Ikco SAMAND User manual

SAMAND

(XU7JPL3)

Service Manual

Heating & Ventilation

Chapter:

Section:

Product:

SAMAND XU7JPL3

Heating and Ventilation

I

SAMAND

Service Manual

Foreword:

This Service Manual contains descriptions of the following categories for the

Samand:

Heating and Ventilation

This manual should be used as service manual and s workbook for

training instructors and technicians. We reserve the right to introduce

change without prior notice.

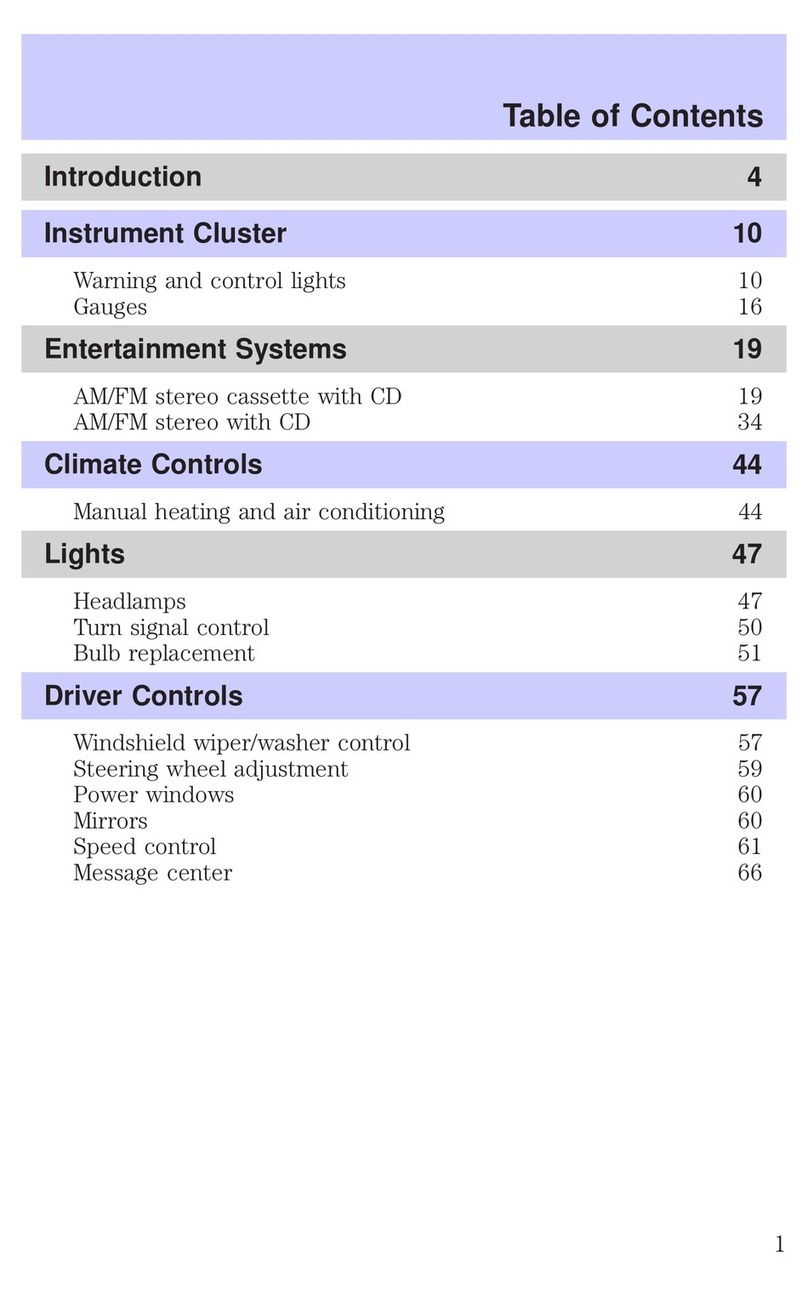

Contents

Heating and ventilation

.......................................... 5

Special tools

Special tools ............................................................ 6

Technical data

Compressor ............................................................. 9

Expansion valve ......................................................... 9

R134a refrigerant ......................................................... 9

Temperature sensor ....................................................... 10

Pressostat .............................................................. 10

Torque settings .......................................................... 11

Technical description

System overview ......................................................... 13

Function of AC system ..................................................... 14

Adjustment and replacement

Refrigerant circuit-draining, vacuum extraction and refilling .......................... 16

Compressor ............................................................. 18

Compressor drive plate .................................................... 20

Compressor drive pulley ................................................... 21

Compressor oil level ...................................................... 22

Compressor air gap ....................................................... 23

Condenser .............................................................. 24

Dehydration reservoir ...................................................... 25

Evaporator .............................................................. 26

Expansion chamber ....................................................... 29

Heater blower ........................................................... 31

Blower module ........................................................... 32

Interior air temperature sensor ............................................... 33

Air conditioning control unit ................................................. 34

Air conditioning control card ................................................. 35

Heater matrix ............................................................ 36

Heater ................................................................. 37

Coolant temperature unit ................................................... 39

Electronic thermostat ...................................................... 40

Scuttle air intake filter ..................................................... 41

Evaporator sensor ........................................................ 42

Air conditioning compressor relay ............................................ 43

Blower relay ............................................................ 44

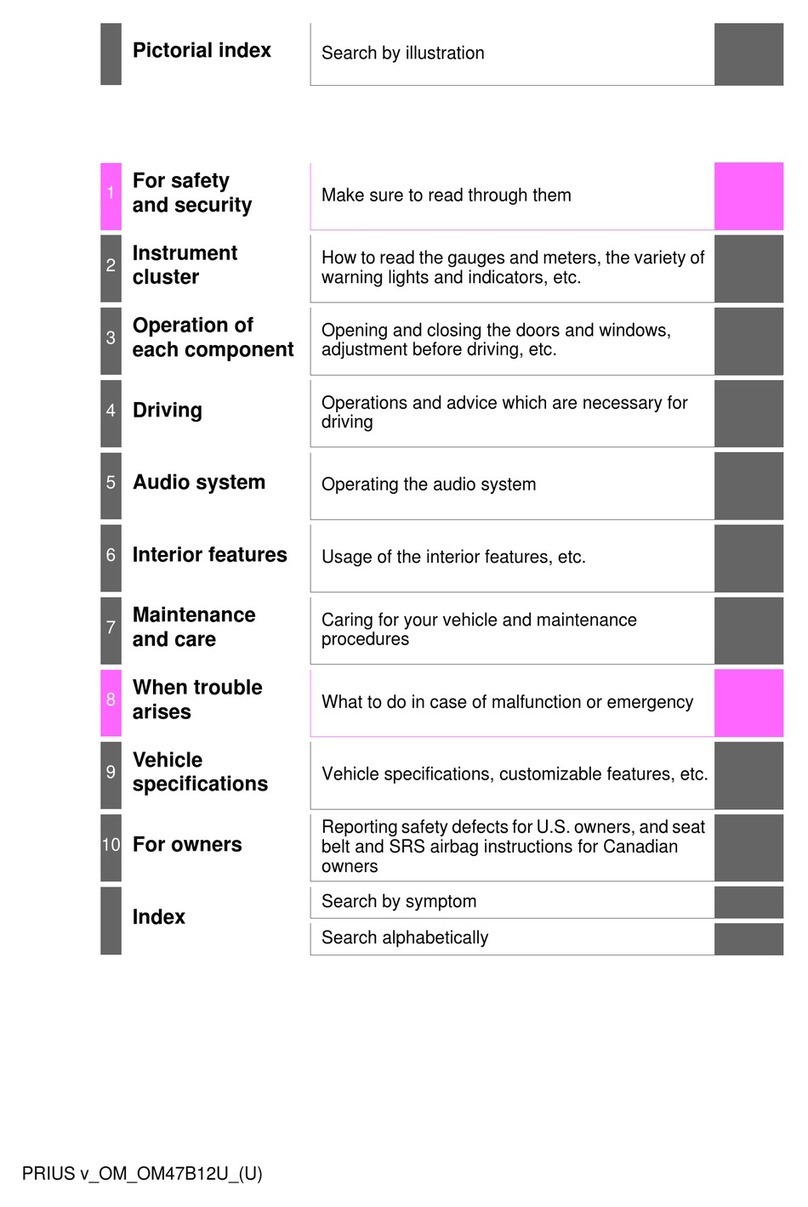

Heating and Ventilation

5

Special tools

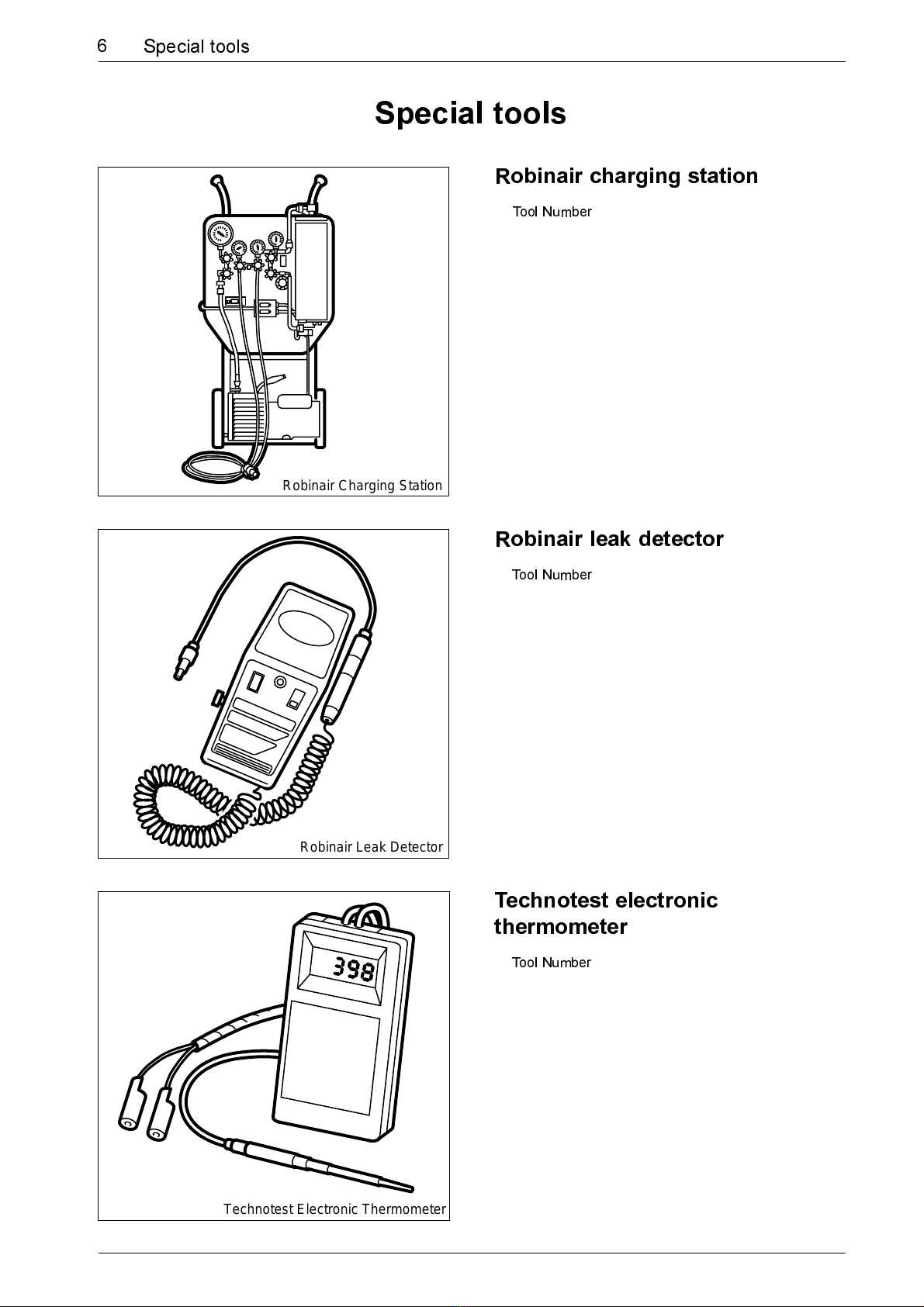

Robinair charging station

Tool Number

Robinair leak detector

Tool Number

Technotest electronic

thermometer

Tool Number

Robinair Charging Station

Robinair Leak Detector

Technotest Electronic Thermometer

6Special tools

Three legged puller

Tool Number

Adjustable peg spanner

Tool number

Compressor dip stick

Tool number

Three Legged Extractor

Adj Peg Spanner

Dipstick

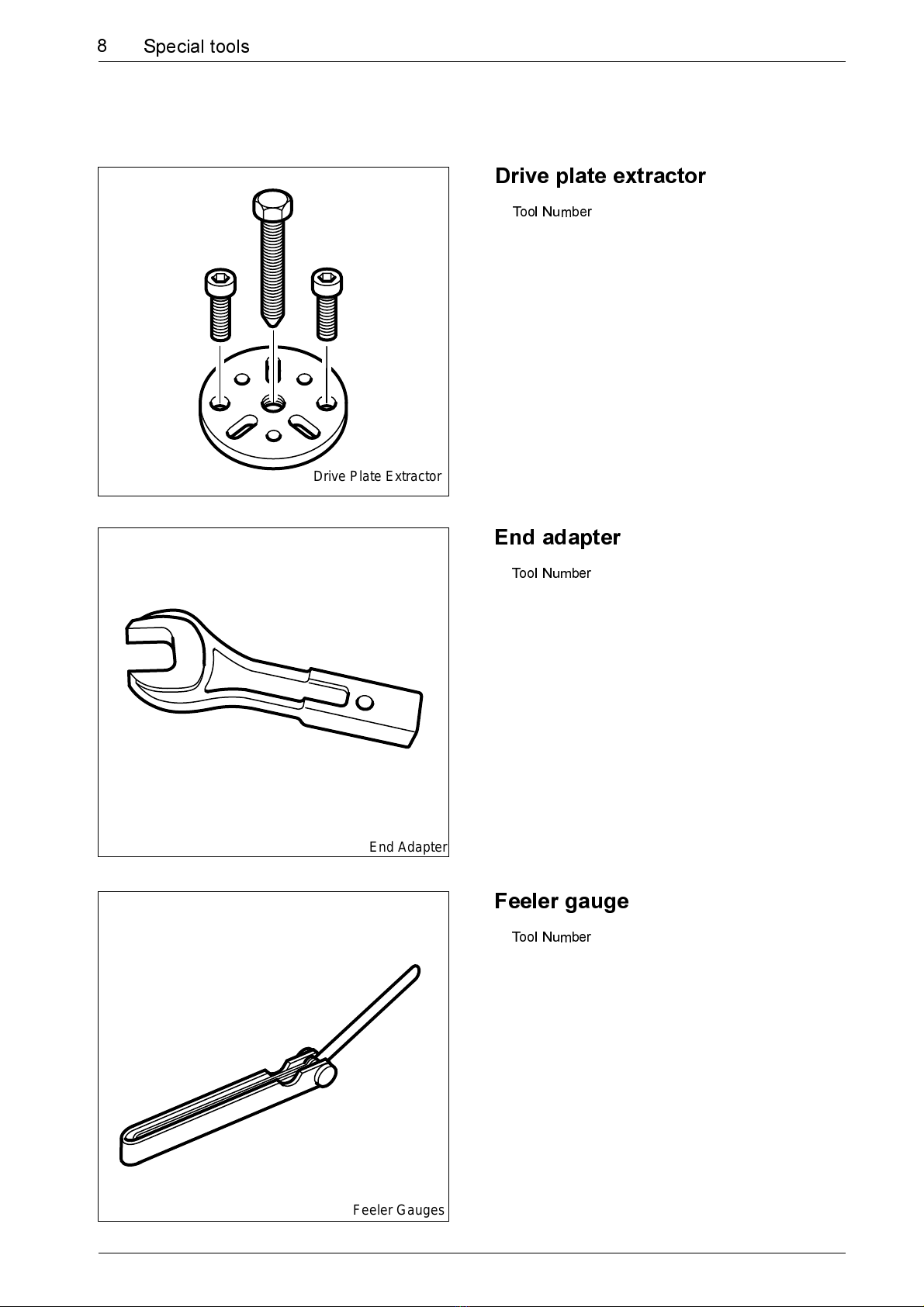

Drive plate extractor

Tool Number

End adapter

Tool Number

Feeler gauge

Tool Number

Drive Plate Extractor

End Adapter

Feeler Gauges

8Special tools

9

Technical data

Peykan

Technical data

Compressor

Type SD7H15

Cylinder volume 154,9cc

Oil capacity 135cc

Clutch type PV

Speed 8000 RPM Max

Wieght 7.2kg

Oil type SP10 OR SP20

Expansion Valve Egelhof

Type

Capacity

Static overheating

R134a

Capacity 600gr+0-50

W710D003

W710D006

W710D005

10 Technical data

Temperature sensor

Reference required

Pressostat

Data 2.5 +-0.5 bar on

Data 17 +-1 bar on

26 +-1.5 off

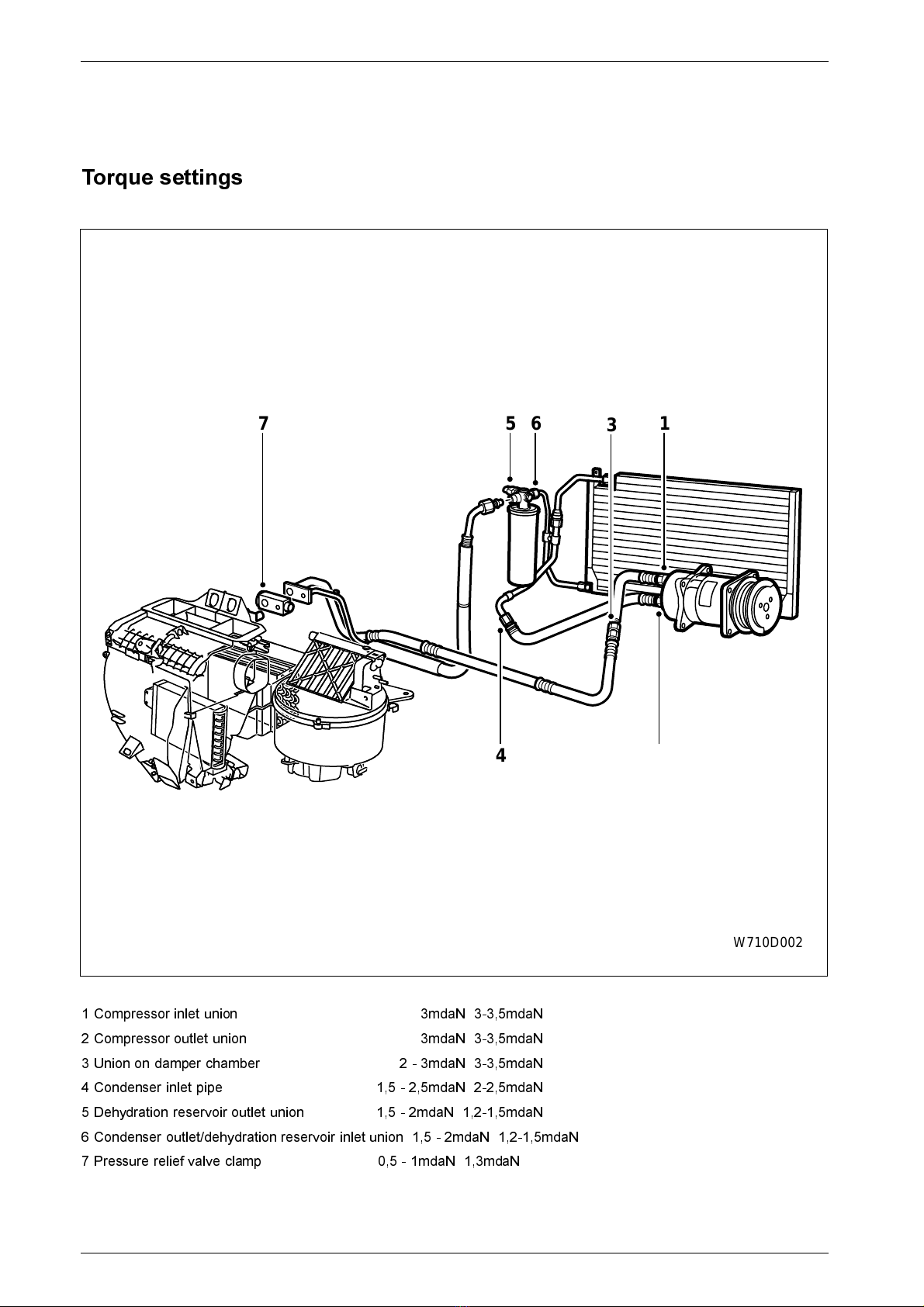

Torque settings

W710D002

61

53

7

42

1 Compressor inlet union 3mdaN 3-3,5mdaN

2 Compressor outlet union 3mdaN 3-3,5mdaN

3 Union on damper chamber 2 - 3mdaN 3-3,5mdaN

4 Condenser inlet pipe 1,5 - 2,5mdaN 2-2,5mdaN

5 Dehydration reservoir outlet union 1,5 - 2mdaN 1,2-1,5mdaN

6 Condenser outlet/dehydration reservoir inlet union 1,5 - 2mdaN 1,2-1,5mdaN

7 Pressure relief valve clamp 0,5 - 1mdaN 1,3mdaN

13

Technical description

Peykan

Technical description

System overview

W710D001

1234

8765

Heating and ventilation

1 Pressure relief valve

2 Dehydration reservoir

3 Condenser

4 Compressor

5 Blower

6 Evaporator

7 Electronic thermostat

8 Heater matrix

W710D003

W710D004

W710D005

14 Technical description

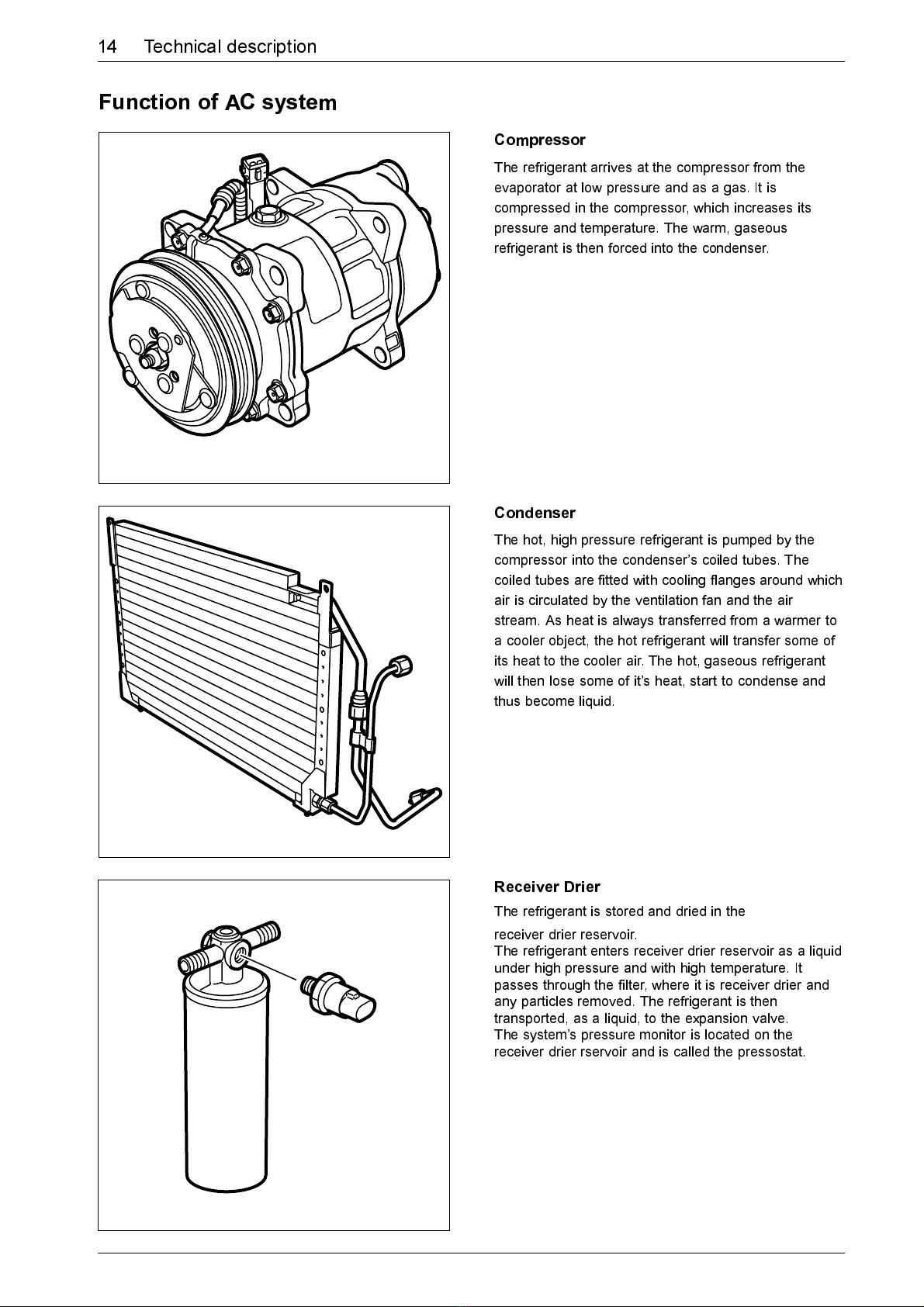

Function of AC system

Compressor

The refrigerant arrives at the compressor from the

evaporator at low pressure and as a gas. It is

compressed in the compressor, which increases its

pressure and temperature. The warm, gaseous

refrigerant is then forced into the condenser.

Condenser

The hot, high pressure refrigerant is pumped by the

compressor into the condensers coiled tubes. The

coiled tubes are fitted with cooling flanges around which

air is circulated by the ventilation fan and the air

stream. As heat is always transferred from a warmer to

a cooler object, the hot refrigerant will transfer some of

its heat to the cooler air. The hot, gaseous refrigerant

will then lose some of its heat, start to condense and

thus become liquid.

Receiver Drier

The refrigerant is stored and dried in the

receiver drier reservoir.

The refrigerant enters receiver drier reservoir as a liquid

under high pressure and with high temperature. It

passes through the filter, where it is receiver drier and

any particles removed. The refrigerant is then

transported, as a liquid, to the expansion valve.

The systems pressure monitor is located on the

receiver drier rservoir and is called the pressostat.

15

Technical description

W710D006

W710D007

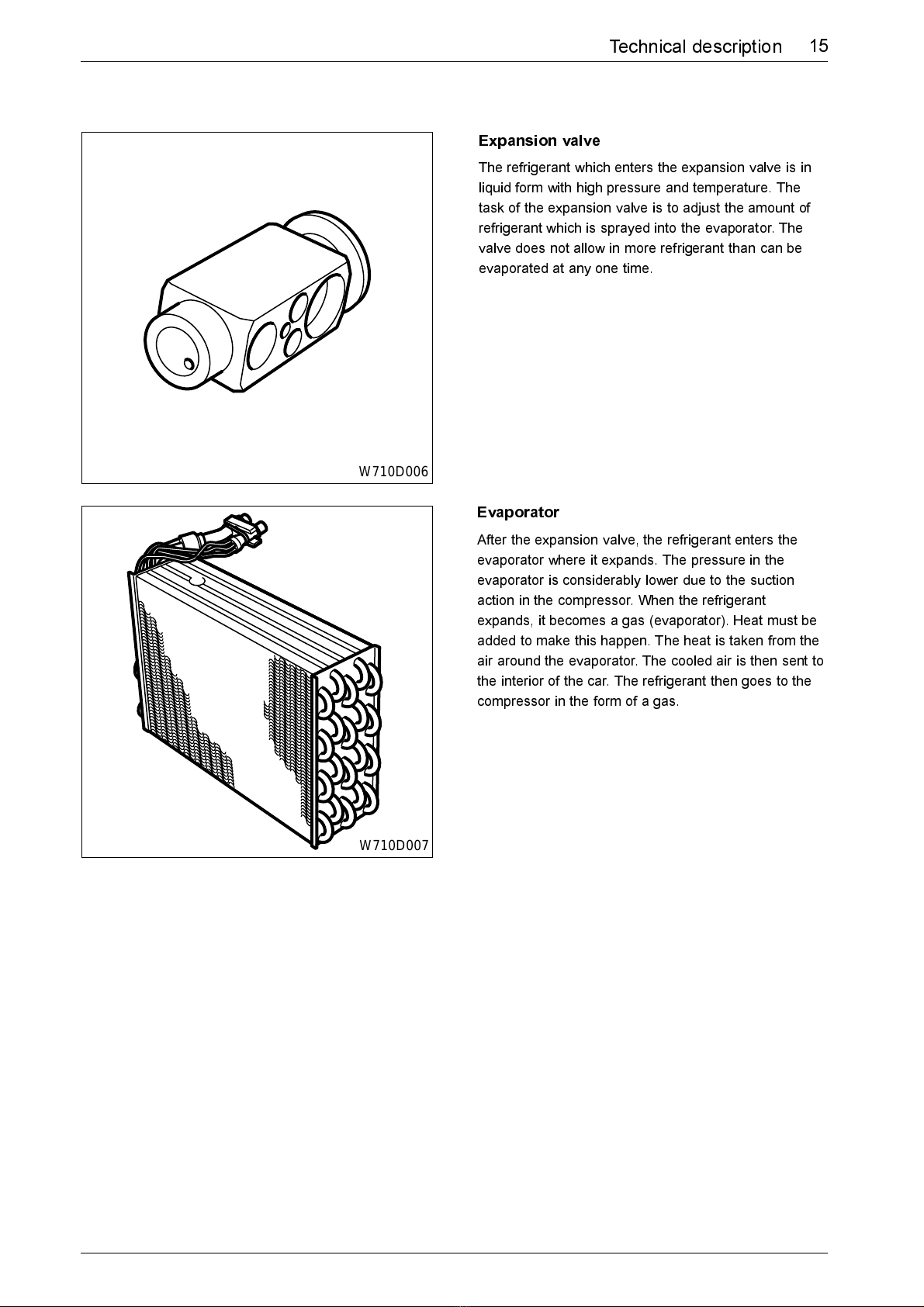

Expansion valve

The refrigerant which enters the expansion valve is in

liquid form with high pressure and temperature. The

task of the expansion valve is to adjust the amount of

refrigerant which is sprayed into the evaporator. The

valve does not allow in more refrigerant than can be

evaporated at any one time.

Evaporator

After the expansion valve, the refrigerant enters the

evaporator where it expands. The pressure in the

evaporator is considerably lower due to the suction

action in the compressor. When the refrigerant

expands, it becomes a gas (evaporator). Heat must be

added to make this happen. The heat is taken from the

air around the evaporator. The cooled air is then sent to

the interior of the car. The refrigerant then goes to the

compressor in the form of a gas.

W710R065

2

1

Draining

1 High pressure valve.

2 Low pressure valve.

Note

The high pressure valve is fitted on the pipe with the

smallest diameter.

Drain the circuit via the low pressure valve (gaseous

zone) very slowly to avoid draining the compressor oil.

Refilling

Imperative

Before filling the circuit with refrigerant, it is necessary

to carry out a vacuum extraction to dry the circuit.

1 Connect the filling equipment to the service

valves.

2 Carry out a vacuum extraction

(draining time 15 minutes)

3 Check the sealing of the circuit:

The vacuum should be held for more than

5 minutes.

4 Carry out a pre-filling:

300g.

5 Check the sealing of the circuit.

6 Drain the refrigerant circuit.

7 Carry out a vacuum extraction

(draining time 30 minutes minimum).

8 Charge the circuit with the specified quantity of

refrigerant.

Adjustments and replacement

Refrigerant circuit - draining, vacuum extraction and refilling

W710R001

4

W710R002

56

7

W710R003

8

8

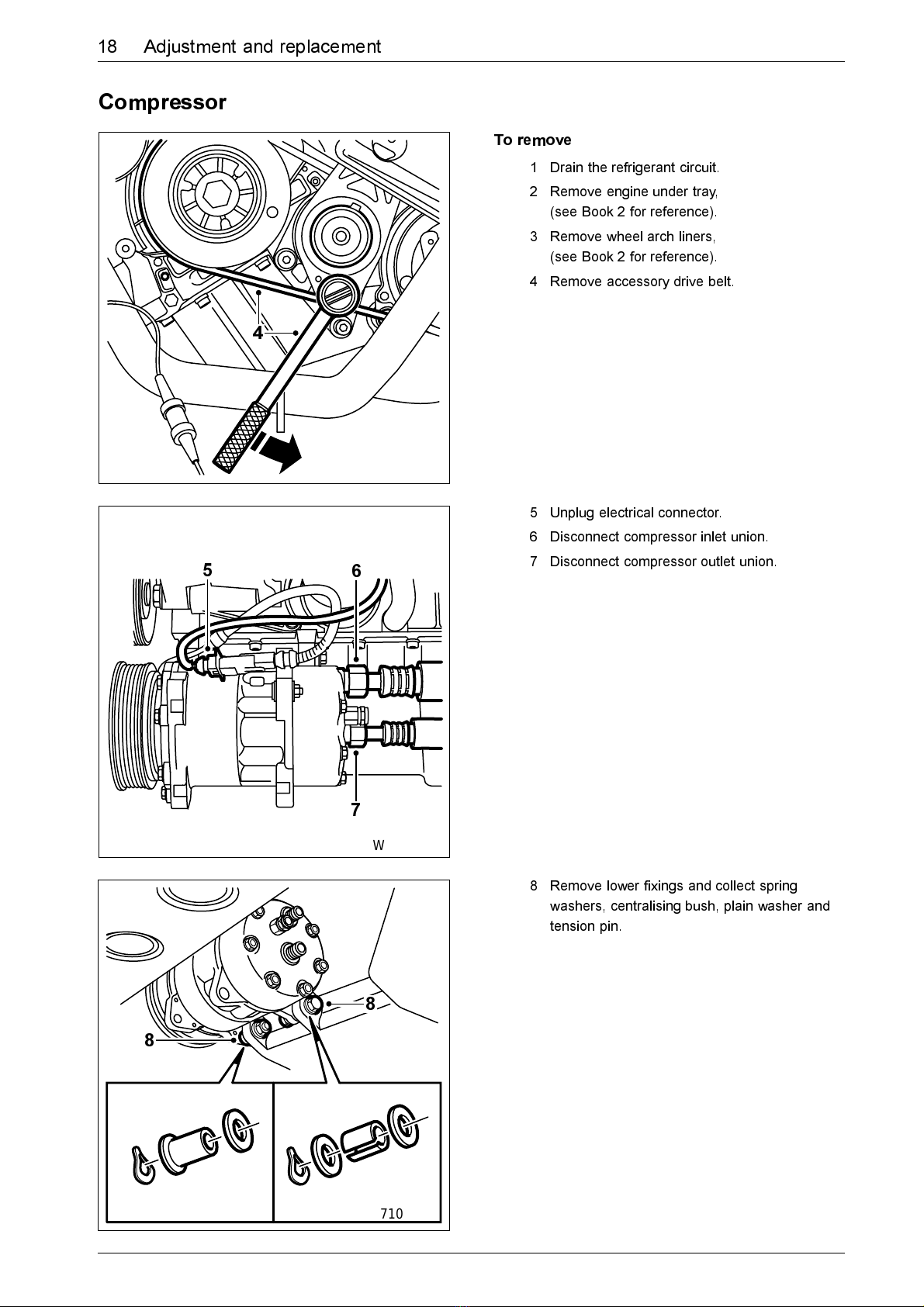

18 Adjustment and replacement

Compressor

To remove

1 Drain the refrigerant circuit.

2 Remove engine under tray,

(see Book 2 for reference).

3 Remove wheel arch liners,

(see Book 2 for reference).

4 Remove accessory drive belt.

5 Unplug electrical connector.

6 Disconnect compressor inlet union.

7 Disconnect compressor outlet union.

8 Remove lower fixings and collect spring

washers, centralising bush, plain washer and

tension pin.

19

Adjustment and replacement

W710R004

99

10

9 Remove upper fixing bolts.

10 Remove compressor.

To fit

Fit in reverse order.

Note

Ensure washers and spacers are correctly fitted.

All fixing bolts have a tightening torque of 5mdaN.

W710R063

3

2

W710R064

4

5

20 Adjustment and replacement

Compressor drive plate

To remove

1 Remove compressor from car.

2 Attach peg spanner.

3 Slacken the central locking nut and remove.

4 Fit the extractor special tool.

5 Extract the drive plate.

To fit

Fit in reverse order.

Note

Fit the old nut and tighten to 3,5-4 mdaN.

Check and adjust the air gap if required.

Fit a new nut in place of the old one and

tighten to 3,5-4 mdaN.

21

Adjustment and replacement

W710R061

3

2

W710R062

4

4

Compressor drive pulley

To remove

1 Remove compressor from car.

2 Remove the drive plate.

3 Remove circlip, washers and key.

4 Fit the extractor special tool and remove

pulley.

To fit

Fit in reverse order.

Note

Fit the old nut and tighten to 3,5-4 mdaN.

Check and adjust the air gap if required.

Fit a new nut in place of the old one and

tighten to 3,5-4 mdaN.

W710R059

1

2

W710R060

3

22 Adjustment and replacement

Compressor oil level

To check

1 Remove plug.

2 Turn compressor pulley by hand to reveal:

a. The inclination of the control plate.

b. The connecting rod, while looking through

the oil filler hole.

3 Position the chamfered face of the dip stick

against the body of the compressor.

Note

The dipstick must enter the compressor without

excessive constraint.

The value should be 6 graduations on the dipstick.

If required, adjust oil level to specified value.

4 Replace plug.

23

Adjustment and replacement

W710R005

W710R006

23

44

W710R007

2,4

Compressor air gap

To measure

1 Measure the air gap between the drive plate

and the pulley.

Measure in at least 3 places.

The air gap should be 0,4 - 0,8mm.

Adjustment

2 If the air gap is incorrect, remove drive plate

retaining nut.

3 Release drive plate and collect washers and

key.

4 Adjust the air gap by changing:

a. Thickness of the washers.

b. The number of washers.

To fit

1 Refit the drive plate.

2 Fit the old nut and tighten to 3,5-4 mdaN.

3 Check and adjust the air gap if required.

4 Fit a new nut in place of the old one and

tighten to 3,5-4 mdaN.

Other manuals for SAMAND

2

Table of contents

Other Ikco Automobile manuals