Hisun HS500ATV User manual

1

HS500ATV Maintenance Manual

2

Catalogue

General Information

……………………………...5

1 Description

…………………………………………………..5

1.1 Identification code………..……………………………..6

1.1.1. Frame No. …………………………………………………6

1.1.2. Engine No.…………………………………………………7

1.2 Special tools, instruments and meters…………………7

1.3 Periodic maintenance chart……………………………….9

Engine

………………………………………………………….11

2. Inspection and adjustment of engine

…………….11

2.1 Inspection of cylinder head, intake

and exhaust valve………………………………………….11

2.2 Inspection of spark Plug………………………………….12

2.3 Inspection of cylinder, piston and piston ring…….14

2.4 Inspection of crankshaft………………………………….17

2.5 Inspection of clutch……………………………………….18

2.6 Inspection of carburetor………………………………….18

2.7 Inspection of air filter………………………………….19

2.8 Inspection of oil filter………………………………….20

2.9 Inspection of lubrication system……………………….20

3

2.10 Lubrication of engine…………………………………….21

2.11 Inspection of cylinder head…………………………….21

3.Disassembly of engine

……………………………………27

3.1 Cylinder head and block………………………………….27

3.2 Piston and connecting rod……………………………….31

3.3 Manual starting mechanism……………………………….32

3.4 Sensor………………………………………………….…….32

3.5 Left crankcase cover……………………………….…….33

3.6 Magneto…………………………………………………..….33

3.7 Oil pump………………………………………….……..….34

3.8 Clutch…………………………………………………...….35

3.9 Carburetor……………………………………………...….36

3.9.1 Structure of carburetor………………………...…..36

3.9.2 Inspection and adjustment of carburetor…....….37

4.Chassis

4.1 Steering operation system………………………...…..39

4.2 Brake system…………………………………………...….51

4.3 Wheels and tires……………………………………...….67

4.4 Transmission system…………………………….…...….70

4.5.gear

geargear

gearshiftmechanism……………………………………..77

4.6

Suspension…………………………..……....….。。。。。.79

4

5. Electrical system

………………………..……....….84

5.1 Ignition system…………………………..……....….87

5.2 Magneto and charging system…………..……....….88

5.3 Battery……………………………………..……....….88

5.4 Lighting system…………………………..……....….90

5.5 Meterand signal system…………………………..……91

5.6 Electrical starting system…………….……..…….92

6.Appendix

………………..…………………..……....…93

6.1 Specification………..…………………..……....….93

6.2 Requirements for torque of fastener……………….99

6.3 Electrical circuits……………………………....….100

5

General Information

1 Description

6

7

1.1 Identification code

1.1.1. Frame No.

The frame No. is engraved in the right bottom of the supporting

frame. See Figure 1-1

Figure 1-1

1.1.2. Engine No.

The engine No. is engraved in the right side of the engine.

See figure 1-2

8

Figure 1-2

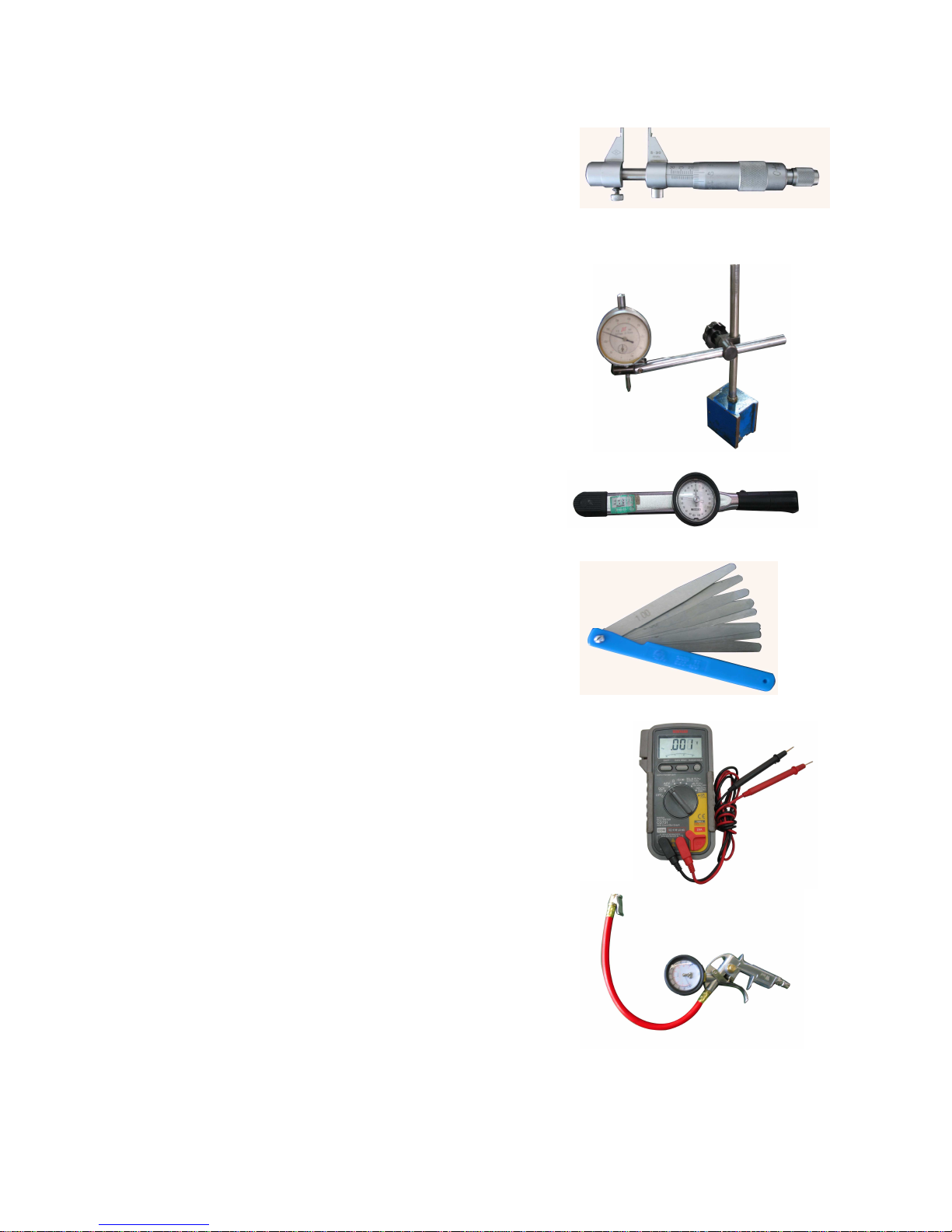

1.2 Special tools, instruments and meters

1.2.1 Oil filter detacher

To fasten and detach the oil filter

1.2.2 Height gauge

To gauge the height of various components

1.2.3 Vernier

To measure the length of various components

1.2.4 尺 Outside micrometer

To accurately measure external

diameter of a column

9

1.2.5 Inside micrometer

To accurately measure internal

diameter of a hole

1.2.6 Dial indicator

To accurately measure a small distance

1.2.7 Torque Spanner

To measure torque force

1.2.8 Feeler gauge

To measure gap-width

1.2.9 Multimeter

To check electrical circuits and parts

1.2.10 Barometer

To measure pressure of the tyre

10

1.2.11 Magneto drawing device

To detach the magneto

1.2.12 Snap ring clampTo install

and detach snap rings

1.3

Pe

riodic maintenance chart

EVERY INITAL

month

1 3 6 6 12

km 320 1,200 2,400

2,400 4,800

(mi) (200) (750) (1,500)

(1,500) (3,000)

ITEM

ROUTINE

Whicheve

comes first

hours 20 75 150 150 300

Valves ● Check valve clearance.

●Adjust if necessary.

○ ○ ○ ○

Sparkplug

●Check condition.

●Adjust gap and clean.

●Rep;ace if necessary.

○ ○ ○ ○ ○

Air fiter element

● clean.

●Replace if necessary.

Every20-40hours

(More often in wet of dusty areas.)

Carburetor* ● Checkandadjustidlespeed/starteroperation.

● Adjust if necessary.

○

○

○

○

Crankcase

breathersystem*

● Check breather hose for cracks of

damage.

● Replace if necessary.

○

○

○

Exhaust system*

● Check for lecakage.

● Tighten if necessany.

● Replace gasket(s) if necessary.

○

○

○

Spark arrester ● Clean.

○

○

○

Fuel line* ● Check fuel hose for cracks or damage.

● Replace if necessaly.

○

○

○

Engine oil ●Replace.(Wamenginebefore draining.)

○ ○ ○ ○

11

Engine oil filter

cartridge ●Replace.

○ ○ ○ ○

Engine oil strainer*

●Clean.

○ ○ ○ ○

Final gear oil

Differential gear oil

● Check for oil leakage.

● Replace eveny 12 months.

○

○

Front brake*

● Check operation/fuid leakage.(See NOTE

page 8).

● Correct if necessary.

○○○○ ○

Rear brake* ● Check operation.

● Adjust if necessary.

○○○○ ○

Select lever safety

system cable

● Check operation.

● Adjust if necessary.

○○ ○

V-belt* ● Check operation.

● Check for cracks or damage.

○○○ ○

Wheel ● Check balance/damage/

● Repair if necessary.

○○○○

Wheel bearing*

● Check bearing assemblies for lossenss/

damage.

● Replace if necessary.

○○○○

Front and rear

suspendion*

● Check operation.

● Correct if necessary.

○○

Steering system* ● Checkoperation./Replace if damaged

● Check toe-in./Adjust if necessaly.

○○○○○

Drive shaft universal

joint*

● Lubricate with lithium–soap–bassed

grease.

○○○

Axle boots* ● Check operation.

● Replace if damaged.

○○○○○

Fittings and

fasteners*

● Check all chassis fittings and fastenrs.

● Correct if necessary.

○○○○○

Lights and

switches*

● Check operation.

● Adijust headinght beams.

○○○○○

engine

2. Inspection and adjustment of engine

2.1.1

2.1.1 2.1.1

2.1.1 Inspection cylinder head, intake and exhaust system

check the pressure of cylinder

12

Preheat the engine, then misfire and unplug the spark

plug.Fix pressure gauge into the hole.

Note: Giving a leakage check to the pressure gauge.

Rotate the engine until the pressure gauge stop rising.

The maximum reading would be greater than0.7- 0.9Mpa

after starting for 4-6

times. See figure 2-1.

Figure 2-1

Check the valve clearance

Note:when adjust valve clearance,the engine must be

cooled.(The tempreture should be less than 35℃ )

Remove the seat cushion and fuel tank,unplug the vision hole

cover ,round the flywheel of magneto anti-clockwise to aim “T”

at the signal of fore cover on the left.

Note: The piston must be fixed to the top dead enter

.

(Figure 2-2)

13

Remove cylinder valve cover,check the clearance between the

valve stem by feeler gauge .

Valve clearance:inlet and exhaust valve: 0.05~0.08mm.

See figure 2-3.

Figure 2-3

Loose the lock nut,rotate the adjusting screw until it

appears that the feeler gauge be pulled .Then fasten the

adjusting screw by valve adjuster,tighten the lock nut and

check the valve clearance .After installing the cylinder

valve cover , vision hole cover,the fuel tank and cushion.See

figure 2-4.

14

Figure 2-4

2.1.2

2.1.22.1.2

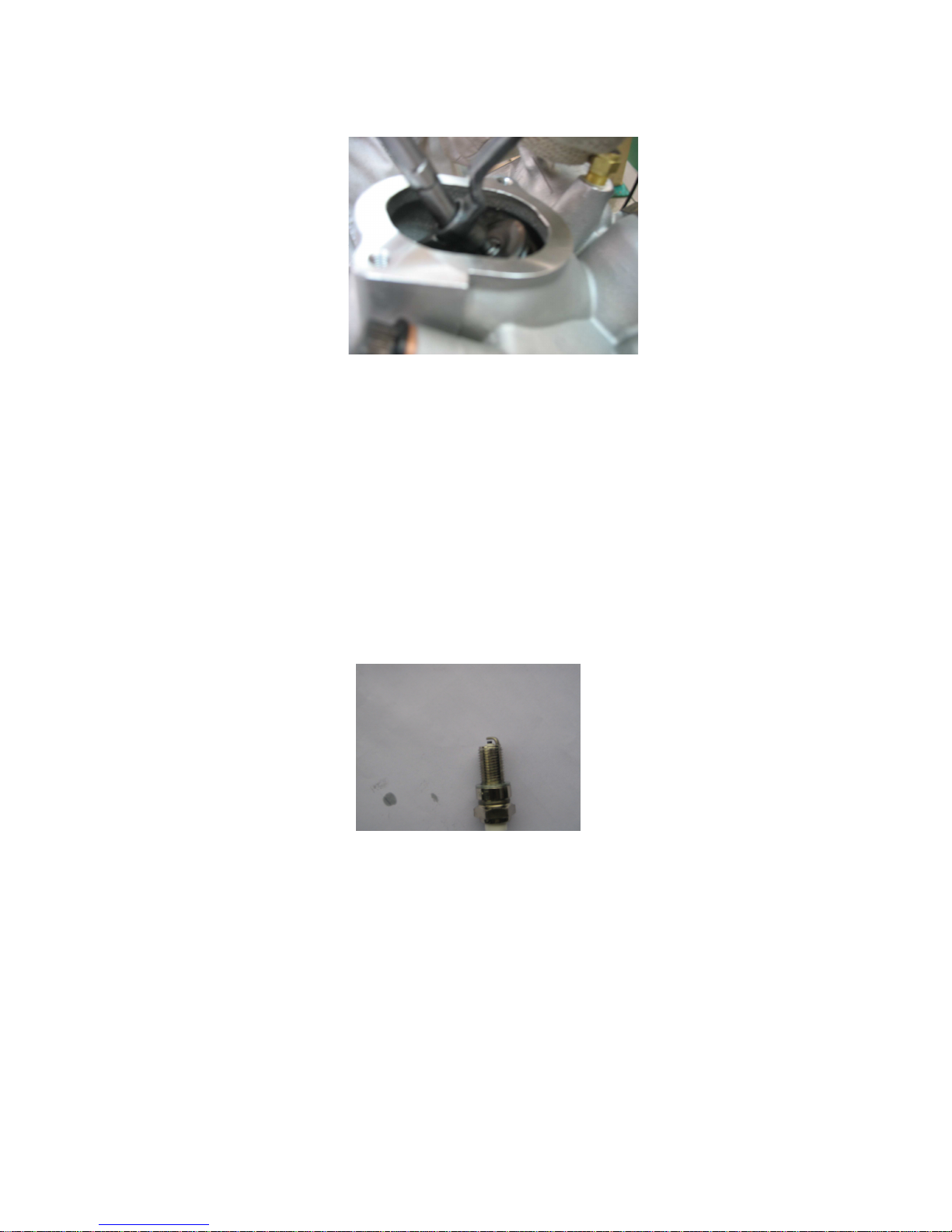

2.1.2 Spark Plug checking

1.Unplug the Spark-Plug cap:remove the spark plug by

spanner,look over whether the spark-plug insulator and

electrode is damaged or sooting. If so ,see figure 2-5.

Figure 2-5

1.

Check the spark clearance by feeler gauge whether it is

between 0.6~0.7mm.Or adjust the gap,clean incrustation with

spark-plug cleaner and steel wire brush and check if the spark

plug sealing washer(Figure 2-6).

15

Figure 2-6

3.Swirl the spark plug and tighten to 18 ~ 20N.m by

spanner ,then fix the spark plug cap when assembling.

2.1.3

cylinder,piston,piston ring

Specification

16

diagnosing and eliminating of malfunction:

●

Emission of black smoke for abrasion of cylinder or piston,

1. Cylinder , piston of piston ring is worn out.

2.The piston ring is not properly assembled.

3. The piston or cylinder wall is scraped.

●

●●

●

overhea

overheaoverhea

overheated

tedted

ted

1

Excessive incrustation of piston.

2 Blast and abnormal noise.

项目item

标准值 mm

standard value: mm

维修极限值 mm

limit value:mm

气缸内径 Inner

diameter of

cylinder

φ84.503~φ84.527

φ84.6

taper 0.0040 0.005

out of roundness 0.0035 0.005

cylinder

degree of warp 0.04 0.10

Outside diameter of piston φ84.47~φ84.45 φ84.35~φ84.25

Inner diameter of piston pin

hole

φ20.002~φ20.01

φ20.05~φ20.1

gap between piston pin and

piston pin hole

0.002~0.019 0.03

Piston ring

end

clearance

Top ring/the

second ring

0.2~0.4 0.5~0.7

oil ring 0.03~0.15 0.3~0.5

top ring 0.03~0.07 0.10~0.15

gap between

piston ring

and piston

groove second ring 0.02~0.06 0.09~0.14

gap between cylinder and

piston

0.033~0.062 0.07~0.10

Piston,piston

ring and

piston pin

outside diameter of piston

pin

φ19.991~φ20 φ19.95~φ19.97

Inner diameter φ 20.016 ~ φ

20.027

φ20.05

Crank shaft

Gap between small end of

connecting rod and piston

pin

φ0.018~φ0.036 0.05

17

3 Abrasion of cylinder or piston.

Inspection of cylinder.

1.Check whether the cylinder is damaged.

2.Measure the bore diameter of cylinder at three spots.

3.At the top,the middle and the bottom of the piston

stroke .And measure the bore diameter at directions of

right-angle intersection

repairing limit value:

out of roundness: 0.005 mm

taper :0.005mm

Inspection of piston and piston ring

1. Measure the gap between piston ring and piston groove.

2. The first ring

3. The second ring

Note:It is forbidden to damaging the piston ring when

assembling.Check whether the piston and the piston

groove is cracked and abraded

.See figure 2-9.

18

Figure 2-9

:0.5mm。

Insert piston ring into cylinder,and measure the end gap.

repairing limit value:the first ring/the second ring: 0.5mm

See figure 2-10 .

Figure 2-10

Measure the bore diameter of piston pin hole.

repairing limit value: see figure 2-11.

19

Figure 2-11

Measure the external diameter 10mm above the bottom of the

piston skirt.

Extreme position :the gap between cylinder and piston

repairing limit value: 0.1mm

See figure 2-12.

1、

Figure 2-12

7. Measure the external diameter of piston pin:

the gap between piston and piston pin:

0.02mm

repairing limit value: 0.02mm .See figure 2-13.

20

Figure 2-13

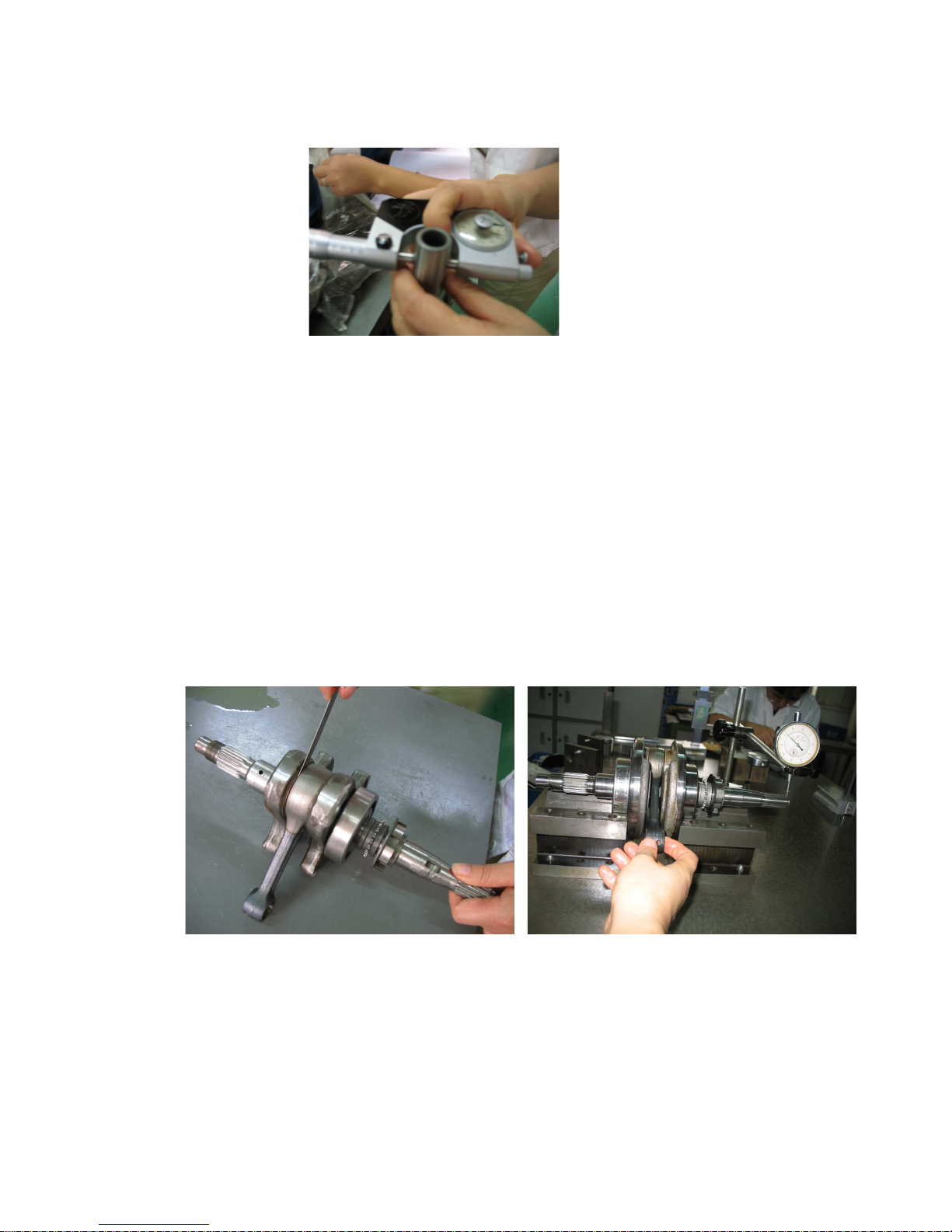

2.1.4 Inspection of crank and connecting rod

Check that whether crank and connecting rod can rotate without

stuck and whether the clearance between crank and connecting

rod is 0.5~0.6mm.The hop of crank shaft should be 0.05mm.If

not so,replace it. See figure 2-14-1, figure 2-14-2.

Figure 2-14-1 Figure 2-14-2

Table of contents

Other Hisun Offroad Vehicle manuals

Hisun

Hisun 700UTV User manual

Hisun

Hisun HS 400 User manual

Hisun

Hisun HS 400 User manual

Hisun

Hisun STRIKE 1000 User manual

Hisun

Hisun HS 500UTV-5/HS User manual

Hisun

Hisun HS 1000UTV User manual

Hisun

Hisun HS750ATV User manual

Hisun

Hisun HS 500 User manual

Hisun

Hisun HS 200UTV-2 User manual

Hisun

Hisun HS800UTV User manual