Innovative Electronic Designs 4400 Series User manual

MODELS 4400 SERIES AND 4800 SERIES

AUTOMATIC MIXERS

GENERAL PROCEDURE

»BEFORE CONNECTING OR DISCONNECTING THE POWER SUPPLY REAR PANEL

CONNECTOR, ANY REAR PANEL WIRING, OR REMOVING OR REPLACING

JUMPERS (SHUNTS), PERFORM THE FOLLOWING STEPS:

1. DEPRESS THE FRONT PANEL POWER SWITCH TO THE OFF POSITION.

2. DISCONNECT THE POWER SUPPLY FROM THE AC POWER OUTLET.

FAILURE TO DO SO MAY RESULT IN DAMAGE TO THE EQUIPMENT AND WILL

VOID THE WARRANTY.

TOOLS REQUIRED

In order to perform all of the setup procedures and installation procedures described in

this document, the tools listed below will be required, but all are not required for each

procedure.

1. # 2 Phillips screwdriver (for removal of the top cover)

2. Small slotted screwdriver with insulated blade (supplied with mixer) for

installing/removing wiring or adjusting pots. GC 8608, or equivalent.

3. Small needle nosed pliers (for jumper removal and replacement)

JUMPERS

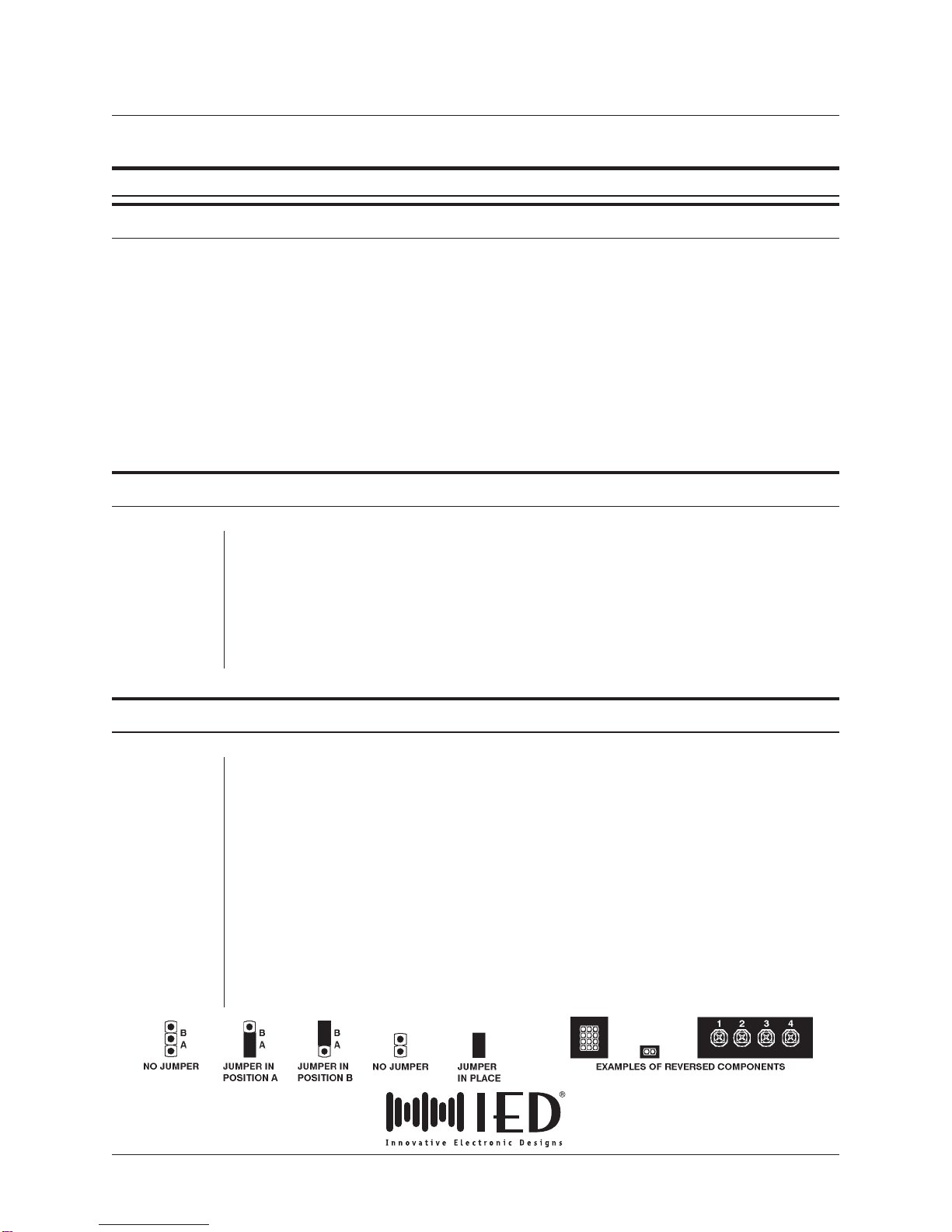

Jumpers, also referred to as shunts, are used extensively in the 4400 and 4800 Series

Automatic Mixers to select or set up alternatives or options. A jumper consists of a small

conductive clip encased in a molded plastic case. It is designed to slide onto two adja-

cent pins in a pin strip array. The pin strips used in this equipment have spacings of .100

inches. In the diagrams in this document, a jumper (shunt) is represented as a solid

black rectangle which covers two adjacent pins. The figure below illustrates several ex-

amples of jumpers.

Also used in this document is a reversed or negative representation of some compo-

nentstoaidinlocatingtheminthediagrams. Somereversedcomponentsarealsoillus-

trated in the figure below. Note particularly the difference between a reversed pin array

and a pin array with a jumper in place. Reversed components are used in the overall

views, only. Jumpers are shown only in the magnified views of the reversed compo-

nents.

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 1

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

MOUNTING AND VENTILATION

The 4400 and 4800 Series Automatic Mixers are designed for rack mounting in a stan-

dard EIA 19 inch equipment rack. When rack mounting these mixers, there are several

considerations which must be kept in mind.

Physically, each mixer requires one EIA rack space (1.75) inches. However, adequate

ventilation space must be provided for heat removal. For this reason, one empty EIA

rack space must be left between mixers. Do not cover the empty rack space with a solid

panel. Use a perforated or louvered vent panel.

Iftheyare not mounted in a rack,donot stack mixers directly on eachother. Spacethem

1.75inchesapart,allowingforthe freeflowofair betweenthem.Donot blockthelouvers

in the tops.

Rack mounting is usually accomplished with four 10-32 flat head machine screws and

cup washers. This prevents scratching of the front panel when appearance is important.

but it does not provide grounding. If grounding to the rack is required, it is recom-

mended that a grounding strap be added. If appearance is not critical, then the use of

fourroundheador pan head screws with lock washers,butnocup washers, will provide

grounding.

SECTION 4GROUP 20 SUB BPAGE 2MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

Figure1-Typical rack layout showing vent spaces

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 3

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

TABLE OF CONTENTS

General Procedure ...........................................1

Tools Required .............................................1

Jumpers .................................................1

Mounting and Ventilation ........................................2

Rear Terminal Connections, Inputs...................................4

Rear Terminal Connections, AC Power and Outputs .........................5

Remote Connector, Input and/or Main Output Option 1 and Auxiliary Input Option A ........6

Input and/or Main Output Option 2 and Logic Out...........................7

Remote Connector, Input and/or Main Output Option 1 Using 412PLC for Remote Level Control . 8

Combining Switch and Remote Output Level Control Using 412PLC ................9

Remote Connector, Force On/Force Off ...............................10

Overall View of Printed Circuit Board.................................11

Direct Output Level Controls .....................................12

Gain Adjustment of Gated Inputs ...................................13

Phantom Power Settings .......................................14

Enabling/Disabling Priority of Gated Inputs .............................15

Filibuster Limit Set of Gated Inputs ..................................16

Last Mic On and Onput for Gated Inputs ...............................17

Force On and Force Off for Gated Inputs...............................18

Digital Attenuator Defeat for Gated Inputs ..............................19

Discriminator Defeat for Gated Inputs ................................20

Discriminator Sensitivity of Gated Inputs...............................21

Release Time Adjustment of Gated Inputs ..............................22

Input Option Control Lines ......................................23

Auxiliary Mix Bus Sources.......................................24

Direct Output Source Selection ....................................25

Auxiliary Input Routing ........................................26

High Pass Filter Enable/Disable....................................27

Gated Off Attenuation of Gated Inputs ................................28

Auxiliary Output Level Controls ....................................29

Output Option Control Lines .....................................30

Phantom Power Option Voltage Selection ..............................31

Fuse Replacement ...........................................32

SECTION 4GROUP 20 SUB BPAGE 4MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

Figure 2 - Rear terminal connections

Inputs

REAR TERMINAL CONNECTIONS, INPUTS

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 5

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 3 - Rear terminal connections

AC power and outputs

REAR TERMINAL CONNECTIONS, AC POWER AND OUTPUTS

SECTION 4GROUP 20 SUB BPAGE 6MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

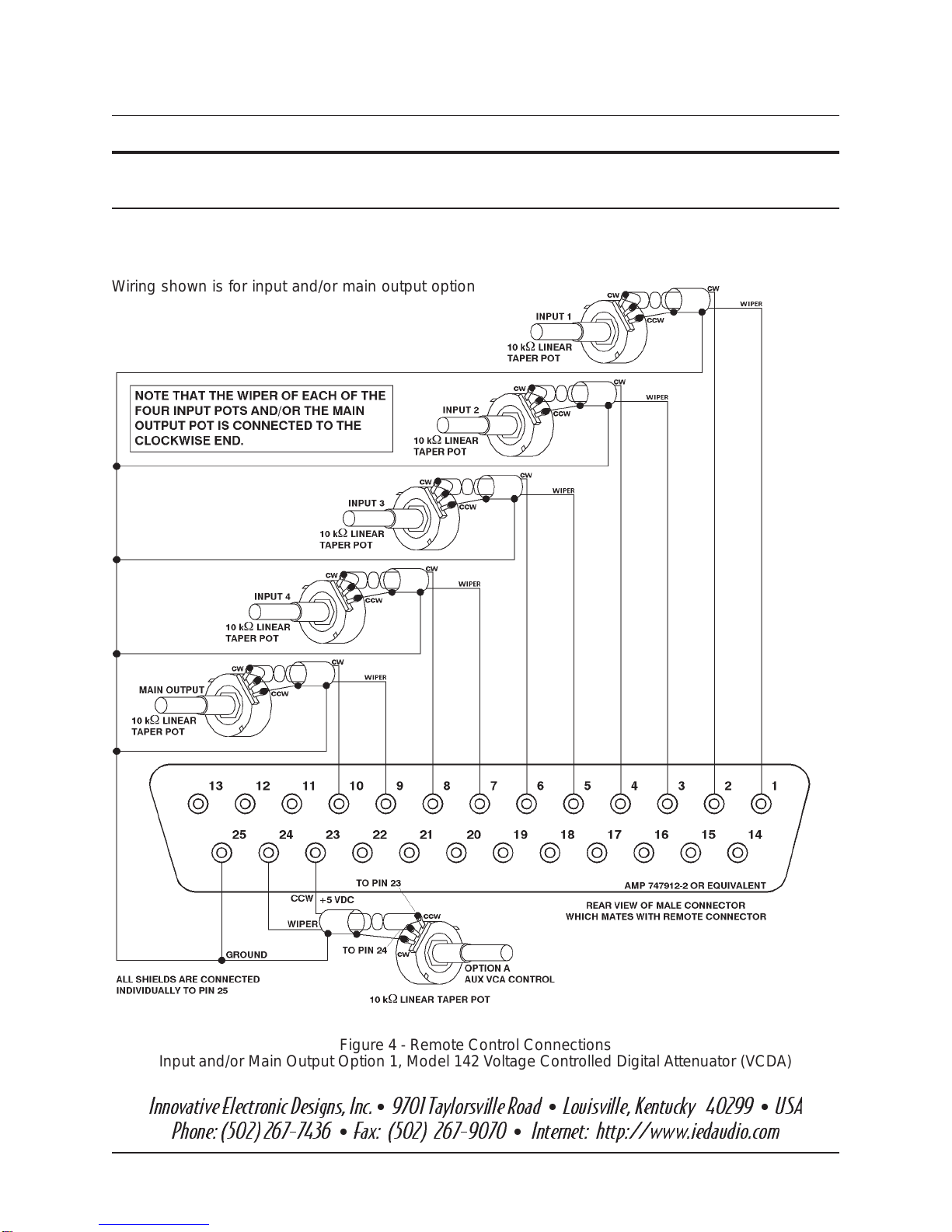

Figure 4 - Remote Control Connections

Input and/or Main Output Option 1, Model 142 Voltage Controlled Digital Attenuator (VCDA)

Wiring shown is for input and/or main output option 1,

110V Voltage Controlled Amplifier. Auxiliary Input VCA

option is Option A.Use 22 AWG twisted pair with overall

shield, Belden 8451 or equivalent.

REMOTE CONNECTOR, INPUT AND/OR MAIN OUTPUT OPTION 1 AND

AUXILIARY INPUT OPTION A

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 7

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 5 - Remote Control Connections, 120P Setup Control

Figure 6 - Remote Control Connections, Logic Output

INPUT AND/OR MAIN OUTPUT OPTION 2 AND LOGIC OUT

SECTION 4GROUP 20 SUB BPAGE 8MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

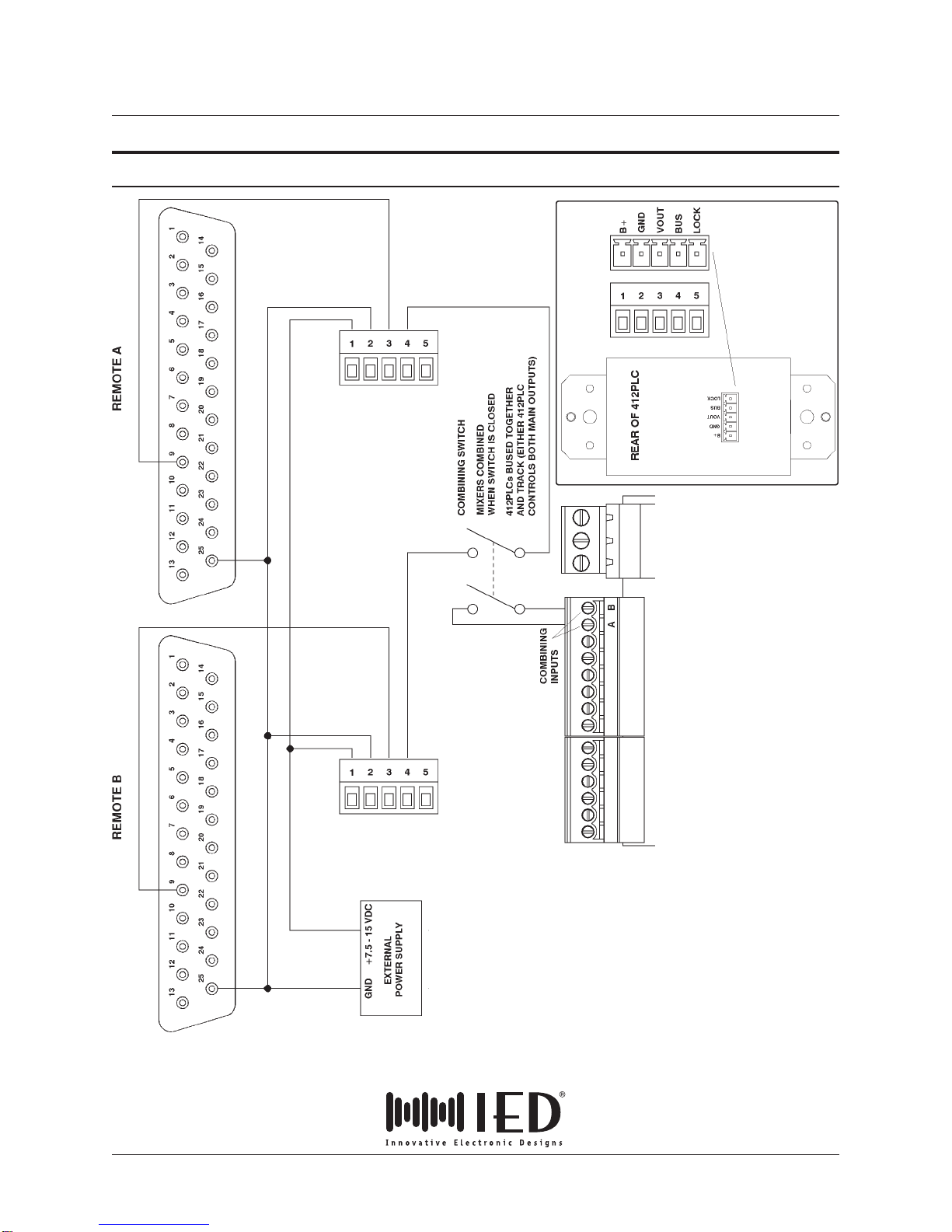

REMOTE CONNECTOR, INPUT AND/OR MAIN OUTPUT OPTION 1 USING

412PLCs FOR REMOTE LEVEL CONTROL

Figure 7 - Rear terminal connections

Input and/or Main Output Option 1 using 412PLC for remote level control

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 9

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

COMBINING SWITCH AND REMOTE OUTPUT LEVEL CONTROL USING 412PLC

Figure 8 - Rear terminal connections

Combining switch and remote output level control using 412PLC

SECTION 4GROUP 20 SUB BPAGE 10 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

Figure 9 - Remote control connections

Force On

Figure 10 - Remote control connections

Force Off

REMOTE CONNECTOR FORCE ON/FORCE OFF

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 11

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 11 - Overall view of printed circuit board

SECTION 4GROUP 20 SUB BPAGE 12 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

Figure 12 - Direct Output Level Controls

Either line or microphone level can be se-

lected for each Direct Output. An overall level

control for each output provides adjustment

from maximum to full off. As seen in the figure,

the level controls are located on the circuit

board near the back edge, just in front of the

screw terminal connector strip. The controls

areaccessablebyremoving thereartopcover

by loosening the thumb screws provided.

Level increases with clockwise rotation.

DIRECT OUTPUT LEVEL CONTROLS

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 13

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 13 - Gain adjustment of gated inputs

Jumper setup

GAIN ADJUSTMENT OF GATED INPUTS

Gated Inputs -The gainofgatedinputs as de-

livered from the factory is set at +35 dB. With

the proper jumpers installed, microphone

level gains between +26 dB and +46 dB

gains between +26 dB and +46 dB can be

achieved by adjusting the pot as shown. By

removing the jumper, a gain of 0 dB can be

achieved. Other gain values are possible by

changing SIP values. Consult the factory for

additional information.

The controls and jumpers are accessible by

loosening the thumb screws and removing

the rear top cover.

SECTION 4GROUP 20 SUB BPAGE 14 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

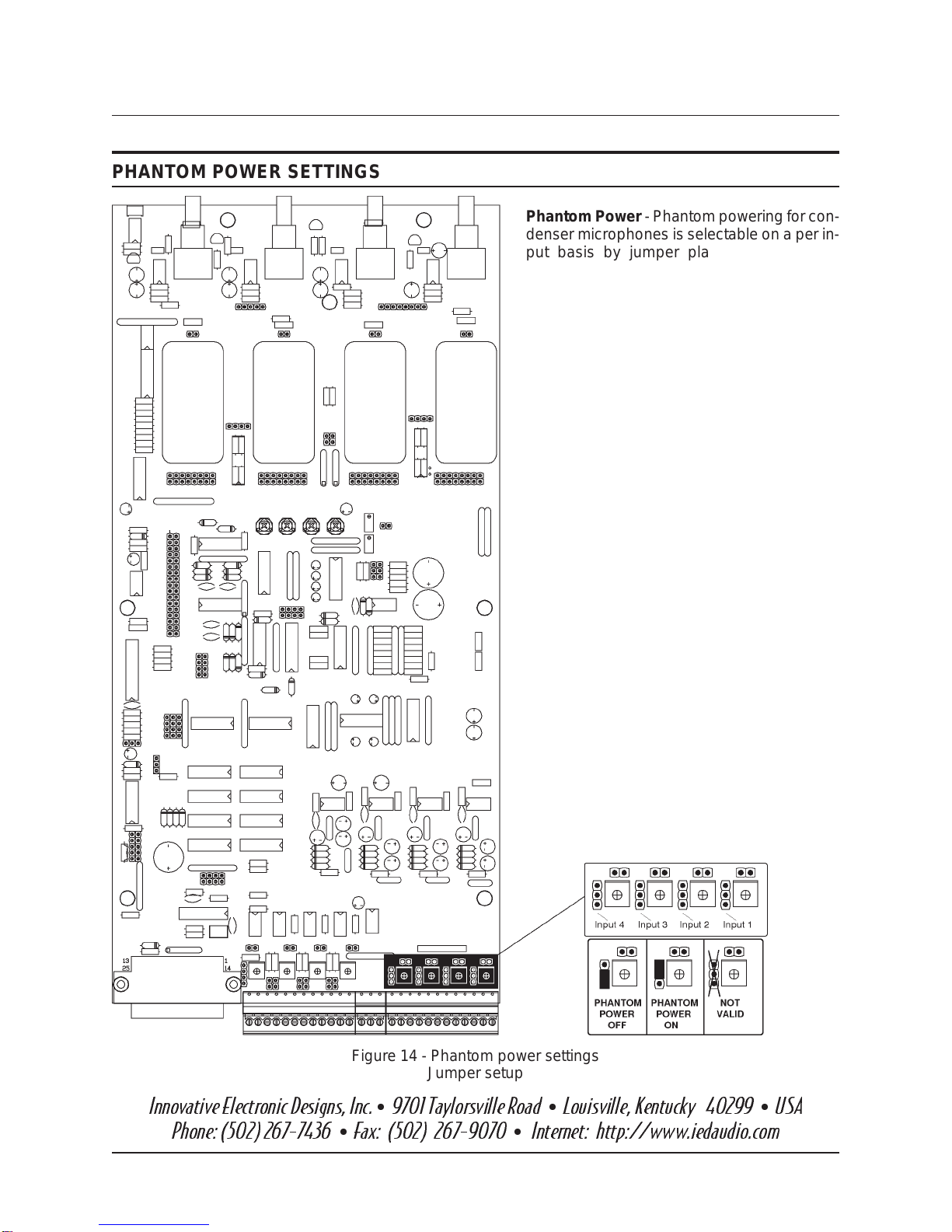

Figure 14 - Phantom power settings

Jumper setup

PHANTOM POWER SETTINGS

Phantom Power - Phantom powering for con-

denser microphones is selectable on a per in-

put basis by jumper placement. Phantom

power for the entire mixer may be turned ‘on’

or ‘off’ by a front panel switch. When the front

panel switch is in the ‘on’ position, only those

inputs which have their jumpers in the ‘on’ po-

sition will have phantom power available. A

jumper MUST be in place in either the ‘on’

or the ‘off’ position, or the input will be

open and floating, and susceptible to extra-

neous noise pickup. Phantom power jumper

positions are shown in the figure below. Phan-

tom power is provided to inputs from the 4822

card. +15 V is standard and +30/48 V can be

provided with the with the pahntom power op-

tion. See figure 31.

Phantom power jumpers are accessible by

loosening the thumb screws and removing

the rear top cover.

Phantom powering should be used for con-

denser microphones only. It should not be

used for dynamic microphones or line level

applications. As shipped from the factory, the

phantom powering jumpers are set to the ‘Off’

position (for line level or dynamic microphone

inputs).

CAUTION! Do not set phantom power

jumpers with power on. So doing incurs the

risk of damaging the inputs, and will void

the warranty.

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 15

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 15 - Enabling/disabling Priority of gated inputs

Jumper setup

ENABLING/DISABLING PRIORITY OF GATED INPUTS

Priority - Priority is the feature, which when

enabled for an input allows that input to take

precedenceover inputs which do not havethe

priority feature enabled. That is to say that

when an input in priority is gated on, other in-

puts not in priority are immediately caused to

gate off. Other inputs which are in priority are

notaffected. Toplaceaninput inpriority,place

a jumper on the appropriate pins as shown in

the figure below. As shipped from the factory,

no priority jumpers are in place, and no inputs

are in priority.

SECTION 4GROUP 20 SUB BPAGE 16 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

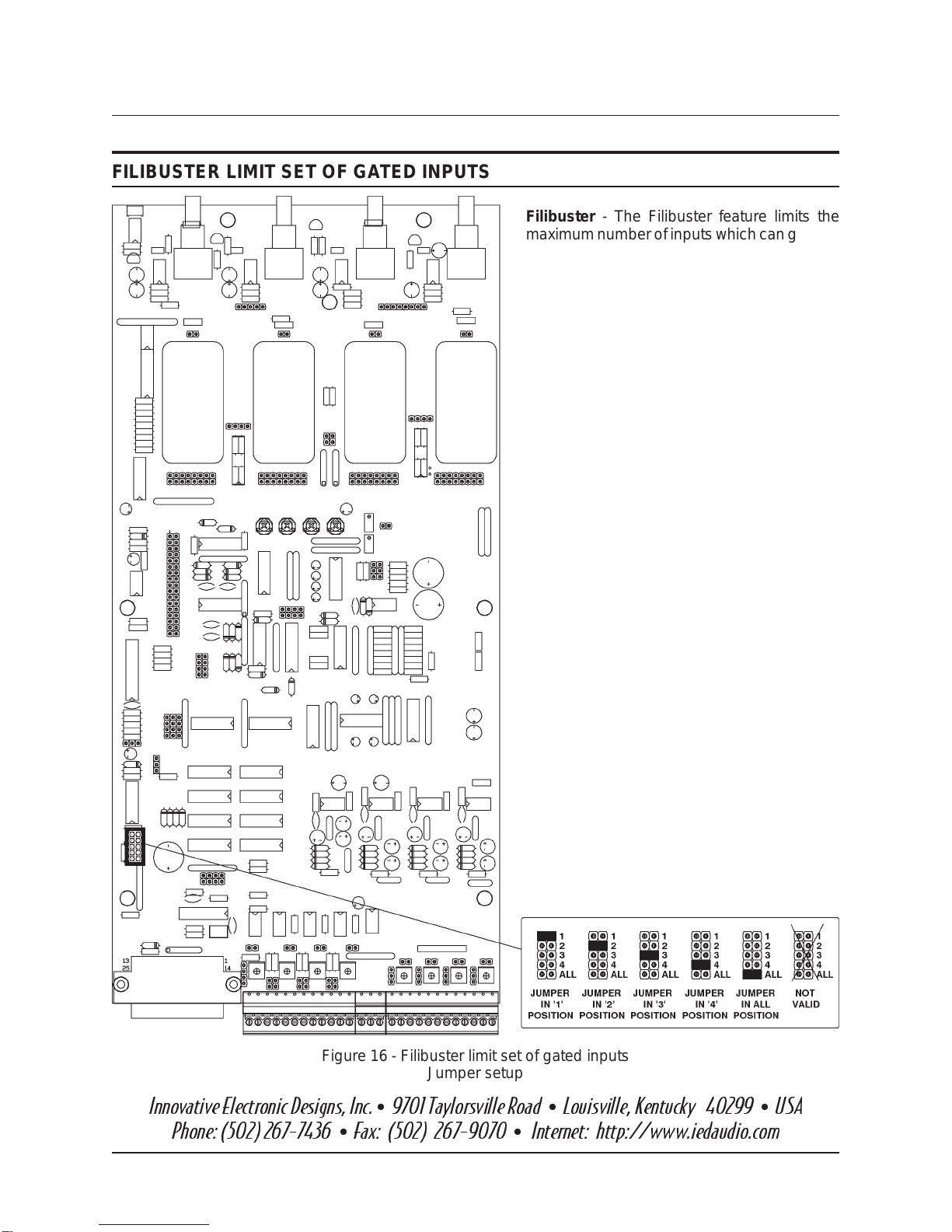

Figure 16 - Filibuster limit set of gated inputs

Jumper setup

FILIBUSTER LIMIT SET OF GATED INPUTS

Filibuster - The Filibuster feature limits the

maximumnumber ofinputswhich cangateon

in a given mixer. If the two 4-input mixers in a

4800 or 4800EQ are combined, the total num-

ber of inputs which are gated on in the com-

bined mixer count toward the limit. The limit

can be set at 1, 2, 3, 4, or ALL. The ALL setting

defeats the feature. If mixers are combined

and the limit on a particular mixer is set for 2,

an input on that mixer can gate on only when

the total number of inputs which are on on

bothmixers is less than 2. A jumper MUST be

placed in one, but not more than one of the

positions, or erratic performance may re-

sult. The figure below shows the details of

jumper placement. Inputs for which the Digital

Attenuator has been defeated do not contrib-

ute to or affect the Filibuster limit, although

they are still subject to it. As shipped from the

factory, there is a jumper in the ‘All’ position,

defeating the Filibuster feature and allowing

all inputs to be on.

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 17

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

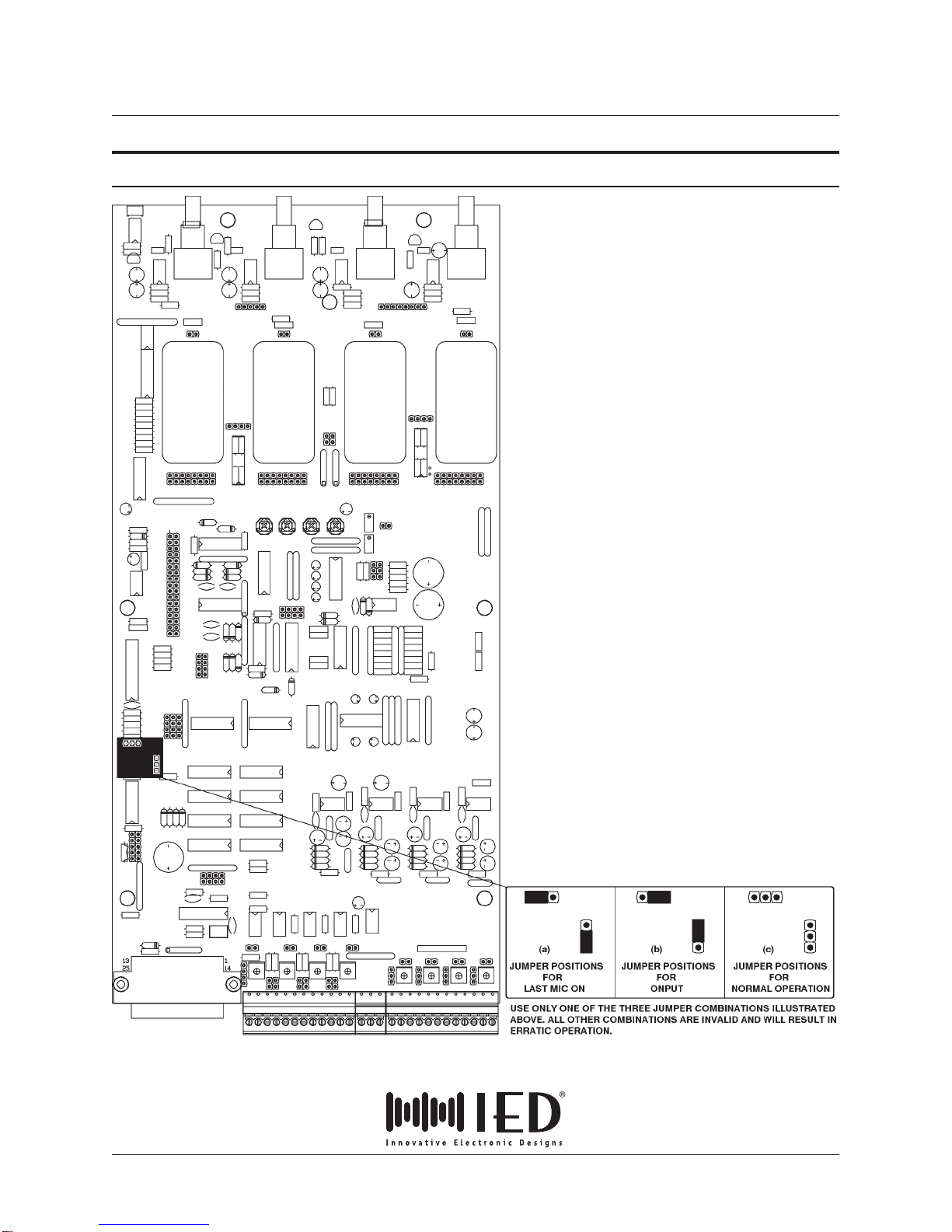

Figure 17 - Last Mic On and Onput for gated inputs

Jumper setup

Last Mic On - When the Last Mic On feature

is enabled, the last input which is gated on re-

mains on until another input is gated on in its

place. This feature prevents the system from

sounding ‘dead’ by always keeping one mi-

crophone on. The figure below shows the de-

tails of Last Mic On jumper placement. When

Last Mic On is used with a combined 8 input

mixer, jumpers must be placed on both input

boards in the Last Mic On position.

Onput - When the Onput feature is enabled,

input number 1 is gated on or remains on until

another input is gated on in its place. This fea-

ture prevents the system from sounding

‘dead’ by turning on the number 1 input when

allother inputs aregatedoff.Shownbeloware

the details of Onput jumper placement. When

using the Onput feature with a combined 8 in-

put mixer, Onput must be selected on only

one of the two input boards. If selected on the

‘A’ board, input 1 will gate on when all other

inputs gate off. If Onput is selected on board

‘B’ then input 5 will gate on when all other in-

puts gate off.

If neither Last Mic On nor Onput jumpers are

in place as in shown below, gated inputs will

gate off normally. Do not attempt to operate

the system with only one jumper in place or

with other jumper combinations. Erratic op-

eration will result.

As shipped from the factory, neither Last Mic

On nor Onput jumpers are in place (normal

operation).

LAST MIC ON AND ONPUT FOR GATED INPUTS

SECTION 4GROUP 20 SUB BPAGE 18 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

Figure 18 - Force On and Force Off for gated inputs

Jumper setup

FORCE ON AND FORCE OFF FOR GATED INPUTS

Force On/Force Off - These functions over-

ride gating operation and place the input in a

continuous on state or a continuous off state,

respectively. When an input is forced on it still

contributes to the attenuation of the Main Out-

put(DigitalAttenuator),totheFilibustercount,

andtotheDiscriminator,unlessspecificallyre-

moved from these functions by defeating the

Digital Attenuator and/or the Discriminator

(see pages 22 and 23).

When an input is forced off, it is continuously

off and removed from the Discriminator, so

that a signal to the input will not affect the

gating of the other gated inputs.

For details of jumper setup, refer to the figure

below.

The 4400 and 4800 Series Automatic Mixers

are shipped from the factory with all inputs set

for normal gating (no jumpers installed).

4400 AND 4800 SERIES MIXERS MAY 1999 SECTION 4GROUP 20 SUB BPAGE 19

INSTALLATION INSTRUCTIONS MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS

Figure 19 - Digital Attenuator defeat for gated inputs

Jumper setup

DIGITAL ATTENUATOR DEFEAT FOR GATED INPUTS

Digital Attenuator Defeat - The Digital At-

tenuator makes adjustments in the main out-

put level as inputs gate on or off. For each

doubling of the number of inputs which are

on, the Main Output is attenuated 3 dB. This is

a measure to help control feedback.

If the inputs operate at the same level, and

since they are summed or added in the mix

bus, doubling the number of inputs would

double the output power, an increase of 3 dB.

By attenuating the output by 3 dB for each

doubling of the number of inputs, the output

level is kept approximately constant.

If an input is used for a source which is not in

the same acoustic environment such as a

source of background music or a microphone

which is in another room, it is desireable to

prevent it from contributing to the Digital At-

tenuator. As shipped from thefactory,jumpers

are installed on all inputs (normal operation).

To defeat the feed to the Digital Attenuator for

a particular input remove the the appropriate

jumper. Refer to the figure below for jumper

application details.

SECTION 4GROUP 20 SUB BPAGE 20 MAY 1999 4400 AND 4800 SERIES MIXERS

MODELS 4400 SERIES AND 4800 SERIES AUTOMATIC MIXERS INSTALLATION INSTRUCTIONS

Innovative Electronic Designs, Inc. 9701 Taylorsville Road Louisville, Kentucky 40299 USA

Phone: (502) 267-7436 Fax: (502) 267-9070 Internet: http://www.iedaudio.com

hh

hh h

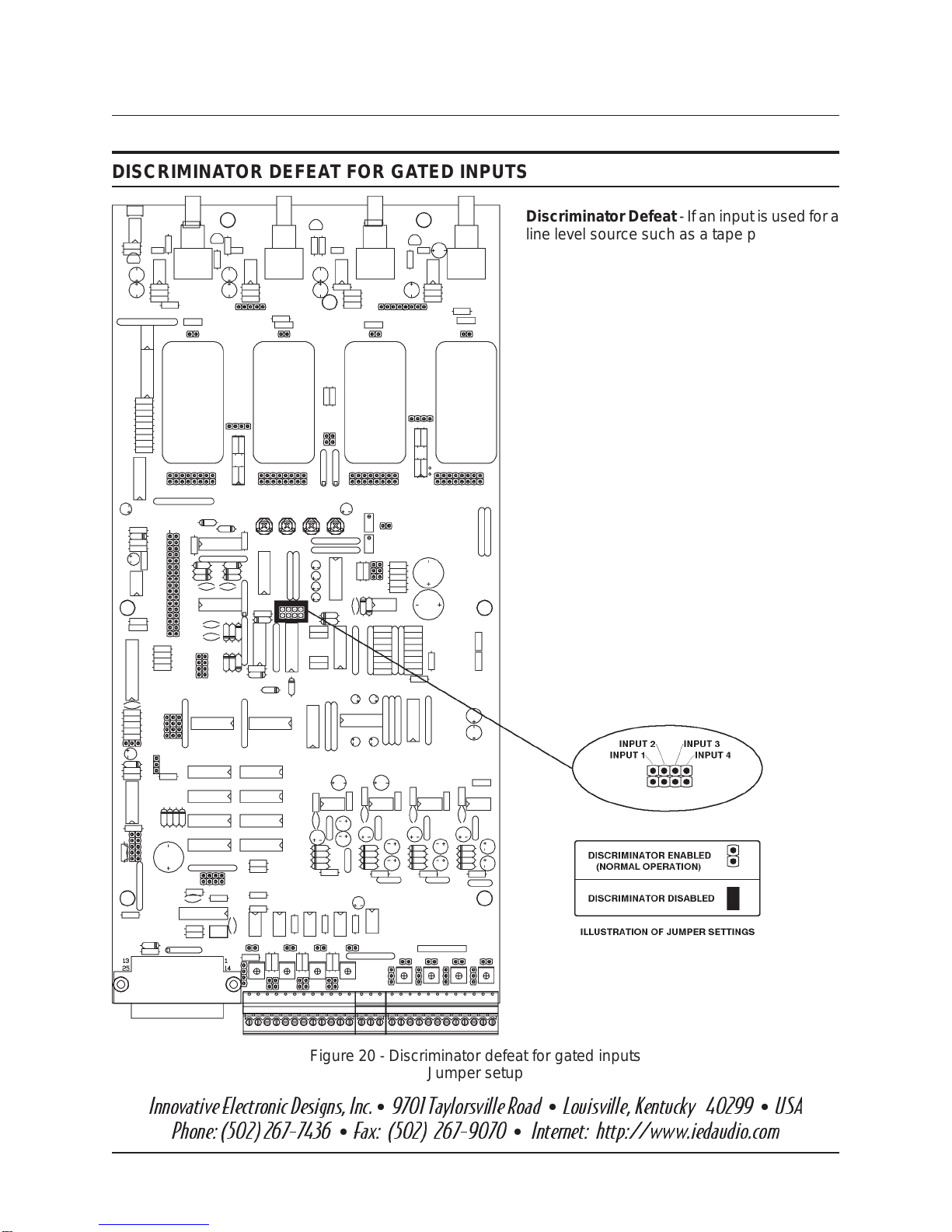

Figure 20 - Discriminator defeat for gated inputs

Jumper setup

DISCRIMINATOR DEFEAT FOR GATED INPUTS

Discriminator Defeat - If an inputisused for a

line level source such as a tape player, then it

isnotdesireableto haveitonthediscriminator

bus. A line level input could raise the level of

the discriminator threshold to such an extent

thatitwouldbeverydifficult togateonanother

gated input. For this reason, the Discriminator

Defeat has been provided. To defeat the

Discriminator function for an input, place a

jumper on the appropriate pins. When the

Discriminator has been defeated for a gated

input, it will no longer gate on in response to

an input signal. Instead, it must be Forced On

(seepage21).Thefigure below shows the de-

tails of jumper placement. As shipped from

the factory, the Discriminator is enabled (no

jumpers).

This manual suits for next models

1

Table of contents