imes-icore iVAC eco+ Quick start guide

1 Version 1 Aug 2012

iVAC eco+

DUST EXTRACTION UNIT

OPERATIONAL INSTRUCTIONS

2 Version 1 Aug 2012

TABLE OF CONTENTS

SAFETY INSTRUCTIONS.....................................................................................................3

Symbols used ................................................................................................................ 3

Electrical safety............................................................................................................. 3

Dangers to eyes, breathing and skin ............................................................................ 3

Warning and Information Labels.................................................................................. 4

INSTALLATION .................................................................................................................5

Extractor Overview ....................................................................................................... 5

Extractor Installation Procedure................................................................................... 6

Feature Considerations................................................................................................. 6

Filter blocked signal......................................................................................... 7

Remote stop/start ........................................................................................... 7

Electrical supply connection ......................................................................................... 7

General Safety Requirements ....................................................................................... 8

OPERATION .....................................................................................................................9

Manual operation......................................................................................................... 9

MAINTENANCE .............................................................................................................. 10

Maintenance General................................................................................................. 10

Cleaning Unit .............................................................................................................. 10

Replacing Filters ......................................................................................................... 10

Pre filter replacement.................................................................................... 11

Consumable Spares .................................................................................................... 11

Maintenance Protocol ................................................................................................ 12

Filter Disposal ............................................................................................................. 12

TROUBLE SHOOTING...................................................................................................... 13

SYSTEM SPECIFICATIONS................................................................................................ 14

Unit: iVAC eco+ ........................................................................................................... 14

3 Version 1 Aug 2012

SAFETY INSTRUCTIONS

Symbols used

Danger 'Risk of Electric Shock' Refers to an immediately impending danger. If

the danger is not avoided, it could result in death or severe (crippling)

injury. Please consult the manual where this symbol is displayed.

Warning Refers to a possibly dangerous situation. If it is not avoided, it could

result in death or severe injury. Please consult the manual where this

symbol is displayed.

Caution Refers to a possibly harmful situation. If it is not avoided, damage

could be caused to the product or to something in its environment.

Important Refers to handling tips and other particularly useful information.

This does not signify a dangerous or harmful situation.

Electrical safety

This extraction unit is designed to meet the safety requirements of the Low Voltage

Directive 2006/95/EC(previously numbered 73/23/EEC).

Warning During works with the pump/motor housing open, live, 230/115 volt

components are accessible. Make sure that rules and regulations

for work on live components are always observed.

Important To reduce the risk of fire, electric shock or injury:

1. Always isolate the system from the mains power supply before

removing the pump/motor panel.

2. Use only as described in the manual.

3. Connect to a properly grounded outlet.

Dangers to eyes, breathing and skin

Once used, the filters in the extraction unit may contain a mixture of particulates,

some of which may be sub micron size. When the used filters are moved it may

agitate some of this particulate, which could get into the breathing zone and eyes of

the operative. Additionally, depending on the materials being used, the particulate

may be an irritant to the skin.

Caution: When changing used filters always wear mask, safety glasses and gloves.

4 Version 1 Aug 2012

Warning and Information Labels

Label/Symbol

Position

Inside Filter Door (at top)

Top Left of rear panel

Rear of unit, next to power

connection

DO NOT COVER

Above motor cooling on rear of

unit

Top Left of Front Door

5 Version 1 Aug 2012

INSTALLATION

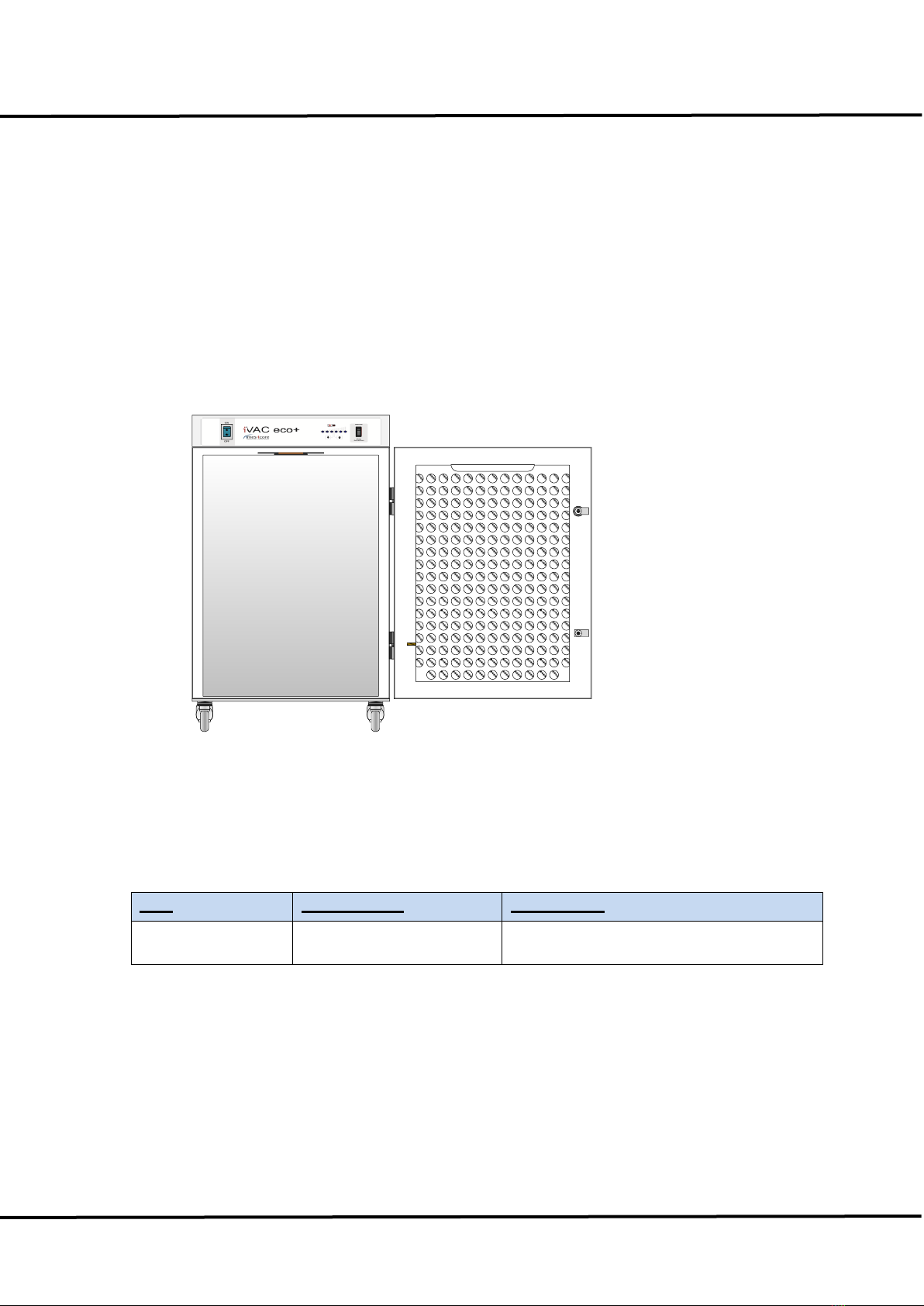

Extractor Overview

This unit provides extraction and filtration of the fume generated by marking, milling,

cutting, etching or engraving. The units are of robust design and feature ease of use

with minimal maintenance. The main components are shown in Fig. 1.

Fig. 1

1. Unit/Filter Condition Display

2. On/Off Switch

3. Motor function switch

4. Hose Inlet Connection 50mm

5. Signal/Interface Connection

6. Power inlet

7. Cooling air inlet

8. Exhaust/Cooling air outlet

9. Filter door catch

Bag Filter

1

23

4

56

78

9

6 Version 1 Aug 2012

Extractor Installation Procedure

Caution

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Read all instructions in this manual before using this extractor.

1. Move the unit to the location where it is going to be installed and remove the unit

from its packaging. The unit should be installed in a well ventilated room.

Caution

Due to the weight involved the extractor unit should only be lifted using suitable lifting

equipment and with regard to appropriate safety precautions. (See Appendix for

product weight details).

2. Ensure that a 0.5m space is available around any louvered areas of the unit to

ensure adequate air flow. Lock the two braked castors, if fitted.

Caution

Do not block or cover any louvers or cooling holes on the unit as this severely

restricts air flow and may cause damage to the unit.

Caution

Under no circumstances should the exhaust outlet/s be covered as this will restrict

the airflow and cause overheating.

3. Check filters are located in their correct position and carefully replace lid/close

door.

4. Connect the extraction ducting between the extractor inlet and the fume capture

device.

Feature Considerations

5. The following features need to be considered when installing the unit:

7 Version 1 Aug 2012

Filter blocked signal

With this, the extraction unit has been fitted with a pressure switch to monitor the

condition of the filters. This is displayed via the Red LED on the front of the unit. This

circuit will not directly stop the extractor motor.

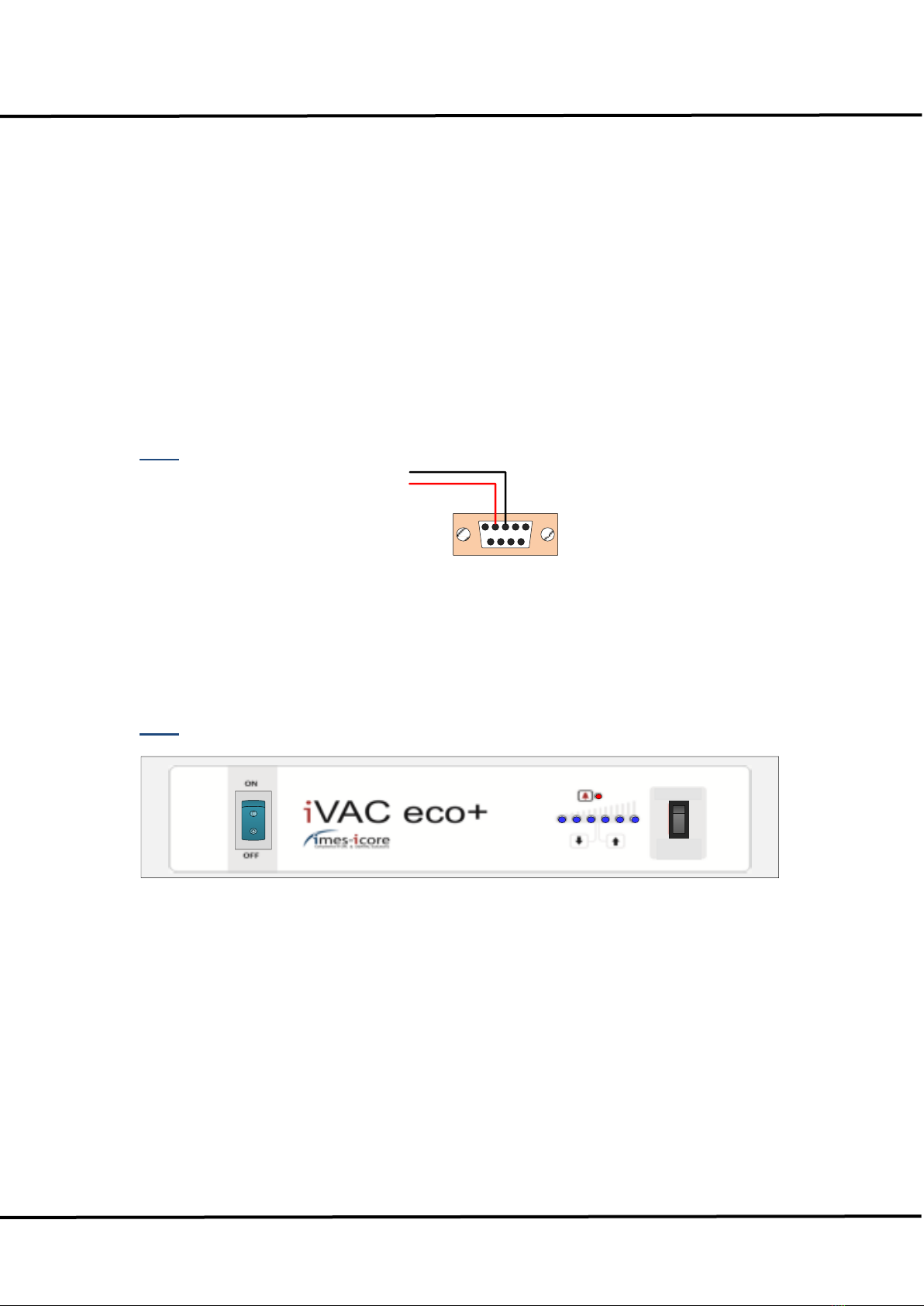

Remote stop/start

This enables the extractor unit to be turned on and off by a signal from the customer.

Pins 3 & 4 of the connector need to be connected to a 24v dc supply to start the unit.

However the mains power switch must be in the “on” position for the signal to be

effective.

Fig 2

Remote operation can be overridden by using the override switch, which is mounted

on the front the unit (see fig. 3).

Fig 3

Manual

Auto

Extraction

Electrical supply connection

6. Check the integrity of the electrical power cable.

Connect the power cable to an isolated electrical supply. The mains socket outlet

should be installed near the equipment and be easily accessible. The cable run to the

machine should be arranged so as not to create a trip hazard.

Pins 3 & 4

Vacuum Motor

Remote

8 Version 1 Aug 2012

Caution:

Check that the mains input at the isolated supply is the same as the voltage Supply

detail on the Serial Number label before plugging the extractor unit in.

General Safety Requirements

Caution

Do not block or cover the cooling vents on the unit, as this severely restricts airflow

and may cause damage to the unit.

Caution

This unit is over 18Kgs in weight and should only be lifted with suitable lifting

equipment.

Caution

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Read all instructions in this manual before using this extractor.

Warning Mains voltage. Dangerous voltages exist in this equipment.

Ensure all covers are fitted before operating this equipment.

The unit is now ready for use.

9 Version 1 Aug 2012

OPERATION

Manual operation

The extraction unit is turned off and on by means of an illuminated rocker switch on

the front of the unit.

Manual

Auto

Extraction

Filter condition signal –indicators & component controls.

The LED on the front panel (see above Fig) indicate when the filter is blocked.

The right switch will allow the vacuum motor to be either On/Off/Auto. Auto will

require a voltage input to the interface connector on the rear of the unit. (see Fig 3)

10 Version 1 Aug 2012

MAINTENANCE

Maintenance General

User maintenance is limited to cleaning the unit and replacing the filters with new.

Only imes-icore trained maintenance technicians are authorised to carry out

component testing and replacement. Unauthorised work or the use of unauthorised

replacement filters may result in a potentially dangerous situation and/or damage to

the extractor unit, and will invalidate the manufacturer’s warranty.

Cleaning Unit

The powder coated finish can be cleaned with a damp cloth and non aggressive

detergent. Do not use an abrasive cleaning product as this will damage the finish.

The cooling inlets and outlets should be cleaned once a year to prevent build up of

dust and overheating of unit.

Replacing Filters

The filter package needs attention when the filter change LED is illuminated or, when

the unit no longer removes the fume efficiently.

A log of filter changes should be maintained by the user.

All filters are tested to BS3928. A certificate on conformity for each filter is available

on request.

It is recommended that a spare set of filters are kept on site to avoid prolonged unit

unavailability. Part numbers for replacement filters can be found on the filters fitted in

your system. Alternatively, refer to the consumable spares table.

Caution

To prevent overheating, units should not be run with a blocked filter condition, or with

dust obstruction of inlets or outlets.

Caution: When changing used filters always wear mask, safety glasses and gloves.

11 Version 1 Aug 2012

Pre filter replacement

The pre filter needs changing when the filter change is illuminated.

Isolate the electrical supply to the extractor.

1. Undo the filter compartment latches on the front of the unit.

2. Remove the pre filter by lowering the supporting plate and replace with a new pre

filter.

3. Push the supporting plate back up so it clips in place, close and fasten filter

compartment latches.

4. Reconnect the electrical supply.

Bag Filter

Consumable Spares

Unit

Part Number

Description

iVAC eco+

513002 0050

5 layer bag filter

12 Version 1 Aug 2012

Maintenance Protocol

Filters to be changed in accordance with instructions. Log the date of filters changed

in the table below:

Unit Serial Number

Pre Filter

Date

Name

Filter Disposal

Pre filters are manufactured from non-toxic materials.

Filters are not re-usable, cleaning used filters is not recommended.

Disposal of the used filters depends on the material deposited on them.

See the following table:

Deposit

EWC listing*

Comment

Non Hazardous

15 02 03

Can be disposed of as non hazardous waste.

Hazardous

15 02 02 M

The type of Hazard needs to be identified and

the associated risks defined. The thresholds for

these risks can then be compared with the

amount of material in the filters to see if they fall

into the hazardous category. If so, the filters will

need to be disposed of inline with the

local/national regulations.

* European Waste Catalogue

14 Version 1 Aug 2012

SYSTEM SPECIFICATIONS

Unit: iVAC eco+

Capacity: 260 m³/hr

Size: Height 750mm x Depth 460mm x Width 440mm

Weight: 30Kg

Exhauster: Centrifugal Blower

Electrical supply: 115-230v 1ph 50/60Hz

FLC: 12.5A

Noise level: Below 75dB (A)

Filters: Pre filter Efficiency F8 95% @ 0.9µ

Environmental Operating Range

Temperature +5°C to +40°C

Humidity Max 80 % RH up to 31°C to Max 50% RH at 40°C

Altitude: Below 2000m

Pollution Degree 2

Table of contents