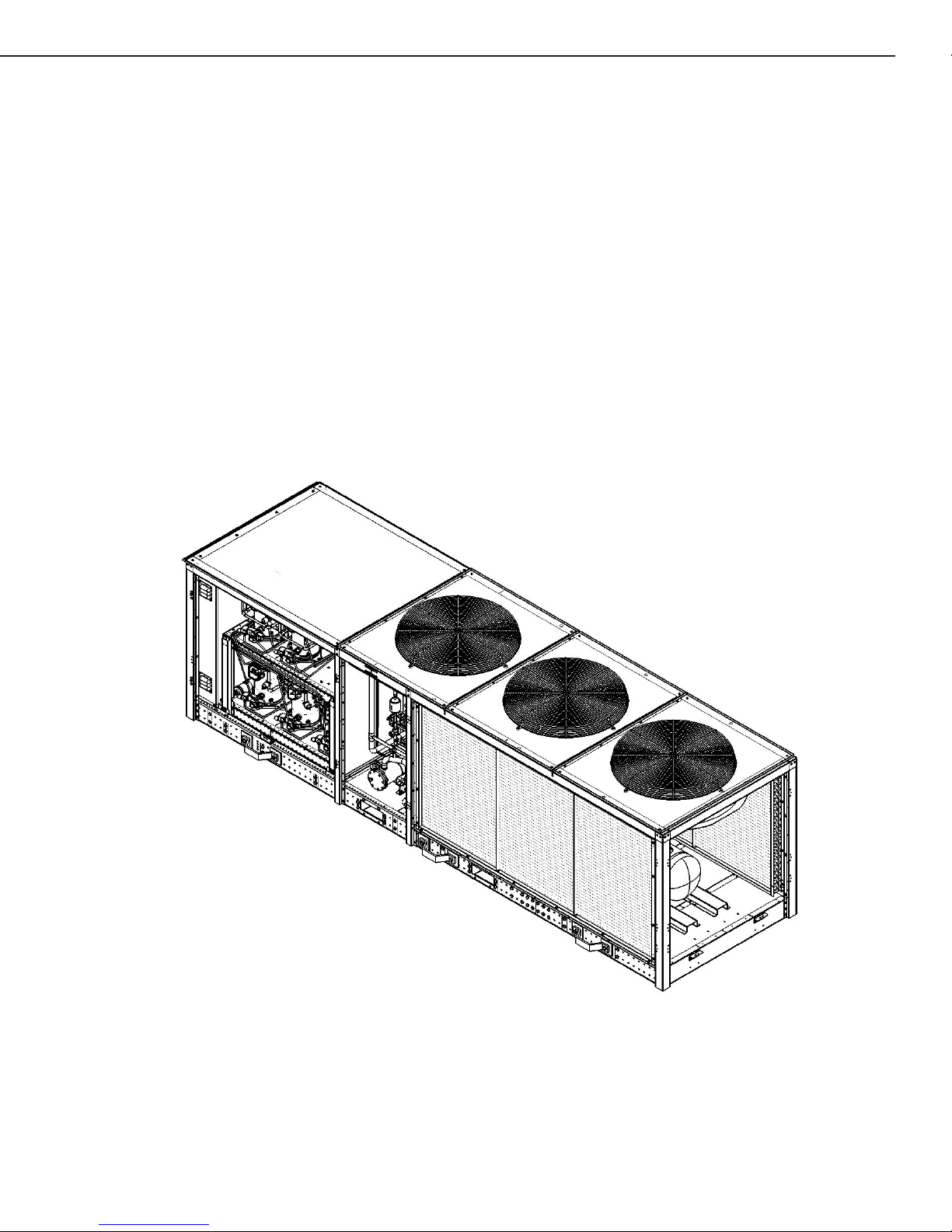

Three Fan AdaptaPAK® Unit

This unit has three condenser fans and two condensers sized appropriately for the design-specied refrigeration

heat removal loads.

The dimensions of the three fan unit, as well as the required clearances for operation and serviceability were

provided earlier on page two.

Of course, the design-specied refrigeration heat removal load would be used in determining the number/capacity of

the compressors, the receiver size, and the details of the parallel system.

A rear, isometric view of the three fan AdaptaPAK® unit is shown below. Note that on this drawing the access panels

and doors have been removed

Note that the condenser coil(s) are located at the rear of the unit. The three fans on the top of the unit would

draw ambient outdoor air in through the condenser coil(s) and exhaust that air through the fans on top. As noted

previously, sufcient clearances are required for proper unit operation.

Three Fan AdaptaPAK® Unit

Rear Isometric View

Access Panels Removed

For Clarity

11

AdaptaPAK® Parallel Refrigeration System

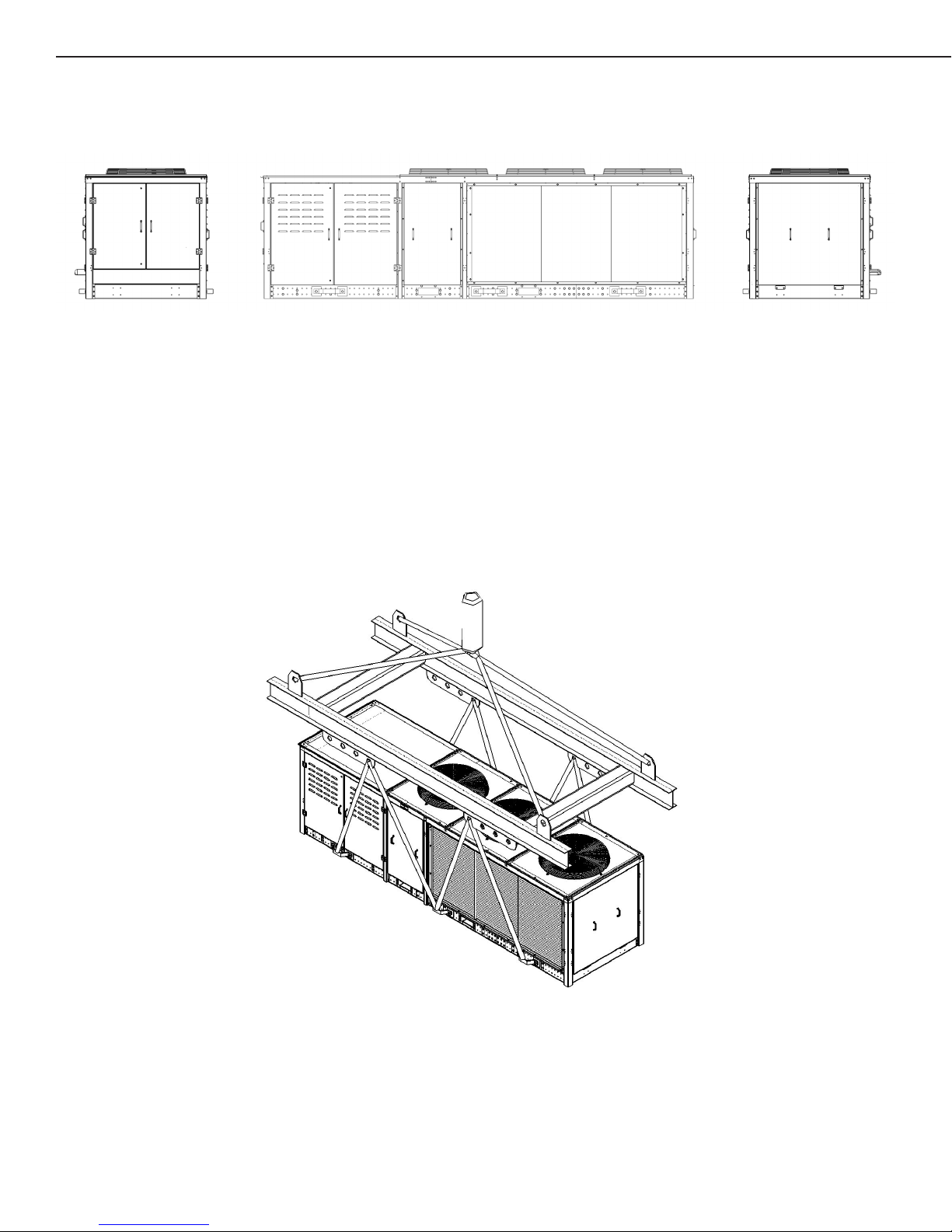

The layout drawing provided below shows the front view of the three fan unit, as well as the two end views.

Also, as previously noted. a drawing is supplied which depicts the lifting points on the three fan AdaptaPAK®

unit, and details an appropriate lifting jig and the necessary rigging for the cable/rope to perform a level lift and

successful placement of this unit.

LEFT END VIEW FRONT VIEW RIGHT END VIEW

Three Fan AdaptaPAK® Unit

Lifiting

Detail

Three Fan AdaptaPAK® Unit

12 AdaptaPAK® Parallel Refrigeration System

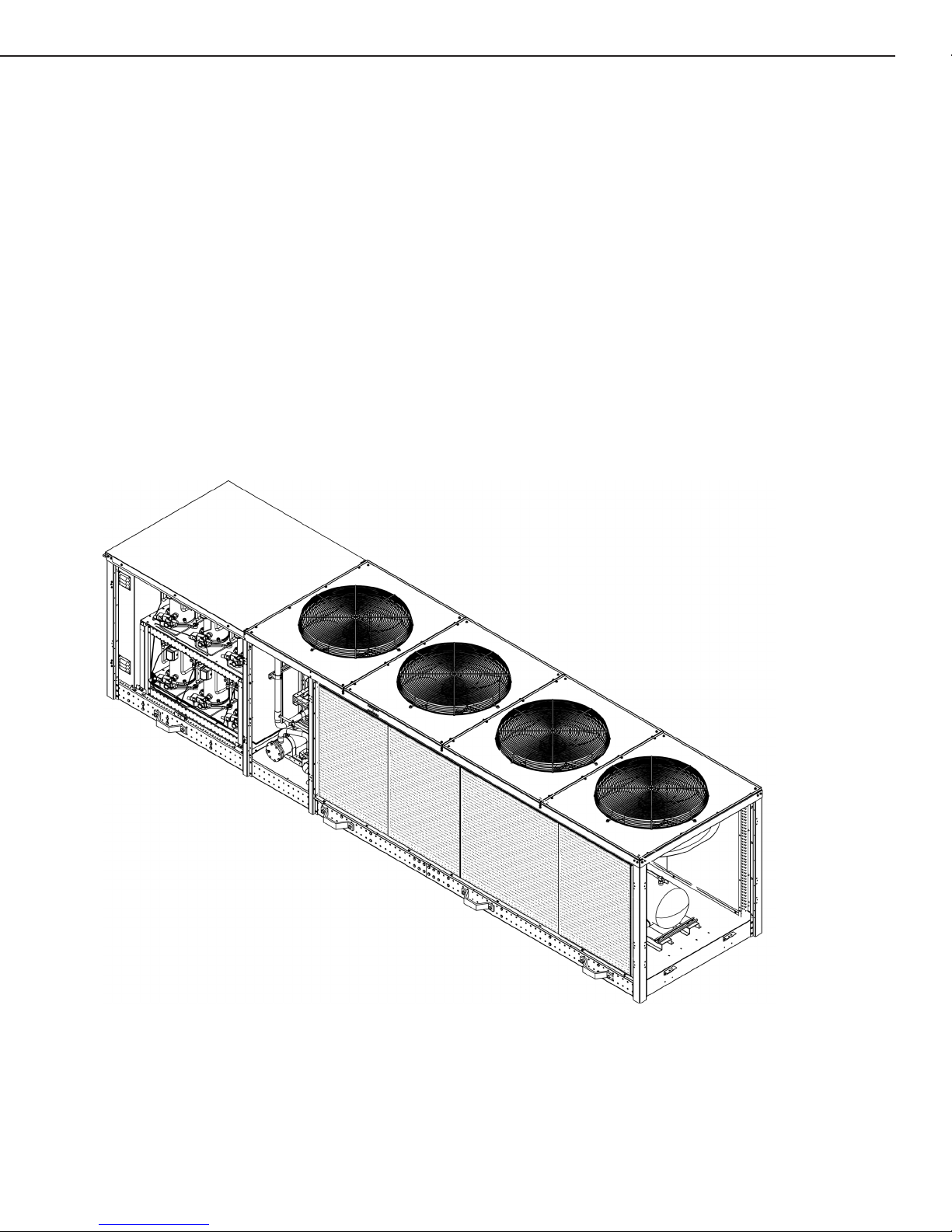

Four Fan AdaptaPAK® Unit

This unit has four condenser fans and two condensers sized appropriately for the design-specied refrigeration heat

removal loads.

The dimensions of the four fan unit, as well as the required clearances for operation and serviceability were provided

earlier on page two.

Of course, the design-specied refrigeration heat removal load would be used in determining the number/capacity of

the compressors, the receiver size, and the details of the parallel system.

A rear, isometric view of the four fan AdaptaPAK® unit is shown below. Note that on this drawing the access panels

and doors have been removed

Note that the condenser coil(s) are located at the rear of the unit. The four fans on the top of the unit would

draw ambient outdoor air in through the condenser coil(s) and exhaust that air through the fans on top. As noted

previously, sufcient clearances are required for proper unit operation.

Four Fan AdaptaPAK® Unit

Rear Isometric View

Access Panels Removed

For Clarity

13

AdaptaPAK® Parallel Refrigeration System

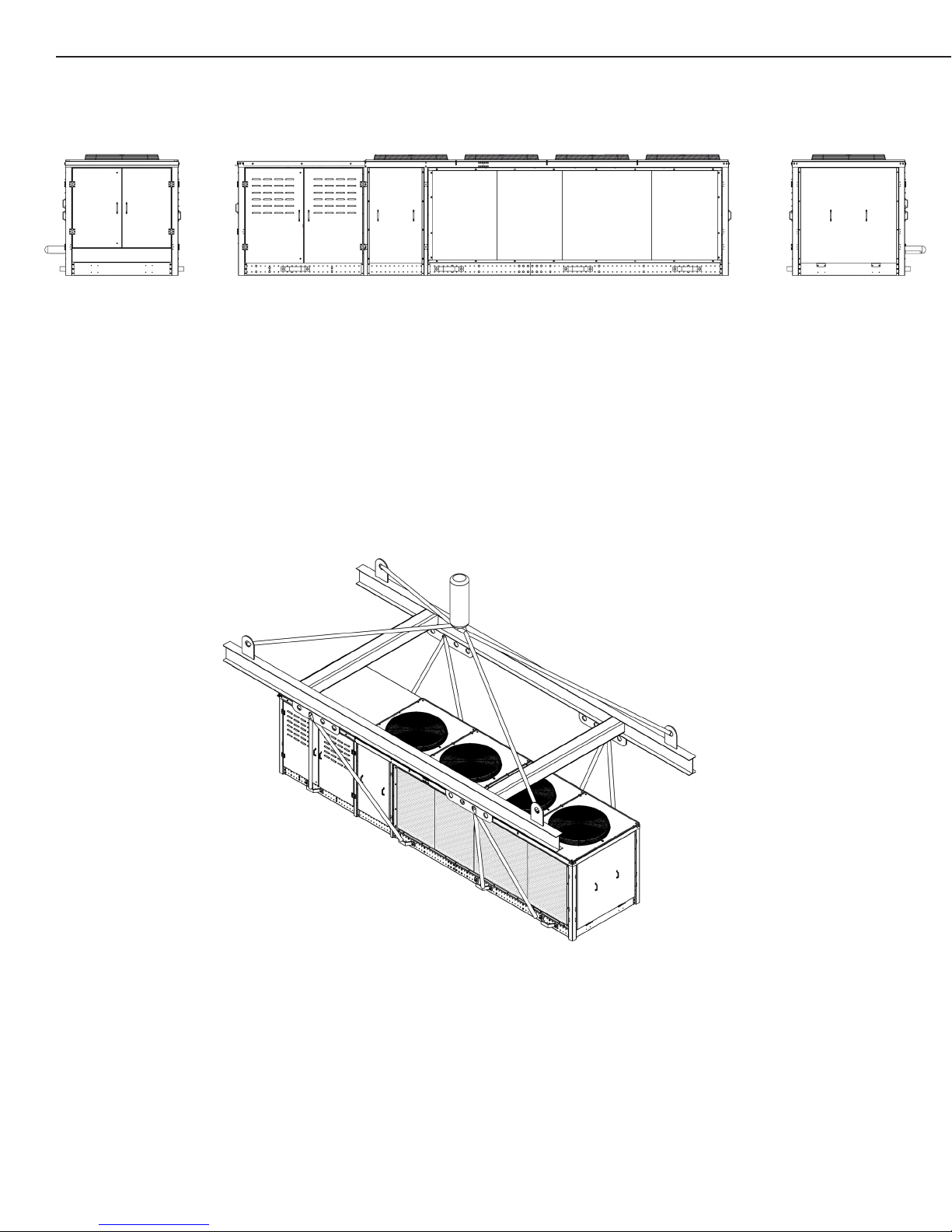

The layout drawing provided below shows the front view of the four fan unit, as well as the two end views.

Also, as previously noted. a drawing is supplied which depicts the lifting points on the four fan AdaptaPAK® unit, and

details an appropriate lifting jig and the necessary rigging for the cable/rope to perform a level lift and successful

placement of this unit.

LEFT END VIEW FRONT VIEW RIGHT END VIEW

Four Fan AdaptaPAK® Unit

Four Fan AdaptaPAK® Unit

Lifiting

Detail

14 AdaptaPAK® Parallel Refrigeration System

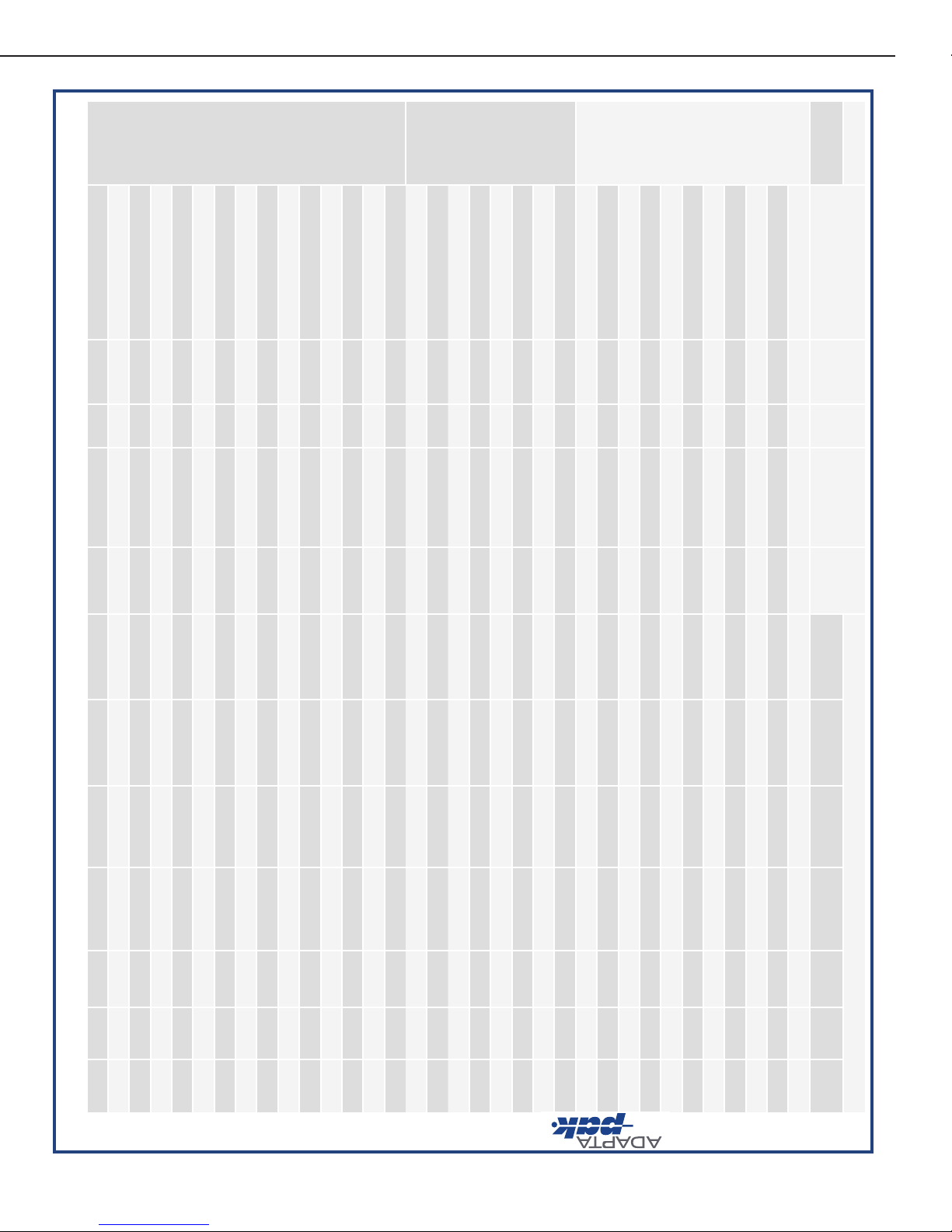

TM

Model Overview

*Not available with split condenser due to single coil design--available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Medium

Temp Units

ADP-M0048-L0000* 21 2 2600 1-5/8 1-1/8 208.0 4 7. 3 60.0

ADP-M0079-L0000* 21 2 2600 1-5/8 1-1/8 208.0 60.9 80.0

ADP-M0106-L0000 22 2 2600 1-5/8 1-1/8 208.0 85.7 110.0

ADP-M0152-L0000 22 3 2700 2-1/8 1-1/8 208.0 108.2 125.0

ADP-M0178-L0000 22 3 2700 2-1/8 1-1/8 208.0 134.2 150.0

ADP-M0198-L0000 22 4 2800 2-1/8 1-1/8 208.0 130.7 150.0

ADP-M0253-L0000 32 6 3400 2-1/8 1-1/8 208.0 185.5 200.0

ADP-M0299-L0000 32 6 3500 2-1/8 1-1/8 208.0 208.0 225.0

ADP-M0349-L0000 32 6 3200 3-1/8 1-1/8 208.0 194.0 225.0

ADP-M0403-L0000 42 6 4000 3-1/8 1-1/8 208.0 232.0 250.0

ADP-M0442-L0000 42 6 4000 3-1/8 1-1/8 208.0 240.0 250.0

Low Temp

Units

ADP-M0000-L0032* 21 2 2600 1-5/8 7/8 208.0 62.2 80.0

ADP-M0000-L0052* 21 2 2600 1-5/8 7/8 208.0 81.8 110.0

ADP-M0000-L0076* 21 3 2700 2-1/8 7/8 208.0 105.7 125.0

ADP-M0000-L0099 22 4 2800 2-1/8 7/8 208.0 129.6 150.0

ADP-M0000-L0122 22 5 2950 2-1/8 7/8 208.0 153.5 175.0

ADP-M0000-L0145 22 6 3100 2-1/8 7/8 208.0 17 7. 4 200.0

ADP-M0000-L0161 32 6 3200 3-1/8 7/8 208.0 187.0 200.0

ADP-M0000-L0190 32 6 3250 3-1/8 7/8 208.0 213.0 225.0

Dual Temp

Units

ADP-M0048-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 64.3 80.0

ADP-M0079-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 7 7. 9 100.0

ADP-M0106-L0012^ 22 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 97. 9 125.0

ADP-M0152-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 120.2 150.0

ADP-M0178-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 146.2 175.0

ADP-M0048-L0032* 21 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 86.8 100.0

ADP-M0079-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 100.4 110.0

ADP-M0106-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.2 150.0

ADP-M0152-L0032 22 4 2950 1-5/8 2-1/8 7/8 1-1/8 208.0 142.7 175.0

ADP-M0048-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 106.4 125.0

ADP-M0079-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.0 150.0

ADP-M0106-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 139.8 175.0

ADP-M0048-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 130.3 150.0

ADP-M0079-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 143.9 175.0

ADP-M0106-L0076 22 5 2950 2-1/8 1-5/8 7/81-1/8 208.0 163.7 175.0

TM

Model Overview

*Not available with split condenser due to single coil design--available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Medium

Temp Units

ADP-M0048-L0000* 21 2 2600 1-5/8 1-1/8 208.0 4 7. 3 60.0

ADP-M0079-L0000* 21 2 2600 1-5/8 1-1/8 208.0 60.9 80.0

ADP-M0106-L0000 22 2 2600 1-5/8 1-1/8 208.0 85.7 110.0

ADP-M0152-L0000 22 3 2700 2-1/8 1-1/8 208.0 108.2 125.0

ADP-M0178-L0000 22 3 2700 2-1/8 1-1/8 208.0 134.2 150.0

ADP-M0198-L0000 22 4 2800 2-1/8 1-1/8 208.0 130.7 150.0

ADP-M0253-L0000 32 6 3400 2-1/8 1-1/8 208.0 185.5 200.0

ADP-M0299-L0000 32 6 3500 2-1/8 1-1/8 208.0 208.0 225.0

ADP-M0349-L0000 32 6 3200 3-1/8 1-1/8 208.0 194.0 225.0

ADP-M0403-L0000 42 6 4000 3-1/8 1-1/8 208.0 232.0 250.0

ADP-M0442-L0000 42 6 4000 3-1/8 1-1/8 208.0 240.0 250.0

Low Temp

Units

ADP-M0000-L0032* 21 2 2600 1-5/8 7/8 208.0 62.2 80.0

ADP-M0000-L0052* 21 2 2600 1-5/8 7/8 208.0 81.8 110.0

ADP-M0000-L0076* 21 3 2700 2-1/8 7/8 208.0 105.7 125.0

ADP-M0000-L0099 22 4 2800 2-1/8 7/8 208.0 129.6 150.0

ADP-M0000-L0122 22 5 2950 2-1/8 7/8 208.0 153.5 175.0

ADP-M0000-L0145 22 6 3100 2-1/8 7/8 208.0 17 7. 4 200.0

ADP-M0000-L0161 32 6 3200 3-1/8 7/8 208.0 187.0 200.0

ADP-M0000-L0190 32 6 3250 3-1/8 7/8 208.0 213.0 225.0

Dual Temp

Units

ADP-M0048-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 64.3 80.0

ADP-M0079-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 7 7. 9 100.0

ADP-M0106-L0012^ 22 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 97. 9 125.0

ADP-M0152-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 120.2 150.0

ADP-M0178-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 146.2 175.0

ADP-M0048-L0032* 21 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 86.8 100.0

ADP-M0079-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 100.4 110.0

ADP-M0106-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.2 150.0

ADP-M0152-L0032 22 4 2950 1-5/8 2-1/8 7/8 1-1/8 208.0 142.7 175.0

ADP-M0048-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 106.4 125.0

ADP-M0079-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.0 150.0

ADP-M0106-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 139.8 175.0

ADP-M0048-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 130.3 150.0

ADP-M0079-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 143.9 175.0

ADP-M0106-L0076 22 5 2950 2-1/8 1-5/8 7/81-1/8 208.0 163.7 175.0

TM

Model Overview

*Not available with split condenser due to single coil design--available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Medium

Temp Units

ADP-M0048-L0000* 21 2 2600 1-5/8 1-1/8 208.0 47. 3 60.0

ADP-M0079-L0000* 21 2 2600 1-5/8 1-1/8 208.0 60.9 80.0

ADP-M0106-L0000 22 2 2600 1-5/8 1-1/8 208.0 8 5.7 110.0

ADP-M0152-L0000 22 3 2700 2-1/8 1-1/8 208.0 108.2 125.0

ADP-M0178-L0000 22 3 2700 2-1/8 1-1/8 208.0 134.2 150.0

ADP-M0198-L0000 22 4 2800 2-1/8 1-1/8 208.0 130.7 150.0

ADP-M0253-L0000 32 6 3400 2-1/8 1-1/8 208.0 185.5 200.0

ADP-M0299-L0000 32 6 3500 2-1/8 1-1/8 208.0 208.0 225.0

ADP-M0349-L0000 32 6 3200 3-1/8 1-1/8 208.0 194.0 225.0

ADP-M0403-L0000 42 6 4000 3-1/8 1-1/8 208.0 232.0 250.0

ADP-M0442-L0000 42 6 4000 3-1/8 1-1/8 208.0 240.0 250.0

Low Temp

Units

ADP-M0000-L0032* 21 2 2600 1-5/8 7/8 208.0 62.2 80.0

ADP-M0000-L0052* 21 2 2600 1-5/8 7/8 208.0 81.8 110.0

ADP-M0000-L0076* 21 3 2700 2-1/8 7/8 208.0 105.7 125.0

ADP-M0000-L0099 22 4 2800 2-1/8 7/8 208.0 129.6 150.0

ADP-M0000-L0122 22 5 2950 2-1/8 7/8 208.0 153.5 175.0

ADP-M0000-L0145 22 6 3100 2-1/8 7/8 208.0 17 7. 4 200.0

ADP-M0000-L0161 32 6 3200 3 -1/8 7/8 208.0 18 7. 0 200.0

ADP-M0000-L0190 32 6 3250 3-1/8 7/8 208.0 213.0 225.0

Dual Temp

Units

ADP-M0048-L0012*^ 21 4 2800 7/8 1- 5/8 1/2 1-1/8 208.0 64.3 80.0

ADP-M0079-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 7 7. 9 100.0

ADP-M0106-L0012^ 22 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 9 7.9 125.0

ADP-M0152-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 120.2 150.0

ADP-M0178-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 146.2 175.0

ADP-M0048-L0032* 21 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 86.8 100.0

ADP-M0079-L0032 22 4 2800 1- 5/8 1-5/8 7/8 1-1/8 208.0 100.4 110.0

ADP-M0106-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.2 150.0

ADP-M0152-L0032 22 4 2950 1-5/8 2-1/8 7/8 1-1/8 208.0 142.7 175.0

ADP-M0048-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 106.4 125.0

ADP-M0079-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.0 150.0

ADP-M0106-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 139.8 175.0

ADP-M0048-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 130.3 150.0

ADP-M0079-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 143.9 175.0

ADP-M0106-L0076 22 5 2950 2-1/8 1-5/8 7/81-1/8 208.0 163.7 175.0

15

AdaptaPAK® Parallel Refrigeration System

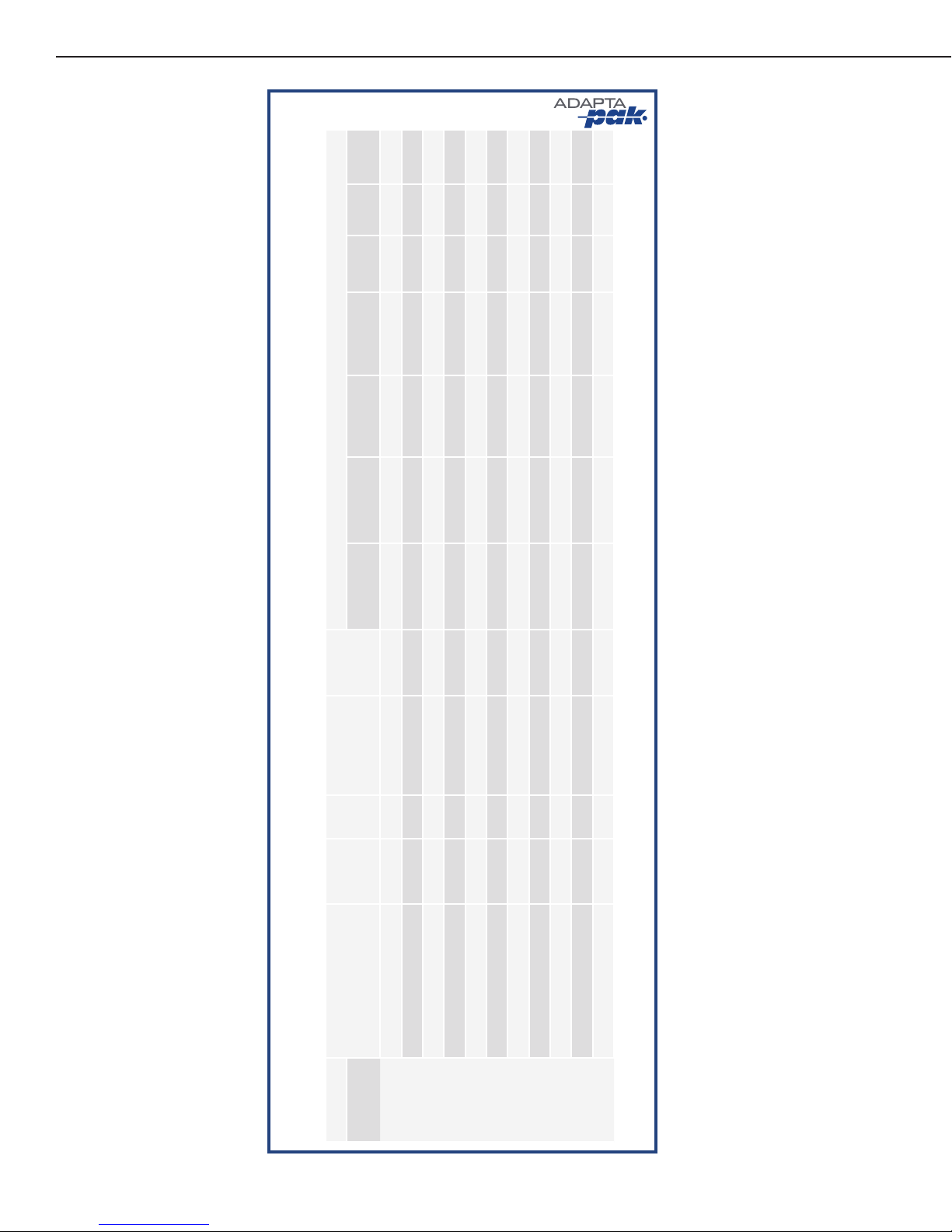

TM

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Dual Temp

Units

Continued

ADP-M0178-L0032 32 5 3400 1-5/8 2-1/8 7/8 1-1/8 208.0 175.6 200.0

ADP-M0152-L0052 32 5 3400 1-5/8 2-1/8 7/8 1-1/8 208.0 169.2 200.0

ADP-M0178-L0052 32 5 3400 1-5/8 2-1/8 7/8 1-1/8 208.0 195.2 225.0

ADP-M0152-L0076 32 6 3500 2-1/8 2-1/8 7/8 1-1/8 208.0 193.1 225.0

ADP-M0178-L0076 32 6 3500 2-1/8 2-1/8 7/8 1-1/8 208.0 219.1 250.0

ADP-M0108-L0090 32 5 3200 2-5/8 2-1/8 7/8 5/8 208.0 169.0 175.0

ADP-M0131-L0095 32 5 3200 2-5/8 2-1/8 7/8 5/8 208.0 182.0 200.0

ADP-M0161-L0095 32 6 3300 2-5/8 2-1/8 7/8 5/8 208.0 196.0 225.0

ADP-M0221-L0052 32 5 3250 2-1/8 2-5/8 5/8 7/8 208.0 184.0 200.0

ADP-M0221-L0062 32 5 3250 2-1/8 2-5/8 5/8 7/8 208.0 193.0 225.0

ADP-M0221-L0095 32 6 3400 2-1/8 2-5/8 7/8 7/8 208.0 223.0 250.0

Model Overview continued...

*Not available with split condenser due to single coil design--available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

TM

Model Overview

*Not available with split condenser due to single coil design--available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Medium

Temp Units

ADP-M0048-L0000* 21 2 2600 1-5/8 1-1/8 208.0 4 7. 3 60.0

ADP-M0079-L0000* 21 2 2600 1-5/8 1-1/8 208.0 60.9 80.0

ADP-M0106-L0000 22 2 2600 1-5/8 1-1/8 208.0 85.7 110.0

ADP-M0152-L0000 22 3 2700 2-1/8 1-1/8 208.0 108.2 125.0

ADP-M0178-L0000 22 3 2700 2-1/8 1-1/8 208.0 134.2 150.0

ADP-M0198-L0000 22 4 2800 2-1/8 1-1/8 208.0 130.7 150.0

ADP-M0253-L0000 32 6 3400 2-1/8 1-1/8 208.0 185.5 200.0

ADP-M0299-L0000 32 6 3500 2-1/8 1-1/8 208.0 208.0 225.0

ADP-M0349-L0000 32 6 3200 3-1/8 1-1/8 208.0 194.0 225.0

ADP-M0403-L0000 42 6 4000 3-1/8 1-1/8 208.0 232.0 250.0

ADP-M0442-L0000 42 6 4000 3-1/8 1-1/8 208.0 240.0 250.0

Low Temp

Units

ADP-M0000-L0032* 21 2 2600 1-5/8 7/8 208.0 62.2 80.0

ADP-M0000-L0052* 21 2 2600 1-5/8 7/8 208.0 81.8 110.0

ADP-M0000-L0076* 21 3 2700 2-1/8 7/8 208.0 105.7 125.0

ADP-M0000-L0099 22 4 2800 2-1/8 7/8 208.0 129.6 150.0

ADP-M0000-L0122 22 5 2950 2-1/8 7/8 208.0 153.5 175.0

ADP-M0000-L0145 22 6 3100 2-1/8 7/8 208.0 17 7. 4 200.0

ADP-M0000-L0161 32 6 3200 3-1/8 7/8 208.0 187.0 200.0

ADP-M0000-L0190 32 6 3250 3-1/8 7/8 208.0 213.0 225.0

Dual Temp

Units

ADP-M0048-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 64.3 80.0

ADP-M0079-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 7 7. 9 100.0

ADP-M0106-L0012^ 22 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 97. 9 125.0

ADP-M0152-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 120.2 150.0

ADP-M0178-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 146.2 175.0

ADP-M0048-L0032* 21 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 86.8 100.0

ADP-M0079-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 100.4 110.0

ADP-M0106-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.2 150.0

ADP-M0152-L0032 22 4 2950 1-5/8 2-1/8 7/8 1-1/8 208.0 142.7 175.0

ADP-M0048-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 106.4 125.0

ADP-M0079-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.0 150.0

ADP-M0106-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 139.8 175.0

ADP-M0048-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 130.3 150.0

ADP-M0079-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 143.9 175.0

ADP-M0106-L0076 22 5 2950 2-1/8 1-5/8 7/81-1/8 208.0 163.7 175.0

TM

Model Overview

*Not available with split condenser due to single coil design- -available with heated and insulated receiver for low ambient applications

^ Uses fixed speed scroll in lieu of digital scroll on low temp due to compressor availability

Model Number

of Fans #

Coils #

Compressors Unit

Weight

Connections

LT Suction

Connection

MT Suction

Connection

LT Liquid

Connection

MT Liquid

Connection

Power

Supply MCA MOPD

Medium

Temp Units

ADP-M0048-L0000* 21 2 2600 1-5/8 1-1/8 208.0 4 7. 3 60.0

ADP-M0079-L0000* 21 2 2600 1-5/8 1-1/8 208.0 60.9 80.0

ADP-M0106-L0000 22 2 2600 1-5/8 1-1/8 208.0 85.7 110.0

ADP-M0152-L0000 22 3 2700 2-1/8 1-1/8 208.0 108.2 125.0

ADP-M0178-L0000 22 3 2700 2-1/8 1-1/8 208.0 134.2 150.0

ADP-M0198-L0000 22 4 2800 2-1/8 1-1/8 208.0 130.7 150.0

ADP-M0253-L0000 32 6 3400 2-1/8 1-1/8 208.0 185.5 200.0

ADP-M0299-L0000 32 6 3500 2-1/8 1-1/8 208.0 208.0 225.0

ADP-M0349-L0000 32 6 3200 3-1/8 1-1/8 208.0 194.0 225.0

ADP-M0403-L0000 42 6 4000 3-1/8 1-1/8 208.0 232.0 250.0

ADP-M0442-L0000 42 6 4000 3-1/8 1-1/8 208.0 240.0 250.0

Low Temp

Units

ADP-M0000-L0032* 21 2 2600 1-5/8 7/ 8 208.0 62.2 80.0

ADP-M0000-L0052* 21 2 2600 1-5/8 7/8 208.0 81.8 110.0

ADP-M0000-L0076* 21 3 2700 2-1/8 7/8 208.0 105.7 125.0

ADP-M0000-L0099 22 4 2800 2-1/8 7/8 208.0 129.6 150.0

ADP-M0000-L0122 22 5 2950 2-1/8 7/8 208.0 153.5 175.0

ADP-M0000-L0145 22 6 3100 2-1/8 7/8 208.0 177.4 200.0

ADP-M0000-L0161 32 6 3200 3 -1/8 7/8 208.0 1 8 7. 0 200.0

ADP-M0000-L0190 32 6 3250 3-1/8 7/8 208.0 213.0 225.0

Dual Temp

Units

ADP-M0048-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 64.3 80.0

ADP-M0079-L0012*^ 21 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 7 7. 9 100.0

ADP-M0106-L0012^ 22 4 2800 7/8 1-5/8 1/2 1-1/8 208.0 97. 9 125.0

ADP-M0152-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 120.2 150.0

ADP-M0178-L0012^ 22 5 2950 7/8 2-1/8 1/2 1-1/8 208.0 146.2 175.0

ADP-M0048-L0032* 21 4 2800 1- 5/8 1-5/8 7/8 1-1/8 208.0 86.8 100.0

ADP-M0079-L0032 22 4 2800 1-5/8 1- 5/8 7/8 1-1/8 208.0 100.4 110.0

ADP-M0106-L0032 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.2 150.0

ADP-M0152-L0032 22 4 2950 1- 5/8 2-1/8 7/ 8 1-1/8 208.0 142.7 175.0

ADP-M0048-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 106.4 125.0

ADP-M0079-L0052 22 4 2800 1-5/8 1-5/8 7/8 1-1/8 208.0 120.0 150.0

ADP-M0106-L0052 22 4 2800 1-5/8 1-5/8 7/ 8 1-1/8 208.0 139.8 175.0

ADP-M0048-L0076 22 5 2950 2-1/8 1-5/8 7/ 8 1-1/8 208.0 130.3 150.0

ADP-M0079-L0076 22 5 2950 2-1/8 1-5/8 7/8 1-1/8 208.0 143.9 175.0

ADP-M0106-L0076 22 5 2950 2-1/8 1-5/8 7/81-1/8 208.0 163.7 175.0

16 AdaptaPAK® Parallel Refrigeration System

Key to Codes in AdaptaPAK Model Numbers

ADP-MXXXX-LXXXX- ______

ADP = AdapatPAK Platform

(X) - Number of Condenser Fans

MXXXX = Medium Temperature Load in KBTUs

LXXXX = Low Temperature Load in KBTUs

SUFFIX - KEY TO OPTIONS

SPLIT

CONDENSER

EC

MOTOR

COATED

COIL

HAIL

GUARD

HEAT

RECLAIM

LP

SWITCH/COMPR

S E C H R P

Example: ADP-M0079-L0012-ER

ADAPTAPAK Model Breakdown

(the number in parentheses is the number of condenser fans)

LOW TEMP

SINGLE SUCTION

MED TEMP

SINGLE SUCTION

MEDIUM TEMP AND LOW TEMP

DUAL SUCTION

ADP(2)-M0000-L0032 ADP(2)-M0048-L0000 ADP(2)-M0048-L0012 ADP(3)-M0178-L0032

ADP(2)-M0000-L0052 ADP(2)-M0079-L0000 ADP(2)-M0079-L0012 ADP(3)-M0152-L0052

ADP(2)-M0000-L0076 ADP(2)-M0106-L0000 ADP(2)-M0106-L0012 ADP(3)-M0178-L0052

ADP(2)-M0000-L0099 ADP(2)-M0152-L0000 ADP(2)-M0152-L0012 ADP(3)-M0152-L0076

ADP(2)-M0000-L0122 ADP(2)-M0178-L0000 ADP(2)-M0178-L0012 ADP(3)-M0178-L0076

ADP(2)-M0000-L0145 ADP(2)-M0198-L0000 ADP(2)-M0048-L0032 ADP(4)-M0221-L0052

ADP(4)-M0000-L0161 ADP(3)-M0253-L0000 ADP(2)-M0079-L0032 ADP(4)-M0221-L0062

ADP(4)-M0000-L0190 ADP(3)-M0299-L0000 ADP(2)-M0106-L0032 ADP(4)-M0221-L0095

ADP(4)-M0349-L0000 ADP(2)-M0152-L0032

ADP(4)-M0403-L0000 ADP(2)-M0048-L0052

ADP(4)-M0442-L0000 ADP(2)-M0079-L0052

ADP(2)-M0106-L0052

ADP(2)-M0048-L0076

ADP(2)-M0079-L0076

ADP(2)-M0106-L0076

ADP(4)-M0108-L0090

ADP(4)-M0131-L0095

ADP(4)-M0161-L0095

17

AdaptaPAK® Parallel Refrigeration System

Section 2:

DX Refrigeration Systems

Direct expansion (DX) refrigeration is one of the most common methods

used for the removal of heat. Such a system takes heat from a place where

it is unwanted and removes it to a place where it is unobjectionable. The

Hillphoenix® AdaptaPAK® units utilize DX refrigeration to remove heat from

store display cases and walk-in coolers/freezers, and transfer it to an outdoor location where it can be rejected.

Refrigeration Through Vapor Compression

Refrigeration is accomplished through application of various mechanical principles that occur as part of a

continuous cycle, commonly known as the Vapor Compression Refrigeration Cycle.

In the vapor compression cycle, heat is absorbed as the liquid refrigerant in the evaporator changes to a vapor. The

refrigerant boils at the new saturation point in the evaporator (located in the display case or cooler) where it changes

to a superheated vapor. From the evaporator, the superheated refrigerant vapor enters the compressor and the

refrigerant is compressed and changed from a low pressure superheated vapor to a high pressure superheated

vapor (more on this later), It then ows to the condenser. In a simple refrigeration system, the ambient air outside of

the condenser ows through the coils of the condenser where it absorbs heat from the vapor refrigerant causing it to

change back to its liquid state before moving through the metering device where it crosses from the high pressure

side of the system to the low pressure side. On the low pressure side, the refrigerant returns to the evaporator and

the process (refrigeration cycle) is then repeated.

Refrigeration System Components

Knowing how the refrigeration process works helps in understanding where in the sequence of operation the major

components of the mechanical system are, and the functions they perform. Almost any refrigeration system is built

around four main components.

The four main components are:

• Compressor

• Condenser

• Metering Device (also known as an expansion valve)

• Evaporator

Beginning on the next page, these main components are individually presented and discussed.

18 AdaptaPAK® Parallel Refrigeration System

Compressor

The compressor in a mechanical, vapor compression refrigeration system performs a basic function. It generates the

pressure differential to move the refrigerant through the complete refrigeration cycle. It accomplishes its function in

several simple steps. These steps are:

• The compressor draws in the low pressure refrigerant vapor from the evaporator (compressor suction side).

• Through mechanical means, the compressor compresses the refrigerant vapor to a high pressure.

• The high pressure refrigerant vapor is forced to exit the compressor through a discharge line.

The compressor performs work on the refrigerant by compressing it and raising its pressure and temperature. It thus

adds energy to the refrigerant vapor.

Different types of compressors are used in different systems for various reasons. Some, called reciprocating

compressors, draw the refrigerant into a cylinder, compress it, and then discharge it at a higher pressure. Other types

compress the vapor between mating pairs of off-center scrolls (scroll compressors). Regardless of the method used, all

types of compressors are designed to compress the refrigerant vapor, and thereby increase its pressure and move it

through the refrigeration system.

Condenser

The condenser in a refrigeration system is designed to reject the heat energy that was picked up in the evaporator

and the compressor, and reject it to the cooler outside ambient air. This process causes the high pressure

refrigerant vapor to condense and become a high pressure liquid. The condenser operates as follows:

• The high pressure/temperature refrigerant vapor enters the condenser via the compressor discharge line.

• As the hot vapor enters the condenser and begins to ow through tubes of the condenser coil, lower temperature

ambient air is drawn across the outside of the condenser’s tubes/ns. An operating fan is often used as the

motive force to move the air through the condenser coil.

• Due to the temperature difference, heat is transferred from the hot refrigerant to the cooler ambient air.

• As the hot refrigerant vapor gives up its heat, it changes state (condenses) and becomes a liquid.

• This liquid refrigerant then leaves the condenser via the “liquid line,” and travels to the metering device.

All refrigeration systems utilize a condenser, with one of the most common types being air-cooled. The tubes of the

condenser have copper or aluminum ns attached to them which act to dissipate the heat more effectively (other

materials are used, but copper and aluminum are the most common).

Pressure is controlled in the condenser by a variety of means. On air-cooled condensers, a valve in the condenser’s

return line closes at a preset pressure in order to maintain pressure in the coil. As the pressure increases, the valve

modulates so that a consistent pressure is maintained. The fans that force ambient air through the condenser are

also cycled on and off to assist in the heat transfer process as needed.

19

AdaptaPAK® Parallel Refrigeration System

Metering Device (Expansion Valve)

After the condenser, the high pressure liquid refrigerant reaches the metering device (expansion valve). The metering

device meters, or controls, the ow of refrigerant from the high pressure, high temperature side of the system to the

low pressure, low temperature evaporator. Important functions include:

• The metering device (expansion valve) regulates how much liquid refrigerant ows and enters the evaporator.

• The small opening for liquid refrigerant ow takes different forms. In some systems the metering device is a

small thin copper tube known as a capillary tube; in others it is a small orice that regulates ow; and in other

refrigeration systems it is a thermostatic expansion valve (TEV or TXV).

• Control of the size of the opening for ow is crucial. It determines how much liquid refrigerant is allowed to

pass. The size of this opening determines the temperature difference that exists between the saturated suction

temperature (SST) and the temperature at the outlet of the evaporator. This temperature difference is so

important that it has its own specic name—superheat.

One of the most common types of metering device is the thermostatic expansion valve (often referred to as a

TXV or TEV). The opening/closing of these valves is controlled by the pressure and temperature at the exit of the

evaporator.

Evaporator

Liquid refrigerant enters the evaporator from the metering device. The evaporator is located in the space that is being

refrigerated. Several things happen in the evaporator:

• The liquid refrigerant entering the evaporator from the metering device (expansion valve) undergoes an

instantaneous large pressure decrease (per the P-T chart, this is also a large temperature decrease).

• As it enters the evaporator, the liquid refrigerant immediately begins to absorb heat from the warm air owing

over the tubes and ns of the evaporator coil.

• With the absorption of heat, the liquid refrigerant also begins to change state (boil) to become a vapor.

• As the refrigerant continues to ow through the tubes of the evaporator, the continued absorption of heat results

in more and more of the liquid refrigerant changing state to become a vapor.

• Prior to its exit from the evaporator, the refrigerant will have completely changed over to the superheated vapor

state, and will then enter the suction line and head back to the compressor.

Inside the evaporator is where the refrigerant absorbs heat to carry it away from the refrigerated space. This could be

the refrigerated space of a display case, a reach-in cooler. or walk-in freezer in which frozen foods are kept.

The basic principle at work here is that heat always moves from areas of higher temperature to areas of lower

temperature. The refrigerant absorbs heat in the evaporator because it is at a lower temperature than the air moving

across the evaporator. This temperature difference (TD) between the refrigerant and the air is approximately 8 to 10 °F.

Other components of refrigeration systems besides these basic ones are mainly just combinations of accessories

and options that expand the capabilities of the system. Several of these are discussed later in this manual.

20 AdaptaPAK® Parallel Refrigeration System

This manual suits for next models

44

Table of contents

Other Hillphoenix Refrigerator manuals

Popular Refrigerator manuals by other brands

Grundig

Grundig GKN 26860 XPHN Instructions for use

CORBERO

CORBERO FE 850 S/2 operating instructions

Sharp

Sharp SJ-NBA22DHXWE-EU user manual

Urban Islands

Urban Islands 21008 Installation & operating instructions

KitchenAid

KitchenAid DHT-486XP installation instructions

Whirlpool

Whirlpool GB2FHDXWQ00 parts list

Electrolux

Electrolux ER2640C instructions

Miele

Miele KF 7654 SNE ed OPERATING AND INSTALLATION Manual

Signature Kitchen Suite

Signature Kitchen Suite SKSUD2402P owner's manual

Hisense

Hisense RB372N4ADE User's operation manual

SEVERIN

SEVERIN KS9783 Instructions for use

Frigidaire

Frigidaire FTE5200SBRE operating instructions