HIRED-HAND 6607-8036 User manual

Manual No. 4801-2994 Rev 10-05 Installation & Operation Manual Feed Manager

Feed Manager

Hired Hand Manufacturing, Inc.

1733 County Road 68

PO Box 99

Bremen, Alabama 35033

Manual No. 4801-2994 Rev 10-05 FEED MANAGER Table of Contents

Table of Contents

Section Title Page

1. Ratings and Specifications.............................................................................................................................3

2. Warnings .......................................................................................................................................................3

3. Limited Warranty ..........................................................................................................................................4

4. Introduction ...................................................................................................................................................5

4.1 Features...................................................................................................................................................5

4.2 System Limitations.................................................................................................................................5

5. Feed Manager Front Panel.............................................................................................................................5

5.1 Mode, + and - Buttons and Main Display..............................................................................................6

5.2 Feed Bin #1, #2, #3, and #4 Buttons and Indicators...............................................................................6

5.3 Alarm Indications ...................................................................................................................................7

6. Programming the Feed Manager ...................................................................................................................8

6.1 P1 – P9 General Parameters ...................................................................................................................8

6.2 P10.x – P19.x Feed Bin Characteristics................................................................................................10

6.3 P40 – P49 Hired-Hand Network...........................................................................................................10

6.4 PS1 – PS9 Sensor Readings..................................................................................................................11

7. Feed Manager Control / Editor Section.......................................................................................................11

7.1 Feed Level ............................................................................................................................................12

7.2 Feed Capacity (%) ................................................................................................................................12

7.3 Bin Status..............................................................................................................................................12

7.4 Min. Feed Capacity (%)........................................................................................................................13

7.5 Max. Fill Time (Minutes) .....................................................................................................................13

8. Wiring Diagrams, Schematics, etc...............................................................................................................15

8.1 Feed Manager Circuit Board Layout....................................................................................................15

8.2 Connecting AC Power to the Feed Manager........................................................................................16

8.3 Connecting Feed Bins to the Feed Manager.........................................................................................17

8.4 Connecting a Current Sensor or Sens-O-Matic III to the Feed Manager ............................................18

8.5 Connecting an Alarm to the Feed Manager..........................................................................................19

8.6 Connecting the Feed Manager to the HH.Net.......................................................................................20

9. Replacement and Optional Parts..................................................................................................................21

10. NOTES........................................................................................................................................................22

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 3 of 22

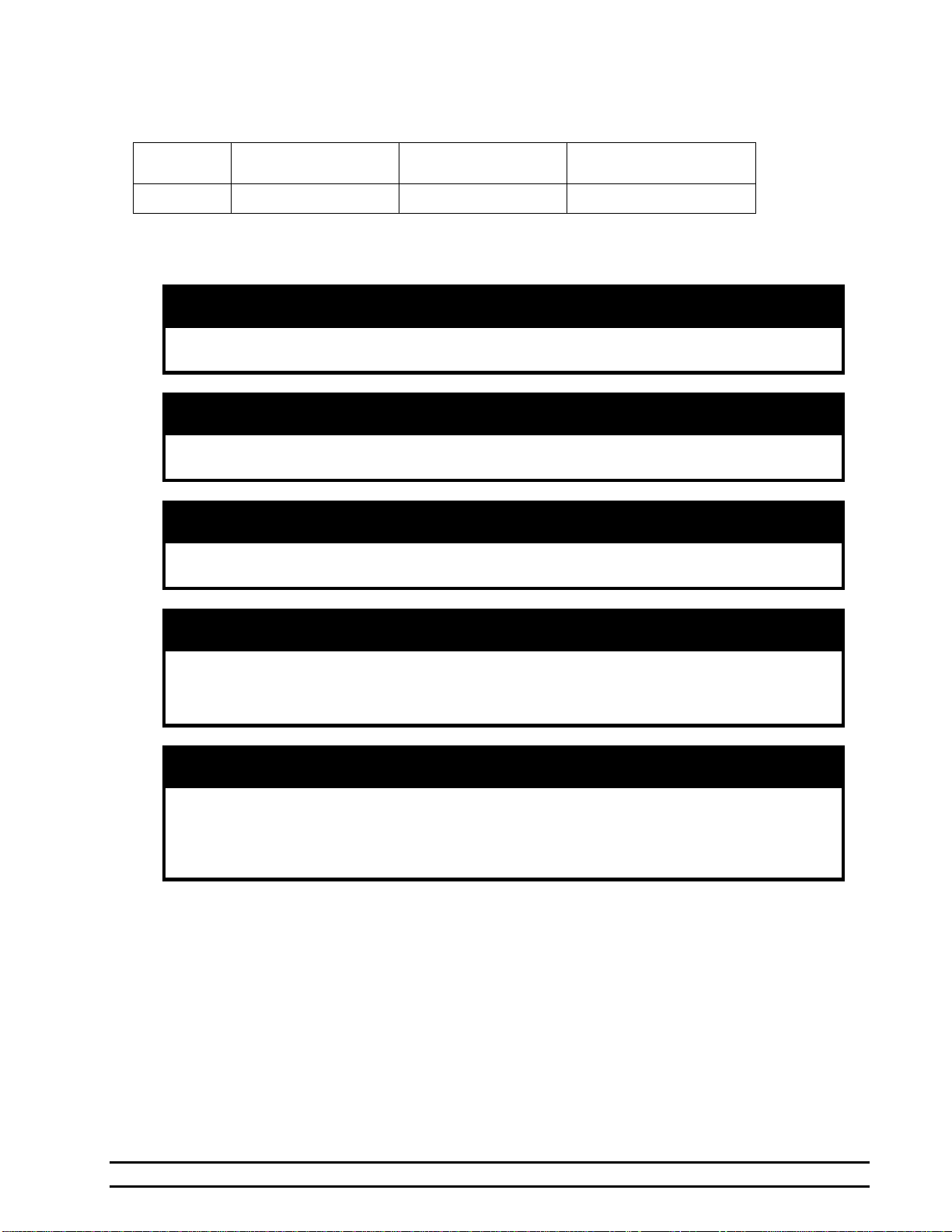

1. Ratings and Specifications

•Temperature Range…………..32°F - 122°F (0°C – 50°C)

HHI Part

Number Description Power Supply Temperature

6607-8036 Feed Manager 120/230 VAC 50/60 Hz 32° F thru 122°F

(0° C thru +50° C)

2. Warnings

Warning!

Only a certified electrician should install or maintain electrical connections.

Warning!

Proper safety equipment must be used during installation of Feed Level Sensor.

Warning!

Do not install or maintain equipment during a lightning storm.

Warning!

Maximum operating temperature of Feed Manager is 0°to +50°C (32°to 122°F).

Maximum operating temperature of Feed Level Sensor is -18°to +54°C (0°to 130°F).

Warning!

When this system is used in a life sustaining application where failure could result

in loss or injury, the user should provide adequate back-up, or accept the risk of

such loss or injury!

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 4 of 22

3. Limited Warranty

All products are warranted to be free from defects in material and workmanship for a period of one

year from the date of purchase if installed and used in strict accordance with the installation

instructions. Liability is limited to the sale price of any products proved to be defective or, at

manufacturers’ option, to the replacement of such products upon their return. No products are to be

returned to the manufacturer, until there is an inspection and/or a return-goods authorization (RGA)

number is issued.

All complaints should be directed first to the authorized distributor who sold the product. If

satisfaction is not obtained or the name of the distributor is not known, write the manufacturer that

appears below, directed to the attention of Customer Service Manager.

This limited warranty is expressly in lieu of any and all representations and warranties expressed or

implied, including any implied warranty of merchantability or fitness for a particular purpose. The

remedy set forth in this limited warranty shall be the exclusive remedy available to any person. No

person has authority to bind the manufacturer to any representation or warranty other than this limited

warranty. The manufacturer shall not be liable for any consequential damages resulting from the use

of our products or caused by any defect, failure or malfunction of our products. (Some areas do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.)

This warranty gives you specific legal rights and you may also have other rights that vary from area

to area.

Warrantor:

Hired-Hand Manufacturing, Inc.

1733 County Road 68

PO Box 99

Bremen, Alabama 35033

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 5 of 22

FEED MANAGER

Mode Indicators Mode Button Option Selection Buttons

Feed Level

Indicators

Auger #2

Fill Indicator

Auger #1

Fill

Indicator Main

Display

Bin #1

Selection

Button

4. Introduction

The Feed Manager is the latest technology in the Hired-Hand controller family. This technology adds the

stand-alone controller capability for monitoring feed levels in bins and run times of feed augers. One Feed

Manager controller can monitor up to four feed bins and two feed augers from two buildings. Beyond

monitoring, it also adds alarm features to help detect feed spills or prevent running out of feed. The ultrasonic

Feed Level Sensors (sold separately) are connected to the Feed Manager to monitor the feed inventory in the

feed bins. The Feed Manager can be connected to a Sens-O-Matic III or Current Sensor (sold separately) to

monitor runtimes of Feed Augers.

4.1 Features

•Input Device Options

Up To 4 Feed Bin Level Sensors (Required) 2 Feed Auger Runtime Sensors (Optional)

HHNet connection for PC compatibility

•Output Devices (Standard)

1 Alarm relay with both N.O. and N.C. contacts

4.2 System Limitations

The Feed Level System is intended to provide a low-cost alternative to load-cell systems for monitoring feed

inventory. It is not an accurate way to track feed consumption or to accomplish restrictive feeding.

This system will provide an estimated feed weight although it is simply estimated. There are many factors

which will cause day to day errors in this estimate. These factors include coning and inaccurate feed density. It

is important to understand that errors in level will occur from time to time due to coning. These errors should

be limited to damp starter feed, therefore, the system should provide accurate readings in almost all cases.

Important Note:

In order to maintain consistent feed levels, the Feed Manager uses a “Rate Filter”. This filter only allows

small changes in the “Feed Level” per second. This technique will slow the reaction time. Therefore, once

installed, allow approximately 20 minutes for the reading to stabilize.

5. Feed Manager Front Panel

The Feed Manager front panel includes four columns of feed level LED indicators with individually selectable

push-button switches directly beneath each column. To the left and right sides of the front panel are the Auger

Fill Indicators. Mode indicators, mode button, and option selection buttons are located to the lower right side

of the front panel.

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 6 of 22

Feed Level

Indicators

Auger #2

Fill

Indicator

Auger #1

Fill

Indicator

Feed Bin #3

Selection

Button

5.1 Mode, + and - Buttons and Main Display

Mode Button – The Mode button is used to select a controller function. Press the Mode button to toggle

between specific feed bins and functions. The Mode Indicators light when a function is selected and

the associated data is displayed in the Main Display. By pressing and holding the Mode button for at

least 5 seconds, the Feed Manager can be placed in the Program Mode as discussed in Section 6 of

this manual.

Plus and Minus Buttons – The plus (+) and minus (-) buttons are used to change or modify a variable's value.

5.2 Feed Bin #1, #2, #3, and #4 Buttons and Indicators

Feed Level Indicators – The Feed Manager includes four columns of feed level LED indicators. As the feed

level inside the feed bin decreases, the Feed Level Indicators also decrease and change color

accordingly. As the feed continues to decrease and the third LED from the bottom turns Off, the two

remaining LED’s will change colors. First, both will be orange; then one orange and one red; two

red; one red; and finally all LED’s will be OFF.

Feed Bin Selection Buttons – Individually selectable push-button switches are located directly beneath each

column of Feed Level Indicators. Pressing a specific switch will allow direct access to the specific

feed bin’s Feed Level, Feed Capacity, and Bin Status. Pressing the Mode switch repeatedly allows

sequential access to each feed bin.

Auger Fill Indicator – To the left and right sides of the front panel are the Auger Fill Indicators. When this

option is used and the Feed Manager is connected to a Current Sensor, the Fill Indicator will turn ON

when the Auger motor is running and OFF indicates the motor is not running.

Function Modes

Mode Indicators

Minus button

(Use to decrease

value of variable)

Plus button

(Use to increase

value of variable)

Mode Select Button

Main Display

1 2 3 4

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 7 of 22

5.3 Alarm Indications

Normal Operation – During normal operation with no alarms present and no specific feed bin or specific

operation selected, the following indications will be shown:

•The Main Display will continuously show the active feed bin numbers.

•The Feed Level Indicators for the active bins will be displaying the feed levels.

•The Auger Fill Indicators will either be solid-ON when the auger motor is running or solid-

OFF when the auger motor is not running.

Minimum Feed Capacity Alarm –The

Min. Feed Capacity feature

monitors the amount feed in the

feed bin and will activate the

Auxiliary Alarm output if the feed

decreases below the selected

amount of minimum feed. Refer to

Section 7.4 for control/editing the

Min. Feed Capacity settings.

When the feed level decreases

below the Min. Feed Capacity (%)

percentage, the specific Feed Bin

Level Indicators will immediately

start flashing.

NOTE:The feed level must continuously remain below the Min. Feed Capacity (%) percentage for

a minimum of 4 minutes for the Auxiliary Alarm to activate.

After 4 minutes, the Auxiliary Alarm contacts will activate, the Main Display will alternate between

showing the active Feed Bins and “Err” (“Err” represents that an Error/Alarm condition exists), and

the specific Feed Bin Level Indicators will continue to repeatedly flash ON and OFF. When the feed

level rises above the Minimum Feed Capacity (%), the Auxiliary Alarm, Feed Bin Level Indicators,

and display immediately return to normal operation.

Maximum Fill Time Alarm – The Max. Fill Time feature monitors the amount of time which the feed augers

remain ON and will activate the Auxiliary Alarm output if the feed auger remains ON longer than the

selected Max. Fill Time limit. Refer to Section 7.5 for control/editing the Max. Fill Time settings.

When the feed auger initially turns ON, the Fill Indicator will also turn ON. If either of the feed

augers remain ON longer than the selected Max. Fill Time (minutes), the Auxiliary Alarm contacts

will activate. When the Auxiliary Alarm is activated, the specific Auger Fill Indicator will

repeatedly flash ON and OFF. The Main Display will also alternate between the active feed bins and

Mode Indicators

Feed Level

Indicators

Auger #2

Fill Indicator

Auger #1

Fill

Indicator Main

Display

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 8 of 22

“Err” representing that an Error/Alarm condition exists. As soon as the alarm condition clears, the

Auger Fill Indicator and Main Display return to normal operation.

NOTE: A Current Sensor (6407-6070 ordered separately) or Sens-O-Matic III feed controller (6606-

2000 for a 120vac model or 6606-2100 for a 230vac model ordered separately) is required for

this function.

6. Programming the Feed Manager

This section introduces the Feed Manager programming software. The Feed Manager controller software

allows the use of four ultrasonic feed level sensors (sold separately) while also monitoring two feed augers.

The feed level sensors are used to monitor the feed inventory in the feed bins. The feed auger connections are

used primarily to monitor the runtime of the cross-fill auger motors. The feed augers can only be monitored

when used with a Current Sensor or Sens-O-Matic III feed switch (sold separately). The following figure

shows the Feed Manager programming options which must be carefully selected to allow accurate monitoring

of the Feed Level. By pressing and holding the Mode button for at least 5 seconds, the Feed Manager can be

placed in the Program Mode as discussed below and on the following pages.

In addition to the feed level capabilities, the optional use of a Current Sensor or Sens-O-Matic III adds a new

alarm feature. The alarm allows you to place a runtime limit on each auger motor to help the user detect feed

spills or protect against running out of feed. If the runtime limit is exceeded, the auxiliary alarm will be

triggered.

FEED MANAGER PROGRAMMING

P 1-9 General Parameters

P1 = Metric Units

YES = Metric Units

NO = English Units

P2 = Feed Sensors Activated

P3 = Feed Sensor Type

P4 = Feed Sensor Dead Zone (ft, m)

P5 = Reset Feed Levels

YES = Reset To Zero

NO = Do Not Reset

P10.x - P19.x Feed Bin Characteristics

‘x’ Represents Bin Number

P10.x = Bin x Diameter (6’, 7’, 9’, 12’)

P11.x = Bin x - # of Rings

P12.x = Bin x Ring Height (Typ. 2.65’ [0.81m])

P13.x = Bin x Cap Angle (30°, 40°)

P14.x = Estimated Bin x Height

P15.x = Estimated Bin x Weight (ton,mton)

P40 - P49 Hired-Hand Network

P40 = HHNET Network Address

P41 = Software Version Number

P42 = Controller Setup

PS1 - PS9 Sensor Readings

PS1 = Feed Sensor 1

PS2 = Feed Sensor 2

PS3 = Feed Sensor 3

PS4 = Feed Sensor 4

6.1 P1 – P9 General Parameters

General parameters are associated with the operation and control of the Feed Manager. These settings should

be entered when the system is installed:

P1 – Metric Units

The units of measure can be selected as either English or Metric Units. Select ‘No’ and measurements

display in English Units. Select ‘Yes’ and measurements display in Metric Units.

Measurement English Metric

Feed Level Feet Meters

Ring Height Feet Meters

Bin Height Feet Meters

Bin Weight Tons Mtons

Dead Zone Feet Meters

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 9 of 22

P2 – Feed Sensors Activated

This general parameter is used to turn additional feed bins ON (press the ‘+’ button) or OFF (press the ‘-‘

button). For example, if you only have two feed bin sensors connected to this control, you can disable bins

#3 and #4 displays by setting this to “1 2 - -“.

P3 – Feed Sensor Type

Program selection not available at this time.

P4 – Feed Sensor Dead Zone (ft, m)

Dead Zone refers to the area that the sensor is hanging into the feed bin. The figure below shows how to

measure the Dead Zone. The measurement should be taken from the top of the cap (excluding the lid ring)

to the bottom of the sensor probe. This measurement is the Dead Zone that should be entered.

P5 – Reset Feed Levels

Select ‘Yes’ to reset the feed bin level. The feed level indicators will reset to the lowest level and

gradually climb to the current feed level.

Dead Zone

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 10 of 22

6.2 P10.x – P19.x Feed Bin Characteristics

Feed bin characteristics are the specific feed bin parameters required to monitor feed bins:

“x” Represents Bin Number

P10.x – Diameter (6’, 7’, 9’, 12’)

Feed Bin #x diameter.

P11.x – # of Rings (1, 2, 3, 4, 5)

Feed Bin #x number of rings.

P12.x – Ring Height (Typ. 2.65’ [0.81m])

Feed Bin #x Ring Height = Measurement from the top/center of one ring to the top/center of the next ring.

Selection Range of English = 1.00’ to 3.50’. Selection Range of Metric = 0.30 to 1.07. The “Ring

Height” can also be used to adjust any errors in controller calculations.

P13.x – Cap Angle (30º or 40º)

Feed Bin #x cap angle at the top of the bin.

P14.x – Estimated Bin Height

Feed Bin #x bin height. The bin height is calculated by using the entered bin size information. This can be

verified by measuring from the top of the boot to the top of the cap (excluding the lid ring). Refer to the

figure on titled Feed Bin Specs. If the “Bin Height (P14.x)”, is incorrect, adjustments can be made to the

“Ring Height” for correction.

P15.x – Estimated Bin x Weight (ton, mton)

Feed Bin #x feed weight. The feed weight is calculated by using the entered bin size information and the

current feed level module results. “Feed Weight (P15.x)” displays the estimated weight of the feed

currently in the bin based on a feed density of 40 lbs/cu. ft.

6.3 P40 – P49 Hired-Hand Network

These parameters are used with Hired-Hand’s Farm Manager Software. The controller has three parameters

which are used to function with the Hired-Hand PC compatible inter-controller network (HH.Net).

P40 – HHNet Network Address

HH.Net permits up to 32 controllers to be addressed on a single communications port of a personal

computer (PC). In order for the computer to recognize the communications from the controllers, each

controller must have a unique network address.

P41 – Software Version Number

This is not settable by the user. It is the version of the controller software.

Top Angle

Bin

Height

Ring

Height

Number of

Rings

Dead Zone

F

Fe

ee

ed

d

B

Bi

in

n

S

S

p

pe

ec

cs

s

Diameter

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 11 of 22

P42 – Controller Setup

This is not settable by the user. It is a unique number that allows the network software (Farm Manager) to

recognize the type of controller.

6.4 PS1 – PS9 Sensor Readings

The Feed Manager will accommodate up to four Feed Level Sensors. The sensor reading will display for PSx

where xis the sensor number. This is a precise reading used mainly for troubleshooting purposes.

NOTE: As the feed level decreases, the sensor reading number will increase (Range = 0 thru 255).

PS1 – Feed Sensor 1

This is the sensor reading for Feed Sensor 1.

PS2 – Feed Sensor 2

This is the sensor reading for Feed Sensor 2.

PS3 – Feed Sensor 3

This is the sensor reading for Feed Sensor 3.

PS4 – Feed Sensor 4

This is the sensor reading for Feed Sensor 4.

7. Feed Manager Control / Editor Section

The Feed Manager Control / Editor Section includes five Mode Indicator LED’s, a Main Display, Mode Select

button, and Plus and Minus editor buttons.

When a specific feed bin is selected, the Feed Level Indicators for the specific bin will flash and the other

remaining feed bin level indicators will be OFF. After approximately 20 seconds of inactivity, the controller

will exit the Control / Editor mode and return to display all active feed bins. The following functions can be

scrolled-thru by using the Mode Select Button or by first pressing the specific Bin Selection Button (1, 2, 3, or

4).

Function Modes

Mode Indicators

Minus button

(Use to decrease

value of variable)

Plus button

(Use to increase

value of variable)

Mode Select Button

Main Display

1 2 3 4

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 12 of 22

2 5

7.1 Feed Level

When the Feed Level indicator is ON,

the Main Display will show the

amount of feed remaining in the

specific feed bin. The Feed Level is

shown in number of feet or meters

from the feed bin’s boot. The unit of

measure (Feet or Meters) can be set in

the Program P1 setting (Refer to

Section 6.1). View the Feed Level by

pressing the specific required Bin

Selection Button (1, 2, 3, or 4). The

specific Feed Bin Level Indicators

will repeatedly flash to indicate the

selected feed bin.

7.2 Feed Capacity (%)

When the Feed Capacity indicator is

ON, the Main Display will show the

percentage of feed remaining in the

specific feed bin. View the Feed

Capacity by first pressing the

specific required Bin Selection

Button (1, 2, 3, or 4). The specific

Feed Bin Level Indicators will

repeatedly flash to indicate the

selected feed bin. Next, press the

Mode select button once until the

Feed Capacity indicator turns ON.

7.3 Bin Status

The selectable Bin Status is used to

turn a specific feed bin’s alarm either

ON or OFF. The feed Bin Status can

be turned OFF (Minus – button) to

disable the Minimum Feed Capacity

alarm and prevent this alarm from

reoccurring until the Bin Status is

manually turned ON (Plus + button).

To view or change the Bin Status,

first press the specific required Bin

Selection Button (1, 2, 3, or 4). The

specific Feed Bin Level Indicators

will repeatedly flash to indicate the

selected feed bin. Next, press the

Mode select button twice until the

Bin Status indicator turns ON. The

Main Display will show the

selectable Bin Status of the specific

feed bin.

Feed Level

5.3

Feed Capacity

Bin Status

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 13 of 22

7.4 Min. Feed Capacity (%)

The Min. Feed Capacity feature

monitors the amount feed in the feed

bins and will activate the Auxiliary

Alarm output if the feed decreases

below the selected amount of minimum

feed. When the feed level decreases

below the Min. Feed Capacity (%)

percentage, the specific Feed Bin Level

Indicators will immediately start

flashing. To view or change the Min.

Feed Capacity setting, press the Mode

Select button repeatedly until the

Minimum Feed Capacity indicator

turns ON.

The Main Display shows the selectable Minimum Feed Capacity percentage for ALL of the active feed bins.

For example, if 30 is selected, the Auxiliary Alarm will activate if the Feed Capacity decreases to 29% or less

overall feed bin capacity.

To increase or decrease the Minimum Feed Capacity percentage, press the Plus + or Minus - button until the

desired value is shown in the Main Display. To turn the Minimum Feed Capacity function OFF for ALL

Feed Bins, repeatedly press the Minus - button until OFF is shown in the Main Display. To disable the

Minimum Feed Capacity alarm only for specific feed bins, turn Bin Status OFF while the specific feed bin is

selected. Refer to Section 7.3.

NOTE:The feed level must continuously remain below the Min. Feed Capacity (%) percentage for a

minimum of 4 minutes for the Auxiliary Alarm to activate.

After 4 minutes, the Auxiliary Alarm contacts will activate, the Main Display will alternate between showing

the active Feed Bins and “Err” (“Err” represents that an Error/Alarm condition exists), and the specific Feed

Bin Level Indicators will continue to repeatedly flash ON and OFF. When the feed level rises above the

Minimum Feed Capacity (%), the Auxiliary Alarm, Feed Bin Level Indicators, and display immediately

return to normal operation.

NOTE: In order for the Minimum Feed Capacity function to be operational, the Bin Status mode must be

turned ON for each required feed bin AND the Min. Feed Capacity (%) must be set to the desired

percentage.

7.5 Max. Fill Time (Minutes)

The Max. Fill Time feature is used

provide an alarm in cases of

excessive feed auger runtimes as a

result of feed spills and/or equipment

malfunction. Max. Fill Time

monitors the amount of time which

the feed augers remain ON and will

activate the Auxiliary Alarm output

if the feed auger remains ON longer

than the selected Max. Fill Time

limit. When the feed auger initially

turns ON, the Fill Indicator will also

turn ON.

If either of the feed augers remain ON longer than the selected Max. Fill Time (minutes), the Auxiliary Alarm

contacts will activate. When the Auxiliary Alarm is activated, the specific Auger Fill Indicator will

repeatedly flash ON and OFF. The Main Display will also alternate between the active feed bins and “Err”

representing that an Error/Alarm condition exists. As soon as the alarm condition clears, the Auger Fill

Indicator and Main Display return to normal operation.

3 0

Min Feed Capacity

Max. Fill Time

1 5

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 14 of 22

For example, if 15 is selected, the Auxiliary Alarm will activate if the run time exceeds 15 minutes.

To increase or decrease the Max. Fill Time minutes, press the Plus + or Minus - button until the desired value

is shown in the Main Display. To turn the Max. Fill Time function OFF for both feed auger motors, repeatedly

press the Minus - button until OFF is shown in the Main Display.

To view or change the Max. Fill Time setting, press the Mode Select button repeatedly until the Max. Fill

Time indicator turns ON.

NOTE: A Current Sensor (6407-6070 ordered separately) or Sens-O-Matic III feed controller (6606-2000 for

a 120vac model or 6606-2100 for a 230vac model ordered separately) is required for this function.

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 15 of 22

8. Wiring Diagrams, Schematics, etc.

The following diagrams describe the Feed Manager circuit board connections and how the Feed manager is

connected to external equipment.

8.1 Feed Manager Circuit Board Layout

HH.Net

1.2 Amp Slo-Blow Fuse – F1

Auxiliary

Alarm

AC Power

Connector

Net Term

Jumper

Voltage

Selector

Switch

Auger #1

Auger #2

Feed Bin # 1

Feed Bin # 2

Feed Bin # 3

Feed Bin # 4

Option Board

Connection

Processor

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 16 of 22

8.2 Connecting AC Power to the Feed Manager

Inset A

Feed Manage

r

Inset B

WARNING:

Ensure that the Voltage Selector Switch

shown in Inset B is set according to the

AC Supply voltage. Equipment damage

will occur if this switch is not set

correctly.

Inset B

OR

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 17 of 22

8.3 Connecting Feed Bins to the Feed Manager

Feed Manager

Circuit Board Connections

(Exploded View)

Feed Level Sensor

(Mounted on top of

the feed bin)

Cable from the feed

bin to the controller

Feed Bin #4

Feed Bin #1

Feed Bin #2

Feed Bin #3

Shield

Vdc

Sig

Gnd

Feed Manage

r

Inset A

Inset

A

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 18 of 22

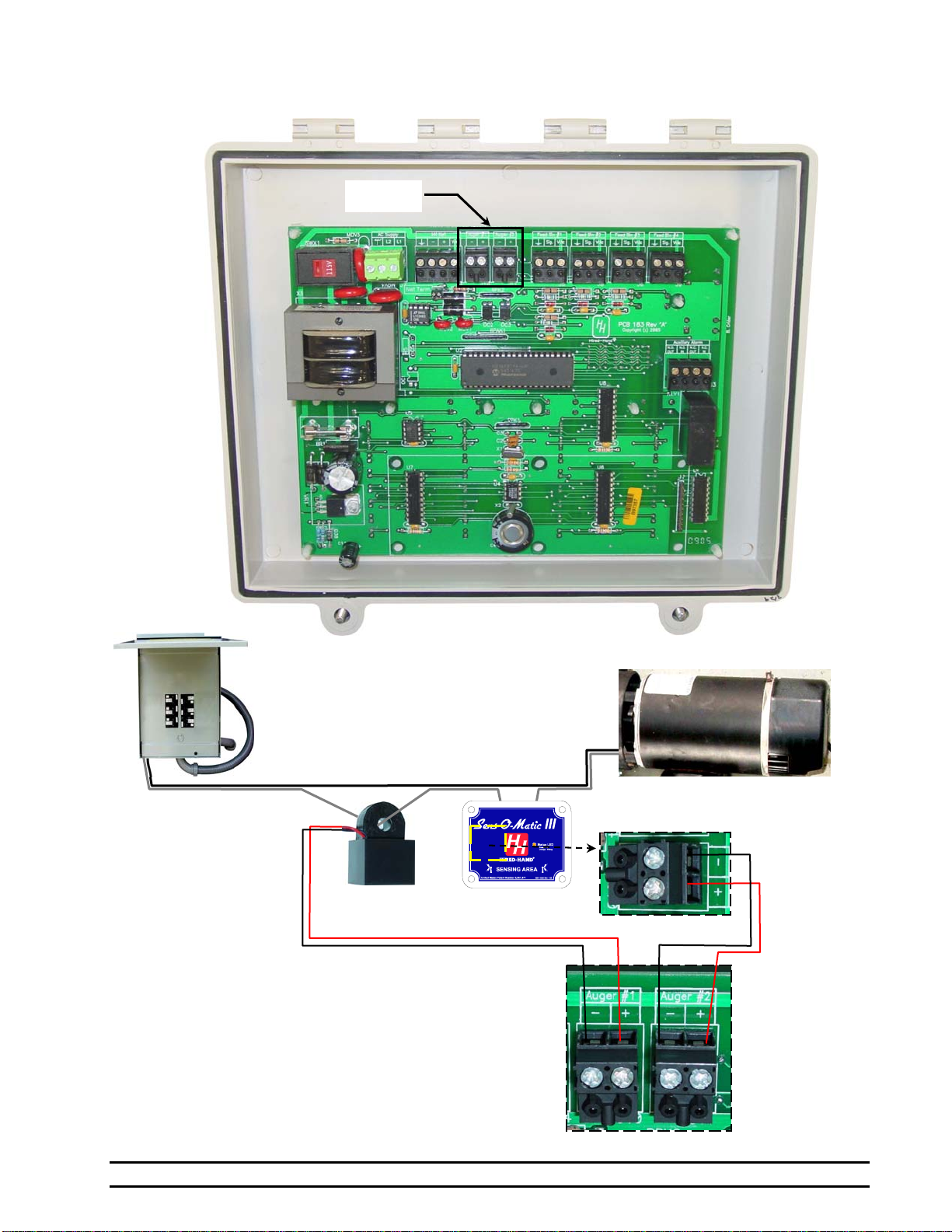

8.4 Connecting a Current Sensor or Sens-O-Matic III to the Feed Manager

Current

Sensor

Feed Auger Motor

L2

L1

Feed Manager

Auger #1 and

Auger #2 Circuit

Board

Connections

(Exploded View)

Black

Red

Feed Manage

r

Inset A

OR

Inset

A

Sens-O-Matic III Circuit Board

Run Sensor Connections (Exploded View)

NOTE: Either a Current Sensor or a

Sens-O-Matic III may be

used to monitor the Feed

Auger Motor Runtime.

Run Sensor

Auger #1 Auger #2

Breaker Box

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 19 of 22

8.5 Connecting an Alarm to the Feed Manager

Feed Manage

r

Inset A

For Parallel

Alarm Connection For Series

Alarm Connection

Internal Circuit Board

Auxiliary Alarm Relay

NOTE: The internal wiring shows the condition of

the relay during normal conditions (no

alarm present). During an alarm

condition, the contact positions will be

reversed.

Part No. 4801-2994 Rev 10-05 FEED MANAGER Page 20 of 22

8.6 Connecting the Feed Manager to the HH.Net

Inset A

Inset B

Feed Manage

r

Table of contents

Popular Network Hardware manuals by other brands

Juniper

Juniper SSR1400 quick start guide

PowerFile

PowerFile Active Archive Appliance A3 installation guide

SonicWALL

SonicWALL ECLASS NSA E8500 Getting started guide

Cabletron Systems

Cabletron Systems W85 user guide

GUILCOR

GUILCOR WebSensor user guide

Mellanox Technologies

Mellanox Technologies MUA9002F-2SF-250 user manual