Infrico Pharma Care Series Dimensions and installation guide

Cabinets

Pharma Care Series

User Manual and Warranty

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

CONTENTS

1. INTRODUCTION............................................................................................................................................ 1

1.1 Intended use............................................................................................................................................ 2

2. SAFETY INSTRUCTIONS................................................................................................................................. 3

2.1 Symbols ........................................................................................................................................................... 3

3. LABELLING.................................................................................................................................................... 4

3.1 Technical label ......................................................................................................................................... 4

4RECEIPT AND INSPECTION............................................................................................................................ 5

5INSTALLATION .............................................................................................................................................. 5

5.1 Location ................................................................................................................................................... 5

5.2 Environmental operating conditions. ...................................................................................................... 6

5.3 Environmental conditions for transportation and storage...................................................................... 6

5.4 Unpacking ................................................................................................................................................ 6

5.5 Electrical connection................................................................................................................................ 6

5.6 Battery ..................................................................................................................................................... 7

5.7 Levelling................................................................................................................................................... 8

5.8 Rubber gasket.......................................................................................................................................... 9

5.9 Remote Alarm Installation....................................................................................................................... 9

5.10 Final Check-up ......................................................................................................................................... 9

5.11 Cleaning and Disinfection ........................................................................................................................ 9

6DRAWERS (OPTIONAL in PER07S, PER07G, PER15S, PER15G, PER36S and PER36G)................................. 11

6.1 Removing the Drawers ...........................................................................................................................11

6.2 Reinstalling the Drawers.........................................................................................................................11

6.3 Changing the position of the drawers ....................................................................................................11

7DIGITAL CONTROL ...................................................................................................................................... 13

7.1 Front panel .............................................................................................................................................13

7.2 The display screen ..................................................................................................................................13

7.3 Unlocking the keyboard..........................................................................................................................14

7.4 Changing the Set Point ...........................................................................................................................14

7.5 Manual defrost .......................................................................................................................................14

7.6 Changing parameters..............................................................................................................................14

7.7 Turning the equipment on and off .........................................................................................................15

7.8 Alarms.....................................................................................................................................................15

8TEMPERATURE MONITORING.................................................................................................................... 17

8.1 Set Point Control.....................................................................................................................................17

8.2 Product Simulation Temperature Probe (Optional) ...............................................................................17

9MAINTENANCE, CLEANING, AND CARE...................................................................................................... 18

9.1 Cleaning Procedure.................................................................................................................................18

9.2 Battery Replacement ..............................................................................................................................19

9.3 Spare Parts and Technical Support.........................................................................................................20

10 TROUBLESHOOTING................................................................................................................................... 21

11 USEFUL LIFE OF THE EQUIPMENT .............................................................................................................. 23

11.1 End of useful life .....................................................................................................................................23

12 TEMPERATURE CHART RECORDER (OPTIONAL)......................................................................................... 24

13 WARRANTY................................................................................................................................................. 25

13.1 Warranty certificate................................................................................................................................26

1

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

1. INTRODUCTION

Pharmaceutical refrigerators are designed to strictly meet the requirements necessary to operate in

pharmacies.

Pharmaceutical refrigerators are classified as CLASS I (Protection against electric shock) and a mode of

CONTINUOUS OPERATION according to UNE_EN_60601.

This product has been manufactured under strict quality controls and meets all the requirements

established by Infrico. Each unit has been tested and its quality is ensured before being shipped. This equipment

has been manufactured with recyclable materials, by means of an environmentally friendly production process.

MODELO

MODEL

Capacidad Bruta

(litros) Gross

Capacity (liters)

Medidas Exterior

(mm) Exterior

dimensions (mm)

Medidas Interior

(mm) Interior

dimensions (mm)

Claro de puerta

(mm) Door

opening (mm)

Nº Estantes

Shelves Number

Dimensiones

Estante (LxP)

Shelf size (LxD)

PER07S

58

445 x 526 x 818

358 x 312 x 523

358 x 516

2

315 x 248

PER07G

60

445 x 508 x 818

358 x 323 x 523

358 x 516

2

315 x 248

PER16S

141

600 x 688 x 824

505 x 451 x 617

505 x 552

3

458 x 398

PER16G

141

600 x 680 x 824

505 x 455 x 617

505 x 552

3

458 x 398

PER24S

236

600 x 688 x 1244

505 x 451 x 1037

505 x 972

4

458 x 398

PER24G

238

600 x 680 x 1244

505 x 455 x 1037

505 x 972

4

458 x 398

PER28S

327

600 x 688 x 1644

505 x 451 x 1437

505 x 1372

5

458 x 398

PER28G

330

600 x 680 x 1644

505 x 455 x 1437

505 x 1372

5

458 x 398

PER37S

373

600 x 688 x 1844

505 x 451 x 1637

505 x 1572

6

458 x 398

PER37G

376

600 x 680 x 1844

505 x 455 x 1637

505 x 1572

6

458 x 398

PTR30ISD

313

595 x 621 x 1876

483 x 426 x 1521

483 x 1311

7

418 x 398

PTR30IGD

328

595 x 621 x 1876

483 x 446 x 1521

483 x 1311

7

418 x 398

PTR40ISD

398

670 x 683 x 1963

568 x 484 x 1338

568 x 1280

7

500 x 443

PTR40IGD

413

670 x 683 x 1963

570 x 504 x 1338

568 x 1280

7

500 x 443

PTR65ISD

506

687 x 870 x 1955

534 x 633 x 1207

534 x 1350

7

452 x 585

PTR65IGD

521

687 x 870 x 1955

534 x 654 x 1207

534 x 1350

7

452 x 585

PTR80ISD

719

797 x 1000 x 1955

645 x 803 x 1388

645 x 1350

7

564 x 750

PTR80IGD

737

797 x 1000 x 1955

645 x 823 x 1388

645 x 1350

7

564 x 750

PTR130ISD

1166

1385 x 834 x 1955

1234 x 681 x 1388

534 x 1350

14

452 x 585

PTR130IGD

1202

1385 x 834 x 1955

1234 x 702 x 1388

534 x 1350

14

452 x 585

Temperature range of the equipment: 2 ºC to 8 ºC (35,6ºF a 46,4ºF)

Accuracy: ± 0.1 ºC (±0,2ºF)

Display error values: ±0.2 ºC (±0,4ºF)

2

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

Please read this manual carefully before installing your new device to become familiar with all of its

advantages.

OBLIGATION! This device must be used only for the purpose described in this manual.

1.1 Intended use

Our equipment is designed for the storage and preservation of pharmaceutical products at a

temperature range of 2 ºC to 8 ºC. (35,6ºF a 46,4ºF)

3

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

2. SAFETY INSTRUCTIONS

In this manual and on the labels of this product, the terms Warning and Caution convey the following

meaning:

•Warning: A potentially hazardous situation which, if not avoided, could result in serious injury or death.

•Caution: A potentially hazardous situation which, if not avoided, may result in minor or moderate injury or

damage to equipment.

Please read this manual and the product labels carefully before installing or using this product. Failure

to follow these instructions may cause the product to malfunction, which may result in injury or damage.

The use of electrical devices implies the implementation of basic safety instructions such as:

•Follow the recommendations in this manual to properly locate and place this device prior to installation.

•Do not allow children to handle the device, as they could damage it, or themselves, seriously.

•Do not touch the cold surfaces of the freezing devices, as such surfaces may adhere to skin.

•Do not store or use flammable products near the device.

•Unplug the device before any cleaning, repair or maintenance operation.

WARNING!: Any manipulation of the device must be carried out by an authorised technical support

service provider.

WARNING!: 'No modification is permitted on this equipment.'

WARNING!: We inform you that the person installing the device is responsible for carrying out the

installation as instructed in the user manual.

WARNING!: We remind you that you are responsible for the proper maintenance of the equipment.

The manufacturer is not to be held liable for issues resulting from improper maintenance.

2.1 Symbols

WARNINGS

OBLIGATION

4

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

PROHIBITION

BATTERY

GROUNDING

3. LABELLING

In our equipment, labels are attached to the inside of the products. Their exact location is the top inner

left side.

3.1 Technical label

5

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

4RECEIPT AND INSPECTION

•All Infrico products are factory tested to assess their quality and performance and are shipped free of defects.

•When you receive your device, it should be carefully examined for any damage that may have incurred during

transportation.

•If any damage is detected on the unit, you must retain all packaging material and report such damage on the

carrier's bill of lading. A claim must be immediately made to the transport company.

•If the damage is found during or immediately after installation, contact your distributor immediately.

WARNING!: Infrico is not to be held liable for any damage caused during transport.

5INSTALLATION

5.1 Location

This device is intended for indoor use only.

Be sure the location chosen for your unit must be able to provide good air circulation efficient

refrigeration.

Avoid locations near heat sources, such as sunny windows, ovens, heaters, as well as direct solar

radiation where temperatures can reach extreme values. In addition, do not choose a location in areas where

temperatures drop below 12 °C or rise above 32 °C.

You should allow enough clearance between the equipment and the side walls so that the 120° door-

opening lock can be used. Doors require a minimum angle of 90° to open properly, in order to use the maximum

door width available.

The surface of the final location where the device is to be placed must be strong enough to support the

total weight of the device considering its full maximum load capacity. In addition, it must be levelled and free of

vibrations. Reinforce the flooring if necessary.

WARNING!: Do not place the equipment so that it is difficult to operate on the disconnecting device

(power cord peg).

6

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

5.2 Environmental operating conditions.

Laboratory refrigerators are designed to be safe under the following conditions.

•Indoor use

•Altitude up to 2000 m (795 mbar)

•Temperatures from 12 ºC to 32 ºC (53,6ºF to 89,6ºF)

•Maximum Relative Humidity: 65 %

•Voltage fluctuations in mains of up to ±10 % of the nominal voltage.

5.3 Environmental conditions for transportation and storage.

Laboratory refrigerators are designed to be safe under the following transportation conditions.

•Storage temperature: from -15 ºC (5ºF) to 55 ºC (131ºF)

•Relative humidity: 20 - 85 % (non-condensing)

5.4 Unpacking

The devices are shipped from the factory on a wooden pallet and are packed in sturdy

wooden/cardboard boxes. The box is screwed to the wooden base. The screws must be removed prior to

unpacking to avoid damage to the unit.

All packaging materials are environmentally friendly and should be reused or recycled. Actively

contribute to the protection of the environment by demanding recyclable packaging and environmentally

friendly disposal methods.

WARNING: Infrico does not recommend knocking the unit forward, sideways or backward. However,

if this occurs, you must ensure that the unit remains in an upright position for at least 24 hours

before connecting it, so that the compressor oil returns to the compressor.

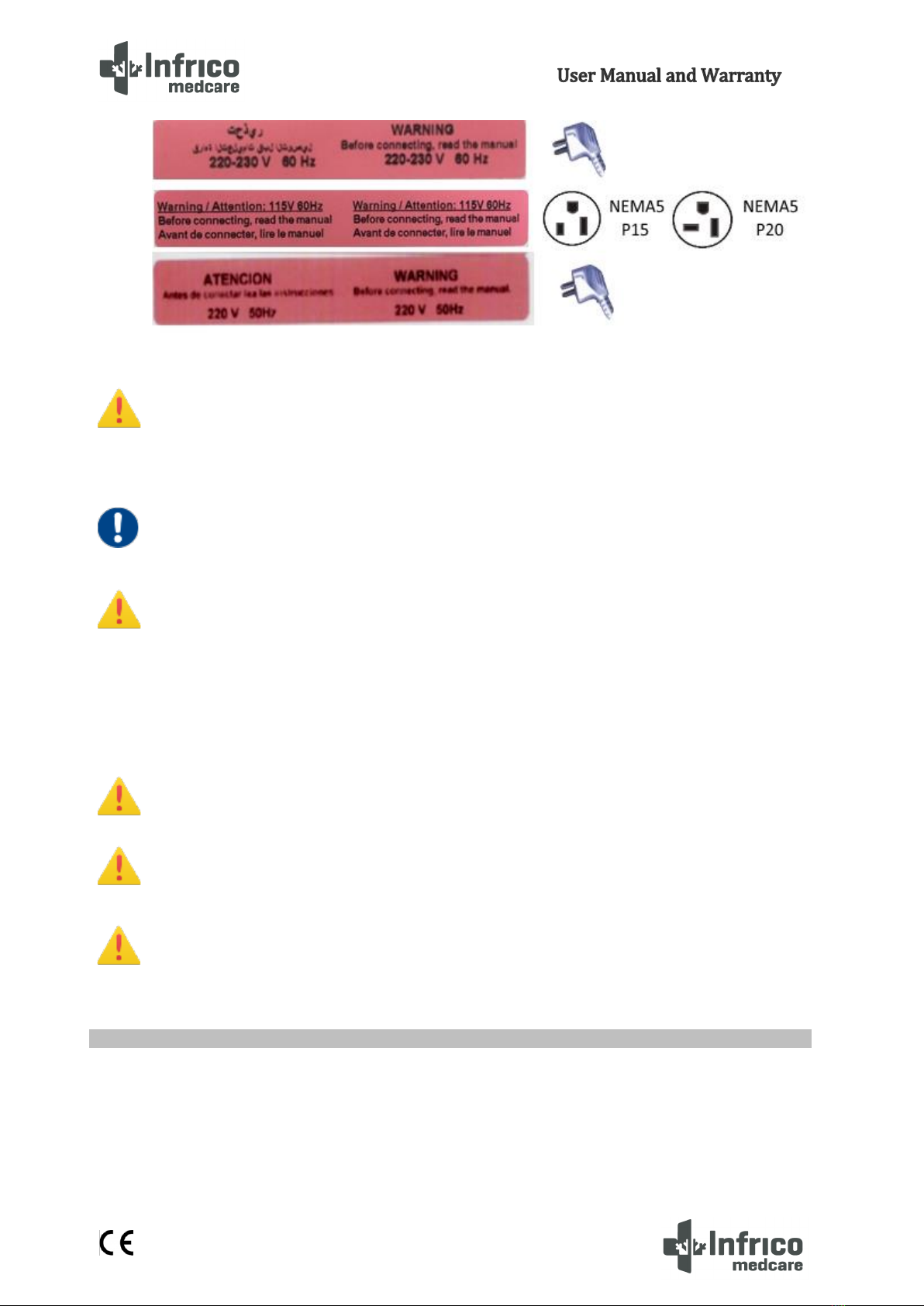

5.5 Electrical connection

WARNING!: Connect the equipment to a dedicated outlet with the correct voltage for the device.

Incorrect power or voltage fluctuations can cause serious damage to the equipment.

The equipment is prepared for power supply 220-230V 50 Hz, 220-230V 60 Hz, 115V, 60Hz. The

equipment has a hose and plug installed in the factory. Check the adhesive on the power cord. If you do

not have the proper outlet, you must install it beforehand. The means to isolate the equipment from

the power supply network is the plug of the power cable.

7

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

WARNING!: This unit must be grounded before use in order to ensure personal safety and the proper

operating of the equipment. A grounding fault may cause damage to personnel or equipment.

Always comply with the National Electrical Code. Do not connect the equipment to power lines that

are already overloaded.

OBLIGATION: The device must be connected to an exclusive dedicated circuit. Failure to comply with

this requirement shall void the warranty.

WARNING!: The device is designed to tackle a voltage fluctuation of around 10 % in relation to the

rated voltage indicated in the rating plate. A compressor fault due to higher fluctuations shall

automatically void the warranty.

Note: It is recommended to install a UPS (Uninterruptible Power Supply) or other system to avoid

voltage peaks or lack of electric current supply.

WARNING!: If the hose or the peg are altered in any way, they may constitute a serious hazard. Any

alteration of these components shall void the warranty.

WARNING: Devices connected to an extension cord are not covered by Infrico's warranty.

WARNING: The power cable can only be replaced by an authorized technical support service

provider.

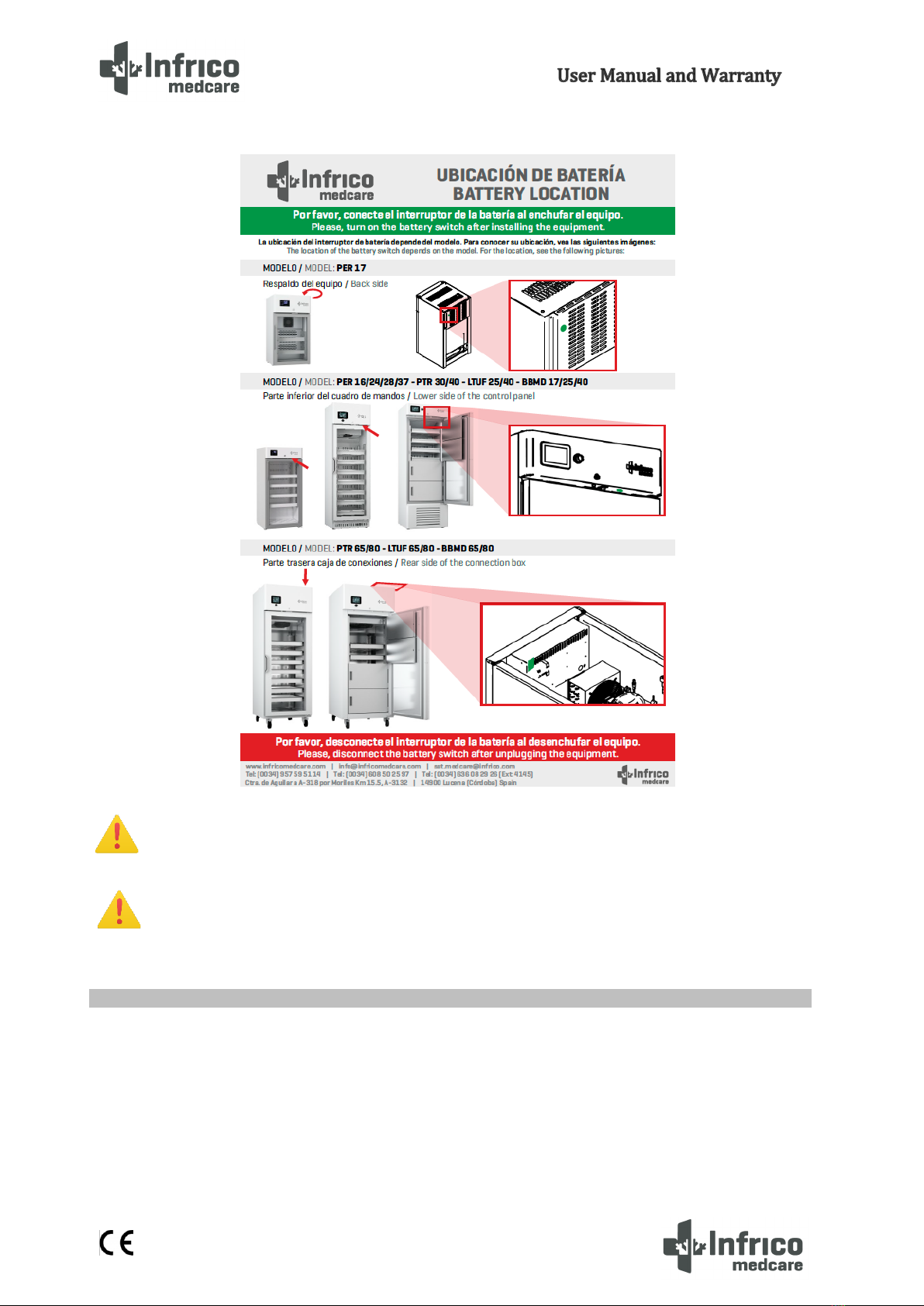

5.6 Battery

The equipment is equipped with a 12V-12Ah rechargeable lead-acid battery. (Except the models

PER07S/PER07G/LER07S/LER07G, which are with a 12V-7Ah rechargeable lead-acid battery).

Once the equipment has been installed, it must be connected by an approved installer. Follow the

instructions below.

8

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

WARNING!: Disconnect the battery switch after unplugging the equipment or in case of power failure

The warranty does not cover battery replacement due to discharge due to this circumstance.

WARNING!: For battery replacement see Section 9.2.

5.7 Levelling

It is very important that the device is perfectly levelled for proper operation, so that it drains properly,

the doors are aligned, and the unit is not subjected to undue stress.

These models are shipped from the factory with adjustable legs. In this case, adjust them until the unit

is completely stable and levelled.

9

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

Optionally, the units can be shipped with non-adjustable wheels for all models. In this case, you must

ensure that the floor where the unit will be located is levelled. The front wheel brakes must be locked for stable

operation.

5.8 Rubber gasket

To verify that the door is sealed, follow the steps below:

1. Opening the door.

2. Insert a strip of paper between the rubber gasket and the rubber gasket profile, and close the door.

3. Slowly remove the paper strip from the outside. While doing so, you should feel a little resistance.

4. Repeat this operation at 10 cm intervals covering the entire door frame. If the door does not close

properly, the gasket needs to be replaced or the door needs to be adjusted.

CAUTION! Hermetic door sealing is essential for blood bank refrigerators to function properly. Faulty

sealing allows humid air inside the device, which results in the accumulation of moisture in the

evaporator, resulting in poor temperature maintenance, increased operating time, and increased

operating costs.

5.9 Remote Alarm Installation

All models of pharmaceutical refrigerators have a remote alarm

connection that is located in the back of the equipment

5.10 Final Check-up

Before commissioning the device, follow the steps below:

1. Make sure the unit is free of all wood or cardboard packaging materials, both on the inside and

outside.

2. Verify the position of the stainless steel drawers. If you want to adjust the height of the drawers,

follow the instructions in section 6.3.

3. Verify that the unit is connected to a dedicated outlet.

5.11 Cleaning and Disinfection

Before commissioning the device, clean and disinfect it to remove any metal, plastic, sticker or residue

left.

10

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

Use water with a neutral detergent and dry properly.

CAUTION! Do not use a brush, acid, diluent, laundry soap, washing powder or boiling water to clean

the device.

These may damage the painted surface, as well as the stainless steel surface, or the plastic and

rubber components. Also, do not clean plastic and rubber components with a volatile material.

11

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

6DRAWERS (OPTIONAL in PER07S, PER07G, PER15S, PER15G, PER36S and PER36G)

6.1 Removing the Drawers

To remove the drawers, complete the following steps:

1. Pull the drawer towards you until the slide rails are fully extended.

2. Press on the back of the side clips to unlock the drawer lock.

3. Lift the front of the drawer and pull it back to remove it.

6.2 Reinstalling the Drawers

To reinstall the drawers, complete the following steps:

1. Insert the drawer in the side slide rails tilting it at about 45º. Once it is fit on the rails, place it in

a horizontal position.

2. Press on the front of the side clips to lock the drawer latch.

3. Insert the drawer all the way in.

6.3 Changing the position of the drawers

The drawer slide rails are height adjustable. You can place these rails in the vertical slits that are spaced

at intervals of 50.

To change the position of the drawer slide rails, complete the following steps:

1. Pull the front of the slide rail upwards until the front flap comes out of its place.

2. Then pull the slide rail forwards until the rear flap comes out of its place too.

3. Change the height as desired by following the steps in reverse to put the slide rail back in

place.

12

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

13

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

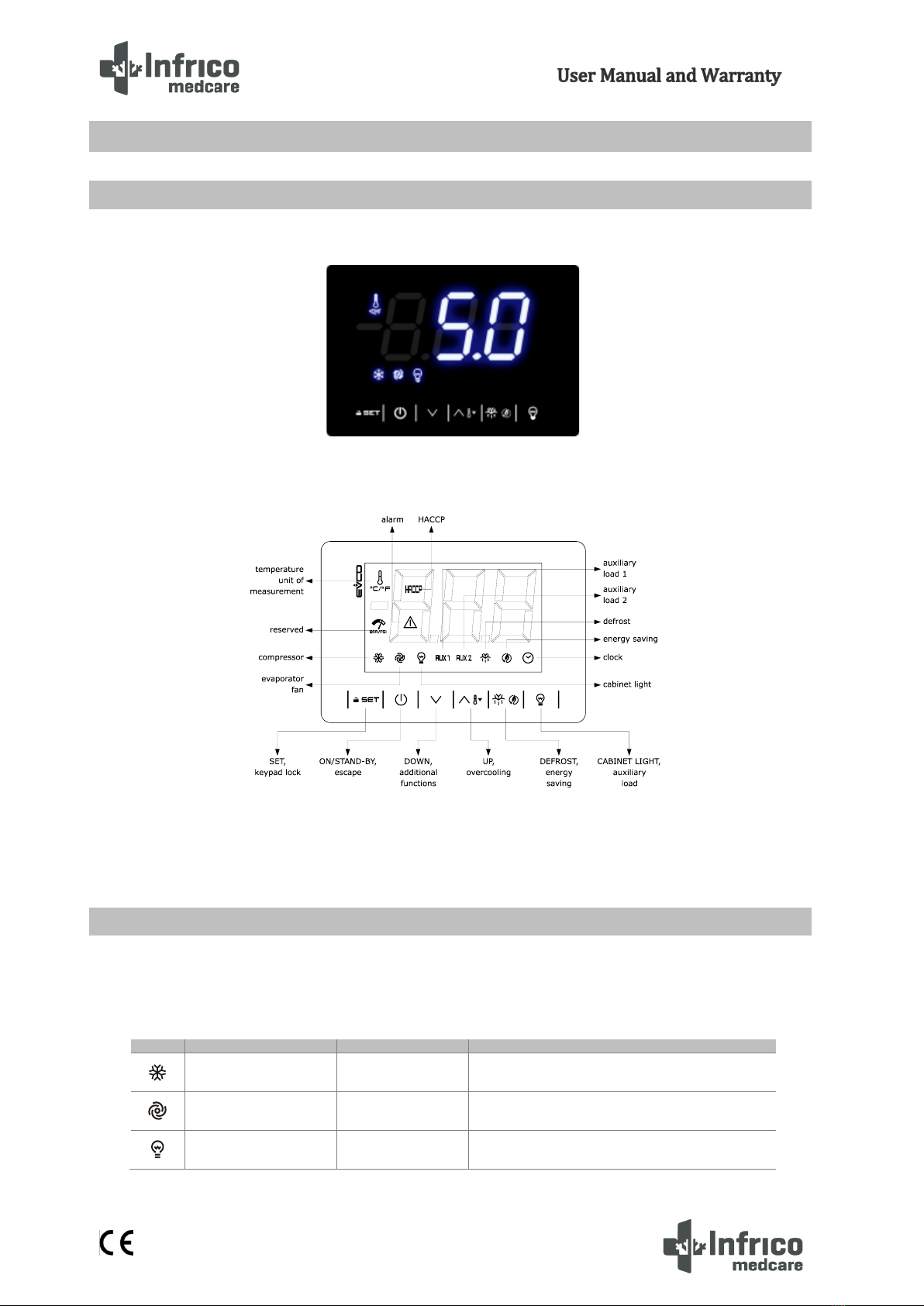

7DIGITAL CONTROL

7.1 Front panel

7.2 The display screen

The following icons appear on the screen:

LED

ON

OFF

FLASHING

compressor ON

compressor OFF

- Compressor protection activated

- Setpoint setting

Evaporator fan ON

Evaporator fan OFF

Fan shutdown activated

Interior light ON

Interior light OFF

Interior light activated via digital input

14

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

AUX 1

Auxiliary function 1

ON

Auxiliary function 1

OFF

- Auxiliary function 1 via digital input

- Auxiliary function 1 via digital input

AUX 2

Auxiliary function 2

ON

Auxiliary function 2

OFF

- Auxiliary function 2 via digital input

- Auxiliary function 2 - delay activated

Defrost or pre-

dripping activated

-

- Defrost delay activated

- Dripping time enabled

- Energy saving

activated

- Low power activated

-

-

View time

-

date, time and day of the current week setting

View temperature

-

Fast refrigeration activated

HACCP

recording of HACCP

alarms

-

new HACCP alarm saved

Alarm activated

-

-

7.3 Unlocking the keyboard

Press any key for 1 second: The screen shows the unlocking message 'UnL'.

7.4 Changing the Set Point

Check that the keyboard is unlocked.

Press the SET key.

Press the up or down key to set a value within the r1 and r2

limits.

Press the Set key (or do not press for 15 s).

7.5 Manual defrost

Check that the keyboard is unlocked, and that quick refrigeration is not active.

Press the Defrost key for 2 s.

If P3 = 1 (by default), defrost is activated whenever the evaporator temperature is below limit d2.

7.6 Changing parameters

15

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

Press the SET key for 4 seconds: the screen will show the message

'PA'.

Press the SET key.

Press the up and down keys to enter the password (by default '-19').

Press the Set Key (or do not press for 15 s). The screen will display

the message 'SP'.

Press the up and down keys to select a parameter.

Press the SET key.

Press the up and down keys to select a value.

Press the Set key (or do not press for 15 s).

Press the SET button for 4 seconds (or do not press for 60 s) to end

the process.

7.7 Turning the equipment on and off

If POF = 1 (by default), press the ON/STAND-BY key for 2 seconds.

If the device is turned on, the screen will display the value P5 ('Temperature inside chamber'); if the screen

displays any alarm code, go to section 5.8 'Alarms'.

7.8 Alarms

CODE.

DESCRIPTION

RESTART

TO CORRECT

Pr1

Chamber probe alarm

automatic

- check P0

Pr2

Evaporator probe alarm

automatic

- check the status of the probe

Pr3

Auxiliary probe alarm

automatic

- check the electrical connection

rtc

Clock alarm

manual

Set date, time and day of the week

AL

Low temperature alarm

automatic

check A0, A1 and A2

AH

High temperature alarm

automatic

check A4 and A5

id

Door open alarm

automatic

check i0 and i1

PF

Power fault alarm

manual

- Press a key

- Check the electrical connection

COH

High condensation

warning

automatic

check C6

CSd

High condensation alarm

manual

- Turn the device off and on again

- check C7

iA

Multifunction input

alarm

automatic

check i5 and i6

iSd

High pressure alarm

manual

- Turn the device off and on again

- check i5, i6, i8, i9

LP

Low pressure alarm

automatic

check i5 and i6

C1t

Compressor thermal

switch alarm

automatic

check i5 and i6

16

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

C2t

Second compressor

thermal switch alarm

automatic

check i5 and i6

dFd

End defrost time alarm

manual

- Press a key

- check d2, d3 and d11

FUL

Full SD card alarm

manual

Free up space in the SD memory or replace the

card.

Sd

SD card missing alarm

manual

Insert SD card or replace it.

17

MAN-U-PER-PTRSD-EN Review: 01 28/03/2022

8.1 Set Point Control

Your unit has been factory set and tested to maintain a chamber temperature of -18°C. For most

laboratory applications, you will not need to change the temperature set point.

The chamber set point value is calculated according to the cut-off service parameters and a differential.

To adjust the set point:

1.- Access the service parameters as shown in section 7.6.

2.- Adjust the cut-off values and differential as necessary.

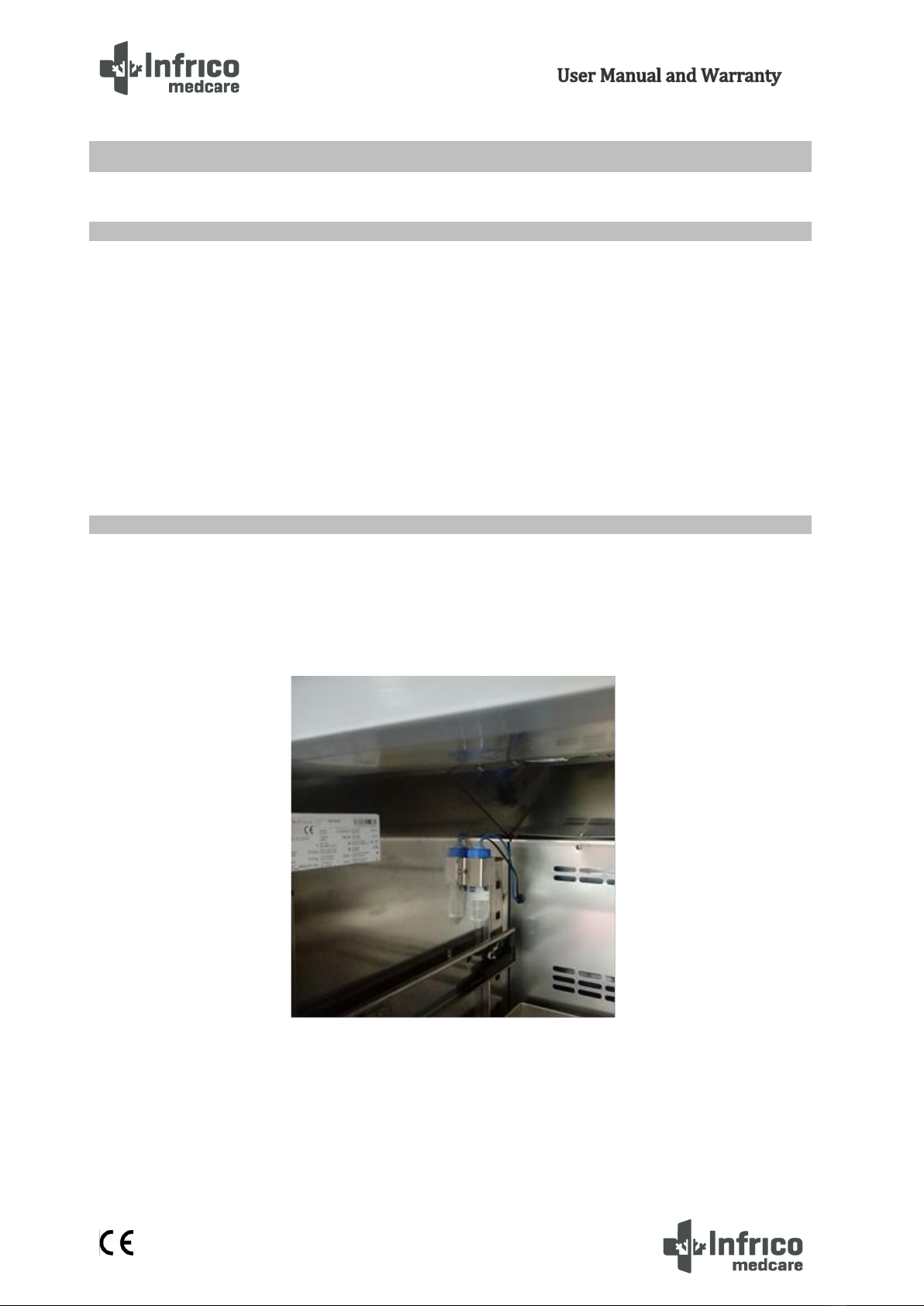

8.2 Product Simulation Temperature Probe (Optional)

The temperature of the chamber is measured by means of two probes inserted in a pot, placed on the side as

shown in the image. The pot contains 5% glycerine and 95% water to simulate samples of vaccines and /

or medications. Keep the sensor canister completely filled to the top.

8TEMPERATURE MONITORING

This manual suits for next models

20

Table of contents

Other Infrico Refrigerator manuals

Popular Refrigerator manuals by other brands

Frigidaire

Frigidaire FPHI2187KR - Professional Top Freezer parts catalog

VOX electronics

VOX electronics KS1430 operating instructions

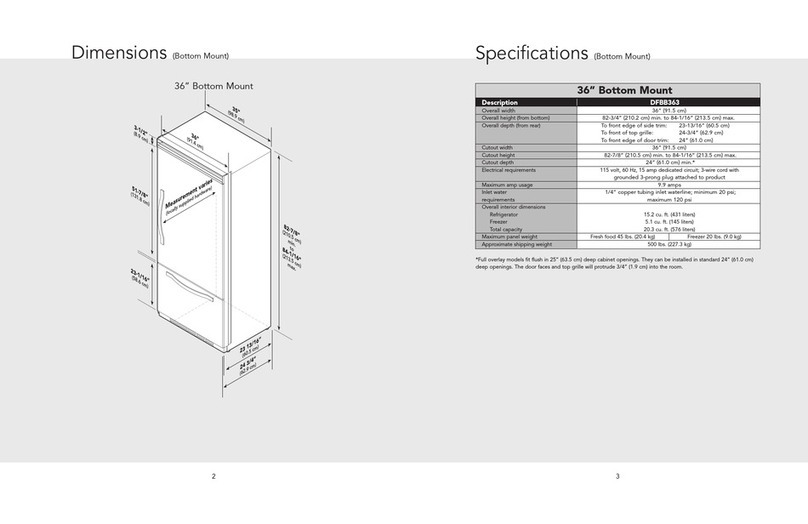

Viking

Viking Designer DFBB363 Instruction

Amana

Amana AFI2538AEW Use & care guide

Zanussi

Zanussi ZBA22421SA user manual

Zanussi

Zanussi ZI 3165A - ZI 3243A Instructions for the use and care