IDEAL Concord CXC 48 User guide

2

Concord CXC - Installation

CAUTION.

To avoid the possibility of injury during the installation, servicing or cleaning of

this appliance, care should be taken when handling edges of sheet steel components.

3

Concord CXC - Installation

CONTENTS

Air Supply......................................................................... 9

Boiler Assembly - exploded view. ............................... 10

Boiler Clearances............................................................ 6

Burner Assemblies - exploded views. .............................

CXC 48-70................................................................. 28

CXC 94-116................................................................ 29

Casing Assembly. .......................................................... 13

Commissioning. ............................................................. 18

Condensate Drain Connection ..................................... 12

Controls. ........................................................................... 5

Electrical Connections. ................................................. 15

Electrical Supply. ........................................................... 10

Fault Finding. ................................................................. 33

Flue System. ..................................................................... 9

Gas Connections. .......................................................... 13

Gas Safety Regulations ................................................... 3

Gas Supply...................................................................... 10

Hydraulic Resistance....................................................... 6

Initial Lighting................................................................. 18

Installation. ..................................................................... 10

Mandatory Requirements. ............................................... 9

Option Kits........................................................................ 5

Pump. ................................................................................ 7

Servicing. ........................................................................ 25

Short List of Parts. ......................................................... 36

Static Head Requirements. ............................................. 7

Ventilation. ........................................................................ 9

Water Circulation. ............................................................ 7

Water Connections. ......................................................... 5

Water Treatment. .............................................................. 8

Wiring Diagrams. ........................................................... 16

INTRODUCTION

CONSTRUCTION

BOILER BODY

The Concord CXC boiler consists of 2 basic parts; a conventional

Concord CXD boiler; plus an additional heat exchanger.

The Concord CXC boiler body is constructed from cast iron

sections,insulatedby a foilbackedfibreglass blanket. It ismounted

on a sheet steel combustion chamber.

Analuminiumised mild steel flue collector hood andstainless steel

condensatesumpis fitted on top of this heat exchanger. The sump

supports the secondary heat exchanger which is constructed from

aluminiumfinnedtubesbetweenaluminium and cast iron headers.

This heat exchanger is also insulated by a foil backed fibre glass

blanket.

Above the primary heat exchanger an induced draught fan is fitted

- capable of overcoming the resistance of a 30m length of 6" flue

pipe. The boiler is supplied with header pipework between the

primary and secondary heat exchanger.

Within this pipework, a 'shunt' pump is provided to ensure an

adequate flow through the primary heat exchanger, independently

ofthesystempump.Thisalso ensures that a sufficienttemperature

is maintained in the primary heat exchanger to prevent corrosion.

CASING

The combined boiler bodies are enclosed in a white, stove

enamelled casing which incorporates a control panel fascia.

The casing is specially designed to ensure easy access for both

servicing and cleaning of both heat exchangers.

BURNERS

The 3 burners are of stainless steel construction.

Gas Safety (Installation and Use) Regulations, 1994,

amendments 1996 or rules in force.

It is the law that all gas appliances are installed and serviced by a

CORGI registered installer (identified by ) in accordance with

the above regulations. Failure to install appliances correctly could

lead to prosecution. It is in your own interest, and that of safety, to

ensure that the law is complied with.

The Concord CXC 48/116 range of boilers has been tested and

certified by British Gas to prEN656 for use with

Natural gas only.

Note.

The CXC 48

and CXC 70 boilers are intended for use as

COMMERCIALBOILERSandareNOTcertifiedfor use in domestic

applications. A domestic installation is defined as an installation

where the boiler takes its combustion air from a living space or

from a room directly or indirectly connected with the living space.

It is important, therefore, that no external control devices - e.g.

flue dampers, economisers etc., are directly connected to this

appliance unless covered by these Installation and Servicing

Instructions or otherwise recommended by

Caradon Plumbing

Limited

in writing. If in doubt please enquire.

Anydirectconnectionofacontrol device not approved by

Caradon

Plumbing Limited

could invalidate the British Gas Certification,

the normal appliance warranty and could also infringe the Gas

Safety Regulations. Table 1, Table 2 and the descriptive notes

which follow contain all the essential data likely to be required by

the installer.

Concord CXC 48-116 (Natural gas) B.G. Certified - P.I. No. 87/AQ/340 Destination Countries: GB and IE

4

Concord CXC - Installation

Boiler CXC 48 CXC 70 CXC 94 CXC 116

Number of sections 3 4 5 6

Flow tappings Rc (in. BSP) 2 (2) - 1 at rear

Return tappings Rc (in. BSP) 2 (2) - 1 at rear

Maximum static head metres (feet) 45.7 (150)

Maximum pressure bar (p.s.i.) 4.5 (65)

Gas inlet connection Rc (in. BSP) 3/4 (3/4) 1 (1 )

Minimum dynamic gas mbar

gauge

15.0 15.0 16.2 15.0

pressure required at the boiler inlet in.w.g. 6.0 6.0 6.5 6.0

Electricity supply 230 Volts- single phase, 50 Hz, fuse 5 A

Power Consumption Watts 96 96 96 96

Nominal flue size (to BS. 835) mm (in.) 152 (6) 152 (6) 152 (6) 152 (6)

Diverter outlet socket mm 154 154 154 154

internal diameter in 6 1/16 6 1/16 6 1/16 6 1/16

Length of burner bars (overall) mm 377 497 617 737

in 14.8 19.5 24.3 29.0

Approx. dry weight kg 298 350 442 494

lb 658 771 974 1090

Water contentm litre 28 36 43 51

gal 6.2 8.0 9.5 11.2

Gas type G20 I2H 20 mbar

Boiler CXC 48 CXC 70 CXC 94 CXC 116

Number of sections 3 4 4 5

Boiler output High Rate kW 48.83 69.84 93.65 116.25

Condensing Btu/h x 1000 166 600 238 300 319 500 396 600

Boiler output High Rate kW 44.63 63.84 85.6 106.3

Non-Condensing Btu/h x 1000 152 300 217 800 292 100 362 700

Boiler Input Gross kW 31.5 45.06 60.42 75

Low Rate Btu/h x 1000 107 500 153 700 206 200 255 900

Nett kW 28.4 40.6 54.44 67.58

Btu/h x 1000 96 900 138 500 185 800 230 600

Boiler Input Gross kW 52.5 75.1 100.7 125

Btu/h x 1000 179 100 256 200 343 600 426 500

High Rate Nett kW 47.3 67.67 90.73 112.6

Btu/h x 1000 161 400 230 900 309600 384 200

Gas rate m3/h 4.4 7.0 9.4 11.6

ft3/h 172 247 331 411

Approx. flue gas 8.0%

CO

2& 60°C. m3/sec 0.023 0.033 0.045 0.056

volume (non condensing)

High rate 8.0%

CO

2 & 140°F. ft.3m49 70 95 119

Manifold setting pressure mbar 3.9 3.9 3.8 4.1

Low Rate in.w.g. 1.6 1.6 1.5 1.6

Manifold setting pressure mbar 11.7 11.8 10.7 11.5

High Rate in.w.g. 4.7 4.7 4.3 4.6

Seasonal efficiency (SEDBUK)* [85.8]% [85.5]% [86.2]% [85.7]%

Electricity supply 230V, 50Hz, fuse 5A

Ignition 5 attempts followed by nonvolatile lockout.

Gas valve High/Low and Off

Gas safety time Maximum of 10 secs with 5 attempts with one min. between attempts.

Safety check The control de-energises every 4 hours to check internal control functions.

Pump Pump overrun operates if the flow temperature is greater than 75 oC.

Boiler thermostat The boiler thermostat hysteresis is a maximum of 3 oC.

Table 3 - Boiler Control specification Maximum Flow Temperature 85 oC

Table 2 - General Data

GENERAL

Table 1- Performance Data

Note.

To obtain gas consumption, divide gross heat input (kW) by a calorific value of 37.8 (MJ/m3)

*The value is used in the UK government's Standard Assessment Procedure (SAP) for energy rating of dwellings.

The test data from which it has been calculated have been certified by BGplc 0087.

5

Concord CXC - Installation

Boiler Size Cold Feed Open Vent

CXC 48 -70 3/4"1"

CXC 94 -116 1" 1 1/4"

Sealed system filling point - refer to Frame 8

GENERAL

GAS CONTROLS

The gas controls consist of a high / low arrangement with direct

burner ignition.

ELECTRICAL CONTROLS

WARNING

.

TheON/STANDBY [1/0] button doesNOTelectrically

isolate the boiler.

The Concord CXC range incorporates an advanced

microprocessor based control system which operates all electrical

functions of the boiler including for operation, ignition, flame

detection,thermostaticcontrol,andhigh/lowoperation.Inaddition,

the microprocessor has onboard servicing and commissioning

instructions and a fault diagnosis programme.

TheilluminatedLEDdisplaygivesacontinualread-outoftheboiler

status and functions, but in the (unlikely) event of a fault condition,

will display the fault areas.

Combustion products are drawn through the boiler by a fan and

air flow is proved by a pressure switch.

The burner flame is ignited by a spark generator.

Blockage of the condensate drain is protected against by a float

switch situated in the sump.

OPTION KITS

Pressure Gauge Kit: A pressure gauge is available for the range

of boilers. Details for fitting are included with the pressure gauge.

Remote Indication Board (volt free): This provides the ability

for remote indication of lockout and overheat conditions.

Outside Sensor: This kit provides a sensor for temperature

compensation when the outside temperature changes. Each

boiler needs to be individually switched on therefore a sensor is

required per boiler.

DUTY

The range of boilers is suitable for: Combined indirect pumped

domestic hot water

and

central heating systems; Independent

indirect pumped domestic hot water

or

central heating systems.

Fully pumped systems may be open vented or sealed.

Flow and return connections are 2" BSP.

Safety Valve

A safety valve must be sized and fitted in accordance with BS.

6644 for every type of system. The valve should be set at 0.7

bar (10 lb/in.2) above the operating pressure in the boiler. The

maximum safety valve setting is 0.7 bar (10 lb/in.2) above the

maximum design operating pressure of 4.5 bar (65 lb/in.2).

Cold Feed/Open Vent

The independent cold feed and the open vent must comply

with BS. 6644 and be of the following minimum size.

1

WATER CONNECTIONS

The range of boilers is NOT suitable for:

1. Gravity DHW systems.

2. Gravity heating systems.

3. Direct domestic hot water supply.

SYSTEM DESIGN

The water efficiency of this range of boilers is higher than

conventional boilers, at any water temperature, because of the

increased heat exchanger area.

Atreturntemperaturesof55°Candbelow, the differencesbecome

more marked because the water in the flue gases starts to

condense,releasing its latent heat. In general, the lower the return

temperature (down to its minimum temperature of 35 °C to protect

the primary heat exchanger) the better the boiler efficiency.

In new systems it is best to design for the lowest flow and return

temperaturesthatarepractical(subject to the lower limit mentioned

above). Of course, the lower the mean water temperature the

greater must be the heating surface area.

PERFORMANCE

The efficiency of the Concord CXC range of boilers is related to

the return water temperature of the boiler. This graph shows that,

in order to achieve maximum efficiency at any given load, the

system controls should be used in a manner which maintains the

lowestreturntemperaturecommensurate with systemperformance

Graph 1 - Boiler efficiency

6

Concord CXC - Installation

GENERAL

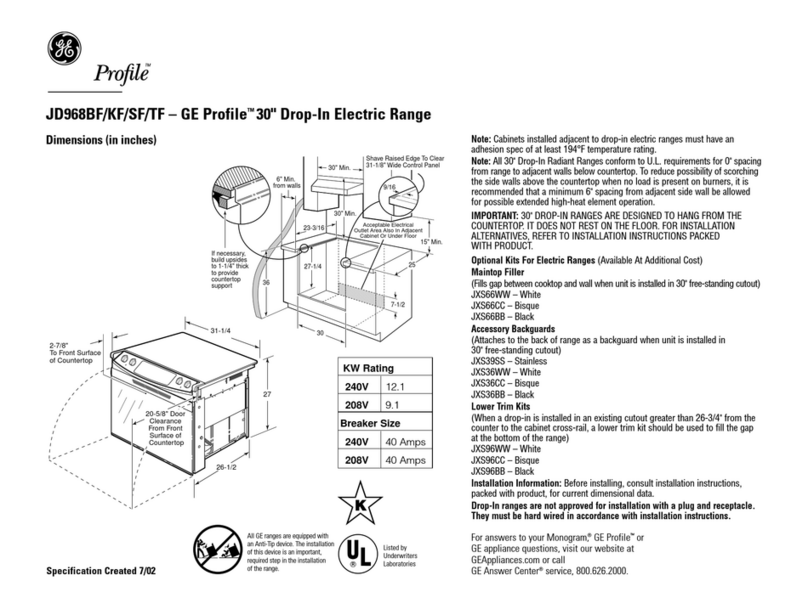

Rear clearance: sufficient clearance should be given

at the rear of the boiler for connection of gas and

water pipework.

*Additional clearance is required for access at either

end of the installation.

POSITION OF BOILER

Minimum clearances required

from walls or other fixed

objects to allow for the free

access of combustion air are

shown in Table 4 above.

However, for maintenance

purposes we suggest a

minimum rear clearance of

200mm.

Any combustible material

adjacent to the boiler and its

flue system must be so placed

or shielded as to ensure that

its temperature does not

exceed 65 oC (150 oF).

MULTIPLE BOILER INSTALLATIONS

The minimum installation clearances must conform to the

dimensions given below:

CXC 48 & 70

Clearance between boilers = 50mm

Clearance at both ends of the multiple installation = 50mm*

CXC 94 & 116

Clearance between boilers = 100mm

Clearance at both ends of the multiple installation = 100mm*

2

CLEARANCES & DIMENSIONS

Boiler Size CXC 48 CXC 70 CXC 94 CXC 116

Front clearance mm (in) 750 (29 1/2)

Rear clearance mm (in) 200 (8) see text

Side clearance mm (in) 50 (2) 50 (2) 50 (2) 100 (4)

Dimension Amm (in) 723(281/2) 846(33 5/16) 969(38 1/8) 1092(43)

Table 4

Graph 2 - Heat Load/ Water Volume Graph 3 - Hydraulic Resistance

7

Concord CXC - Installation

GENERAL

3

OPEN VENTED SYSTEMS - Minimum static head requirements

Note A.

This minimum height must be increased, if necessary, to

comply with the minimum head required by the pump

manufacturer in order to avoid cavitation.

Note B.

This diagram does not show safety valves, water flow

switches, etc., necessary for the safe operation of the

system.

Table 5 - Flow rates for fully pumped systems

Boiler Minimum flow rates for a

temperature difference of 35 oC (63 oF)

l/s g.p.m.

CXC 48 0.33 4.4

CXC 70 0.48 5.3

CXC 94 0.64 8.5

CXC 116 0.79 10.4

Particular reference should be made to BS. 6644: Section 2;

Subsection 10 and Guidance note PM5 "Automatically controlled

steam and hot water boilers" published by the Health and Safety

Executive.

The information and guidance given below is not intended to override

any requirements of either of the above publications or the

requirements of the local authority, gas or water undertakings.

Other British Standards applicable are BS.5422 and BS.6700.

The information provided is based on the following assumptions:

1. An independent open vent/safety pipe connection is made to the

redundant boiler flow tapping or is positioned immediately after

the system flow pipe connection to the header, as shown (C).

2. An independent cold feed/expansion pipe connection is made to

theredundantboilerreturntapping("D"). Cold feed/expansion pipe

connections made to the pumped system return will result in an

increase in the static head requirement, caused by the additional

resistance of the distributor tube. Surging may also increase.

3. The maximum flow rate through the boiler is based on a

temperature difference of 11°C at full boiler output and the

circulating pump is positioned in the flow to the system.

4. The boiler is at the highest point of circulation in the system.

Systems designed to rise above the boiler flow tappings will

automatically require a minimum static head higher than that

shown.

5. The position of the open vent/safety pipe above the expansion

cistern water level is given as a guide only ("B"). The final position

will depend upon the particular characteristics of the system.

Pumpingoverofwaterintotheexpansioncisternmustbeavoided.

and cost. Graph 1 is based on a 20°C temperature difference

across the boiler.

WATER CIRCULATION SYSTEM

Due to the compact nature of the boiler the heat stored within the

castings at the point of shutdown of the burner must be dissipated

into the water circuit in order to avoid the overheat thermostat

tripping. In order to allow pump operation after burner shutdown

the boiler control box incorporates a pump overrun facility which

operateswhentheboiler switches offanduntiltheflow temperature

is below 75 0C and, in order to make use of this, the pump must be

wired to the appropriate terminal L2(pump) in the boiler control

box.

1. The minimum flow rate as given in Table 5 must be maintained

whenevertheboiler isfiringandduring the pumpoverrunperiod.

2. Duringtheperiodof pump overrun there mustbeanopencircuit

of adequate water volume and/or load. The minimum size of

this circuit is given by the use of Graph 2.

Examples shown on Graph 2

a. For the CXC 116 the minimum circuit during pump overrun

could be a load of 6 kW with a volume of 31 litres or any

other combination given by the relevant line.

b. For the CXC 94 the minimum circuit during pump overrun

could be a load of 2 kW with a volume of 45 litres or any

other combination given by the relevant line.

The above circuit capacity during pump overrun may be

achieved either by provision of an adequate bypass circuit

or by ensuring that a zone of suitable size is open for

circulation during this period by relevant control of zone

valves or pumps.

The wiring diagrams in Frames 16, 17 and 18 illustrate

the control methods for achieving the above.

3. Pump selection should take account of the hydraulic

resistance given in Graph 3.

PUMP POSITIONS

Whenever practically possible the circulating pump(s) should be

positioned so that it pressurises the system being served. The

vertical distance between the pump(s) and any cold feed and

expansion cistern MUST comply with the pump manufacturers

requirements in order to avoid cavitation. These requirements

overridetheinformationgiveninFrame3ifthestaticheadrequired

for the pump(s) exceeds that required for the boiler.

8Concord CXC - Installation

4

SEALED (PRESSURISED) SYSTEMS automatic reset. In the event of shut down both visual and

audible alarms may be necessary.

Pressure vessels used must comply with BS. 4814 and must

be sized on the basis of the total system volume and initial

charge pressure.

Initial minimum charge pressure should not be less than 0.5

bar (7.2 psi) and must take account of static head and

specification of the pressurising equipment. The maximum

water temperatures permissible at the point of minimum

pressure in the system is specified in Guidance Note PM5.

When make up water is not provided automatically it will be

necessary to fit controls which shut down the plant in the event

of the maximum system pressure approaching to within 0.35

bar (5 psi) of safety valve setting.

Other British Standards applicable to commercial sealed

systems are:- BS. 6880: Part 2.

BS. 1212

BS. 6281: Part 1

BS. 6282: Part 1

BS. 6283: Part 4

GENERAL

the cold feed pipe that system water expands into the tank when

the boiler passes heat into the system. Conversely, when the

system cools, water previously expelled is drawn back from the

tank into the system, together with a quantity of dissolved oxygen.

Even if leakage from the heating and hot water system is

eliminated there will be evaporation losses from the surface of

the tank which, depending upon ambient temperature, may be

high enough to evaporate a large portion of the system water

capacity over a full heating season.

There will always be corrosion within a heating or hot water system

to a greater or lesser degree, irrespective of water characteristics,

unless the initial fill water from the mains is treated. Even the

water in closed systems will promote corrosion unless treated.

Aluminium Heat Exchanger

The secondary heat exchanger of the Concord CXC is made of

aluminium finned tube and so any water treatment must be

suitable for systems containing aluminium.

Under no circumstances should the boiler be fired before

the system has been thoroughly flushed.

Caradon Plumbing Limited recommend only the use of Fernox

or Betz Dearborn water treatment products, which must be used

in accordance with the manufacturers instructions. For further

information contact :-

Fernox Manufacturing. Co. Ltd, Tandem House, Marlowe Way,

Croydon, Surrey CRO 4XS, Tel 0870 5601 5000 or

Betz Dearborn Ltd, Widnes, Cheshire, Tel. 0151 424 5351

IMPORTANT: Any other treatment for this product will render

the guarantee of Caradon Plumbing Limited INVALID.

Notes.

1. If an inhibitor is used, and in hard water areas where treatment

to prevent lime deposits is necessary, it is most important that

the water treatment MUST be maintained at the correct

concentrations recommended by the treatment manufacturer.

Persons responsible for the continued operation of this boiler

should be made aware of this requirement.

If the boiler is installed in an existing system then any unsuitable

water additives MUST be thoroughly drained.

MINIMUM FLOW OF WATER - Refer to Table 5

The system design must provide for an adequate flow rate through

the boiler at all times when the boiler is firing. The minimum flow

rate should correspond to a temperature difference across the

boiler flow and return of 35 0C (63 0F), assessed at catalogue

rating.

It is essential that the main pump and shunt pump both overrun

to dissipate the residual heat in the primary heat exchanger. This

is done automatically if:

a. An unswitched live supply is connected to the boiler control

box (for details see 'Electrical Connections').

b. The shunt pump (prewired) and main pump are connected to

the boiler control box (for details see 'Electrical Connections').

c. Part of the system is available to the main pump when the

call for heat by external controls is satisfied.

The boiler produces condensate when the system return water

temperature falls below 55 °C (the Dew Point of the combustion

products).

This condensate must be led away by a condensate drain

connected to the steel pipe at the rear of the boiler and installed

in accordance with IM22 (see 'Condensate Drain').

WATER TREATMENT FOR HOT WATER AND

HEATING BOILERS

There is a basic need to treat the water contained in all heating and

indirect water systems, particularly open vented systems. It is

assumed, incorrectly, that because boilers are operating in

conjunction with what is apparently a closed circuit an open vented

system will not, under normal circumstances, allow damage or loss

of efficiency due to hardness salts and corrosion once the initial

charge of water has been heated up a few times.

1mm of lime reduces the heat transfer from metal to water by 10%.

In practice the deposition of these salts is liable to cause noises

from the boiler body or even premature boiler failure. Corrosion and

the formation of black iron oxide sludge will ultimately result in

premature radiator failure.

Open vented systems are not completely sealed from the atmosphere

if proper venting and expansion of system water is to be achieved.

The same tank is used to fill the system with water and it is through

Working pressure 4.5 bar maximum.

Particular reference should be made to BS. 6644: Section 6

and Guidance note PM5 "Automatically controlled steam and

hot water boilers" published by the Health and Safety Executive.

The information and guidance given below is not intended to

override any requirements of either of the above publications or

the requirements of the local authority, gas or water undertakings.

In general, commercial closed pressurised systems are provided

with either manual or automatic water make up.

On both instances it will be necessary to fit automatic controls

intended to protect the boiler, circulating system and ancillary

equipment by shutting down the boiler plant if a potentially

hazardous situation should arise.

Examples of such situations are low water level and operating

pressure or excessive pressure within the system. Depending

on circumstances, controls will need to be either manual or

138423-7.pmd 11/7/2005, 9:48 AM8

9

Concord CXC - Installation

GENERAL

capacity to support the weight of the boiler (when filled with water)

and any ancillary equipment.

If the boiler is mounted on a plinth then the dimensions must exceed

the plan area of the boiler by at least 75mm on each side.

VENTILATION

Safe, efficient and trouble-free operation of conventionally flued

gas boilers is vitally dependent on the provision of an adequate

supply of fresh air to the room in which the appliance is installed.

Ventilation by grilles communicating directly with the outside air is

required at both high and low levels. The minimum free areas of

these grilles must be according to the scale in Table 6.

Position ventilation grilles to avoid the risk of accidental obstruction

by blockage or flooding. If further guidance on ventilation is required

then consult BS.6644.

AIR SUPPLY BY MECHANICAL VENTILATION

The supply of air by mechanical means to a space housing the

boiler should be by mechanical inlet with natural or mechanical

extraction. Mechanical extract ventilation with natural inlet must

not be used.

Where a mechanical inlet and a mechanical extract system is

applied, the design ventilation flow rates should be as in Table 4 of

BS.6644.

The requirements for air supply by mechanical ventilation are given

in BS.6644.

Note. For mechanical ventilation systems an automatic control

should be provided to cause safety shutdown or lockout of the

boiler(s) in the event of failure of air flow in either inlet or extract

fans.

IMPORTANT. The use of an extractor fan in the same room as the

boiler (or in an adjacent, communicating room) can, in certain

conditions, adversely affect the safe operation of the boiler. Where

such a fan is already fitted (or if it is intended to fit an extractor fan

after installation of the appliance) the advice of the gas supplier

should be obtained.

FLUE SYSTEM DESIGN

The Concord CXC condensing boiler is supplied with an integral

fan which is fully matched to the boiler in each case to provide

correct combustion air flow.

The power of this fan is such that there is a large reserve of pressure

available to overcome a significant length of the flue without

affecting the combustion performance of the boiler. The pressure

available at the base of the flue to overcome flue resistance is

0.25 mbar (0.1 w.g.) This is sufficient to overcome the resistance

of approximately 30 metres of 150mm diameter smooth, straight

flue pipe.

Material

The type of flue pipe used should conform BS.715: Section 2

Stainless Steel or be of equivalent corrosion resistance. Advice

regarding the availability of proprietary types of flue system can

be obtained by contacting Caradon Plumbing Ltd. All joints or

connections in the flue system must be impervious to condensate

leakage and also any low points in the flue system should be

drained using pipe of material resistant to condensate corrosion.

Care should also be taken in the selection of flue terminals as

these tend to accentuate the formation of a plume.

Care should be taken to ensure the specification of the chimney is

suitable for the application by reference to the manufacturers

literature. Caradon Plumbing Ltd can offer advice on the design

of suitable chimney systems.

INSTALLATION REQUIREMENTS

The appliance must be installed by a CORGI registered installer,

identified by . The installation of the boiler must be in accordance

with the relevant requirements of the Gas Safety Regulations, current

IEE (BS.7671) Regulations, Model Water Bye-laws, local water

authority bye-laws and it should also comply with any relevant

requirements of the local gas supplier, local authority and the relevant

British Standard Codes of practice and building regulations.

Limitations of Intended Operating Environment

These appliances are NOT suitable for installation where they will

be exposed to the elements.

A boiler room shall be constructed or adapted to meet the

requirements of BS. 6644.

The maximum ambient temperature is 32° C at 1.5 metres from

the floor, with a maximum humidity of 90% RH.

FOR SMALL PIPE INSTALLATIONS:

BS. 6891: Installation of low pressure pipework

FOR LARGE PIPE INSTALLATIONS

Gas Installations

IGE-UP-1: Purging Procedures of Non-domestic Gas

Installations. Soundness Testing Procedures

for Industrial and Commercial.

IGE-UP-2: Guidance notes on the Installation of Gas

Pipework, Boosters and Compressors in

Customer’s Premises Equal to or Greater

than 25mm (Non-domestic).

IGE-UP-10: Installation of Gas Appliances in Industrial and

Commercial Premises.

BS.6644: Installation of Gas Fired Hot Water Boilers

70kW to 1.8MW (net).

BS 6880 Pt 1-3: Control Heating by Low Pressure Hot Water.

CP342:2: Centralised Hot Water Supply.

Model Water Bye-laws

Manufacturers notes must not be taken, in any way, as

overriding statutory obligations.

The appliance must be installed in a room separated from living

rooms and provided with appropriate ventilation direct to the outside

- see Table 6.

2. Artificially softened water must not be used in the system, under

any circumstances.

3. In all systems the fitting of a filter to the return pipework, in order

to prevent debris reaching the heat exchanger, is essential.

FOUNDATION

The boiler must stand on a non-combustible floor (i.e. concrete

or brick) which must be flat, level and of a suitable load bearing

Table 6 - Ventilation Requirements

Required area (cm2) per kW of total rated input (net)

Boiler room Enclosure

Low level (inlet) 4 10

High level (outlet) 2 5

Note: Where a boiler installation is to operate in summer

months (e.g. DHW) additional ventilation requirements

are stated, if operating for more than 50% of time (refer

to BS6644).

138423-7.pmd 11/7/2005, 9:48 AM9

10

Concord CXC - Installation

CONDENSATE DRAIN

The Concord CXC boiler will produce condensate whenever the

temperature of the return water from the system is below

approximately 55 oC(theDewPoint of the combustion products).

Natural gas condensate is mildly acidic with a pH value of about

4 and therefore corrosion resistant materials must be used in the

construction of the condensate drain. Standard PVC pipe is

suitable for this purpose and should be connected to the steel

drain fitted on the boiler.

GAS SUPPLY

If there is any doubt regarding the capacity of the gas meter, the

available gas pressure, the adequacy of existing service pipes

or the size required for new service pipes then the advice of the

gas supplier should be requested. Installation pipework should

INSTALLATION

INSTALLATION

be fitted and tested for gas soundness in accordance with BS.

6891 for small installations or IGE-UP-1 and IGE-UP-2 for large

installations.

Thelocalgassupplier must be consultedifitisnecessary to employ

a gas pressure booster.

ELECTRICAL SUPPLY

WARNING.

This appliance must be efficiently earthed.

A 230 V ~ 50 Hz mains supply is required, fused at 5 amps.

Wiring external to the appliance MUST be in accordance with the

I.E.E. (BS. 7671) Wiring Regulations and any local regulations

which apply.

For details of connections see Frame 14.

5

CONCORD CXC BOILER ASSEMBLY - Exploded view

6. Float switch

7. Shunt pump.

8. End section.

Legend

1. Collector hood

2. Cleanout cover

3. Fan

4. Secondary heat exchanger

5. Air pressure switch.

9. Middle section.

10.Tie rods.

11. Base plate.

12.Combustion chamber.

13.Section bolt.

14.Front plate.

15.NOx duct.

16.Drain cock.

17.Burner manifold assy.

18.Gas cock.

19.Flueway baffles.

20.Thermostat pocket.

11

Concord CXC - Installation

1. Remove the jacket carton and outer packaging frame.

2. Remove the jacket pack support frame.

3. Remove the controls package and installation pack.

4. Remove the 2" BSP steel handling bars from installation

pack.

5. Remove 4 base bolts holding the assembly to the

packaging base.

6. Remove the wood screws securing the front cross

member on the packaging base.

7. Remove the gas cock by unscrewing the union and screw

in the handling bars into the 2 front tappings. Protect the

exposed inlet gas union from ingress of dirt.

8. Knock out front spacing blocks from the packaging base,

ensuring that the boiler assembly is supported, using 2"

BSP handling bars.

9. Using the handling bars, manoeuvre boiler forwards on the

packaging base and slide over the collapsing base on to

the floor.

Note.

Before manoeuvring the boiler into its final position see

Frame

8.

INSTALLATION

INSTALLATION

6

PACKAGING

The Concord CXC boiler is despatched from the factory fully

assembled except for the casing, controls and installation

packs which are packed separately within the same wooden

crate as the boiler.

JACKET PACK contains

!Lower front panel ................. 1 off

!Upper front panel ................ 1 off.

!Lower LH side panel ........... 1 off.

!Lower RH side panel........... 1 off.

!Upper LH side panel ........... 1 off.

!Upper RH side panel........... 1 off.

!Lower top panel .................. 1 off.

!Upper top panel .................. 1 off.

!Infill panel............................ 1 off.

!Support bracket................... 2 off.

!Flue brush ........................... 1 off.

!Jacket hardware pack ......... 1 off.

!Lower rear panel ................. 1 off.

!Upper rear panel ................. 1 off.

!Upper middle rear panel ..... 1 off.

!Lower middle rear panel ..... 1 off.

CONTROLS PACK contains

!Controls box complete ....... 1 off

!Controls installation pack ... 1 off

INSTALLATION PACK contains

!R2 sq. hd. plug .................................... 3 off.

!R2 installation pipe.............................. 2 off.

!Installation & Servicing Instructions .... 1 off.

!Users instructions ............................... 1 off.

!System warning label ......................... 2 off.

7

PACKAGING AND BOILER REMOVAL

12

Concord CXC - Installation

Manoeuvring the boiler

1. Remove the gas cock to access the LHS tapping.

2. Screw the 2 handling bars (2" pipe supplied) into the 2

top tappings.

3. Screw in 2 bars (not supplied), 1 into the LH rear top

tapping and the second into the tee at the RH top

tapping.

4. Use these bars to manoeuvre the boiler into position.

5. Complete the system connections, using suitable

jointing compound, as follows:

a. The flow connection must be made to the upper

tapping on the primary heat exchanger.

10

FLUE CONNECTION

The 150mm (6") flue should conform to BS.715: Section 2

Stainless Steel or be of equivalent corrosion resistance.

The flue must be designed to have no greater resistance

than that of 30m of straight, smooth 150mm (6") pipe.

All joints must be impervious to condensate leakage.

The condensate drain must be 1 1/4" diameter PVC pipe

from the pre-fitted drain at the rear of the boiler.

The condensate drain may be led directly into the normal

drainage system. The pipe should be installed with an

adequate slope (e.g. 1 in 50) and consideration should be

given to frost protection.

The drain should be in accordance with IM 22.

Connections to BS.5355 can be used directly, or

connections to BS.5354 may be used with a suitable

adaptor.

Note.

A condensate trap is built into the boiler sump therefore an

external trap is not necessary.

b. The return connection must be made to the upper

tapping on the secondary heat exchanger.

c. Complete the water connections by plugging the 2

front top and 1 rear top tappings with the 2" BSP

plugs provided. The remaining 1" lower tapping

should be plugged if not used for cold feed on an

open vent system or connection of a pressure

vessel, if on a sealed system.

3. Position the overheat thermostat phial into the LH side

thermostat pocket.

The illustration shows the rear of the boiler with the

flow and relative overheat thermostat position.

Ensure that the overheat thermostat phial is correctly

secured in the pocket. Refer to Frame 13.

8

BOILER ASSEMBLY AND SYSTEM CONNECTIONS

INSTALLATION

INSTALLATION

9

CONDENSATE DRAIN CONNECTION

13

Concord CXC - Installation

11

GAS CONNECTION

1. Refit the gas cock.

2. Connect the gas supply to the gas pipe elbow.

The gas pipe should enter the boiler at the top LH side of

the boiler.

3. Table 2 gives details of the inlet connection size and the

minimum working pressures.

5. Fit clips to the top of each side panel.

6. Fit the spire clips to the side casing panels.

7. Hook on the control box to side panels.

8. Screw in self tapping screws at the bottom of the

control box to fix it to the side panels.

Push in the mains plug into the socket at the back

of the control box.

Unpack the control box from its carton and find the mains plug

strapped to the back of the box.

The boiler casing should now be fitted.

The jacket hardware pack contains all the screws required for assembly.

1. Fit support angles to the

collector hood and sump. The

angle with the hole for the

earth screw fits to the front.

Ensuretherear support angle

is fitted as shown.

2. Wire up the mains input cable

to the plug provided.

Runthiscablealongthelower

clips (using the cable ties in the hardware pack) of the LH side panel with

the plug placed at the front.

3. Slide bottom of lower side panels on to studs on base tray.

4. Screw lower side panel to support angles.

Repeat for other side.

INSTALLATION

INSTALLATION

12

CASING ASSEMBLY

14

Concord CXC - Installation

10.Ensure that the Heyco bush is correctly located

and that the top of the bush is at the marked line.

Route the cables from the temperature probe, air

pressure switch and float switch through the clips

on the RH side panel.

Neatly coil up any excess length of cable and

push in the plug-in connector into the connection

box.

11. Hook the upper side panel into the keyhole slot.

12.Fix the upper side panel in position.

One screw into the lower side panel, one screw

into the upper support angle.

Repeat for the other side.

13.Clip in the upper top panel.

Fit the infill panel around the flue and secure

underneath top panel with the 2 self tapping

screws provided.

14.Fit earth leads as

shown.

9. Route the overheat thermostat capillary through the cable clips as

shown.

Ensure the phial is correctly seated in the correct pocket opposite

side to the flow connection - refer to Frame 8.

Secure with the split pin provided.

Complete the following after reaching Frame 32

15.Fit the lower top panel.

Fit the lower front panel.

16.The upper front panel has 2 hooks at the bottom.

Drop in these 2 hooks behind the back edge of the

lower top panel, push home onto the 4 catches and

secure with the top screw.

17.Fit rear panels in the sequence shown. Do NOT

tighten the screws until all panels are fitted.

Fit No.1 panel with the top 2 screws only.

Fit No.2 panel with the bottom 2 screws only.

Fit No.3 panel with the 4 screws engaging panels 1 and 2.

Fit No.4 panel with the 4 screws.

Align all panels and tighten all screws.

13

CASING ASSEMBLY - continued

INSTALLATION

INSTALLATION

15

Concord CXC - Installation

14

ELECTRICAL CONNECTIONS

WARNING.

This boiler must be efficiently earthed.

The internal wiring of the boiler control box is shown in Frame

15.

Connection must be made in a way that allows complete

isolationof the electrical supply - such as adoublepole switch,

having a 3mm (1/8") contact separation in both poles, or a

plug and socket serving only the boiler and system controls.

The means of isolation must be accessible to the user after

installation.

This should serve only the boiler, together with its controls and

pumps. The supply must be wired direct to the boiler control

box and must not be interrupted by any system controls. The

pump(s) and any system controls must be wired back to the

boiler control box.

The control box incorporates a pump overrun device which is

necessary to dissipate residual heat after plant shutdown. It is

essential that the main pump is wired to the pump terminals

marked L2, N on the plug-in mains voltage connector shown

below and in Frame 15.

If no external controls are fitted it is essential that a link is

wired in place of one on the "Fan/pump plug-in connector".

The flow switch should be connected via volt-free contacts to

the 'Flow S' terminals. A link may be fitted in place of the flow

switch but the control will not be able to analyse the faulty flow

switch, if such a failure should occur. Either of the above must

be fitted or the boiler will not operate.

Anysystemcontrols should beconnected,viavolt free contacts,

totheterminalsmarked'EXTC'.Do NOT connect an external

clock to these contacts or any mains voltage. If no external

controls are fitted a link must be fitted across EXT C.

The boiler provides frost protection via the boiler sensor. If an

external frost thermostat is required contact Caradon

Plumbing Limited.

Wiring should be PVC insulated cable, not less than 0.75mm2

(24/0.2mm). All fuses must be ASTA approved to BS. 1362.

The length of the conductors between the cord anchorage

and the terminals must be such that the current conductors

become taut before the earthing conductor, if the cable or

cord slips out of the cord anchorage.

BOILER CONNECTIONS

Ensure the boiler is ELECTRICALLY ISOLATED.

The live supply cable should be fitted before assembly of the

jacket - see Frame 12 for details.

All wiring between entry at the rear of the boiler and the

connection box must be secured neatly under the cable

clips provided.

Wiring must never be allowed to come into contact with

any heated surfaces.

1. Checkthatthe mains plug is pushed firmly into its socket.

2. Check that the temperature/float/air pressure plug-in

connector is fitted into the RH connection box.

3. Carefully route the electrical leads from the gas valve/

spark generator behind the LH panel return and secure

with the clip as shown.

Fit this plug-in connector into the bottom connection

box.

4. Route the fan and shunt pump cables through the clips

at the top of the LH side panel.

5. Wire the main system pump (L2 & N), flow switch and

external controls into the Fan/pump plug-in connector

(see below). The earth wires should be looped back

through the cable clamps and fixed to the earth post as

shown in Frame 13.

The earth connections MUST NEVER be omitted.

6. Fit the fan/pump plug-in connector into the mains voltage

connection box behind the control box.

INSTALLATION

INSTALLATION

16

Concord CXC - Installation

16

ZONES WITH BI-DIRECTIONAL MOTORISED VALVES

IMPORTANT

Terminal L2 may control the appropriate

pump(s) directly, provided that the total

running or starting current does not

exceed 6A (resistive or inductive): if this

rating would be exceeded, then

appropriate switchgear must be used to

control the pumps indirectly.

Three zones are illustrated but the

principles may be extended as required,

provided the above conditions are met.

Each relay will then require as many

contacts as there are zones.

Overrun

Since any zone may be the load during

overrun, all zones MUST individually be

able to satisfy the conditions in the

foregoing paragraph. If not all zones can

do this, then consider other means of

control detailed on other sheets.

Normal operation

When any thermostat is satisfied while

others are calling for heat, power is

15

INTERNAL WIRING

At the start of the next call for heat (or the next clock period)

valves on the zones not calling for heat will motor-shut.

Water circulation system - refer to page 7

LEGEND vviolet

pk pink

y/gyellow/green

or orange

yyellow

wwhite

br brown

rred

bblue

bk black

INSTALLATION

INSTALLATION

available via relay contacts to close the valve for that zone.

When all thermostats are satisfied (also when the clock period

ends) all relays will be off so the zone valves which were open

will remain open for the pump overrun period.

17

Concord CXC - Installation

IMPORTANT

Terminal L2 may control the appropriate

pump(s) directly, provided that the total

running or starting current does not exceed

6A (resistive or inductive): if this rating would

be exceeded then appropriate switchgear

must be used to control the pumps indirectly.

Three zones are illustrated but the principles

may be extended as required, provided the

above conditions are met. Only one relay is

required, irrespective of the number of zones.

Overrun

During overrun and dormant periods, Zone

Valve 1 is held open. This zone, therefore,

MUST satisfy the conditions in the foregoing

paragraphs and Graph 2.

Normal operation

During a call for heat on Zone 1 only, the

boiler is energised via Zone 1 thermostat and

the normally closed contacts of the relay.

During a call for heat on other zone(s), the

relay will be energised by the auxiliary switch

on the zone valves. This provides power to

energise the boiler. If, in addition, Zone 1 now

calls for heat, its thermostat will open Zone 1

valve via the normally open contacts of the

relay.

17

ZONES WITH INDIVIDUALLY PUMPED ZONES (3 zones shown)

IMPORTANT

Terminal L2 may control the appropriate

pump(s) directly, provided that the total running

or starting current does not exceed 6A (resistive

or inductive): if this rating would be exceeded

then appropriate switchgear must be used to

control the pumps indirectly.

Three zones are illustrated but the principles

may be extended as required, provided the

above conditions are met. For each zone

(except Zone 1) a relay with 2 C/O contacts is

required.

Overrun

During overrun periods, Zone 1 pump performs

the overrun facility; this zone, therefore, must

satisfy the conditions in the foregoing

paragraphs and Graph 2.

Normal operation

During a call for heat on Zone 1 only, Zone 1

thermostat energises the boiler, which in turn

energises Zone 1 pump from terminal L2.

During a call for heat on other zones, the

appropriate relay directs power to L1 to

energise the boiler, at the same time ensuring

that Zone 1 pump is controlled by Zone 1

thermostat.

Water circulation system - refer to page 7

When the clock period ends, Zone valve 1 will (stay) open via normally

closed relay contacts to achieve pump overrun.

Water circulation system - refer to page 7

INSTALLATION

INSTALLATION

18

ZONES WITH SPRING-RETURN MOTORISED VALVES

18

Concord CXC - Installation

19

COMMISSIONING AND TESTING

GENERAL

Check that all drain cocks are closed, that any stop valves

fitted to the flow and return pipes are open and that the

system has been filled and properly vented. Ensure that the

caps on both secondary heat exchanger automatic air vents

are open.

Check that the shunt pump is set to maximum and that both

isolation valves are open.

PURGING

Check that the electricity supply is switched OFF.

Remove the jacket lower front panel.

Extinguish all naked lights and open all doors and windows.

The Concord CXC incorporates an advanced

microprocessor based control system which

operates all electrical functions of the boiler

including automatic ignition, flame detection,

thermostatic control, and high/low burner

operation. In addition, the microprocessor also

has onboard commissioning and servicing

instructions and a fault diagnosis programme.

The next section describes the minimum

procedure to light and commission the boiler. Full

operating instructions for the microprocessor

control and details of the high/low operation

system are included in Frames 27-30.

1. Check that the gas and electricity supplies to the boiler are

turned off.

2. Connect a gas pressure gauge to the inlet pressure test

point. (Frame 23 or 24).

3. Turn on the gas and electricity supplies. The display will

initially show a start-up code followed by;

4. Press the [1/0] button The display will change to:

then change every few seconds to indicate the boiler

status. The boiler will commence its ignition sequence.

5. The fan will start and the boiler should light, initially at low

rate, for a maximum period of 3 minutes, if less than 55°C,

before proceeding to maximum rate. If the boiler fails to

light, allow the controls to cycle until ignition is established.

If the boiler fails to light after 5 attempts, the display will

show "Detection Fault". In this case, the ignition sequence

should be reset by pressing the [COPY] button. Check that

the gas inlet pressure is at least the minimum value stated

in Table 2 when the boiler is firing at maximum rate (High).

6. Whilst the boiler is warming up, observe the display to

become familiar with its operation. The display changes

automatically between the:

"Boiler status and flow temperature

"Hours run

"Temp set

"Programmer status

"Enter for menu

"Day

"Date and time

Note.

As the boiler flow temperature approaches the

thermostat setting, the boiler is automatically reduced to low

rate.

This feature is designed to improve overall operating efficiency

and reduce short cycling under low load conditions. The

controls will automatically switch the boiler between high and

low upon demand.

21

LIGHTING INSTRUCTIONS

INSTALLATION

INSTALLATION

20

INITIAL LIGHTING

DO NOT SMOKE. Check that the gas supply is turned ON at

the meter and open the main gas inlet cock. Loosen the union

and allow air to be purged from the gas line until gas is

smelled. Refer to BS 6891 or IGE-UP-1 for further details.

Retighten the union.

TESTING FOR GAS SOUNDNESS

Close the gas supply cock at the meter.

Remove the screw in the inlet pressure test point (Frames 23/

24) and connect a gas pressure gauge to the test point. Take

particular care to ensure a gastight connection. Open the gas

supply cock at the meter and the appliance gas cock; record

the static pressure. Next, close the gas supply cock at the

meter. Wait for 1 minute for temperature stabilisation then

observe the pressure gauge over a period of 2 minutes.

Any leaks must be cured.

Replace all pressure test point screws.

19

Concord CXC - Installation

22

CHECKING THE MANIFOLD PRESSURES

23

ADJUSTING THE MANIFOLD PRESSURES

5. Press the [0/1] button to turn the appliance off, then

disconnect the high/low solenoid connector plug (10)

from the gas valve. Turn the appliance on and repeat the

above sequence but using the low rate adjustment screw

(6) inside the spindle.

6. Turn the appliance off, reconnect the high/low solenoid

plug, refit the dust cover over the adjustment screws and

refit both pressure test point screws. Check for gas

soundness.

7. Press [EXIT] to leave the commissioning mode and

return to the main menu.

8. Press [EXIT] again to return to the status displays.

1. Press the [ENTER] button on the fascia panel, then press

either the [UP] or [DOWN] arrow button until the display

shows:

then press [ENTER]. The microprocessor is now in

commissioning mode. Failure to enter the Commissioning

mode will result in a fault condition being detected when

the following actions are carried out.

2. If desired, it is possible to use the onboard commissioning

instructions, using the [UP] / [DOWN] arrow buttons.

However the following paragraphs provide more detailed

instructions and are recommended until the installer is

familiar with the Concord CXC.

3. It is essential to adjust the maximum setting first.

4. Adjust the system controls to ensure that the boiler will

operate at high rate for a reasonable period, then remove

the dust cover and adjust the high rate burner pressure

setting, using a suitable spanner. Turn the maximum

adjuster (7) clockwise to increase, or anticlockwise to

decrease, the pressure. After setting to the indicated

pressure allow the boiler to operate for about 5 minutes to

stabilise then recheck the burner pressure.

CXC 48 & 70 ONLY

6. Screw - minimum adjuster.

7. Gas rate adjuster - maximum.

8. Burner setting pressure test

point.

9. Inlet pressure test point.

10.High/low solenoid connector.

LEGEND

1. Fascia panel display.

2. Overheat thermostat

reset button.

3. Main gas inlet cock.

4. Union.

5. Gas control valve.

Turn the boiler OFF by pressing the [0/1] button and allow the

flow temperature to cool to less than 50°C.

Connect a pressure gauge to the burner manifold test point

(Frame 23 or 24). Press the [0/1] button again to turn the boiler

ON.

The boiler will operate at low rate for approximately 3 minutes

before proceeding to high rate (this will only happen if the flow

temperature is below 55 0C otherwise the boiler will proceed

immediately to high rate).

Observe the burner pressures and compare them to the

values given in Table 1. If either pressure differs by more than

10%, reset the pressures by following the procedure in Frame

23 or 24.

INSTALLATION

INSTALLATION

20

Concord CXC - Installation

24

ADJUSTING THE MANIFOLD PRESSURES

1. Press the [ENTER] button on the fascia panel, then press

either the up or down arrow button until the display shows:

then press [ENTER]. The microprocessor is now in

commissioning mode. Failure to enter the commissioning

mode will result in a fault condition being detected when

the following actions are carried out.

2. If desired, it is possible to use the onboard commissioning

instructions using the up/down arrow buttons. However the

following paragraphs provide more detailed instructions

and are recommended until the installer is familiar with the

Concord CXC.

3. It is ESSENTIAL to adjust the LOW setting first.

4. Press the [0/1] button to turn the appliance OFF, then

disconnect the power leads from the right hand (HIGH)

gas valve.

LEGEND

1. Fascia panel display.

2. Overheat thermostat reset button.

3. Main gas inlet cock.

4. Union.

5. Gas control valve low rate.

6. Gas control valve high rate.

7. Low rate adjusting screw.

8. High rate adjusting screw.

9. Burner setting pressure test point.

10.Inlet pressure test point.

11. RH (high) gas valve power

connector.

The Concord CXC features direct burner ignition, high/low

burner operation, and a microprocessor control system.

Upon a demand for heat, the controls start the fan, the air

pressure switch senses flow then the controls open the low

rate gas valve and provides a rapid spark at the ignition

electrode for up to 10 seconds.

The burner will light and remain at low rate for approximately 3

minutes before proceeding to high rate (when the

microprocessor opens the remaining gas valve).

If the boiler fails to light, the gas valve is closed and there will

be a delay of 1 minute before the cycle is repeated. If, after 5

attempts, the burner has failed to light, the boiler will go to

lockout and

will be displayed on the screen.

When the boiler flow temperature reaches the thermostat set

point, the controls will turn the burner to low rate. If the flow

temperature continues to rise, the burner and fan will be

turned off at 3 oC above the set point.

If, however, the temperature falls below the set point whilst on

low fire, the controls will automatically turn the burner back up

to maximum rate.

This system has the advantages of ensuring that the boiler

accurately maintains the set temperature (without the large

temperature swings that can be associated with on/off

boilers), prevents rapid or short cycling, and provides more

efficient system operation.

CXC 94 & 116 ONLY 5. Press the [0/1] button again to light the burner. Allow the

burner to run at low rate for several minutes then check

that the low burner pressure is as shown in Table 1 for

the appropriate boiler size. If necessary, adjust the low

burner pressure adjusting screw (7).

6. Press the [0/1] button to turn the boiler off, reconnect the

power leads to the RH valve and press the [0/1] button

again to relight the boiler. Adjust the system controls to

allow the boiler to fire at high rate for several minutes,

then remove the dust cover and adjust the high burner

pressure adjusting screw (8). After setting to the indicated

pressure replace the dust cover and allow the boiler to

operate for about 5 minutes to stabilise then recheck the

burner pressure.

Note.

If high rate pressure is not achievable as above

check that the gas restrictor in the low-rate valve is fitted

(see Frames 39 & 42).

7. Press the [0/1] button to turn the boiler off, then refit both

pressure test point screws. Check for gas soundness.

8. Press [EXIT] to leave the commissioning mode and

return to the main menu.

9. Press [EXIT] again to return to the status displays.

INSTALLATION

INSTALLATION

25

OPERATING INSTRUCTIONS

This manual suits for next models

3

Table of contents

Popular Range manuals by other brands

Frigidaire

Frigidaire BGEF3044KFA use & care

GE

GE Profile JD968KFCC Dimensions and installation information

Candy

Candy TRIO 9501 Instructions for use and installation

Maytag

Maytag MES5875BAB - 30" Slide-In Electric Range Use and care guide

Whirlpool

Whirlpool WFE715H0ES User instructions

Fisher & Paykel

Fisher & Paykel OR36S Gas Gas installation guide

Maytag

Maytag MGS5875BDQ - Gas 4.5 cu. Ft. Slide-In Range Repair parts list

Whirlpool

Whirlpool WGG745S0FS installation instructions

Garland

Garland S680 SERIES Installation, operating and service instructions

Panasonic

Panasonic MQ-W Series instruction manual

Thermador

Thermador PRD304GHC Use and care guide

Amana

Amana AEP200VA installation instructions