4

1.1

1.2

General warnings

Fundamental safety rules

After unpacking, make sure that all the components are

present. If not, contact the INNOVA agent who sold the

appliance to you.

INNOVA appliances must be installed by an authorised

installer who, on completion of the work, will release a

declaration of conformity to the client in respect of the

laws in force and the indications given by INNOVA in the

instructions leaflet supplied together with the appliance.

These appliances have been designed both for

conditioning and/or heating environments and must

be destined for this use only and compatibly with their

performance characteristics.

INNOVA accepts no responsibility, either contractual or

extra-contractual, for any damage caused to persons,

animals of property as a result of incorrect installation,

adjustment or maintenance or improper use.

In case of water leaks, turn the master switch of the

system to "OFF" and close the water taps.

As soon as possible, call the INNOVA technical service

department or else professionally qualified personnel

and do not intervene personally on the appliance.

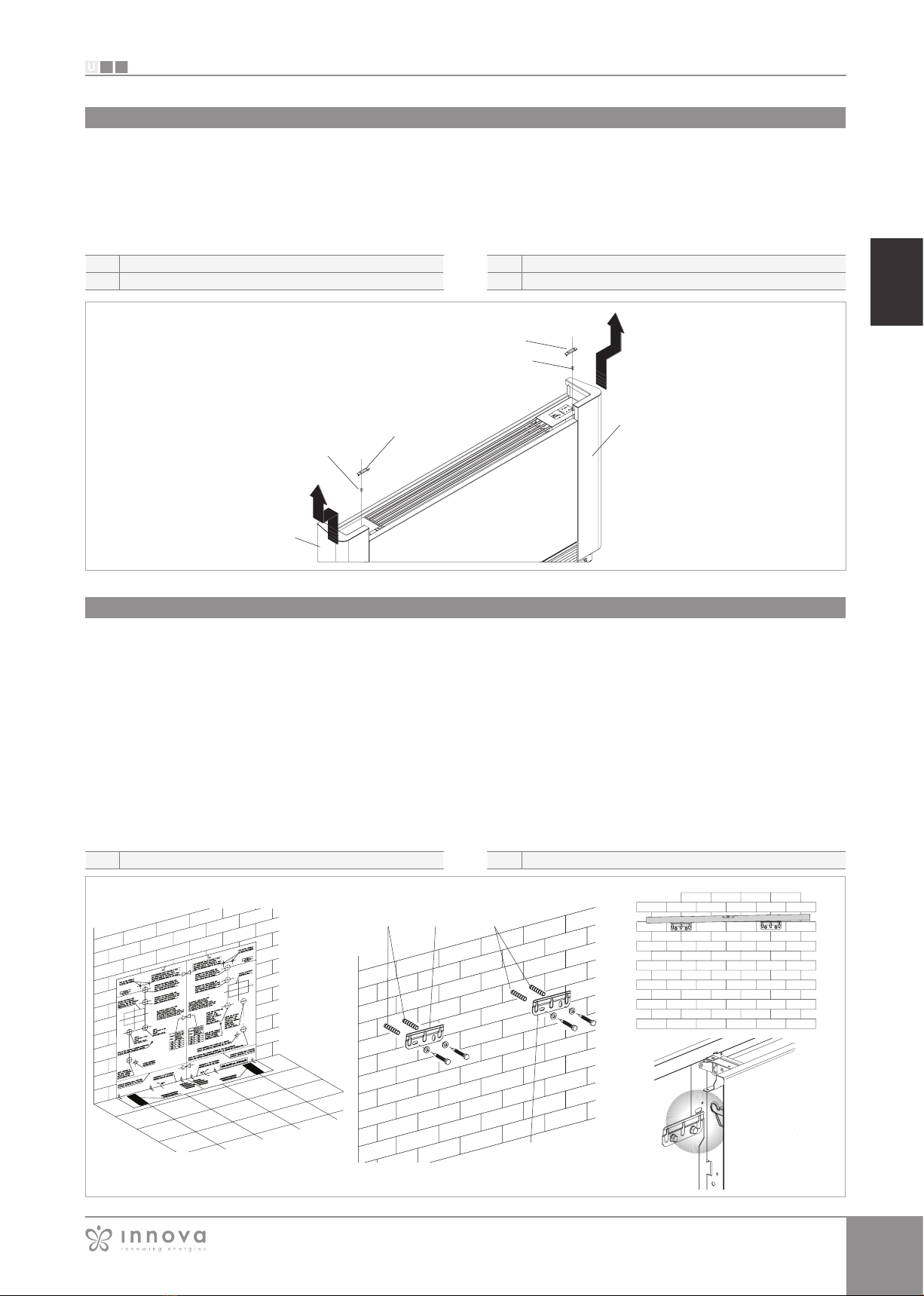

The imbedded Air Leaf SLI, RSI and SLSI series do not

have a grill or covering plate. Provide safety guards and

air inlet/outlet grills to prevent accidental contact with the

device.

If the appliance is not used for a log period of time, the

following operations should be performed:

- Turn the master switch of the system to "OFF"

- Close the water taps

- If there is the risk of freezing, make sure that anti-freeze

has been added to the system otherwise empty the

system.

If the room temperature is too low ot too high it is

damaging for the health and is also a useless waste of

energy.

Avoid prolonged contact with the direct air flow.

Do not leave the room closed for long periods.

Periodically open the windows to ensure a correct

change of air.

This instruction leaflet is an integral part of the

appliance and consequently must be kept carefully

and must ALWAYS accompany the appliance, even

when it is passed to a new owner or user or transferred

onto another system. If it is lost or damaged, please

contact the local INNOVA technical service centre.

All repair or maintenance interventions must be

performed by the technical service department or by

professionally qualified personnel as foreseen in this

booklet. Do not modify or intervene on the appliance

as this could create dangerous situations and the

manufacturer will not be responsible for any damage

caused.

Danger from burns - take care when touching

Remember that some fundamental safety rules should

be followed when using a product that uses electricity

and water, such as:

It is forbidden for the appliance to be used by children

or unassisted disabled persons.

It is forbidden to touch the appliance with wet hands

or body when barefoot.

It is forbidden to carry out any cleaning before having

disconnected the appliance from the electricity mains

supply by turning the system master switch to "OFF".

It is forbidden to modify the safety or adjustment

devices or adjust without authorisation and indications

of the manufacturer.

It is forbidden to pull, cut or knot the electrical cables

coming out of the appliance, even if it is disconnected

from the mains supply.

It is forbidden to poke objects or anything else through

the inlet or outlet grills.

It is forbidden to open the doors which access the

internal parts of the appliance without first turning the

system master switch to "OFF".

GENERAL