IDROBASE Enjoy Your Life AVANA User manual

Certicazione di qualità

Quality assured rm

Сертификат качества

Certicazione di qualità

Quality assured rm

Сертификат качества

Rev. 00 - 04/2014Rev. 00 - 09/2015

LIB.0086

Manuale uso e manutenzione

IT

Use and maintenance manual

GB

IMPORTANTE!

Prima di installare e utiliz-

zare la macchina è obbli-

gatorio che l’installatore

e l’utilizzatore leggano e

comprendano in tutte le

sue parti il presente ma-

nuale.

Il manuale è parte inte-

grante della macchina e

deve obbligatoriamente

essere conservato per

futuri riferimenti no alla

demolizione della mac-

china.

IMPORTANT!

Before installing and

using the machine impe-

rative that the installer

and the user read and un-

derstand all parts of this

manual.

The manual is an integral

part of the machine and

must necessarily be kept

for future reference until

the demolition of the ma-

chine.

ENJOY YOUR LIFE - Night & Day

OASI &

AVANA

OASI &

AVANA

www.enjoyyourfurniture.com

www.idrobasegroup.com

Copyright ©2015 Idrobase Group. All rights reserved.

22

Thanking you for the preference you gave us, IDROBASE GROUP Srl is glad to include your rm in the list of its

preferred customers and relies that the use of this machine will be fully satisfactory.

This manual is intended to provide all instructions and precautions to be followed to properly use the machine in

safety and productivity; It is therefore appropriate that the operator consult this manual before using the machine.

The manual must always be available to the operator and kept in good condition; is the user's responsibility to wor-

ry about the training of personnel assigned to the use and maintenance for safety purposes . The replacement of

parts not manufactured or approved by the ngers IDROBASE GROUP Srl may aect the performance or durabi-

lity of the machine and create the potential risk to the machine itself or the sta, as well as make void the warranty.

The descriptions and illustrations contained in this publication are not binding; IDROBASE GROUP Srl therefore

reserves the right to make changes at any time, without obligation , to update the publication , to change bodies ,

details, accessories supplies for further improvement, or for any other manufacturing and / or commercial function

greater safety.

The instructions, drawings , tables, and all that is contained in the following le are technical in nature and reser-

ved, for this reason, any information can not be communicated to third parties without written authorization from

IDROBASE GROUP Srl that is its sole owner.

In case of dispute the valid jurisdiction is that of Padua (Italy).

GOOD JOB !

GB

Copyright ©2015 Idrobase Group. All rights reserved.

23

INDEX

GB

1 LAYOUT OF MANUAL

1.1 INFORMATION 24

2 APPLICATIONS

2.1 GENERAL WARNINGS 25

2.2 MACHINE IDENTIFICATION 25

2.3 WARRANTY 25

2.4 CONDITIONS FOR RETURN 26

2.5

CASES THAT RELIEVE THE MANUFACTURER OF ANY RESPONSIBILITY

26

2.6 SAFETY 26

2.7 SIMBOLS 28

2.8 GLOSSARY 28

2.9 NOTES ON THE LABELS 28

3 PRODUCT PRESENTATION

3.1 PURPOSE 29

3.2 COMPOSITION 29

4 TECHNICAL DATA AND SPECIFICATION

4.1 TECHNICAL DATA 30

5 UNPACKING

5.1 UNPACKING 31

5.2 TOWER PACKING 31

5.3 BASE PACKING 31

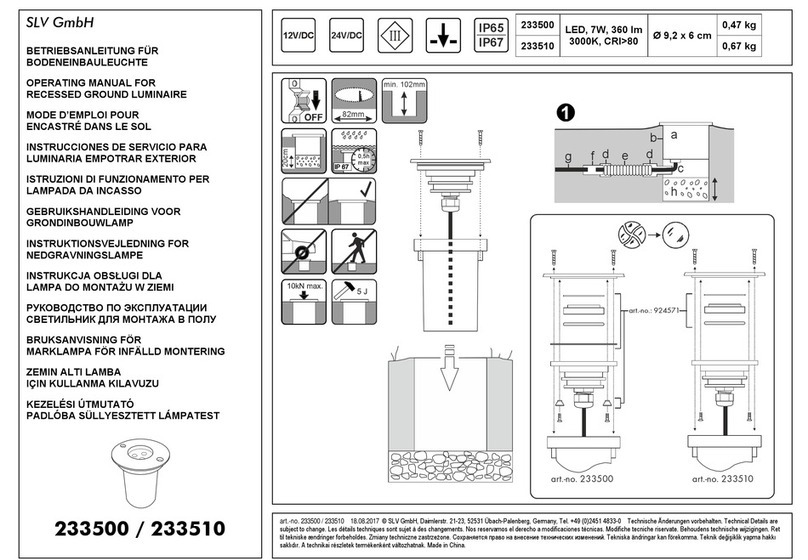

6 ASSEMBLY AND INSTALLATION 32

7 OPERATION AND USE

7.1 MAIN CONTROL 34

7.2 RANGE APPLICATIONS 36

7.3 WORKING LIMITS 36

7.4 SAFETY DEVICE 36

7.5 LABELS 36

7.6 TRAINING 36

8 CLEANING AND DISINFECTING

8.1 CLEANING AND DISINFECTING 37

8.2 REINSTALLATION AND REUSE 37

8.3 DEMOLITION AND DISPOSAL 37

9 MAINTENANCE

9.1 MAINTENANCE 38

9.2 CLEANING NOZZLES 38

9.3 CLEANING WATER INTAKE FILTER AND TANK 38

9.4 ELECTRIC SYSTEM 39

9.5 WEEKLY MAINTENANCE 39

10 DESTRUCTION AND DISPOSAL 39

11 CAUSES AND SOLUTIONS 40

Copyright ©2015 Idrobase Group. All rights reserved.

24

1.1 INFORMATION

This manual is an essential document for the safe use of the equipment. It should be kept

in a safe place and must be accessible to the user / repairer to ensure the correct use of the

machine and thereby avoid any risks through incorrect Installation, misuse or negligence.

We recommend to follow carefully the instructions below, as the manufacturer is not liable

for any damage caused to persons or property, or suered from the machine when used

dierently than what described, or if you do not comply with maintenance and safety requi-

rements.

This manual should always be available to the user and/or maintenance, which must be infor-

med about the correct use of the machine and any residual risks.

The instructions in this manual do not supersede the safety and technical data, installation

and also use for operating, which are applied directly on the machine.

The user must follow the safety regulations to the country of installation, in addition to the

rules dictated by common sense.

You should not use the machine if you note any defects or damages that could compromise

the original security; the responsible for the installation, the user or maitenance technician

has to report any anomalies to the manufacturer.

The machine is built for specic applications. It should not be changed and/or used for appli-

cations dierent than those specied in the eld of use.

Instructions, drawings, tables and all that is contained in the following documents are of

technical nature, and therefore any condential information can not be provided to third

parties without the written permission of IDROBASE GROUP Srl which is the sole owner.

Descriptions and illustrations contained in this publication do not mean demanding; IDRO-

BASE GROUP Srl therefore reserves the right to make changes at any time to bodies, details,

accessories supplies, appropriate for any manufacturing or commercial improvement.

1 LAYOUT OF MANUAL

GB

Copyright ©2015 Idrobase Group. All rights reserved.

25

2 APPLICATIONS

2.1 GENERAL WARNINGS

BEFORE INSTALLING AND USING THE MACHINE IT IS COMPULSORY THAT THE INSTALLER AND THE

USERS READ AND UNDERSTAND ALL OF THE INFORMATION IN THIS MANUAL.

THIS MANUAL IS AN INTEGRAL PART OF THE MACHINE; IT MUST ALWAYS BE AVAILABLE DURING

THE NORMAL OPERATION OF THE MACHINE AND IT IS IMPERATIVE THAT IT IS RETAINED FOR FUTU

RE REFERENCE UNTIL THE DISPOSAL OF THE MACHINE.

THE COPYRIGHT OF THIS MANUAL “INSTRUCTION FOR INSTALLATION AND USE” IS THE PROPERTY

OF IDROBASE GROUP SRL. ALL OF THE INFORMATION TEXT, DRAWINGS, DIAGRAMS, ETC. CON

TAINED IN THIS MANUAL IS CONFIDENTIAL. NO PART OF THIS MANUAL CAN BE REPRODUCED AND

DISTRIBUTED EITHER IN PART OR COMPLETE BY ANY MEANS OF REPRODUCTION, PHOTOCOPIES,

MICROFILM, OR OTHER WITHOUT WRITTEN AUTHORIZATION FROM IDROBASE GROUP SRL.

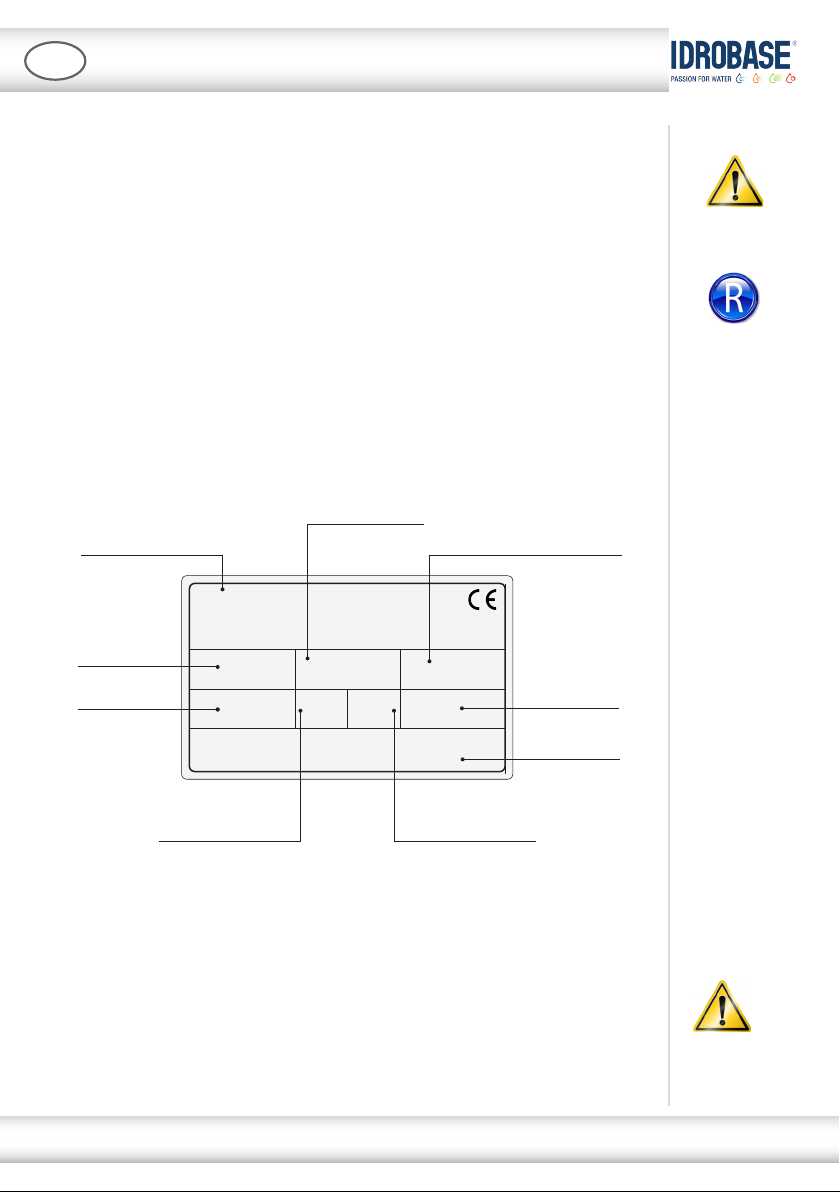

2.2 MACHINE IDENTIFICATION

The machine is distinguished by a manufacturer’s plate

2.3 WARRANTY

All of our equipments are subjected to accurate and rigorous tests and are covered under warranty of 1

year in accordance with statutory law from manufacturing defects.

THE WARRANTY IS INVALIDATED IF THE USE OF THE MACHINE DOES NOT CONFORM TO THE INSTRUC-

TIONS FOR USE CONTAINED IN THIS MANUAL, AND IF THE ORIGINAL COMPONENTS, ACCESSORIES,

SPARE PARTS AND CONTROL SYSTEMS ARE NOT USED.

The warranty starts from the date of purchase within the meaning of the act concerning warranty in the

country of sale.

GB

IDROBASE GROUP S.r.l.

Via dell’Industria, 25

35010 BORGORICCO (PD) - ITALY

Tel. +39 049 9335903 r.a. Fax +39 049 9335922

Modello

Model Matricola

Production nr. Anno

Year

Volt Hz Watt Ampere

Pressione nominale

Nominal pressure

MODEL

VOLTAGE

DATE OF PRODUCTION

FREQUENCY POWER ABSORBED

NOMINAL

PRESSURE

CURRENT

ABSORBED

MANUFACTURER

NAME

PRODUCTION

NUMBER

Copyright ©2015 Idrobase Group. All rights reserved.

26

1 APPLICATIONS

GB

IDROBASE GROUP SRL undertakes to repair or replace free of charge any parts that have manufacturing

faults within the warranty period. Faults not clearly due to materials or manufacturing shall be examined at

one of our Technical Assistance Centres or at our headquarters and charged according to the results. The

following are excluded from the warranty: accidental damage due to transport, negligence or inappropria-

te treatment, incorrect or improper use or installation, i.e. not complying to the instruction manual, and

any situations that do not depend on machine standards and operation, or on electrical and equipment

use. The warranty is invalidated if the equipment is repaired or tampered with by unauthorized third par-

ties. The equipment shall not be replaced nor the warranty extended after it has been repaired for faults.

The warranty does not cover cleaning the working parts or replacing consumable components such as

pump oil, nozzle, etc.

IDROBASE GROUP SRL IS NOT LIABLE FOR ANY DAMAGE TO PERSONS OR OBJECTS DUE TO IN

CORRECT INSTALLATION OR IMPROPER USE OF THE EQUIPMENT.

2.4 CONDITIONS FOR RETURNS

It will be the responsibility of the end user to return the product to the retailer; or telephone for further

information to the number

+39 049 93 35 136

2.5 CASES IN WHICH THE MANUFACTURER IS NOT LIABLE

The manufacturer is not liable for damage caused by the following:

•Improper use of the machine or use by untrained people.

•Use of non genuine spare parts.

•Non-compliance with maintenance.

•Unauthorized modications or operation.

•Non-observance, in total or part, of the instruction manual.

•Non-observance, in total or part, of the safety regulation in force in the country where the machine is

used.

READ AND SAVE THESE INSTRUCTIONS

2.6 SAFETY

OASI BASE is well-advanced from a technical point of view and for a proper installation, good ope-

ration, proper use and maintenance, it needs trained, responsible sta who has to comply with the

following rules of safety and conduct.

•The device can be used by children aged 8 and by people with physical, sensory and mental capa-

bilities or without 'experience and knowledge appropriate ONLY IF THEY HAVE BEEN EDUCA

TED about the use of the machine and have understand the potential dangers. Children should

not play with the appliance. Cleaning and maintenance should not be performed by children

unless supervised by an adult.

•The electrical system connected to the machine MUST BE made in compliance with the laws in

force in the country of installation.

•You MUST follow the rules imposed by the Fire Department or by local entrusted bodies.

•It is RECOMMENDED the presence of a dierential circuit breaker, with a sensitivity of 30 mA

above the socket or power plant.

•In dangerous situations, the machine SHOULD BE STOPPED immediately.

•DO NOT touch the plug with wet hands or feet!

•The integrity and insulation of the electric cable and equipment MUST BE checked, because the

work environment is necessarily exposed to water and humidity conditions that preclude the

natural system insulation.

Copyright ©2015 Idrobase Group. All rights reserved.

27

2 APPLICATIONS

GB

•Do NOT run the pump without water. Do not run the pump with liquids with sand or other solid particles

that compromise the ecient running of the seals;

•Do NOT expose the machine to freeze and the outside weather in general. Freezing can cause severe da-

mages to the pump and circuit. The prolonged downtime at temperatures below 5°C can cause damages

or break pump and pipes, it is better to do a complete emptying;

•Avoid accidental operation. You MUST place the switch OFF before inserting or removing the

plug from the socket.

•DO NOT use the machine if the cable is damaged or worn; disconnect the device from the net-

work and contact an authorized service center.

•DO NOT pull the cord to remove the plug.

•KEEP the machine clean and tidy.

•DO NOT remove or tamper with the safety devices and protection installed on the machine.

•It is RECOMMENDED not to place the machine on ramps or sloped oor, possibly remember to

lock the wheels with the appropriate mechanisms.

•During the handling of the machine on sloping surfaces, potholes or on particularly unstable

ground there is a risk that the machine chutes. The movement of the machine under the cir-

cumstances described above MAY RESULT in malfunction due to sudden impact or overturning.

•ARE OBLIGED to place the machine on a at and level for both installation and storage.

•Absolutely NO MOVE the machine during operation.

•Absolutely NO MOVE the machine when connected to mains electricity.

•The table (see par. 3.2) MUST BE used to place objects to a total load under 5 kg. DO NOT sit or

rest.

•DO NOT install the machine near ammable materials (expecially on environments with airborne

particles: plastics, resins, acids, inks, etc.).

•Keep at a distance not less than 2 meters from ammable materials such as furniture, pillows,

bedding, paper, clothing, tents, etc.

•DO NOT USE the machine near splashing water or subjected to environments with high humidity

(mist).

•DO NOT WASH the machine with high pressure washers.

•DO NOT COVER the heater when is working to avoid overheating.

•DO NOT TOUCH the heater when it is on.

•USE the machine outdoors ONLY coverage;

•IN CASE OF RAIN, the machine must be covered (after 60 minutes after turning o the heater) to

cover use code IT. 0965 or carried away.

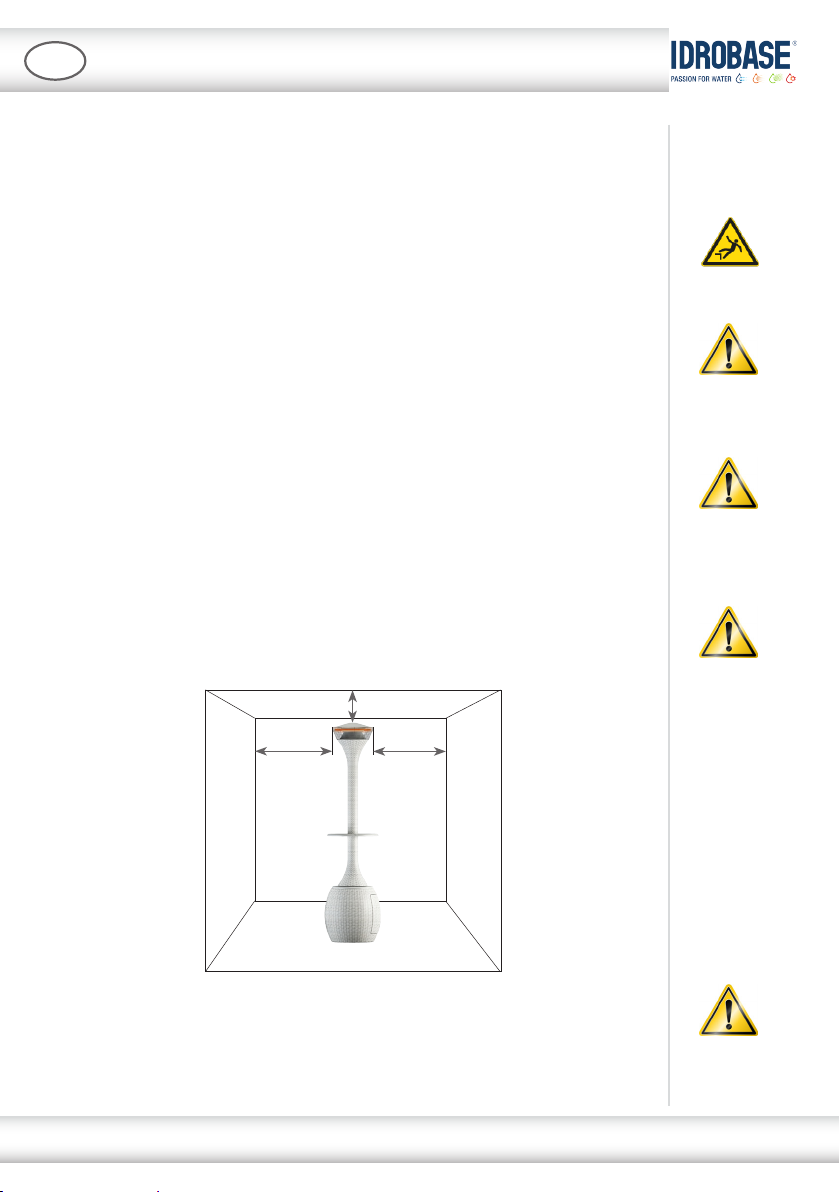

•IF USED LIKE HEATER INSTALL the unit at a minimum distance of 20 cm from the ceiling and

from 60 cm side walls.

20 cm

60 cm 60 cm

Copyright ©2015 Idrobase Group. All rights reserved.

28

2 APPLICATIONS

GB

2.7 SYMBOLS

In this manual the symbols depicted describe important functions of the machine for the

installation, and for the use and disposal. For correct and safe use of the machine the operator

must read carefully all parts of this manual paying special attention to the warning symbols

and manufacturer’s plate.

PAY ATTENTION TO SAFETY IN THE WORKPLACE!

FOLLOW THE INSTRUCTIONS DISPLAYED ON THE WARNING SIGNS. FAILURE TO DO SO MAY

CAUSE SEVERE INJURY OR ENDANGER PERSONAL SAFETY. ENSURE THAT THE SIGNS ARE PRE

SENT AND LEGIBLE. IF THEY ARE NOT, THEY SHOULD BE FITTED OR REPLACED.

THIS MANUAL MUST BE READ BEFORE USING OR CARRYING OUT MAINTENANCE OR OTHER

OPERATIONS ON THE MACHINE. DO NOT ALLOW UNAUTHORIZED PERSONNEL TO USE THE

MACHINE.

2.8 GLOSSARY

The following symbols advise the operator of dangerous situations or the important opera-

tions for the correct running of the machine.

WARNING SIGNS!

THIS MANUAL MUST BE READ BEFORE USING OR CARRYING OUT MAINTENANCE OR OTHER

OPERATIONS ON THE MACHINE.

INFORMATION!

THE INFORMATION CONTAINED IN THIS MANUAL SHOW THE RIGHT PROCEDURES FOR THE

CORRECT MAINTENANCE AND USE OF THE MACHINE

INFORMATION!

THE CAUTION INDICATES SPECIAL PROCEDURES THAT IF NOT OBSERVED CAN CAUSE DAMA

GE TO PERSONS OR PROPERTY.

WARNING!

MAINTENANCE OR REPAIRS MUST NEVER BE CARRIED OUT WHITE THE MACHINE IS LIVE/

SWITCHED ON. ALWAYS DISCONNECT FROM THE ELECTRICAL SUPPLY BEFORE CARRYING

OUT REPAIRS OR REMOVING THE COVER.

WARNING!

PROTECTIVE GARMENTS SHOULD BE WORN.

2.9 NOTES ON THE LABELS

Never remove the labels from the machine. If they have deteriorated, ask your retailer or the

manufacturer directly for a replacement.

THE MANUFACTURER IS NOT LIABLE IN ANY WAY IN THE EVENT OF ACCIDENTS OR BREAKA

GE DUE TO NONOBSERVANCE OF THE WARNINGS.

IN CASE OF LOSING THIS MANUAL OR ANY MISUNDERSTANDING CONTACT THE RETAILER

IMMEDIATELY.

THE STICKER SHOWING THE WAY OF USE AND RESTRICTIONS HAS NEVER TO BE REMOVED

FROM THE PLACE THEY ARE.

Copyright ©2015 Idrobase Group. All rights reserved.

29

3.1 PURPOSE

OASI has the dual functions of heat by means of a heater or cooling by means of a misting device.

The infrared heater heats gives a feeling of comfort from the moment it is turned on; It is safe because it does not

use gas; silent because electric; ecological because it has zero carbon dioxide emissions.

The atomizing device utilizes the principle of adiabatic cooling, the ambient temperature is lowered by the evapo-

ration of the water spray.

Civil applications are: gardens, pool sides, terraces, patios, gazebos, bars and restaurants

3.2 COMPOSITION

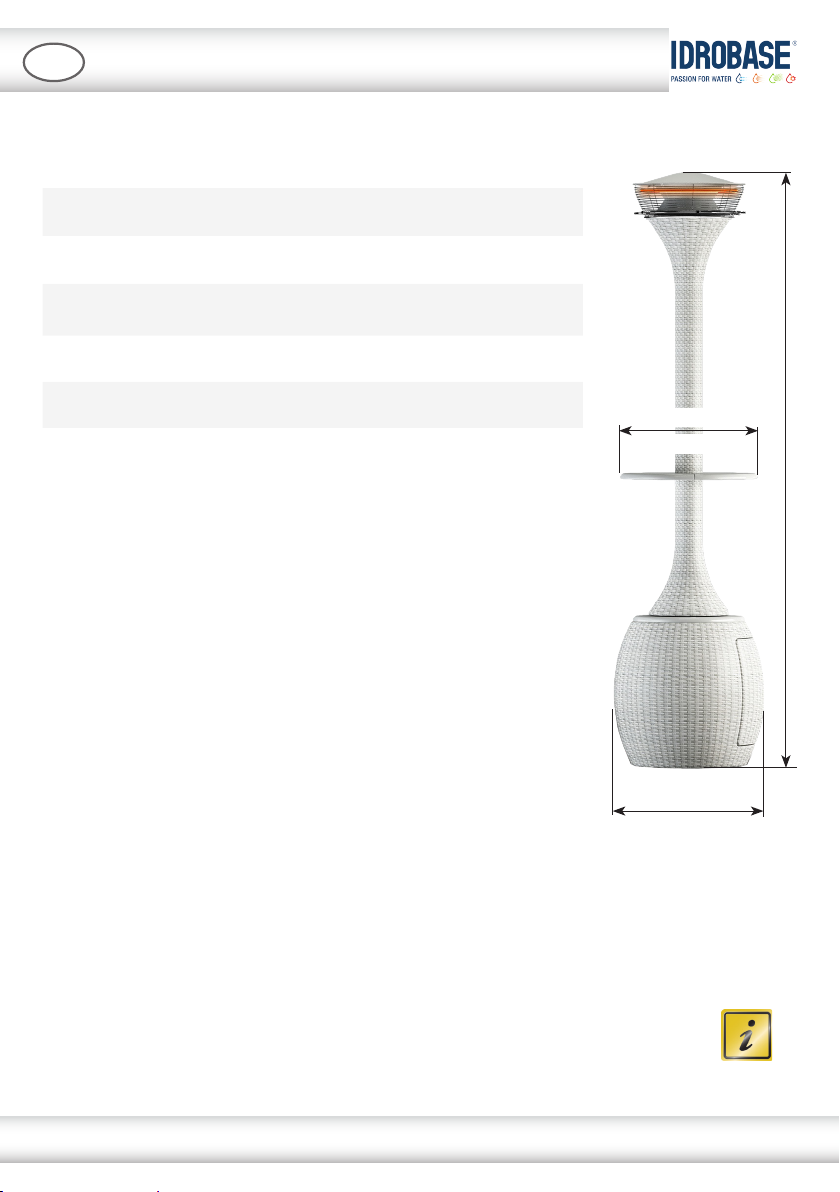

The main components of the machine are:

3 PRODUCT PRESENTATION

GB

4

85

7

6

POS. DESCRIPTION

1HEATER

2RING WITH FOG NOZZLES

3TOWER MADE OF SYNTHETIC RATTAN

4TABLE *

5BASE MADE OF SYNTHETIC RATTAN

6THREE LIGHTS

7MISTING DEVICE

8REMOTE CONTROL

The misting device is composed of the pump unit with 10 liters tank and electric panel with analog timer for setting

/ pause cycles work, switch on / o lights, operating mode switch heater / nebulizer.

The remote control can turn on / o only the lights and misting.

* Avana version has table with smoking kit

Copyright ©2015 Idrobase Group. All rights reserved.

30

GB

INFORMATION!

TO GET THE PROPER EFFECT OF FOGGING MUST BE RESPECTED THE VALUES OF THE POWER SUPPLY.

2150 mm = 84,65 in

Ø 19,69 in

Ø 500 mm

Ø 21,65 in

Ø 550 mm

4.1 TECHNICAL DATA

The following table describes models and specications of the machine.

ZX.5165 OASI

WHITE ZX.5167 OASI

BROWN ZX.5166 OASI

WOODEN

ZX.5165-S AVANA

WHITE ZX.5166-S AVANA

WOODEN

Weight 70 Kg

154 lb Voltage 230 V Nozzles

number 6

Max Load

Table Top

5 kg

11 lb Frequency 50 Hz Water

Tank

10 L

2,64 US gal

Covered

Area

30 m2

36 yd2Absorption 6,8 A Max

Pressure

25 bar

362,6 psi

Noisiness 51 Db Power 1570 W

2 HP

Flow rate 18 L/h

0,079 USGpm

4 TECHNICAL DATA AND SPECIFICATIONS

Copyright ©2015 Idrobase Group. All rights reserved.

31

GB

5.1 UNPACKING

OASI is shipped in two parts, packed in customized packaging. After having unpacked the machine make sure that

the machine is complete, including all of the requested accessories.

5.2 TOWER PACK

•Rattan tower with heater, electric connection;

•Table (N.2 semitables with centering pins);

•Assembling blister packaging.

5.3 BASE PACK

•Rattan base with misting device and control panels;

5 UNPACKING

Copyright ©2015 Idrobase Group. All rights reserved.

32

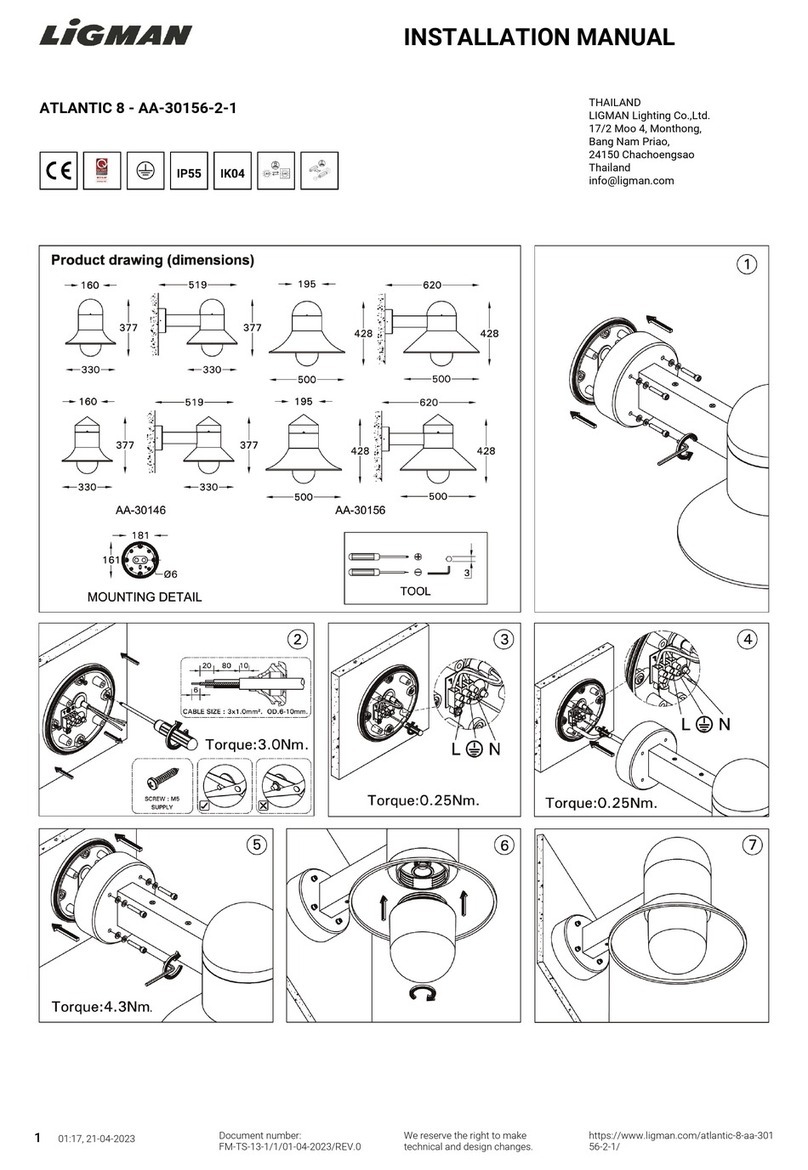

6 ASSEMBLY AND INSTALLATION

GB

A

B

C

H2O

ASSEMBLING

BLISTER

PACKAGING

A + B+ C

1. PLACE THE TOWER HORIZONTALLY

AND ON THE SIDE OF THE BASE IN

RATTAN.

6. FIX THE TOWER TO THE BASE

TIGHTENING SCREWS KIT A.

7. INSERT THE HOLE CAPS KIT A.

8. INSERT THE CENTERING PINS IN THE

TWO SEMITABLES KIT B.

9. JOIN THE TWO SEMITABLES

POSITIONED ABOVE THE BRACKETS

ATTACHED TO THE RATTAN TOWER.

10. FIX SEMITABLES TIGHTENING THE

SCREWS KIT C.

2. OPEN THE DOOR OF THE BASE IN

RATTAN AND PULL OUT THE TANK.

5. CONNECT WHITE PIPE OF THE WATER

TO THE MISTING DEVICE AND CLOSE THE

DOOR OF THE RATTAN BASE.

11. SCREW THE NOZZLES

3. INSERT INTO THE CENTER HOLE OF THE

RATTAN BASE, ELECTRIC CABLES AND

WHITE PIPE OF THE WATER.

4. CONNECT THE CABLES OF THE LIGHTS

AND HEATER.

THE ASSEMBLY MUST BE MADEIN TOTAL SAFETY. IT

IS THE RESPONSIBILITY OF THE INSTALLER ENSURE

THE SAFETY OF PERSONNEL.

Copyright ©2015 Idrobase Group. All rights reserved.

33

1. FOLLOW THE STEPS FROM 1 TO 7 AND POINT 11 OF THE PREVIOUS PAGE.

2. INSERT THE CENTERING PINS TO THE TWO SEMITABLES.

3. JOIN THE TWO SEMITABLES BY POSITIONING IT ON THE BRACKETS FIXED TO THE TOWER RATTAN.

4. FIX THE TABLE ASSEMBLED ON THE BRACKETS BY TIGHTENING THE SCREWS.

5. FIX THE JOINING PLATES TABLES WITH SCREWS.

6. INSERT THE ASHTRAYS INTO THE HOLES ON THE TABLES.

ASSEMBLY OF THE SMOKING KIT

GB

6 ASSEMBLY AND INSTALLATION

Copyright ©2015 Idrobase Group. All rights reserved.

34

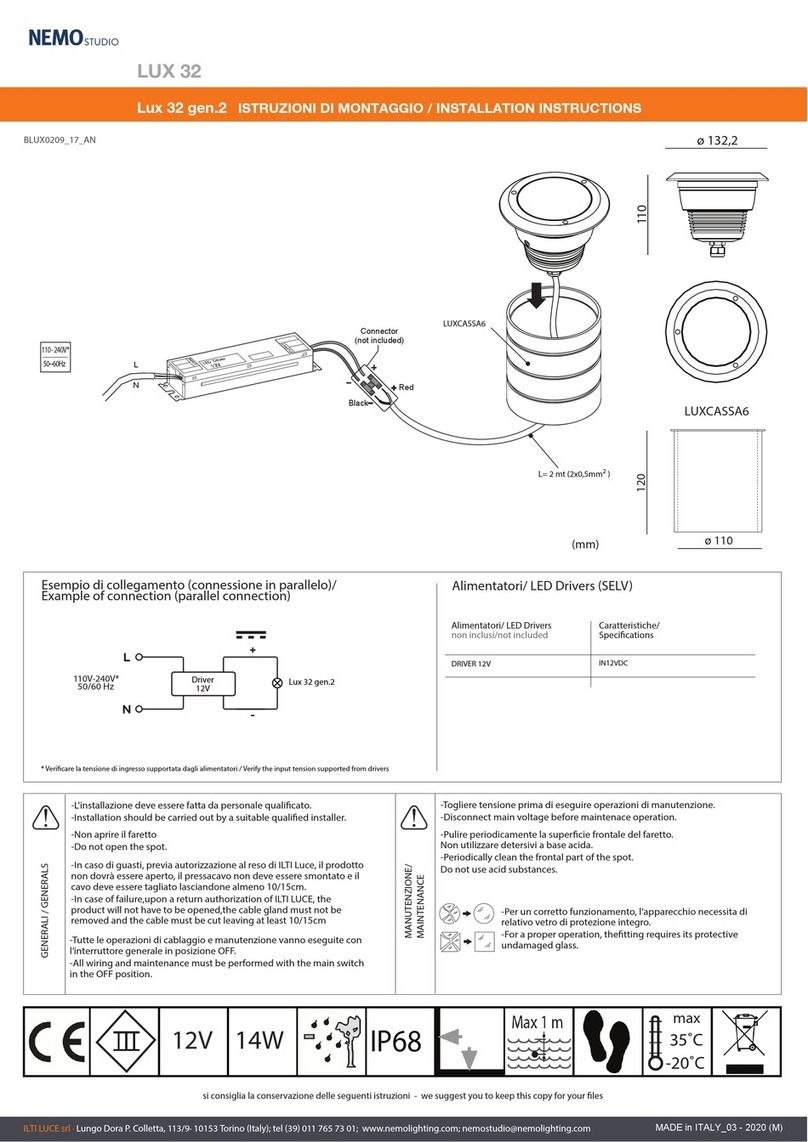

7 - OPERATION AND USE

GB

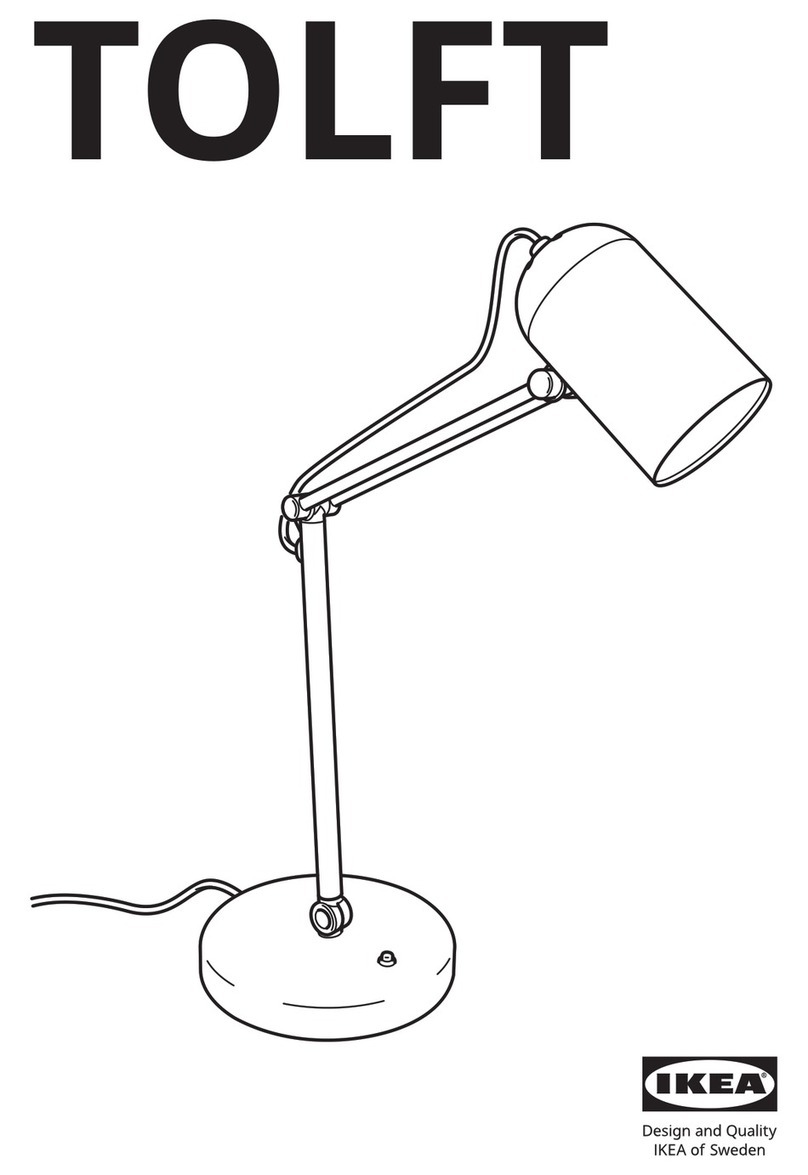

7.1 MAIN CONTROL

After lling the tank with clean water and connected the machine to the power supply, open the door of the rattan

base for you have access to the main control panel.

MACHINE OFF

With selector (X) in a central position OFF, the machine is o.

WINTER MODE heater and lights control

Move the selector to the right (X) to activate WINTER mode

Using the bottom switch (Z) is possible select ON / OFF heater:

Heater ON (switch on the left)

Heater OFF (switch on the right)

Using the bottom switch (Y) is possible select ON / OFF lights:

Lights ON (switch on the left)

Lights OFF (switch on the right)

•DO NOT USE the machine near splashing water or subjected to environments with high humidity (mist).

•DO NOT WASH the machine with high pressure washers.

•DO NOT COVER the heater when is working to avoid overheating.

•DO NOT TOUCH the heater when it is on.

•USE the machine outdoors ONLY coverage;

X

Y

Z

WINTER MODE

MODE SELECTION

Copyright ©2015 Idrobase Group. All rights reserved.

35

7 - OPERATION AND USE

GB

Move the selector to the left (X) to activate SUMMER mode

•ENSURE that the ow of water, is not wet the electrical components;

•DO NOT run the pump without water. Do not run the pump with liquids with sand or other solid particles that compromise the

ecient running of the seals;

•DO NOT expose the machine to freeze and the outside weather in general. Freezing can cause severe damages to the pump

and circuit. The prolonged downtime at temperatures below 5°C can cause damages or break pump and pipes, it is better to do

a complete emptying;

SUMMER MODE - misting and lights control

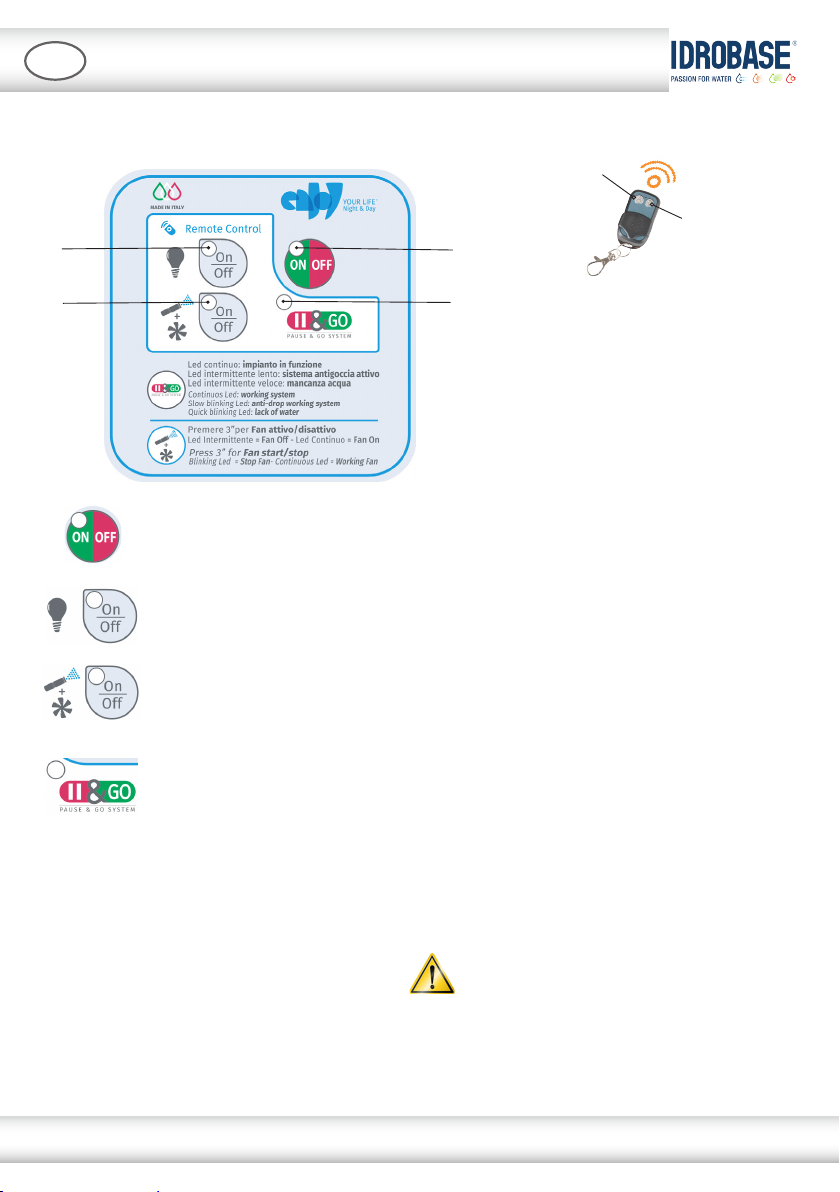

ON / OFF MACHINE

Pressing this button, the MACHINE turns on or o.

The power of the machine is indicated by the LED.

ON / OFF LIGHTS

With module turned on by pressing this button, the LIGHTS will switch on or o.

The lighting of the lamps is indicated by the LED.

ON / OFF PUMP

With machine on, press this button, it enables or disables the operating cycle of the PUMP.

BLOCK PUMP

If, during operation of the pump there is no pressure in the line (tank empty or broken hydraulic

hose), the pump stops. This is indicated by the LED light ashing quickly.

After verifying the cause of the block (the tank is empty or broken plumbing pipe) and have inter-

vened to restore the operation of the machine, turn o and on by pressing the ON / OFF and restart

operating cycle of the pump pressing button ON / OFF PUMP.

ENABLING AND DISABLING RADIO CONTROL

With machine turned on, if you press for 2 seconds the button ON / OFF, it enables or disables the

radio control. The activation of the radio control is indicated by the LED intermittent.

I

L

P

O

I

L

P O

A

B

FUNCTIONS OF REMOTE CONTROL

At the discretion of the customer, the re-

mote radio can be programmed with a key

to activate / deactivate the misting and a

button to turn on / o the lights.

NB. To control the lights with remote con-

trol, the lights switch of the main control

panel must be OFF.

SUMMER MODE

Copyright ©2015 Idrobase Group. All rights reserved.

36

7 OPERATION AND USE

GB

7.2 RANGE OF APPLICATIONS

•Cooling of internal and external areas (only coverage) such as: bars, restaurants, swiming

pools, discos, theme parks, meeting places, poultry farms, livestock farming, machine shop

and industries.

•Humidication of internal and external areas .

WARNING!

DON'T USE IN ENVIRONMENTS WHERE EXPLOSIVE POWDERS ARE PRESENT. DON'T USE TO

DISTRIBUTE TOXIC CHEMICALS OR PRODUCTS THAT CAUSE HARM TO PEOPLE OR THE EN

VIRONMENT. THE MANUFACTURER IS NOT RESPONSIBLE FOR ANY DAMAGE CAUSED BY IM

PROPER OR INCORRECT USE OR FAILURE TO OBSERVE THE RULES SET OUT IN THIS MANUAL.

7.3 WORKING LIMITS

Prolonged inactivity (machine stopped) with temperatures lower than 5°C (5 degrees cen-

tigrade) can cause damage or breakage to the pump, hoses, and to the parts in general. It

is therefore advisable to empty the system completely. For more information contact the

retailer or manufacturer.

In case of rain, the machine must be covered by ENJOY coverage, code IT. 0965, or moved

inside.

7.4 SAFETY DEVICES

In the case of overturning of the equipment with the heater switched on, a safety switch and strip

o the power supply to the heater.

7.5 LABELS

On the machine and manual signs and pictograms are shown in order to highlight or draw

any hazardous situations or behaviors to be followed for safe operation.

WARNING!

NEVER PUT ANY PART OF THE BODY AND / OR OBJECTS THROUGH THE OPENINGS OF

THE FAN, WHERE THERE IS A NEED,YOU MUST FIRST DISCONNECT THE POWER SUPPLY.

WARNING!

NEVER REMOVE THE SAFETY DEVICES WITHOUT FIRST DISCONNECTING THE VOLTAGE

AND ABSOLUTELY DO NOT TURN ON THE MACHINE WITHOUT THESE DEVICES.

7.6 TRAINING

It is the responsibility of the owner and/or supervisor to assign an operator and train him in

the use of the machine according to the instructions in this manual.

WARNING!

THE SYSTEM MUST BE USED ONLY BY A TRAINED OPERATOR, WHO USES THE MACHINE IN

ACCORDANCE WITH THE INSTRUCTIONS CONTAINED IN THIS MANUAL AND/OR THE MA

NUAL FOR ANY EXTERNAL EQUIPMENT. NO LIABILITY SHALL BE ACCEPTED FOR ANY IMPRO

PER USE OF THE MACHINE NOT ENVISAGED IN THIS MANUAL.

HEATER OFF

Copyright ©2015 Idrobase Group. All rights reserved.

37

8 CLEANING AND DISINFECTING

8.1 CLEANING AND DISINFECTION

Every day the tank must be emptied and lled with clean water the next day.

After a period of inactivity of the system, before to reuse it, it is better to clean and disinfect

whole the pipe line. For this operation contact a qualied technician or the retailer.

8.2 REINSTALLATION AND REUSE

To reuse the machine after a period of inactivity carry out the steps in section 9.

8.3 DESTRUCTION AND DISPOSAL

WARNING!

THE DESTRUCTION OF THE MACHINE MUST BE CARRIED OUT ONLY BY A TRAINED PERSON

OR BY A QUALIFIED TECHNICIAN.

When it has been decided to destroy the machine and render it unusable it is recommended

that all parts which could be dangerous are rendered safe, removing all of the electrical com-

ponents, while conforming to current legislation regarding the scrapping of these materials.

The various components should be brought to the appropriate recycling centres.

WARNING!

THE DISPOSAL OF THE MACHINE MUST BE CARRIED OUT ACCORDING TO THE LAWS OF THE

COUNTRY IN WHICH IT IS TO BE DISPOSED.

FUR FURTHER INFORMATION CALL

+39 049 93 35 136

GB

Copyright ©2015 Idrobase Group. All rights reserved.

38

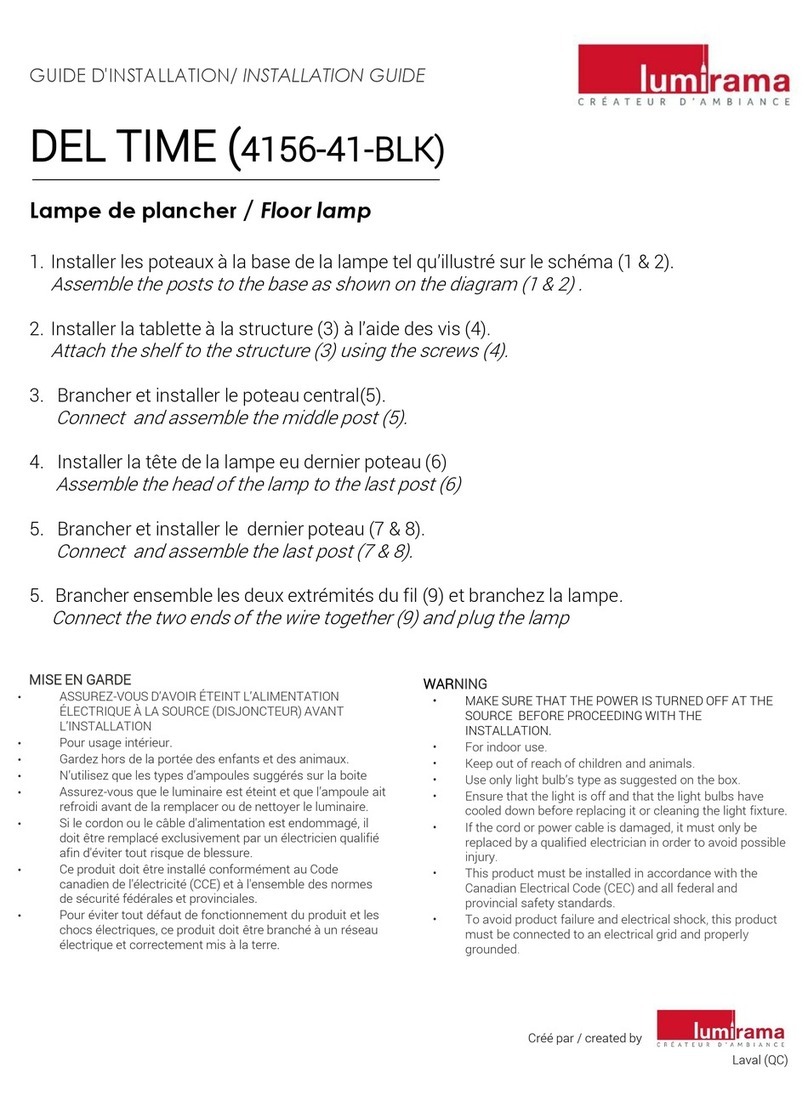

9 MAINTENANCE

WARNING!

EVERY TIME THE MACHINE IS CLEANED OR MAINTAINED IT MUST FIRST BE STOPPED BY FOL

LOWING THE STEPS DESCRIBED IN PARAGRAPH 8.4.

TO GUARANTEE MACHINE SAFETY, YOU ARE ADVISED TO USE ONLY SPARE PARTS AUTHO

RIZED BY THE MANUFACTURER. DO NOT CARRY OUT TEMPORARY OR DANGEROUS REPAIRS.

CAUTION!

DURING OPERATION, THE SYSTEM MUST MAINTAIN A NOISE LEVEL THAT COMPLIES WITH

LEGISLATION. FURTHERMORE, THERE MUST BE NO WATER LEAKAGE FROM THE PUMPING

MODULE OR THE LINE.

9.1 MAINTENANCE

MACHINES contain a high pressure water supply, an electric motion system and a control

system that need a big maintenance. Everything works, most of the time, in awful climatic

conditions: bad weather, humidity, ice, hot, hard and non-stop usage and, not always ade-

quate water, not always strained fuel.

The solution is preventing breakages. How to do it?

Simply replacing the components before they cause breakages.

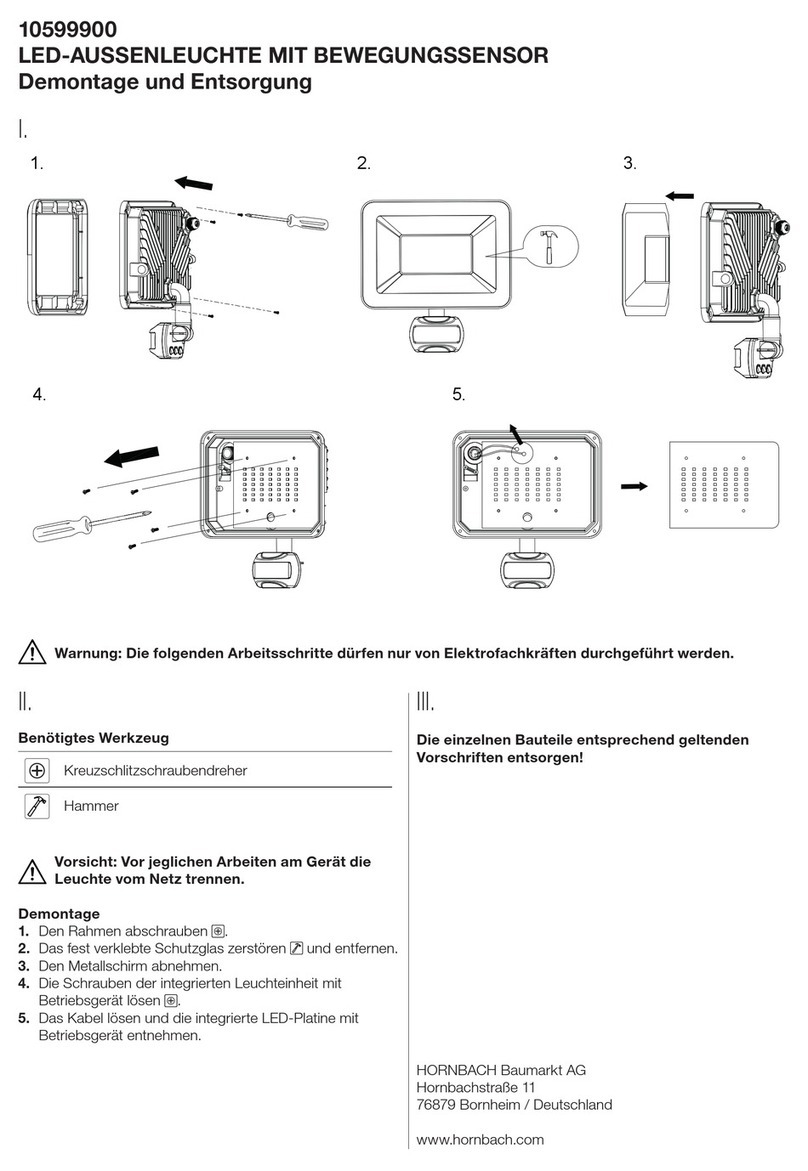

9.2 CLEANING NOZZLES

Check every 50 hours the proper functioning of the nozzles of the crown group that could get

clogged due to the formation of limestone or using unclean water. A nozzle is clogged note

because drips or has a spray angle is not uniform.

To clean the nozzle follow the procedure:

- Disassemble the nozzle unscrewing the stainless steel body (1);

- Soak for 4 hours in a mixture, 80% distilled water 20% white vinegar, the components

stainless steel body with o-ring (1), impeller plate (2), stainless steel spring with rubber ball

seal (3), stainless steel adapter with o-ring (4);

- DO NOT soak the lter (5), but clean it with air or replace depending on its wear;

- Reassemble the nozzle.

When replacing the nozzles in the nozzles ring do not tighten with excessive force. Each con-

tact tip stamped its own characteristics, ow and spray angle.

9.3 CLEANING WATER INTAKE FILTER AND TANK

Locate the water inlet lter connected to the water intake pipe and place inside the tank and

clean with sanitizing products.

Clean the tank that is located inside the rattan base, with sanitizing products.

GB

1

2

5

3

4

1

4

Copyright ©2015 Idrobase Group. All rights reserved.

39

9 MAINTENANCE

9.4 ELECTRIC SYSTEM

Check annually the functioning of the electrical system and check the fastening of the links. The

change of temperature and possible vibrations can cause loosening of the electrical connections

with its overheating.

WARNING!

IT IS GOOD TO REMEMBER THAT THE MAINTENANCE CARRIED OUT PROPERLY, CAN MINIMI

ZE THE DOWNTIME DUE TO FAILURE.

A REPAIR DONE IN A TIMELY MANNER TO AVOID FURTHER DETERIORATION.

USE AS MUCH AS POSSIBLE, ORIGINAL SPARE PARTS.

9.5 WEEKLY MAINTENANCE

•Power cable in good condition

•Water pipes and ttings in optimum condition and undamaged.

Replacing the nozzles that spray visually unevenly even after they are cleaned.

10 DESTRUCTION DISPOSAL

GB

GB

WARNING!

THE DESTRUCTION OF THE MACHINE MUST BE CARRIED OUT ONLY BY A TRAINED PERSON

OR BY A QUALIFIED TECHNICIAN.

When it has been decided to destroy the machine and to render it unusable, It is recommen-

ded that all parts which could be dangerous are rendered safe, removing all of the electrical

components, while conforming to current legislation regarding the scrapping of these mate-

rials. The various components should be brought to the appropriate recycling centres.

WARNING!

THE DISPOSAL OF THE MACHINE MUST BE CARRIED OUT ACCORDING TO THE LAWS OF THE

COUNTRY IN WHICH IT IS TO BE DISPOSED.

Copyright ©2015 Idrobase Group. All rights reserved.

40

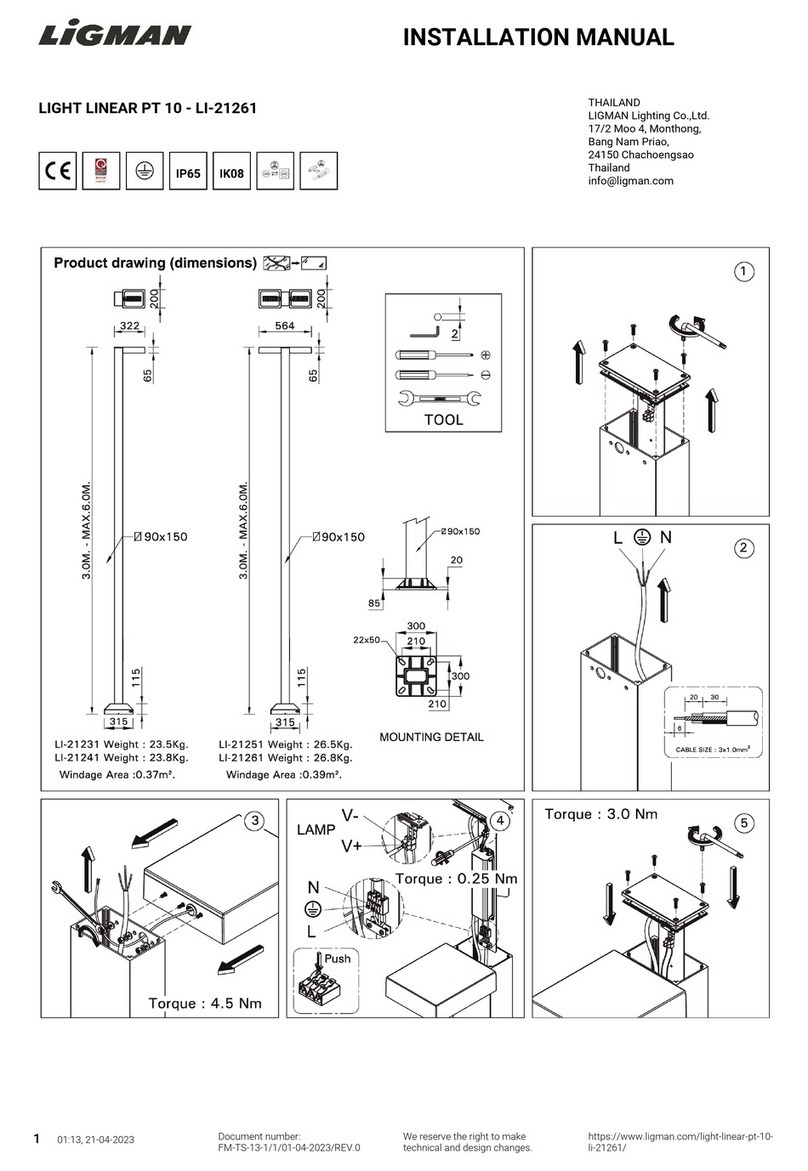

11 CAUSES AND SOLUTIONS

GB

The following table shows the drawbacks encountered and remedies that can be made also directly from the user.

PROBLEM CAUSES SOLUTIONS

The machine doesn’t start •Machine not connected to

the electricity grid

•Faulty electrical components

•Connect the plug to the power outlet

•Call Service

The machine does not turn

o

•Faulty components •Disconnect the plug from the power outlet

and contact the service center

The light does not turn on •Machine not connected to

the electricity grid

•Faulty light

•Connect the plug to the power outlet

•Replace the light

The heater does not work •Machine not connected to

the electricity grid

•Faulty heater

•Connect the plug to the power outlet

•Call Service

The machine vibrates a lot

and / or is noisy

•Water level in the tank insuf-

cient

•Faulty pump

•Fill the tank with drinking water

•Call Service

The machine turns on but not

nebulizes

•Faulty pump

•Empty tank

•Clogged hydraulic compo-

nents

•Replace the pump

•Fill the tank with drinking water

•Call Service

Nozzles not nebulize well •Clogged nozzles •Clean / replace clogged nozzles

•Call Service

Water leakage •Hydraulic circuit faulty •Check that the hydraulic hoses are con-

nected properly

•Call Service

The radio control does not

work

•The remote control has the

discharged battery

•Radio control mode o

•Change the battery in the remote control

•Repeat the process of activation of the

remote control

FOR REQUESTING SERVICE CALL NUMBER

+39 049 9335903

Copyright ©2015 Idrobase Group. All rights reserved.

This manual suits for next models

1

Table of contents