Elimination of waste material

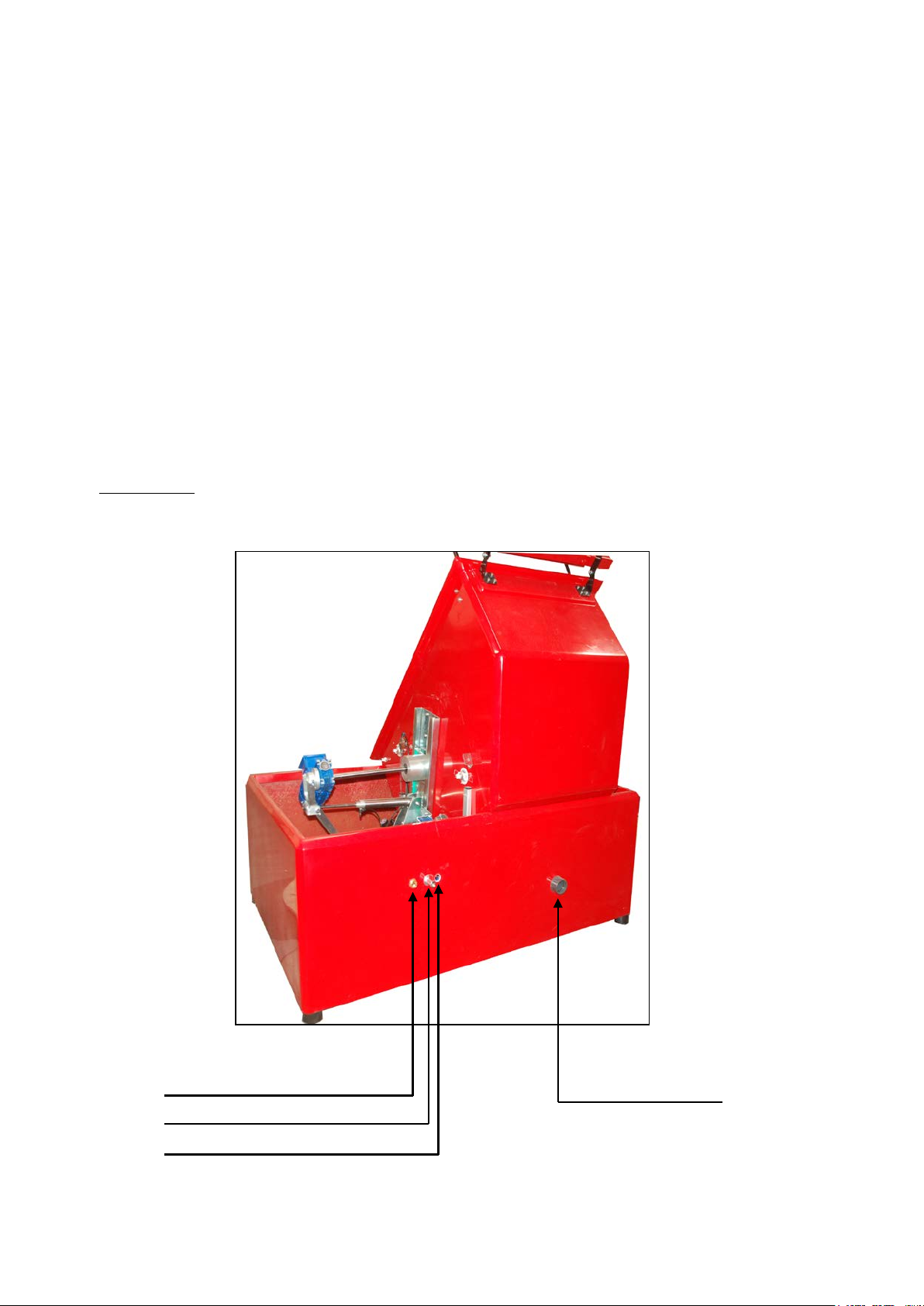

Packing of the new washing machine

-Eliminate the packaging materials of the new washing machine correctly. Remember that the packaging

material I not a toy for children!

-All the materials used in the packaging is recyclable and non-contaminating.

-The cardboard of the packaging is made with 80% - 100% used paper. The wooden parts have not been

treated chemically. The plastics are polyethylene (PE), the tapes are polypropylene (PP).

-All these materials are pure recyclable hydrocarbon combined.

-The preparation and recovery of the above-mentioned material represents a saving of raw materials and a

reduction in the volume of rubbish.

Put your old washing machine out of use:

-Extract the mains plug, cut the cable and remove it together with the plug.

-The old washing machine possesses valuable material that can be recovered. Be aware about what this

means for the Environment and ensure that the remains of the washing machine are eliminated or recycled in

a non-contaminating way.

-Ask for information from the local authorities to find out how best to eliminate the remains of the old machine.

Safety advice and warnings

ATTENTION. Simple safety precautions must be taken when using electrical machinery to reduce the risk of

electrical shocks and physical injury.

Before using the machine:

-Read the contents of the manual carefully, as this contain important information about the installation, use

and safety of the washing machine.

-Keep the manual and, if need be, hand them to any later owner of the machine.

-Install the washing machine following the instructions in the installation manual.

-Dismount the transport safety catches and keep them in a safe place.

-Never connect a machine that is visibly damaged. In case of doubt, consult your supplier or contact of our

technical help centres.

To transport the washing machine:

-Fit the transport safety catches.

-¡Be careful when transporting the washing machine, risk of injury!

-¡Do not lift the machine by the pieces that protrude!

Always connect it to a differential switch and automatic switch.

Keep your workstation tidy.

Untidiness in the workstation increases the danger of accidents.

Ensure that the workstation is well it.

Do not use electrical machinery in a damp or wet environment. Do not use

electrical machinery near inflammable liquids or gases.

7